For anyone working with outdoor machinery, grasping the intricate details of its components is essential for efficient operation and maintenance. This knowledge not only enhances performance but also extends the lifespan of your equipment. A clear visual representation of all the individual elements can greatly assist in identifying each part and understanding its function within the system.

When it comes to optimizing the use of your tools, familiarity with the layout and connections of various components is invaluable. An organized view helps in troubleshooting issues, making repairs, and conducting regular maintenance tasks. By having a comprehensive reference, you can ensure that every piece operates harmoniously, contributing to overall efficiency.

Whether you are a seasoned professional or a weekend warrior, knowing how to interpret a visual guide of your machinery’s components can be a game-changer. It empowers users to take proactive steps in upkeep, minimizing downtime and maximizing productivity. As we delve deeper into the subject, we will explore essential elements and their relationships, providing you with the insights needed to keep your equipment running smoothly.

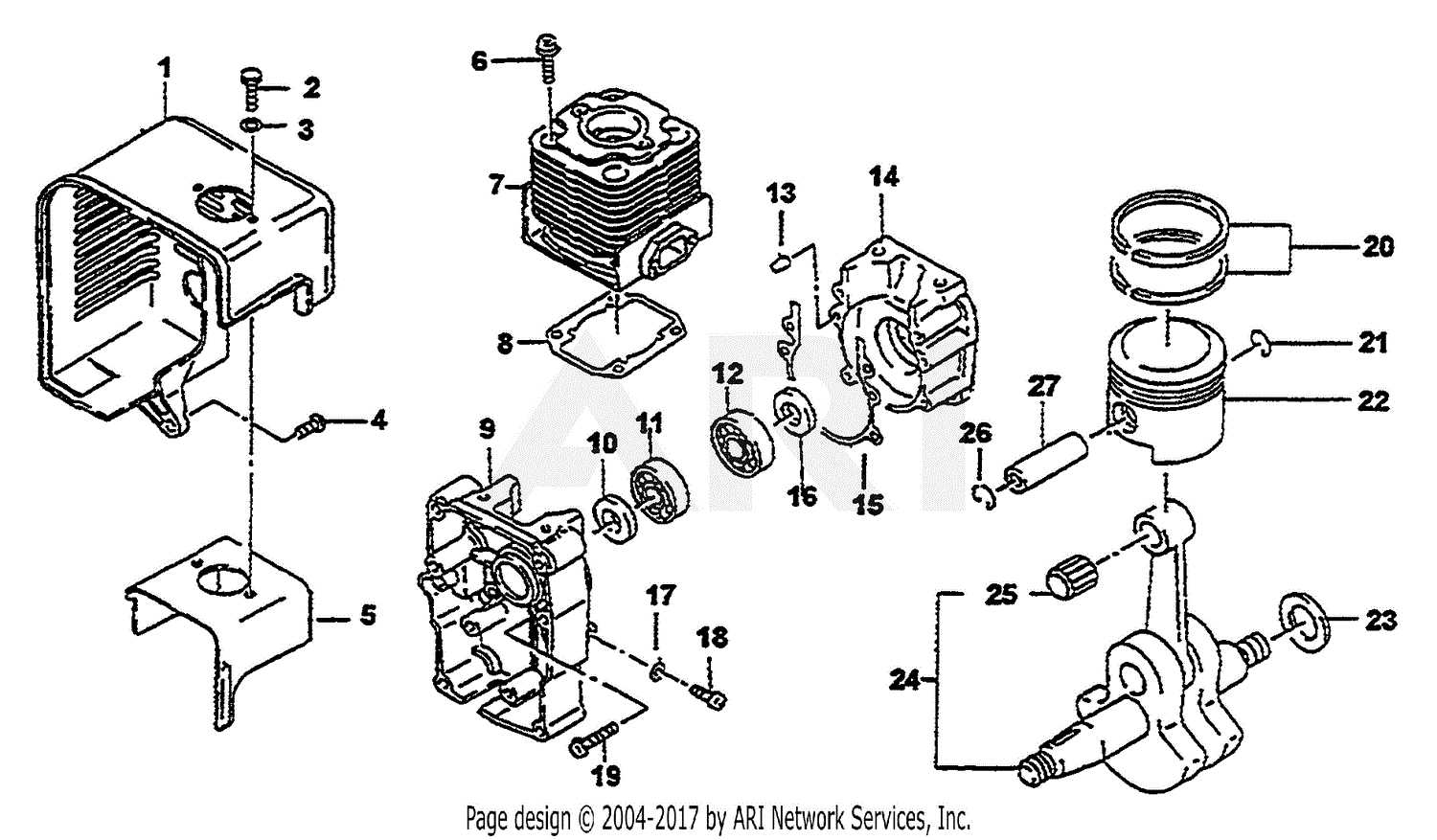

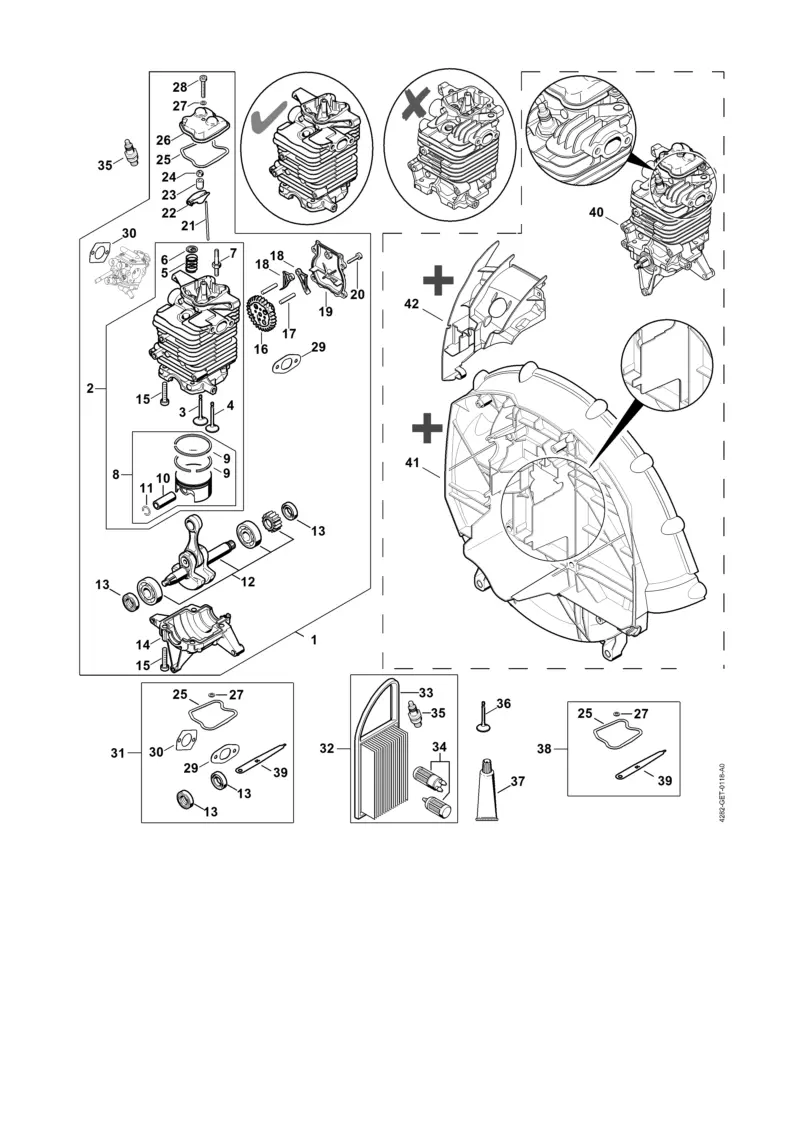

Understanding the Stihl BR600 Components

Grasping the intricate elements of a powerful outdoor tool is essential for effective maintenance and optimal performance. Each component plays a vital role in the overall functionality, contributing to both efficiency and durability. By examining these elements, users can ensure their equipment remains in peak condition, ultimately extending its lifespan.

Key Elements of the Equipment

The machinery consists of several crucial parts that work together seamlessly. Each section serves a distinct purpose, influencing the tool’s ability to perform tasks efficiently. Understanding these parts is imperative for troubleshooting and repair.

| Component | Function |

|---|---|

| Engine | Powers the machine, providing necessary energy for operation. |

| Fuel Tank | Holds the fuel that feeds the engine, ensuring prolonged usage. |

| Air Filter | Prevents dirt and debris from entering the engine, maintaining performance. |

| Fan Housing | Directs airflow, helping to cool the engine during operation. |

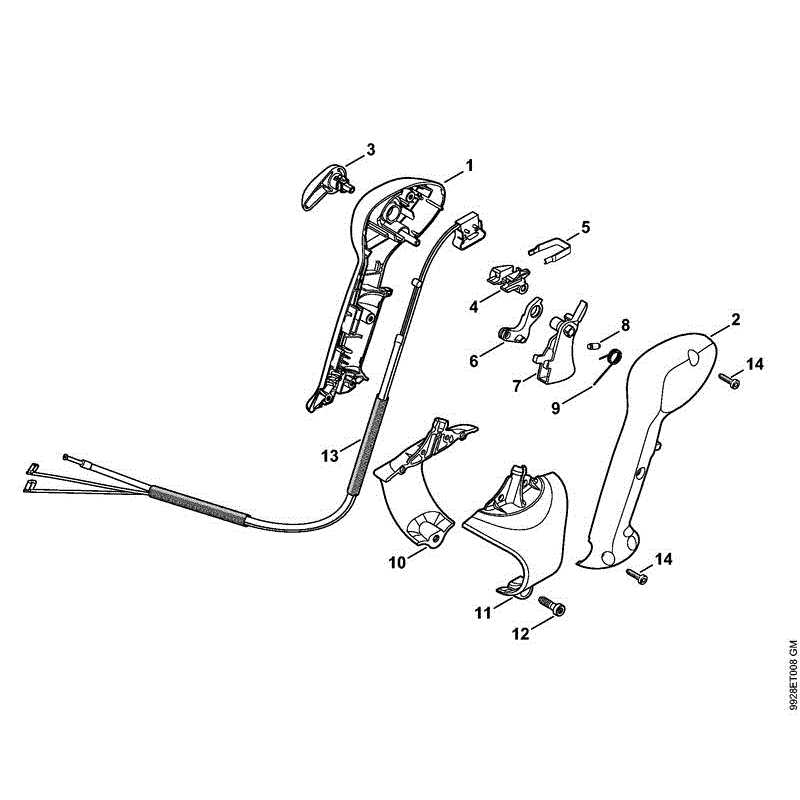

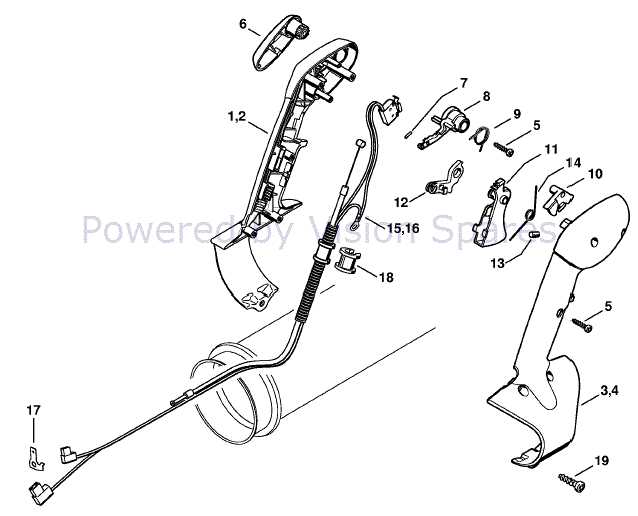

| Throttle Control | Regulates engine speed and power output, allowing for versatility in use. |

Maintenance Tips

Regular checks and upkeep of these vital elements can prevent many common issues. Cleaning the air filter, checking fuel levels, and inspecting the engine regularly can significantly enhance performance and reliability. By understanding each component’s role, users can better maintain their equipment and ensure it operates smoothly for years to come.

Key Features of the BR600 Model

This model stands out due to its exceptional performance and advanced engineering, making it a favorite among outdoor maintenance enthusiasts. With a focus on power, efficiency, and user comfort, it caters to a variety of landscaping needs.

Power and Efficiency

- Robust engine providing high air speed for effective debris removal.

- Fuel-efficient design that minimizes consumption while maximizing output.

- Innovative technology ensuring reliable start-up in various conditions.

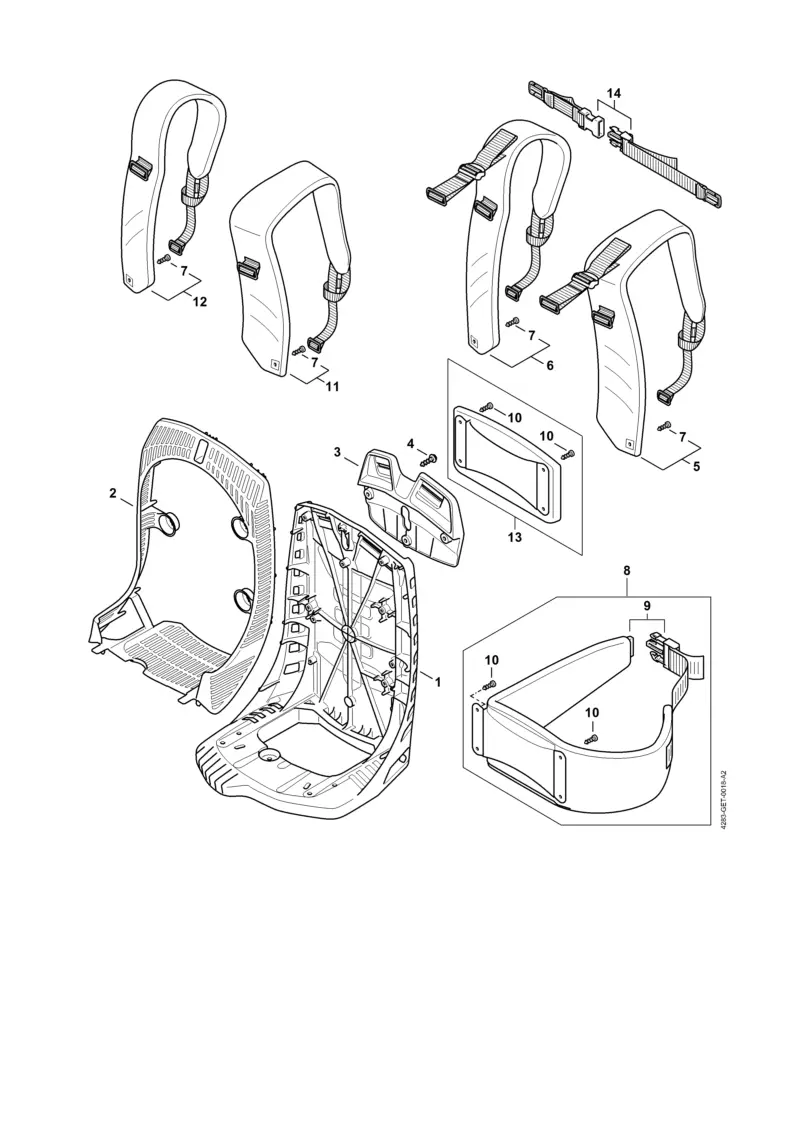

User Comfort and Ergonomics

- Lightweight construction reducing user fatigue during prolonged use.

- Adjustable harness system allowing for a personalized fit.

- Low vibration levels enhancing comfort and control.

Essential Parts for Maintenance

Regular upkeep of outdoor equipment is crucial for ensuring optimal performance and longevity. Knowing the key components that require attention can significantly enhance the efficiency and reliability of your tools.

- Air Filter: Keeps dust and debris from entering the engine, promoting efficient combustion.

- Fuel Filter: Prevents impurities in the fuel from clogging the system, ensuring smooth operation.

- Spark Plug: Essential for ignition, a well-maintained spark plug enhances starting and performance.

- Throttle Cable: Controls the engine speed, and its proper function is vital for maneuverability.

- Fuel Line: Transports fuel from the tank to the engine; a damaged line can lead to leaks and performance issues.

Regular inspections and timely replacements of these components will help maintain the efficiency of your equipment, reduce the risk of breakdowns, and ultimately save on repair costs.

- Check the air filter every month for dirt buildup.

- Replace the fuel filter annually to ensure clean fuel flow.

- Inspect the spark plug after every few uses for wear and tear.

- Test the throttle cable for smooth operation during each use.

- Examine the fuel line for cracks or leaks regularly.

By prioritizing these essential elements, users can enjoy a more reliable and efficient experience with their outdoor machinery.

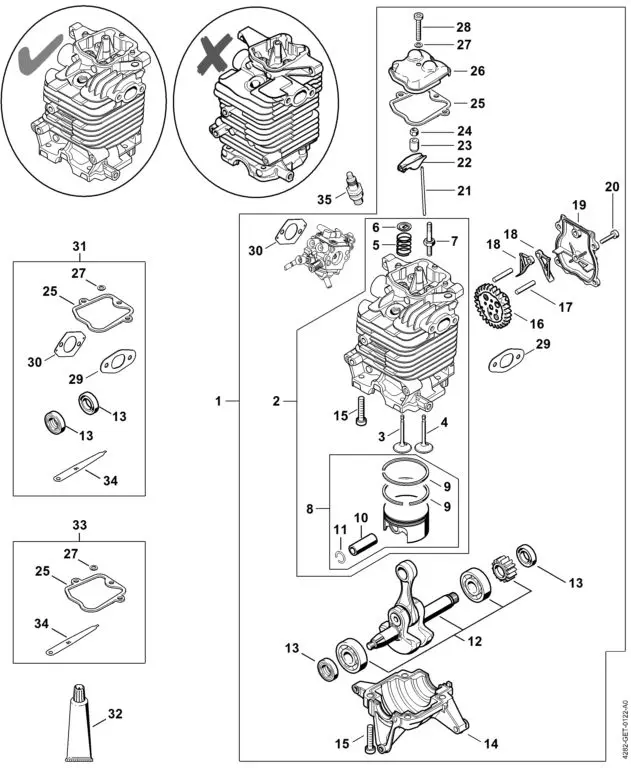

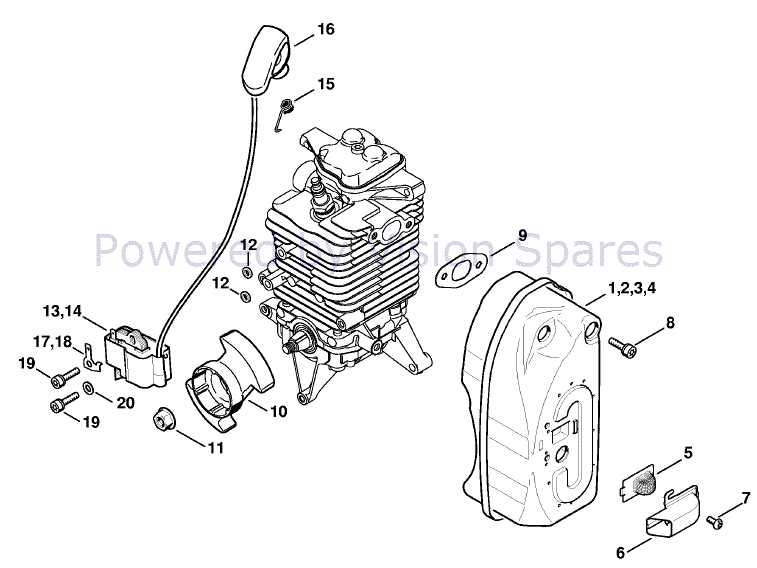

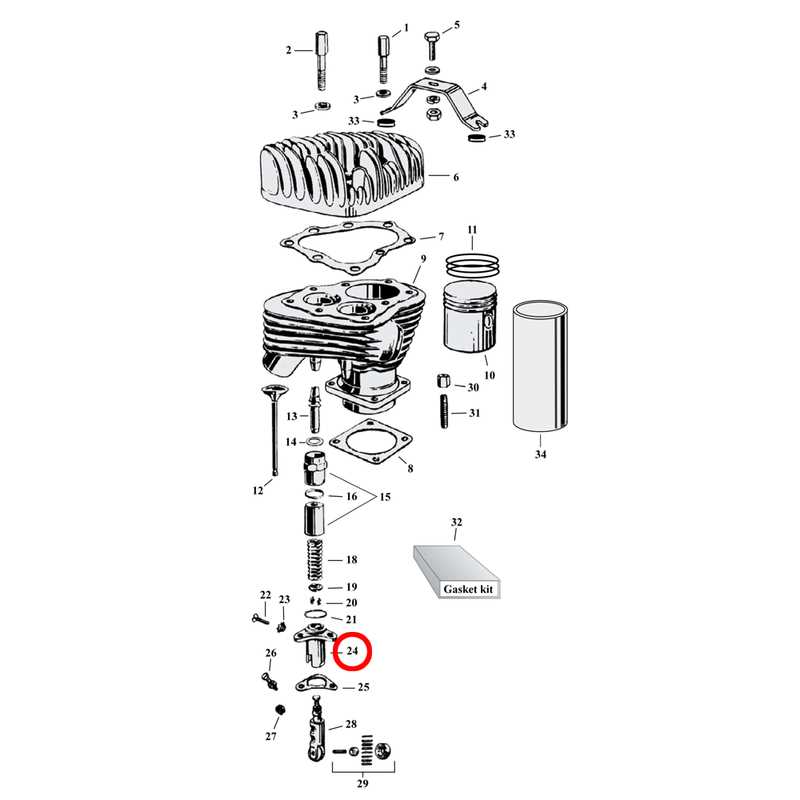

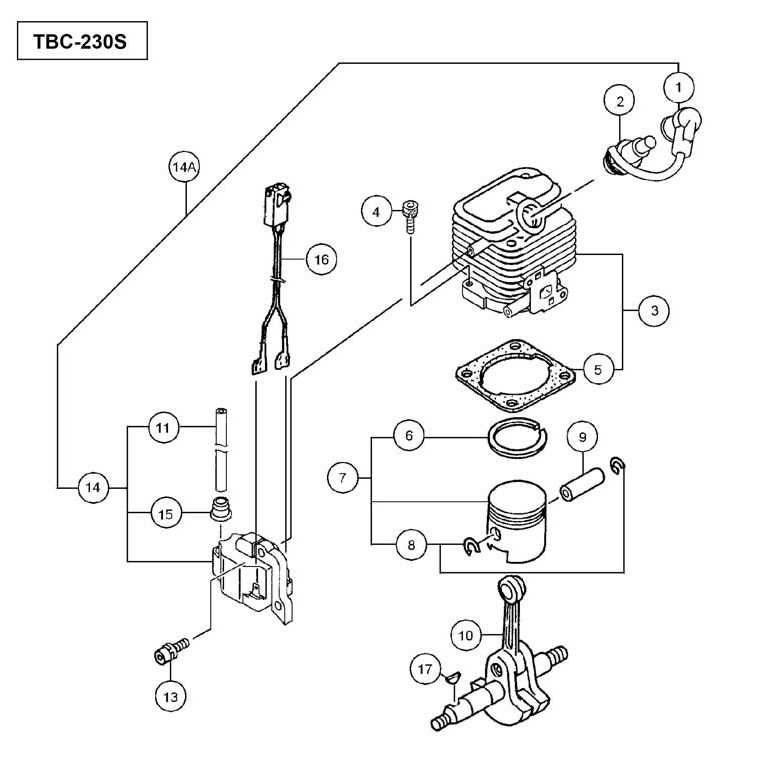

How to Interpret the Diagram

Understanding a technical illustration can significantly enhance your ability to troubleshoot and maintain equipment effectively. These visuals provide a comprehensive overview of components and their interrelations, making it easier to identify issues and perform repairs.

Key Elements to Focus On

- Labels: Each part is usually accompanied by specific identifiers, ensuring clarity.

- Connections: Pay attention to how different elements are linked, as this reveals their functionality.

- Legend: Many illustrations include a legend that explains symbols or color codes used.

Steps for Effective Interpretation

- Begin by familiarizing yourself with the overall layout.

- Identify and study the labeled components.

- Cross-reference with the legend for better understanding.

- Take notes on critical connections that may affect operation.

Common Replacement Parts Explained

Understanding essential components is crucial for maintaining and optimizing outdoor power equipment. Each machine relies on specific elements that may require periodic replacement to ensure optimal performance. Familiarity with these key items not only enhances longevity but also contributes to efficient operation.

One of the most vital components is the air filter, which prevents debris from entering the engine and maintains airflow. Regular replacement helps avoid performance issues and prolongs the life of the machinery. Another critical item is the spark plug, which ignites the fuel mixture; a worn spark plug can lead to starting difficulties and reduced efficiency.

Fuel lines are equally important, as they transport gasoline to the engine. Over time, these lines can degrade, causing leaks that compromise performance. Additionally, the cutting head or blade must be inspected and replaced when dull to ensure effective operation. Regularly addressing these elements keeps equipment running smoothly and minimizes the risk of breakdowns.

Tools Needed for Repairs

When tackling maintenance tasks, having the right equipment is essential for achieving optimal results. Various instruments can streamline the repair process, ensuring that you work efficiently and effectively. This section will outline the necessary tools that facilitate smooth operations and enhance your overall experience.

First and foremost, a reliable set of screwdrivers is crucial for loosening and tightening screws in different sizes. Pliers are also invaluable, offering grip and leverage for various components. Additionally, a socket set can provide the versatility needed for numerous applications, making it easier to work with nuts and bolts.

For precise adjustments, consider using a torque wrench, which helps in applying the correct amount of force. Safety goggles and gloves are essential for protecting yourself during the repair process. Lastly, having a clean workspace equipped with a sturdy workbench can greatly improve your efficiency and organization.

Step-by-Step Repair Process

This section outlines a comprehensive approach to restoring your equipment efficiently. Following these steps will help ensure that the repair is effective and lasting, minimizing the chances of future issues.

Preparation and Assessment

Begin by gathering all necessary tools and materials. Carefully assess the condition of the equipment, identifying any visible damage or wear. This initial inspection is crucial for planning the subsequent steps and understanding what needs to be addressed.

Disassembly and Replacement

Proceed with disassembling the unit methodically. Keep track of all components and their positions. Replace any damaged parts with new ones, ensuring that each piece fits securely. Reassemble the equipment in the reverse order of disassembly, verifying that everything is in its correct place. Final checks before usage are essential to confirm that the repair was successful.

Identifying Wear and Tear

Recognizing signs of degradation in equipment is crucial for maintaining optimal performance and longevity. Regular inspection can help identify issues before they escalate, ensuring efficient operation and preventing costly repairs.

Common indicators of deterioration include:

- Unusual noises during operation

- Reduced efficiency or power

- Excessive vibrations

- Visible damage or wear on components

To effectively monitor condition:

- Conduct routine visual checks.

- Listen for abnormal sounds while in use.

- Track performance changes over time.

- Keep a log of any repairs or maintenance performed.

By staying vigilant and addressing these signs promptly, users can ensure their equipment remains in peak condition for the ultimate task ahead.

Ordering Genuine Stihl Parts

When maintaining equipment, acquiring authentic components is crucial for optimal performance and longevity. Using high-quality replacements ensures reliability and efficiency, making it essential to source items from reputable suppliers.

Benefits of Genuine Components

- Enhanced durability and performance

- Guaranteed compatibility with your machinery

- Access to manufacturer support and warranties

How to Order

- Identify the specific component needed for your equipment.

- Visit authorized dealers or trusted online platforms.

- Provide the model number and description to ensure accuracy.

- Confirm the order and check for shipping options.

Comparing BR600 with Other Models

This section explores the similarities and differences between a particular blower model and its competitors. By examining key features, performance metrics, and user experiences, we can better understand how this model stands out in the marketplace.

When evaluating power equipment, factors such as engine efficiency, weight, and noise levels are crucial. This model offers robust performance with a powerful engine, making it suitable for both residential and commercial use. In contrast, some alternatives may prioritize lighter weight for ease of handling, but at the expense of raw power.

Another important aspect to consider is the design and ergonomics. This model often features a well-balanced build that enhances user comfort during extended periods of operation. Some rival units might lack similar ergonomic considerations, leading to fatigue over time.

Additionally, maintenance requirements can vary significantly among different brands. This particular model is designed for easier servicing, which can be a considerable advantage for users who want to minimize downtime. On the other hand, competitors might necessitate more frequent or complex maintenance routines.

Ultimately, choosing the right blower involves assessing specific needs and preferences. While this model excels in power and comfort, other options may appeal to those prioritizing portability or lower noise levels. Understanding these differences is key to making an informed decision.

Tips for Efficient Use

Maximizing performance and longevity of your equipment requires attention to detail and best practices during operation. Understanding the nuances of your machine can significantly enhance its efficiency, reduce wear, and ultimately save time and resources.

Maintenance Practices

Regular upkeep is crucial for ensuring optimal function. Here are some key maintenance tips:

| Task | Frequency | Description |

|---|---|---|

| Inspect Fuel System | Before each use | Check for leaks and ensure proper fuel mix for peak performance. |

| Clean Air Filter | Weekly | Remove dirt and debris to maintain airflow and engine efficiency. |

| Sharpen Blades | After every 10 hours of use | Keep cutting edges sharp for effective operation and reduced strain. |

| Check Spark Plug | Monthly | Inspect for wear and replace if necessary to ensure reliable ignition. |

Operational Techniques

Employing the right techniques during use can also lead to improved results. Consider these strategies:

- Utilize appropriate attachments based on the task for enhanced efficiency.

- Maintain a steady pace while working to ensure thorough coverage without overexerting the machine.

- Plan your approach to avoid unnecessary backtracking, optimizing your time and effort.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance on equipment is crucial to prevent accidents and injuries. Proper precautions can significantly reduce risks associated with repair work. Following guidelines and using the right protective gear will contribute to a secure working environment.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use gloves, goggles, and sturdy footwear to protect yourself from potential hazards. |

| Disconnect Power Source | Before beginning any repairs, ensure that the equipment is unplugged or the fuel is removed. |

| Work in a Well-Ventilated Area | Make sure your workspace is properly ventilated to avoid inhaling harmful fumes. |

| Keep Tools Organized | Maintain a tidy workspace by organizing tools and materials to minimize tripping hazards. |

| Follow Manufacturer Guidelines | Refer to the manufacturer’s manual for specific safety instructions related to your equipment. |

Frequently Asked Questions about Parts

This section addresses common inquiries regarding components used in outdoor power equipment. Understanding these elements can enhance maintenance and ensure optimal performance for users.

What should I consider when replacing components?

When seeking replacements, evaluate the compatibility, quality, and authenticity of the items. Choosing high-quality replacements can lead to improved efficiency and longevity of your equipment.

How can I identify the right component for my equipment?

To pinpoint the correct element, refer to the manufacturer’s manual or consult authorized dealers. Additionally, utilizing online resources and forums can provide valuable insights and assistance in your search.