When it comes to maintaining your outdoor machinery, having a clear understanding of its various elements is crucial. Whether you are a seasoned professional or a weekend warrior, knowing how each piece fits together ensures optimal performance and longevity of your device.

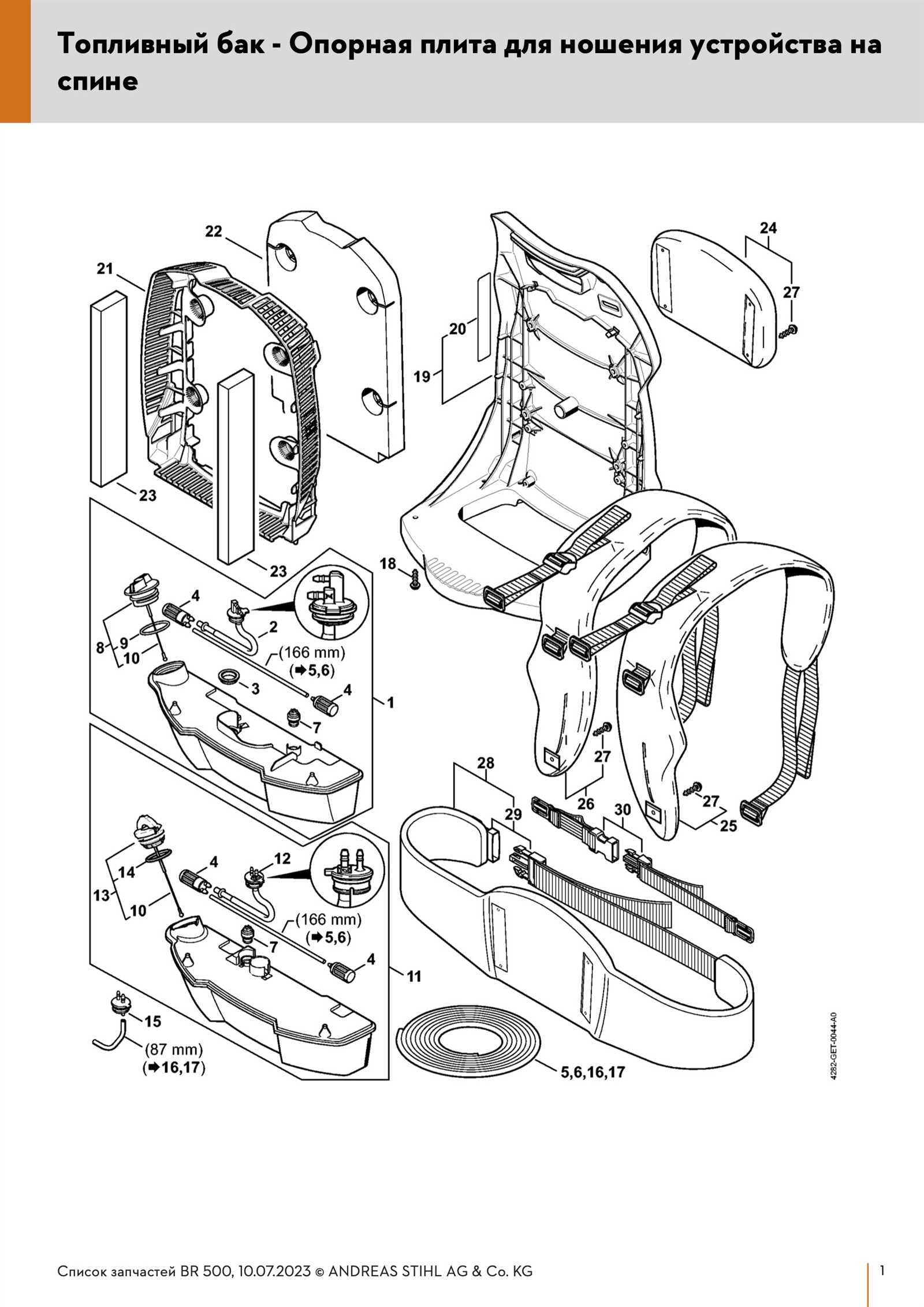

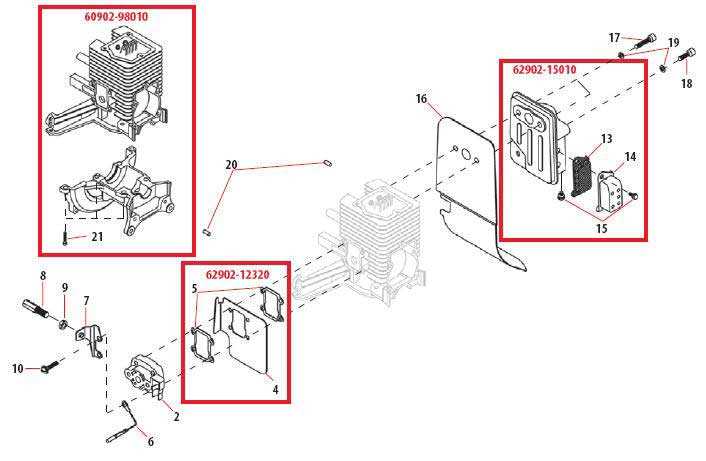

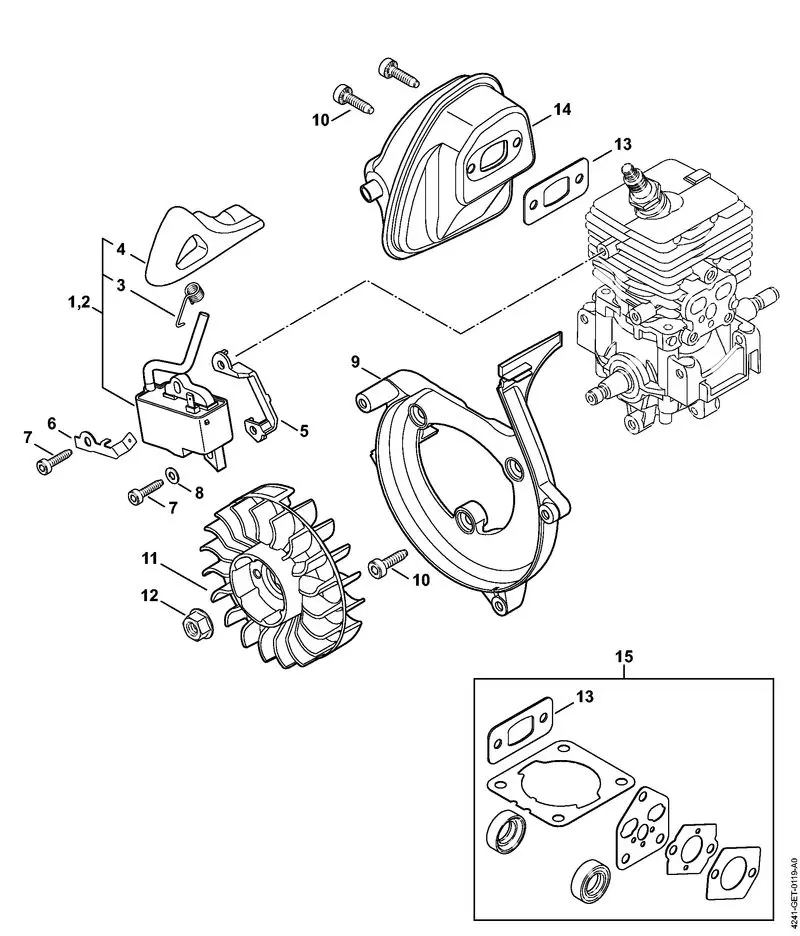

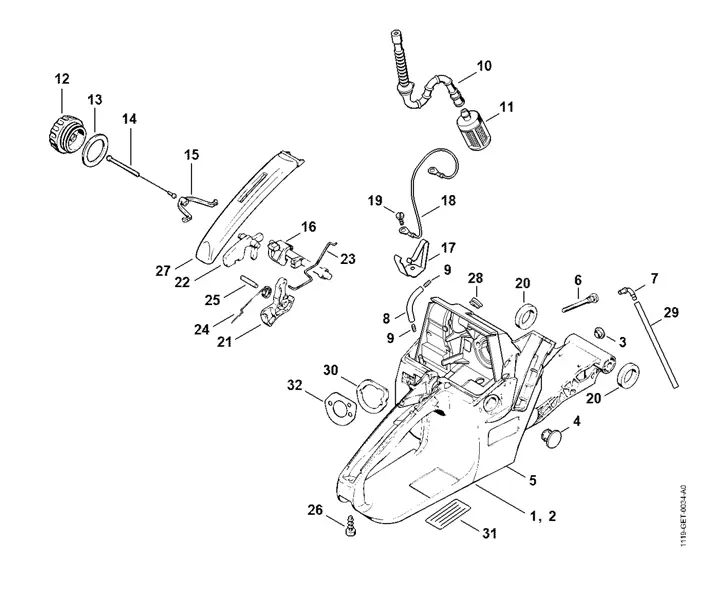

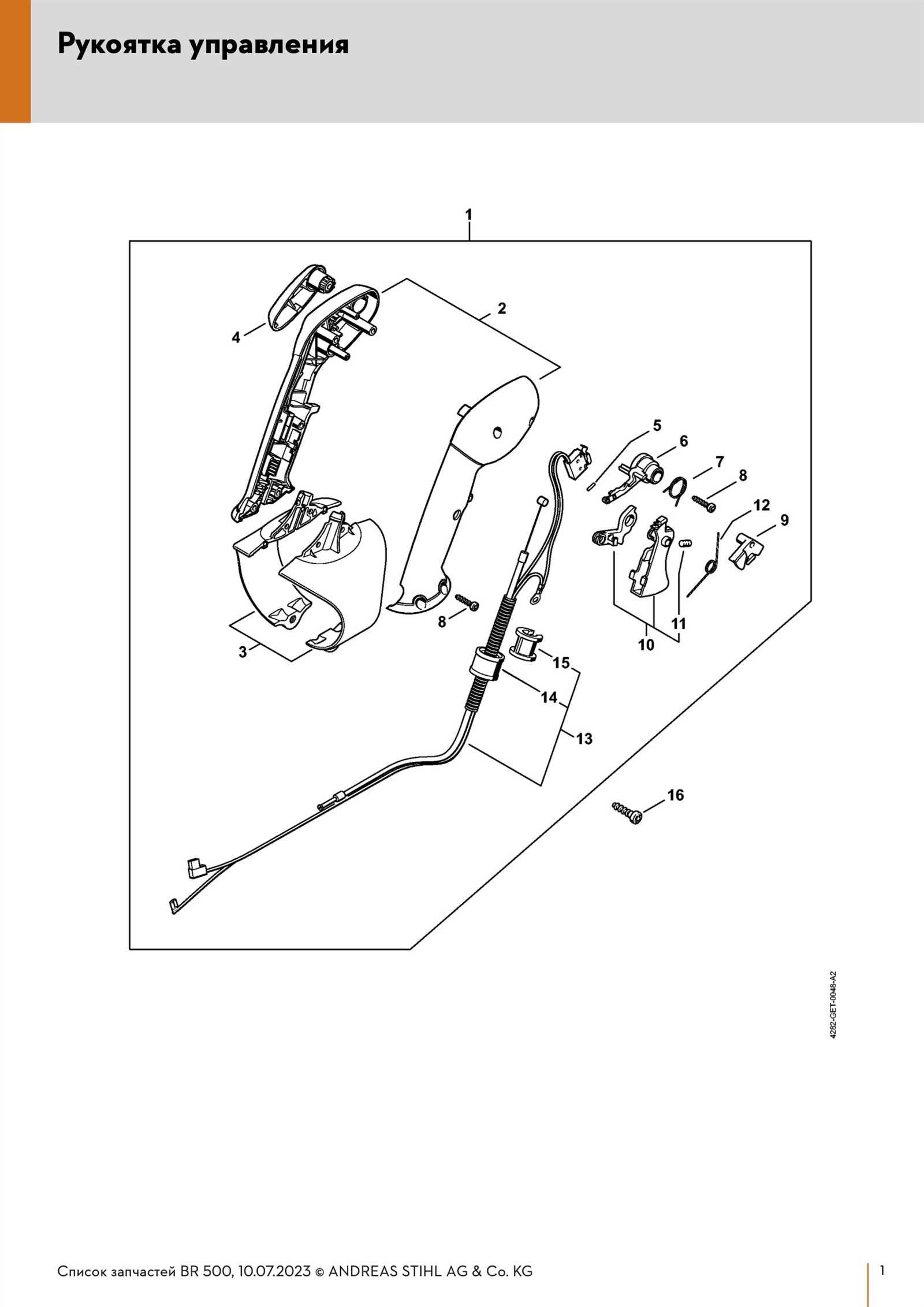

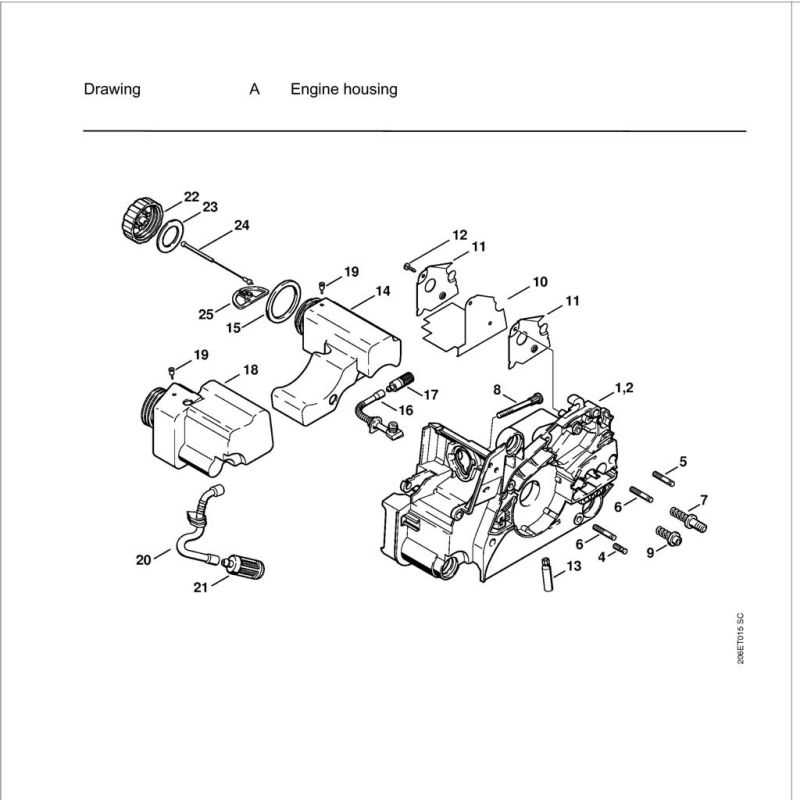

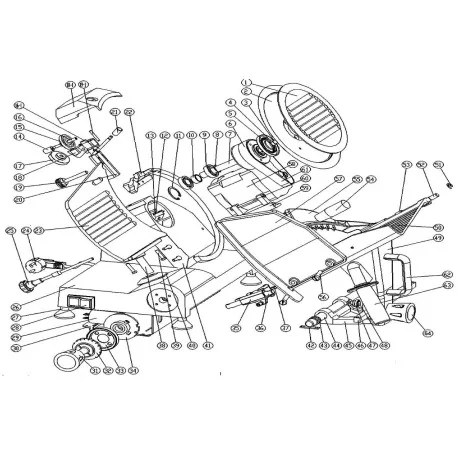

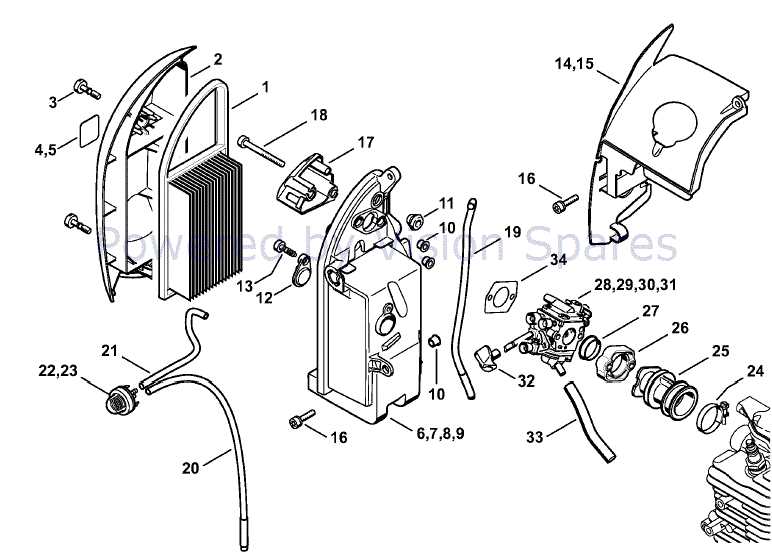

Visual representations of the intricate parts can significantly enhance your ability to troubleshoot and perform repairs. By studying these illustrations, you can easily identify specific components and their functions, which ultimately leads to more efficient upkeep.

Equipped with this knowledge, you can confidently approach maintenance tasks, ensuring that your equipment remains in peak condition. Proper care not only enhances functionality but also saves you time and money in the long run.

Understanding Stihl BR 350 Overview

This section aims to provide a comprehensive understanding of a popular outdoor power tool, focusing on its functionality, components, and overall importance in landscaping and maintenance tasks.

Key features of this equipment include:

- High performance for efficient operation.

- User-friendly design for ease of use.

- Durability, ensuring longevity under various conditions.

- Lightweight structure for enhanced maneuverability.

To fully appreciate its capabilities, one should consider:

- The engine specifications that drive its power.

- The ergonomic aspects that contribute to user comfort.

- The maintenance requirements to keep it functioning optimally.

- The safety features designed to protect the user during operation.

By exploring these aspects, users can delve into the ultimate experience this tool offers for their outdoor projects.

Key Components of Stihl BR 350

This section explores the essential elements of a powerful outdoor tool designed for efficient performance. Understanding these components is crucial for maintenance and optimal functioning.

- Engine: The heart of the machine, providing the necessary power.

- Fuel System: Ensures proper combustion for smooth operation.

- Air Filter: Protects the engine from dust and debris.

- Blower Tube: Directs airflow to enhance efficiency.

- Handle Assembly: Offers comfort and control during use.

Each of these elements plays a vital role in achieving the ultimate performance and longevity of the equipment.

Importance of Parts Diagrams

Visual representations of equipment components play a crucial role in maintenance and repair. They provide clarity on how different elements interact, ensuring that users can identify and address issues effectively. Such illustrations serve as a roadmap, guiding users through the intricacies of assembly and disassembly.

Benefits of Visual Guides

Utilizing visual aids can significantly enhance the efficiency of repair tasks. They allow technicians to quickly locate the necessary components, reducing downtime and preventing potential errors during reassembly.

Enhancing User Knowledge

Moreover, these illustrations contribute to a deeper understanding of the machinery, empowering users with the knowledge needed for effective upkeep. Familiarity with the layout can lead to better preventative maintenance strategies, ultimately extending the lifespan of the equipment.

| Benefit | Description |

|---|---|

| Time Efficiency | Reduces time spent on identifying components. |

| Accuracy | Minimizes errors in assembly and repair. |

| Understanding | Enhances knowledge of equipment operation. |

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repair of various equipment. These illustrations provide a comprehensive overview of individual elements and their interconnections, enabling users to identify what is needed for replacements or upgrades.

Key Components of Visual Representations

When examining these illustrations, it is essential to recognize several key features that facilitate comprehension:

| Feature | Description |

|---|---|

| Labels | Identifying each item clearly, usually with numbers or letters, for easy reference. |

| Connections | Indicating how different parts fit together, often shown with lines or arrows. |

| Sections | Dividing the illustration into manageable areas, focusing on specific components for clarity. |

| Legends | Providing additional information about symbols or color codes used in the representation. |

Interpreting the Information

To effectively use these visual guides, begin by familiarizing yourself with the layout and symbols employed. Cross-reference the labels with any accompanying documentation to ensure accuracy in identifying necessary components. Taking the time to understand these aspects can significantly enhance repair efficiency and reduce errors.

Common Issues with Stihl BR 350

When operating outdoor power equipment, users may encounter various challenges that can affect performance and efficiency. Recognizing these issues early on is essential to maintain optimal functionality and prolong the lifespan of the machine. Common concerns often stem from maintenance oversights, fuel-related problems, or wear and tear over time.

Fuel System Problems

One prevalent issue is related to the fuel system. Users might experience difficulty starting the machine or inconsistent operation, often due to stale or contaminated fuel. Regularly checking and replacing fuel, as well as ensuring proper fuel lines are intact, can mitigate these problems significantly.

Air Filter and Spark Plug Maintenance

Another common area of concern involves the air filter and spark plug. A clogged air filter can restrict airflow, leading to reduced performance and increased fuel consumption. Similarly, a worn spark plug can hinder ignition, resulting in poor starting and irregular engine performance. Regular inspection and cleaning of these components are crucial for smooth operation.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your outdoor equipment requires regular upkeep. By following a structured maintenance routine, you can prevent premature wear and extend the life of your machinery.

Routine Checks

Conduct frequent inspections to identify any signs of wear or damage. Regularly cleaning air filters and spark plugs can significantly improve efficiency and reduce potential issues.

Proper Storage

When not in use, store your equipment in a dry and sheltered area. Protecting it from moisture and extreme temperatures will prevent rust and degradation.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Clean air filter | Every 10 hours of use | Improves airflow and performance |

| Check spark plug | Every 25 hours of use | Ensures efficient ignition |

| Inspect fuel lines | Monthly | Prevents leaks and fuel contamination |

| Lubricate moving parts | Every 20 hours of use | Reduces friction and wear |

Where to Find Replacement Parts

When it comes to maintaining outdoor equipment, sourcing the right components is crucial for ensuring optimal performance and longevity. Various avenues exist for obtaining necessary items, catering to both professional landscapers and DIY enthusiasts alike.

Authorized Dealers: One of the most reliable sources is an official dealer. These establishments offer genuine components, ensuring compatibility and quality. They often provide expert advice, helping users identify the right pieces for their specific models.

Online Retailers: The internet has revolutionized shopping, allowing access to a vast array of suppliers. Numerous websites specialize in outdoor machinery, featuring detailed listings and customer reviews. This can assist in comparing prices and locating hard-to-find items.

Local Repair Shops: Visiting a nearby repair shop can yield unexpected treasures. Many technicians keep a stock of frequently replaced components and can offer insights based on their extensive experience with various models.

Aftermarket Suppliers: For those looking to save money, aftermarket options are worth considering. While these alternatives can be less expensive, it’s essential to verify their quality to avoid future issues.

Online Marketplaces: Platforms like eBay or Amazon can be valuable resources for both new and used components. Engaging with sellers directly might also lead to better deals or hard-to-find items.

Ultimately, knowing where to look for these essential elements can make a significant difference in maintaining the efficiency and effectiveness of your outdoor tools.

Stihl BR 350 Repair Guides

Proper maintenance and repair techniques are essential for keeping your equipment in optimal working condition. This section provides valuable insights and instructions for addressing common issues, ensuring longevity and efficiency. With the right approach, you can tackle various repairs and enhance the performance of your machinery.

Common Issues and Solutions

- Starting Problems: Check the fuel system, ignition components, and air filters. Ensure that the spark plug is clean and properly gapped.

- Reduced Power: Inspect the air intake and exhaust systems for blockages. Clean or replace the necessary filters to restore airflow.

- Vibration Issues: Examine the engine mounts and fasteners. Tightening loose components can often reduce unwanted vibrations.

Maintenance Tips

- Regularly clean the equipment after use to prevent dirt accumulation.

- Replace filters and fluids as per the manufacturer’s recommendations.

- Inspect and sharpen cutting tools frequently to maintain performance.

Comparing Stihl BR 350 to Competitors

When evaluating different models in the world of outdoor power equipment, it is essential to analyze key features, performance metrics, and overall user satisfaction. This comparison aims to highlight the strengths and weaknesses of a specific blower against its rivals, helping consumers make informed decisions.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Engine Power | 25cc | 30cc | 28cc |

| Weight | 9.5 lbs | 10 lbs | 9 lbs |

| Air Speed | 150 mph | 160 mph | 155 mph |

| Fuel Efficiency | 50 mpg | 45 mpg | 48 mpg |

| Price | $299 | $349 | $319 |

By considering these aspects, users can delve deeper into which model ultimately meets their needs and expectations, allowing for a well-rounded purchase decision.

Upgrades for Enhanced Performance

Improving the efficiency and power of your equipment can significantly enhance its overall functionality. By exploring various enhancements, users can unlock greater potential and experience a more satisfying operation. These upgrades often focus on optimizing engine output, improving air circulation, and refining user control.

Engine Optimization

Upgrading the engine components can lead to noticeable improvements in performance. Consider replacing standard parts with high-performance alternatives that allow for increased horsepower and torque. This modification not only boosts efficiency but also extends the lifespan of your machine.

Airflow Enhancement

Enhancing airflow is crucial for maximizing combustion efficiency. Installing advanced air filters or intake systems can significantly improve the air-fuel mixture, resulting in smoother operation and better throttle response. These adjustments ensure your equipment runs at its ultimate capacity.

User Experiences and Reviews

This section explores the feedback and insights shared by users regarding a specific outdoor power tool. These reflections often highlight the strengths and weaknesses encountered during various tasks, providing potential buyers with valuable perspectives.

However, there are mentions of challenges as well, such as the need for regular maintenance to ensure optimal functionality. A few users have also reported occasional issues with specific components, prompting discussions on the importance of understanding the tool’s mechanics.

Overall, the collective experiences serve as a helpful guide for individuals considering this tool, enabling them to make informed decisions based on real-world usage.