Maintaining the proper function of any outdoor equipment relies on understanding the essential elements that keep it running smoothly. Whether you’re dealing with an older or newer version of a well-known leaf blower, knowing how the different sections work together is critical for efficient upkeep and repair. This guide delves into the specifics of a widely used blower model, breaking down its key components and their roles.

Each mechanism has a vital function that contributes to the overall operation, from the engine to the smaller details within the assembly. Learning about these individual parts ensures better performance and helps in troubleshooting common issues. By having a clear picture of how everything is connected, you can keep your equipment in optimal condition for longer periods.

We will explore the layout of these elements in detail, highlighting the significance of every feature. With this knowledge

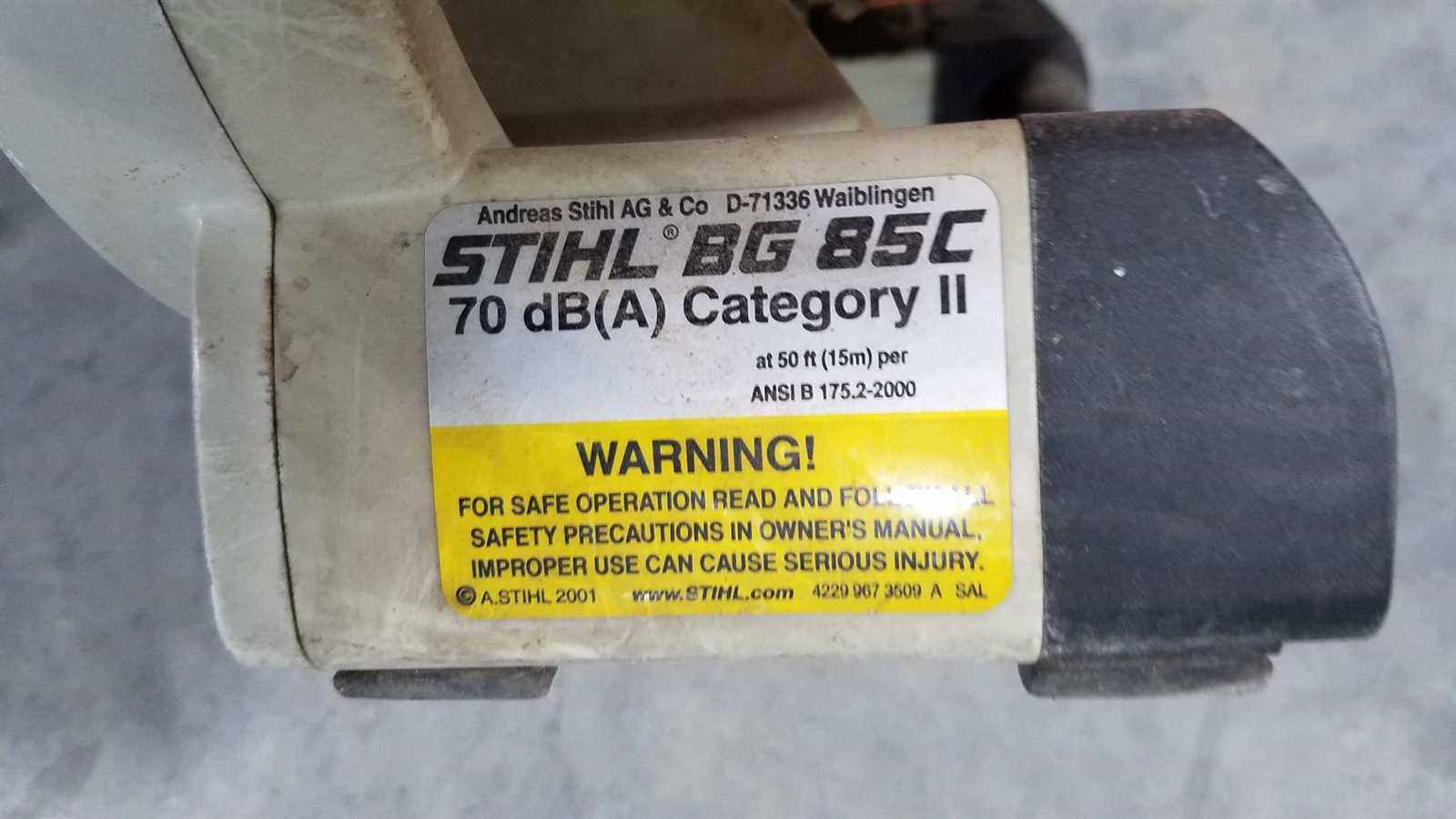

Understanding the Components of Stihl BG85C Blower

The functionality of this leaf blower relies on a combination of essential elements that work together to provide efficiency and power. Each component is designed to serve a specific role in optimizing the device’s overall performance, ensuring both reliability and ease of use.

Key Structural Elements

The design features several important mechanical and electrical parts that contribute to the blower’s operation. These parts are engineered for durability and longevity, allowing the machine to perform well under different conditions.

- Engine housing: Provides a protective shell for the motor and other internal systems, reducing wear and exposure to the elements.

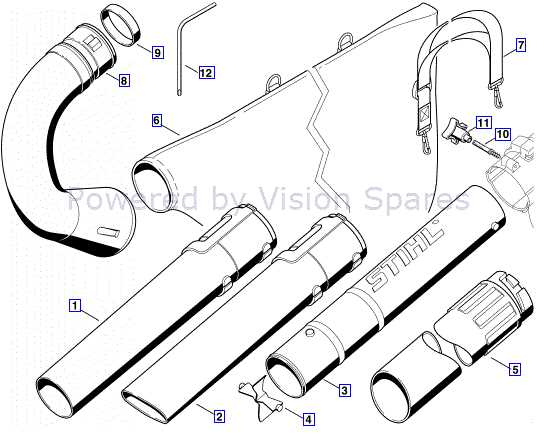

- Blower tube: Channels the air from the unit, allowing for precise direction and control when clearing debris.

- Fuel tank: Holds the energy source, with easy access for refueling and maintaining optimal energy levels during use.

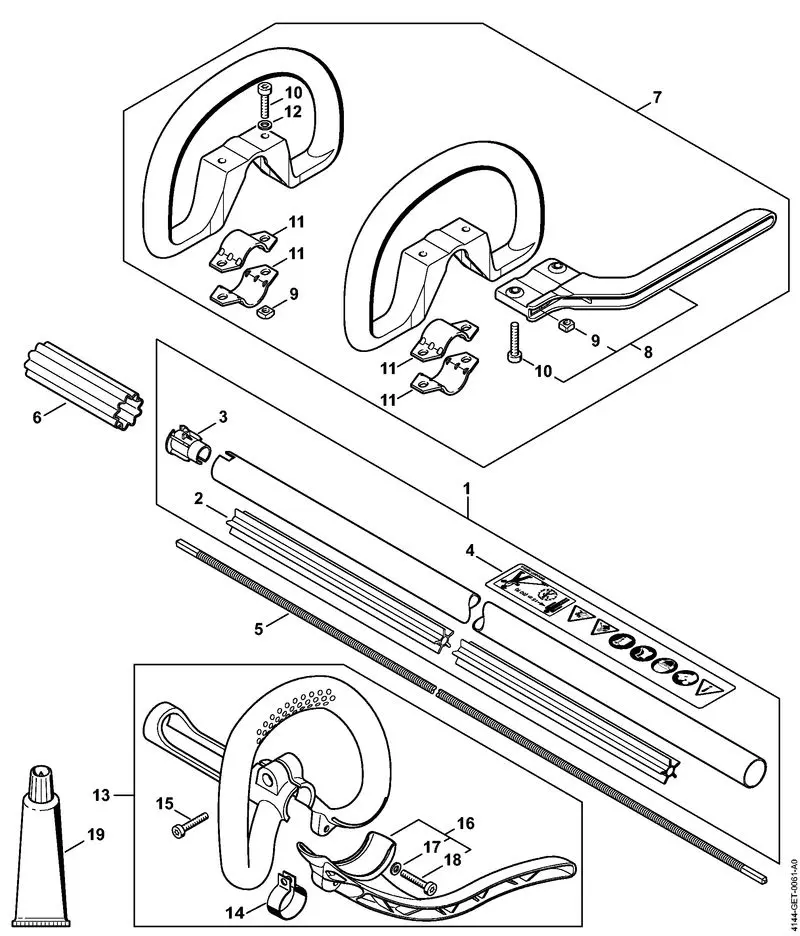

- Handle: Ergonomically shaped to provide a comfortable grip and better control

Key Features of Stihl BG85C Blower Parts

The components of this blower are designed to ensure reliable performance, efficiency, and longevity. These elements work together to optimize air circulation, durability, and user comfort, providing a superior outdoor cleaning experience.

- High-Performance Engine: The motor is built to deliver powerful airflow, ensuring that debris is cleared quickly and effectively.

- Lightweight Design: The ergonomic construction makes it easy to handle and operate for extended periods without causing strain.

- Durable Materials: Crafted from tough materials, the components are resistant to wear and designed for prolonged use in demanding conditions.

- Efficient Fuel Consumption: The system is optimized to use fuel efficiently, reducing the

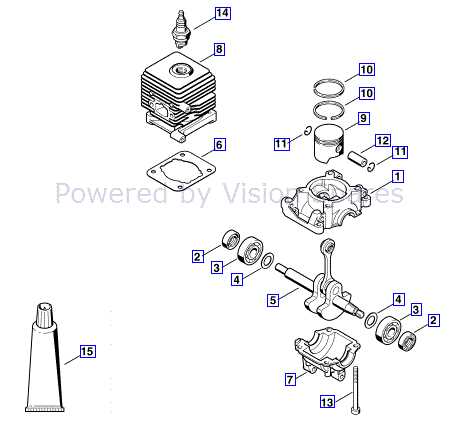

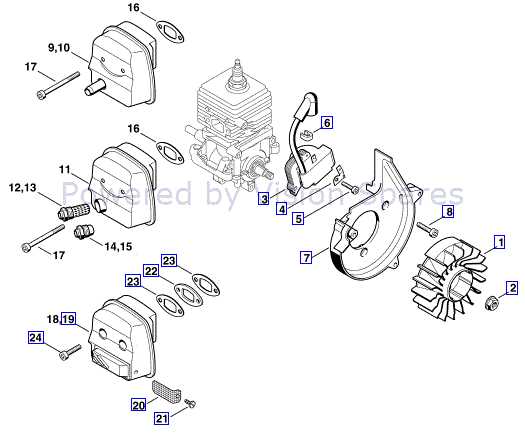

How to Identify Blower Components

The components of a handheld blower are key to ensuring its proper function and longevity. Recognizing the various elements allows you to maintain, repair, or replace them when necessary. This section provides guidance on how to easily recognize and categorize the essential parts of your blower unit, so you can keep it running smoothly.

Fan Housing: The fan housing is designed to protect the internal mechanisms and direct airflow efficiently. It’s often one of the largest components and plays a critical role in the blower’s performance.

Air Filter: Located near the intake area, the air filter helps prevent debris from entering the engine. Keeping it clean ensures optimal airflow and engine health.

Spark Plug: Positioned at the top of the engine, the spark plug is essential for ignition. Identifying this small but vital part is important for regular maintenance checks

Maintenance Tips for Stihl BG85C Parts

Regular upkeep of your equipment ensures its longevity and optimal performance. By consistently inspecting and cleaning individual components, you can avoid larger issues down the road. Whether it’s addressing wear and tear or simply keeping everything free from debris, proper care will help maintain efficiency and reliability.

Check for Wear: Periodically examine all mechanical elements for any signs of damage or aging. Replace any worn-out parts immediately to prevent further complications.

Clean Regularly: Dirt and debris can build up quickly. Ensure that you clean all areas thoroughly to keep the machine running smoothly. A clean tool performs better and lasts longer.

Lubrication: Make sure to lubricate moving parts regularly to reduce friction and prevent unnecessary wear. This simple step can greatly extend

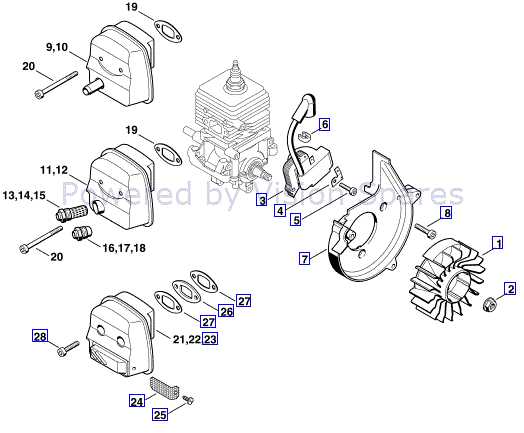

Stihl BG85C Ignition System Overview

The ignition mechanism plays a crucial role in ensuring the smooth operation of this specific blower model. Without it, the engine would not be able to start or function efficiently. This section provides an in-depth look into the key elements that enable the combustion process, ensuring optimal performance.

Key Components of the Ignition System

The ignition system is composed of several essential components, each contributing to the firing process. These components work together to ignite the fuel-air mixture in the engine, ensuring reliable starts and consistent operation. The core elements include the ignition coil, spark plug, and flywheel, all of which must function harmoniously to

Common Issues with Stihl BG85C Blower Parts

Powerful blowers are essential for efficient yard maintenance, yet users often encounter various complications that can hinder their performance. Understanding these common problems can lead to quicker resolutions and prolonged equipment lifespan.

Frequent Problems

- Fuel Leakage: A prevalent issue occurs when fuel seeps from the tank or lines, potentially causing hazardous conditions.

- Starting Difficulties: Many users report challenges in starting the blower, often linked to clogged filters or faulty spark plugs.

- Overheating: Overheating can arise from debris buildup around the engine, reducing airflow and causing performance drops.

- Loss of Power: A decrease in blowing power may be due to wear on the impeller or restrictions in the air intake.

Maintenance Tips

- Regularly inspect and replace filters to ensure optimal airflow.

- Check fuel lines for cracks and ensure secure connections to prevent leaks.

- Keep the engine clean and free from debris to enhance cooling.

- Monitor spark plugs and replace them if signs of wear or fouling appear.

How to Replace Stihl BG85C Air Filter

Changing the air filter is a crucial maintenance step that enhances the efficiency and longevity of your equipment. A clean filter ensures that the engine receives the right amount of air for optimal performance. Here’s a step-by-step guide on how to carry out this task effectively.

- Gather Necessary Tools:

- New air filter

- Screwdriver (if needed)

- Clean cloth

- Locate the Air Filter:

The air filter is typically situated near the engine. Refer to the user manual for exact positioning.

- Remove the Cover:

Use a screwdriver to detach the cover, if applicable. Carefully set it aside to access the filter.

- Take Out the Old Filter:

Gently remove the old filter from its compartment. Be cautious to avoid any debris falling into the engine.

- Clean the Area:

Use a clean cloth to wipe any dust or debris from the filter compartment. This step helps in ensuring that the new filter fits securely.

- Install the New Filter:

Place the new air filter into the compartment, ensuring it fits snugly and is properly aligned.

- Reattach the Cover:

Secure the cover back in place using the screwdriver if necessary. Ensure it is fastened tightly to prevent any air leaks.

- Check the Installation:

Finally, verify that everything is properly secured and that the new filter is in place. Start the engine to ensure it runs smoothly.

Regularly replacing the air filter will help maintain peak performance and prevent potential engine issues. Follow these steps to ensure your machine operates efficiently.

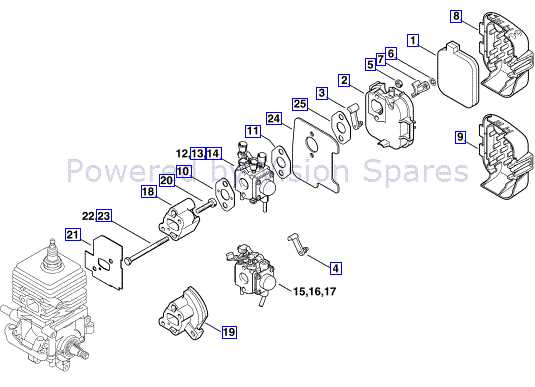

Guide to Stihl BG85C Fuel System Parts

The fuel system of a gardening device plays a crucial role in its overall performance and efficiency. Understanding the various components involved can enhance maintenance efforts and ensure optimal operation. This section provides an overview of the essential elements that contribute to a well-functioning fuel system.

Key Components of the Fuel System

Several vital components make up the fuel system, each serving a unique purpose. The fuel tank stores the necessary fuel for the operation of the equipment, while the fuel lines transport the mixture from the tank to the engine. Additionally, the fuel filter plays a critical role in keeping impurities away from the engine, ensuring a clean supply of fuel. Proper functioning of these elements is essential for smooth operation and longevity of the device.

Maintenance Tips for Fuel System Components

Regular maintenance is key to prolonging the life of the fuel system components. It is advisable to check the fuel filter periodically for clogs and replace it when necessary. Keeping the fuel tank clean and free from contaminants will also contribute to better performance. Furthermore, inspecting fuel lines for any signs of wear or leaks can prevent potential issues down the line. Implementing these maintenance practices will ensure the system operates effectively and efficiently.

Where to Find Stihl BG85C Spare Parts

When looking for replacement components for your outdoor equipment, it’s essential to know the best sources to ensure quality and compatibility. Various avenues exist for acquiring the necessary elements to keep your machinery in optimal condition.

Online marketplaces, specialized retailers, and local service centers can provide a wide selection of items. Each option has its advantages, whether it’s convenience, expert advice, or immediate availability.

Source Advantages Considerations Online Marketplaces Convenient, wide variety, competitive pricing Quality may vary, ensure seller reputation Specialized Retailers Expert advice, high-quality items Potentially higher prices, limited stock Local Service Centers Immediate availability, installation assistance Limited selection, possibly higher costs Troubleshooting Stihl BG85C Engine Components

When working with a specific engine model, understanding its operational challenges is essential for effective maintenance and repair. Various components can lead to performance issues, and identifying these problems can significantly enhance the longevity of the equipment. This section delves into common troubleshooting techniques and strategies to address engine-related concerns.

Common Engine Issues

Engine malfunction may manifest in several ways, including difficulty starting, erratic idling, or decreased power output. These symptoms can often be traced back to a few critical components. Fuel delivery systems, ignition parts, and air filters should be thoroughly examined to ensure optimal performance. Inspecting fuel lines for clogs and checking the condition of the spark plug are good initial steps.

Diagnostic Steps

To effectively diagnose engine problems, a systematic approach is recommended. Start by checking the fuel quality; stale or contaminated fuel can hinder operation. Next, inspect the air intake system for blockages that might restrict airflow. Additionally, verifying that all electrical connections are secure can help identify any electrical issues. For a more thorough analysis, using diagnostic tools can pinpoint specific component failures.