When it comes to ensuring optimal performance and longevity, understanding the internal structure and key elements of your equipment is essential. This detailed guide will walk you through the various mechanical elements and their functions, helping you maintain efficiency and prolong the lifespan of your device.

Each element plays a crucial role in how the machinery operates, contributing to its overall performance and reliability. Knowing how these components interact can make it easier to troubleshoot issues and ensure smooth operation, especially during demanding tasks. Whether you’re performing routine upkeep or replacing individual elements, this guide provides a clear breakdown of the essential components.

In the following sections, you will find detailed insights into how each part is connected and what role it plays in the overall system. This knowledge will empower you to make informed decisions when handling repairs or regular maintenance, ensuring that every

Stihl BG 55 Blower Component Overview

The machine features several critical elements that work together to ensure efficient operation. Each part plays a vital role in maintaining optimal performance, contributing to the overall reliability of the device. Understanding how these components function can help users ensure long-term durability and effective maintenance.

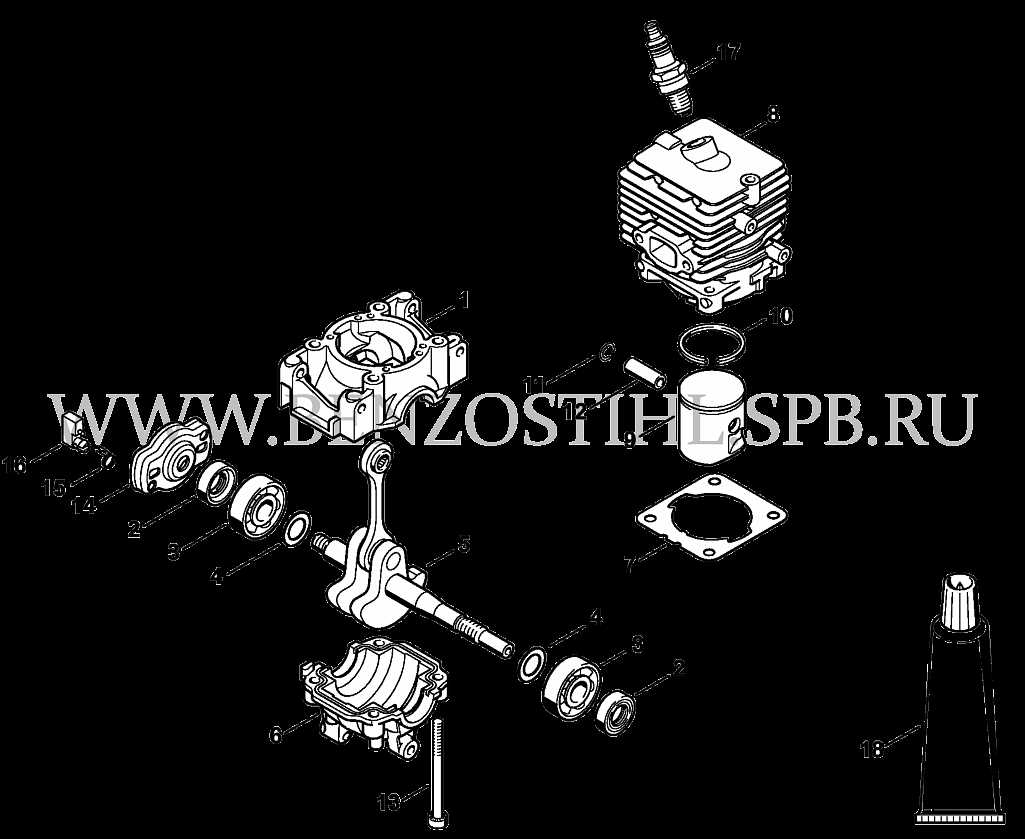

Engine Unit and Housing

The core of the system is its engine, which is enclosed in a robust casing. This section not only provides the power needed for the device but also protects the internal mechanisms from external damage. The design of the housing is engineered for ease of access, allowing for straightforward servicing and repairs.

Air Intake and Flow System

Airflow is managed by a combination of filters, ducts, and other essential elements. These ensure that the air moves efficiently through the machine, preventing blockages and maintaining consistent operation

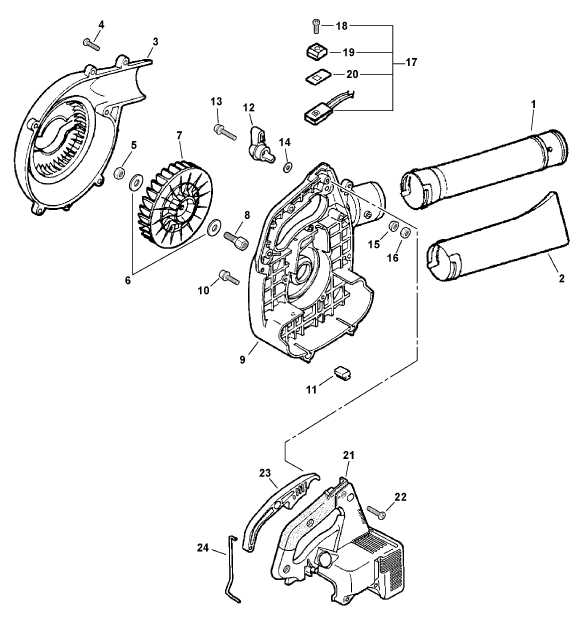

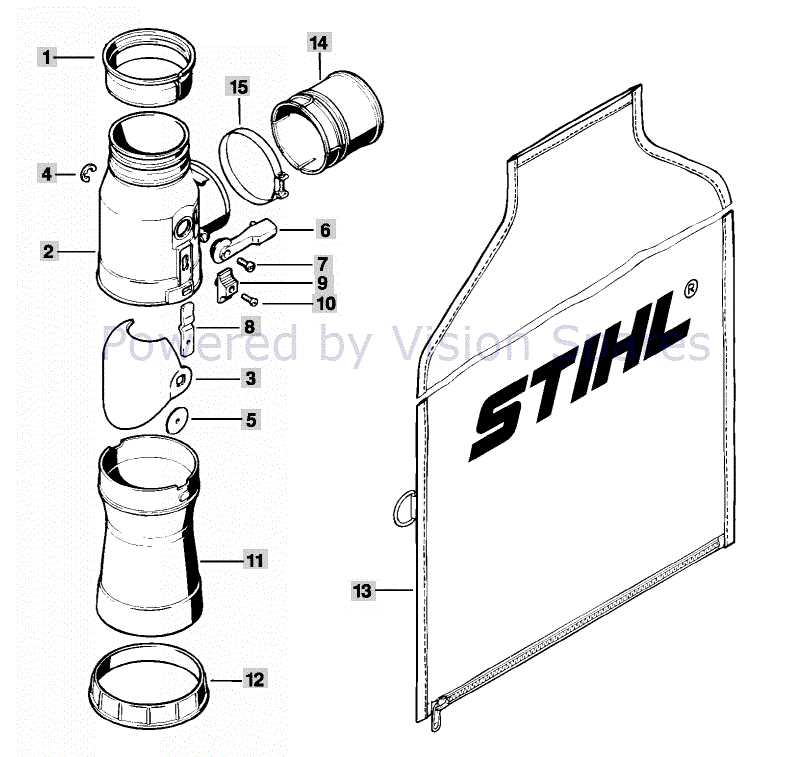

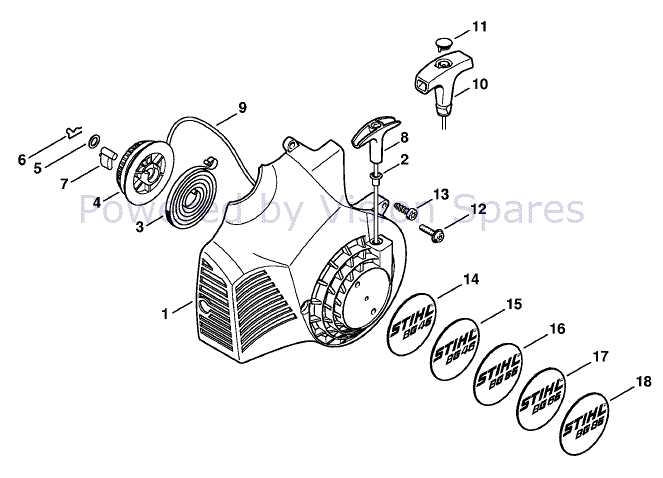

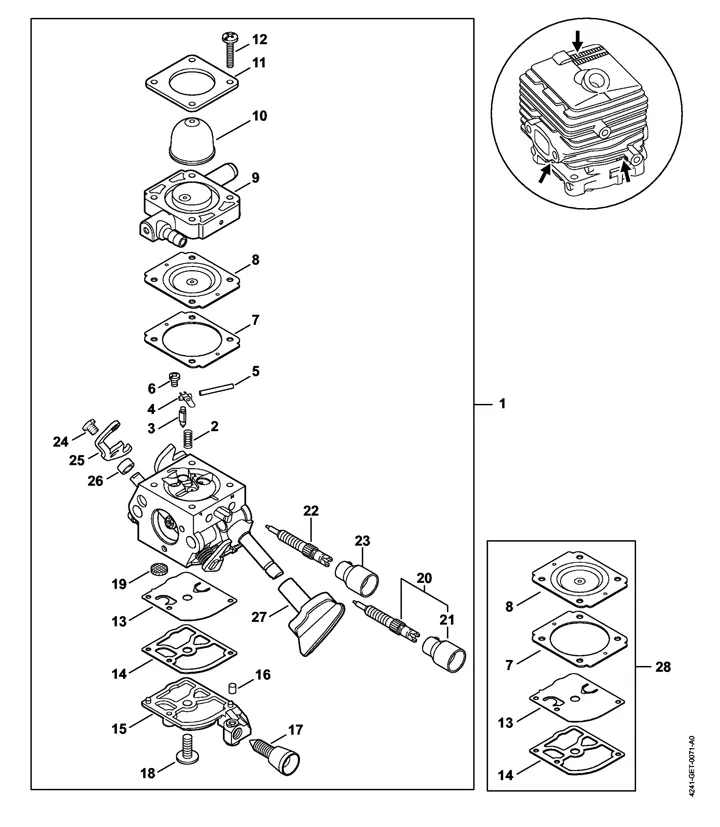

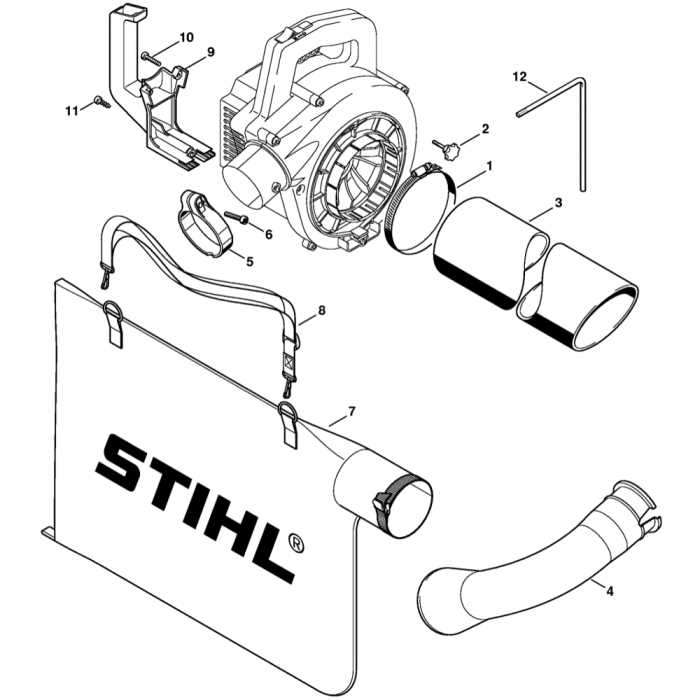

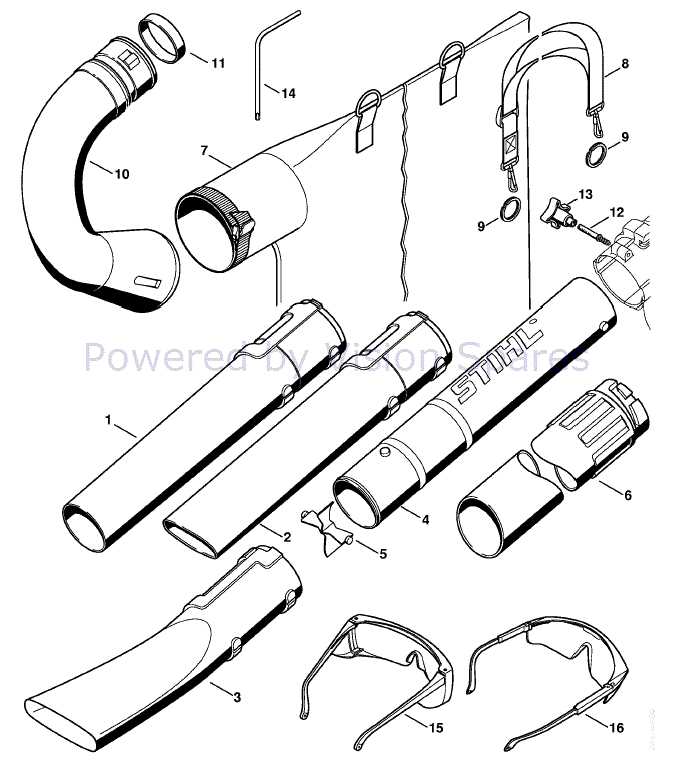

Exploded View of Blower Parts

An exploded view is a detailed visual representation that breaks down each individual component of a complex device. This type of image provides a clear understanding of how all the elements fit together, making it easier to identify and examine each piece in isolation. Whether you’re performing maintenance, replacing components, or simply learning about the structure, such a layout can offer valuable insight into the inner workings of the equipment.

Key Components and Their Arrangement

The assembly consists of various sections that are critical for the device’s functionality. The primary structure includes several moving and static elements that work in unison. By observing this layout, it’s possible to trace the connections between the major parts, such as the engine housing, fan, and nozzles, all of which play distinct roles in the operation.

Visual

Main Assemblies in the BG 55 Model

The BG 55 model is composed of several key assemblies that work together to ensure efficient functionality. Each component is designed to fulfill a specific role, contributing to the overall performance. Understanding how these assemblies interact is crucial for maintenance and operation.

- Engine Section: The core of the unit

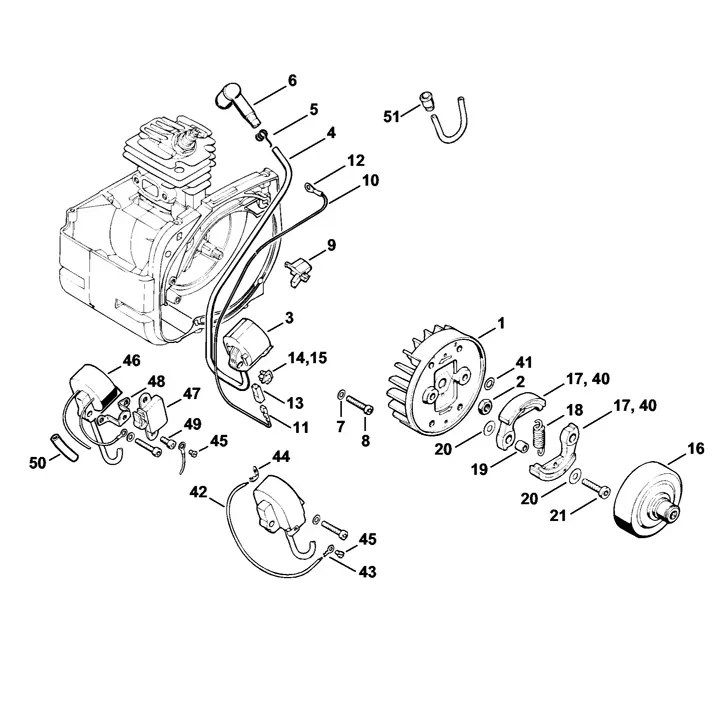

Ignition System and Related Components

The ignition system is essential for initiating the operation of any engine-driven device. It ensures that the engine starts smoothly and continues running efficiently. This system includes several interconnected elements that work together to produce the necessary spark for combustion. Each component plays a critical role in maintaining optimal performance.

Spark plug: A key element responsible for generating the spark required for igniting the fuel mixture. Proper maintenance of the spark plug is crucial for reliable engine function.

Ignition coil: This component amplifies the electrical energy to a high voltage, sending it to the spark plug to create the spark. Any malfunction in this element can lead to misfires or engine starting issues.

Flywheel: The flywheel helps maintain the momentum of the engine, but it also houses magnets that assist the ignition coil in generating the necessary

Air Filter and Intake Mechanism

The air filtration system and intake function play a vital role in maintaining the efficient operation of outdoor equipment. This section focuses on how the filtration unit works to protect the internal components by preventing dust and debris from entering the engine, ensuring optimal airflow and extending the lifespan of the machinery. Understanding the structure and maintenance of this mechanism helps to improve performance and reliability.

The filter is designed to trap fine particles, while the intake passage is responsible for drawing air into the engine

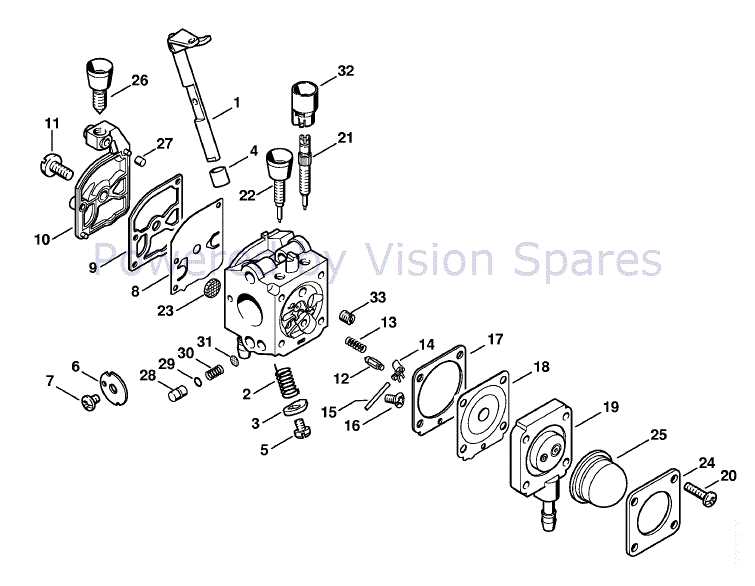

Fuel System Breakdown

The fuel system is a critical component of any engine, responsible for delivering the necessary energy to ensure optimal performance. Understanding its structure and functionality is essential for maintenance and troubleshooting. This section will delve into the various elements that comprise the fuel system, highlighting their roles and interconnections.

Key components of the fuel system include:

- Fuel Tank: Stores the fuel until it is needed by the engine.

- Fuel Filter: Removes impurities from the fuel to protect the engine from damage.

- Fuel Pump: Transfers fuel from the tank to the engine, ensuring a steady supply.

- Fuel Lines: Carry the fuel from the tank to the engine, designed to withstand pressure.

- Carburetor or Injector: Mixture of fuel and air is created for combustion, essential for efficient engine operation.

Regular inspection and maintenance of these components can prevent performance issues and extend the lifespan of the engine. Key steps include:

- Check for leaks in the fuel lines and connections.

- Replace the fuel filter periodically to ensure cleanliness.

- Inspect the fuel pump for proper operation and pressure levels.

- Clean or service the carburetor/injector to maintain the correct fuel-air mixture.

By comprehensively understanding the fuel system and its components, users can ensure their engine operates efficiently and effectively.

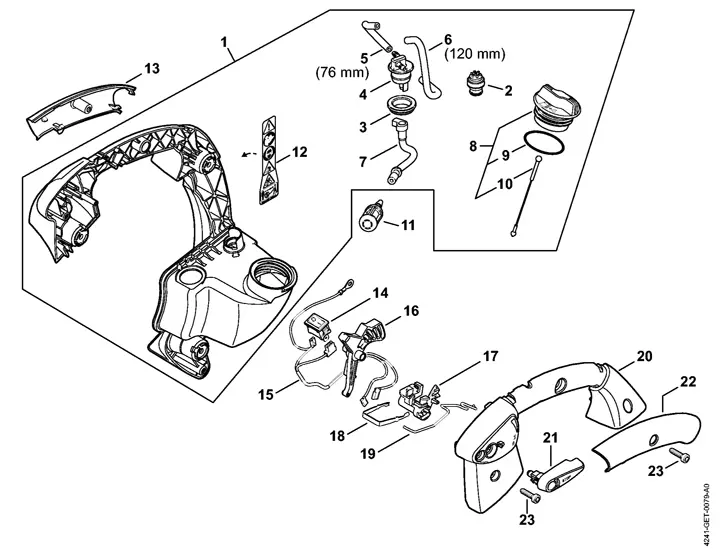

Fan Housing and Blower Wheel Structure

The design of the air-moving apparatus plays a crucial role in its overall efficiency and functionality. Understanding the components that contribute to air circulation is essential for proper maintenance and performance. This section delves into the framework that houses the rotating element, highlighting its significance in optimizing airflow and enhancing the device’s operation.

Components of the Air Movement Assembly

The structure comprises several key elements that work in unison to facilitate the movement of air. These components are intricately designed to ensure a seamless operation while minimizing energy loss. Below is a table outlining the main elements and their respective functions:

Component Function Fan Housing Encases the rotating element, directing airflow efficiently. Rotating Element Generates airflow through rapid rotation, creating a pressure difference. Intake Port Allows air to enter the assembly for movement. Exhaust Outlet Channels the expelled air, enhancing airflow direction. Importance of Efficient Design

Proper design of the housing and rotating element not only maximizes airflow but also improves the longevity of the apparatus. A well-structured assembly reduces wear and tear, allowing for prolonged use and reliable performance. Regular inspection and maintenance of these components ensure optimal functioning and contribute to the overall effectiveness of the device.