When it comes to maintaining outdoor power equipment, having a clear grasp of its various elements is crucial for optimal performance. This section aims to provide a comprehensive overview of the intricate components that contribute to the functionality of a specific model. By familiarizing yourself with these elements, you can ensure that your equipment operates smoothly and efficiently.

For users and enthusiasts alike, recognizing how each component interacts within the overall system can simplify troubleshooting and repairs. By delving into the configuration of this model, you will gain insights into its essential features and mechanisms. This understanding not only enhances the longevity of the device but also empowers users to address common issues independently.

Ultimately, a thorough comprehension of the various components is indispensable for anyone looking to enhance their knowledge and expertise. Whether you are a casual user or a dedicated hobbyist, this guide will serve as a valuable resource for navigating the complexities of this outdoor tool.

Understanding the Components of Stihl FS 56 C

The intricate design of this gardening tool incorporates various essential elements that work harmoniously to ensure optimal performance. Each component plays a vital role in the overall functionality, contributing to the efficient operation and longevity of the equipment.

Engine serves as the heart of the machine, providing the necessary power for cutting tasks. Its design enhances fuel efficiency and reduces emissions, making it an eco-friendly choice for landscaping.

The cutting head is crucial for achieving precise trimming and edging. Equipped with sharp blades or strings, it adapts easily to different types of vegetation, ensuring versatility in usage.

Handle design influences user comfort and control. Ergonomically shaped, it allows for prolonged use without causing fatigue, which is especially important during extended gardening sessions.

Additionally, the fuel system is engineered to deliver a consistent flow of energy to the engine. This system ensures that the machine runs smoothly and efficiently, reducing the likelihood of interruptions during work.

Finally, the starter mechanism simplifies the process of powering up the device, providing users with a hassle-free experience right from the beginning. Understanding these components is essential for proper maintenance and effective operation.

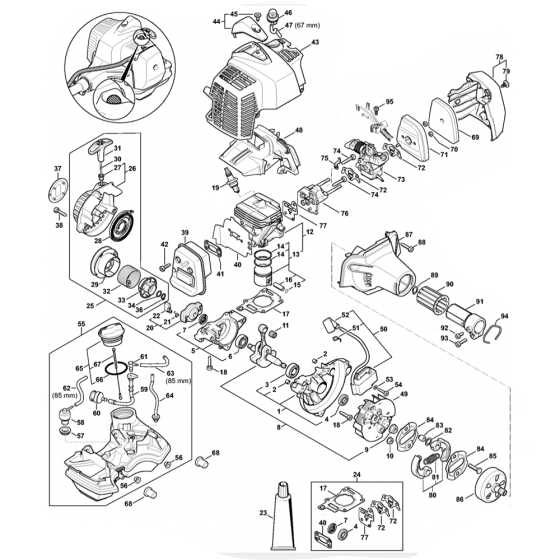

Engine Assembly Overview

The heart of any power tool is its engine, which serves as the driving force behind its performance. This section delves into the intricate components that comprise the engine unit, highlighting their roles and how they work together to ensure efficient operation. Understanding these elements is crucial for anyone looking to maintain or repair such machinery.

Each engine assembly includes several key components, such as the cylinder, piston, and crankshaft, all of which contribute to the machine’s power output and reliability. Proper maintenance of these parts is essential for optimal functioning. Regular inspections can help identify wear and tear before they lead to significant issues, ensuring longevity and sustained performance.

Additionally, it’s vital to recognize the significance of fuel delivery systems and ignition components, which play a crucial role in the engine’s overall efficiency. By familiarizing oneself with the assembly’s layout and functionality, operators can enhance their understanding of the equipment, leading to better care and informed decision-making regarding repairs or upgrades.

Throttle Mechanism Breakdown

The throttle mechanism plays a crucial role in regulating the engine’s power output by controlling the air-fuel mixture. Understanding its components and functionality is essential for maintaining optimal performance and ensuring efficient operation.

Key elements of this mechanism include:

- Control Lever: This is the part the operator engages to adjust the throttle position, influencing engine speed.

- Linkage System: Comprising rods and connectors, this system transmits motion from the control lever to the throttle valve.

- Throttle Valve: This component regulates airflow into the engine, directly affecting power and speed.

- Return Spring: Responsible for returning the throttle lever to its default position when not in use, ensuring safety and control.

Regular inspection and maintenance of these components can prevent performance issues and extend the lifespan of the equipment. Ensuring that the throttle mechanism operates smoothly is vital for achieving the desired cutting power and efficiency.

Handle Parts and Functions

The handle assembly plays a crucial role in the overall functionality and user experience of outdoor power tools. This section explores the various components associated with the handle, their roles, and how they contribute to the efficient operation of the device.

- Main Handle: The primary grip area that allows for comfortable maneuvering and control during operation.

- Throttle Trigger: A control mechanism that regulates the engine speed, allowing for precision in operation.

- Trigger Lock: A safety feature that prevents accidental activation of the throttle, enhancing user safety.

- Support Handle: Provides additional stability and support, particularly during extended use or when navigating challenging terrains.

- Grip Pads: Textured surfaces that enhance traction and comfort, reducing fatigue during prolonged usage.

Understanding the functionality of these components is essential for users aiming to maintain their equipment effectively. Each element works together to ensure optimal performance and safety, allowing for seamless operation.

Fuel System Layout and Components

The fuel mechanism is essential for the proper functioning of any small engine, ensuring a smooth delivery of the energy source to the combustion chamber. This intricate system is designed to manage the flow, mixture, and delivery of fuel, contributing to optimal performance and efficiency. Understanding its various components helps in maintaining and troubleshooting the device effectively.

At the core of the fuel arrangement is the fuel tank, which stores the liquid used for powering the engine. Connected to this tank is a fuel line, allowing for the transfer of fuel to other components. The fuel filter plays a critical role in this system by removing impurities from the fuel before it reaches the engine, preventing potential damage and ensuring longevity.

Additionally, the carburetor is a vital element that mixes the fuel with air in the right proportions, allowing for efficient combustion. This mixture is then delivered to the engine through the intake system, ensuring that the engine receives the correct amount of fuel and air for optimal operation. Proper maintenance of these components is crucial for the overall performance and reliability of the equipment.

Air Filter and Housing Diagram

This section provides a detailed overview of the components responsible for maintaining optimal airflow within the engine system. Proper air circulation is vital for ensuring efficient operation, preventing contaminants from entering the engine, and prolonging the equipment’s lifespan.

Key Components

- Filter Element: The primary barrier that traps dust and debris.

- Housing: The protective casing that encases the filter and ensures a tight fit.

- Intake Ports: Openings that allow air to flow into the housing.

- Mounting Screws: Fasteners that secure the housing in place.

Functionality Overview

The air filtration system operates by drawing in ambient air through the intake ports. As air passes through the filter element, particulates are captured, preventing them from reaching the engine. This process is crucial for maintaining engine efficiency and performance.

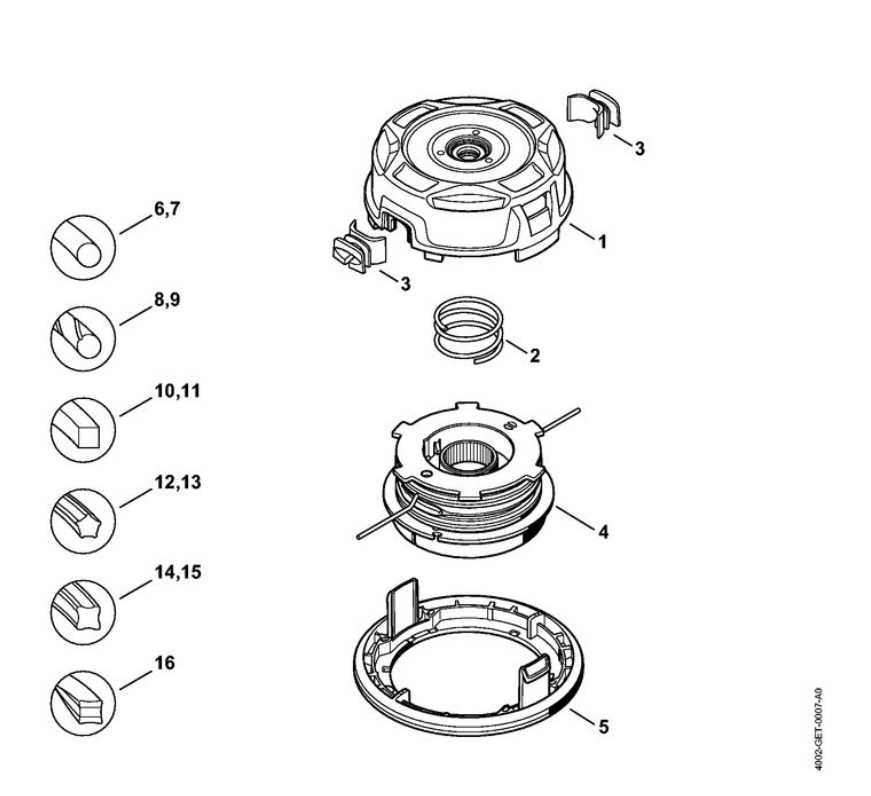

Clutch System and Associated Parts

The clutch mechanism is a vital component in the operation of various outdoor power equipment. It facilitates the engagement and disengagement of the cutting tool, allowing for efficient control during operation. Understanding this assembly is essential for proper maintenance and troubleshooting.

Key Components of the Clutch Mechanism

- Clutch Drum: This is the housing that connects to the engine and transmits power to the cutting attachment.

- Spring: These elements provide the necessary tension to engage the clutch, allowing for smooth operation.

- Clutch Shoes: These components engage with the drum to transfer torque from the engine to the cutting tool.

- Drive Gear: It connects the engine to the clutch, playing a crucial role in power transmission.

Maintenance Tips for the Clutch Assembly

- Regularly inspect the clutch drum for wear and damage.

- Ensure the springs are functioning properly to maintain optimal engagement.

- Clean the clutch shoes to remove debris that may hinder performance.

- Replace any worn components promptly to avoid further issues.

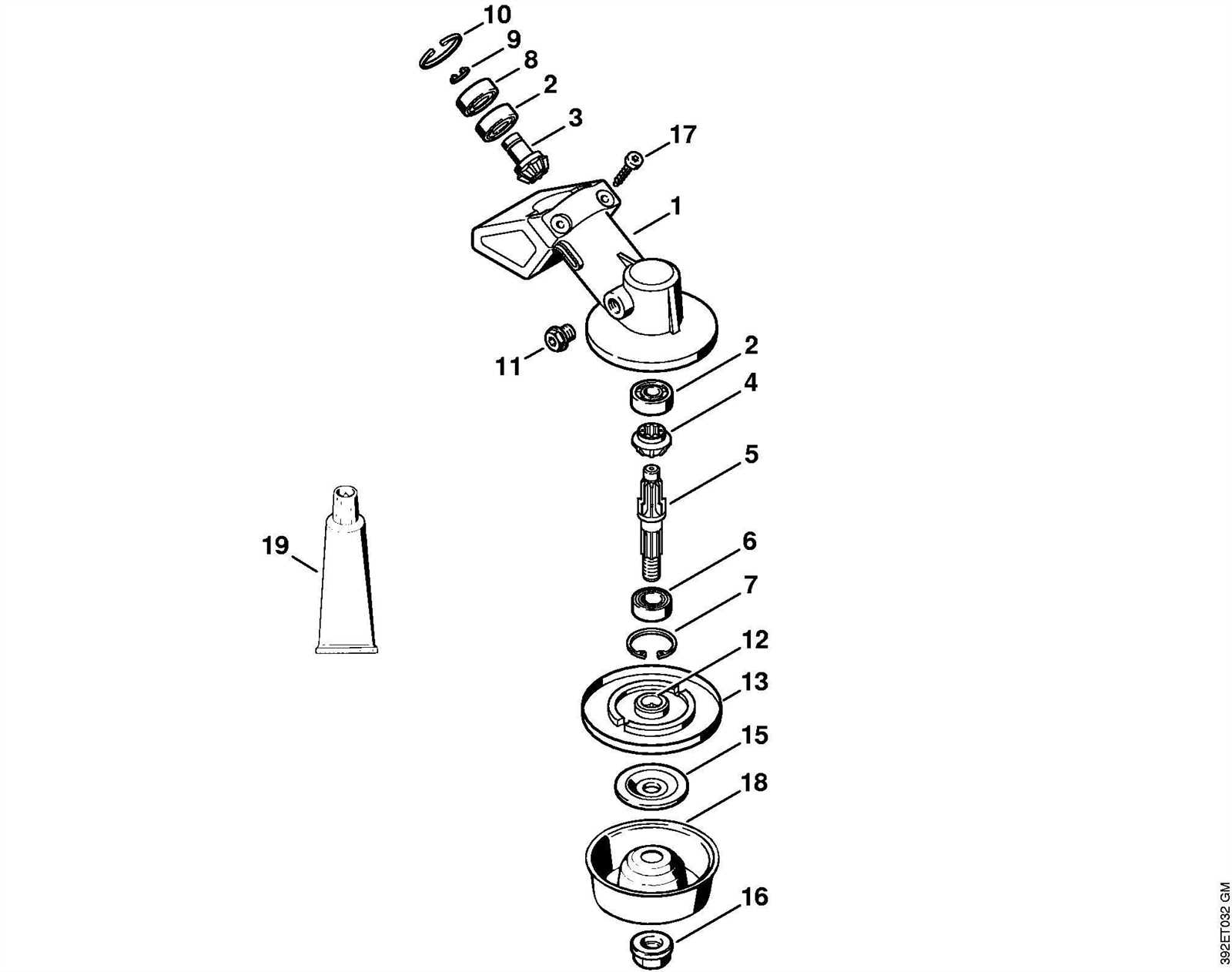

Cutting Head Configuration

The arrangement of the cutting mechanism plays a crucial role in the efficiency and performance of the trimming tool. Understanding how this assembly works can enhance the user’s experience and ensure optimal results in various landscaping tasks. A well-designed cutting head allows for seamless operation, adapting to different environments and requirements.

Types of Cutting Heads

There are several types of cutting mechanisms available, each suited for specific tasks. Fixed line heads are popular for their simplicity and ease of use, while spool heads offer the convenience of automatic line feeding, allowing for uninterrupted operation. Metal blades are ideal for tougher vegetation, providing durability and effectiveness in challenging conditions.

Maintenance Tips

To maintain optimal performance, regular inspection and maintenance of the cutting head are essential. Ensure that the line is properly wound and free of tangles. Check for any signs of wear on blades or components and replace them as needed. Keeping the assembly clean and lubricated will enhance longevity and performance, allowing for efficient trimming and cutting.

Drive Shaft Assembly Insights

The drive shaft assembly is a crucial component in the efficient functioning of cutting machinery. This assembly transmits power from the engine to the cutting head, ensuring optimal performance during operation. Understanding its structure and functionality can greatly enhance maintenance and troubleshooting efforts, leading to improved longevity and reliability of the equipment.

Key Components of the Assembly

Several elements work together to form the drive shaft assembly. These include the main shaft, couplings, and bearings. Each part plays a vital role in facilitating the smooth transfer of rotational motion. Regular inspection of these components can help identify wear and tear, which may lead to performance issues if left unaddressed.

Maintenance Tips for Longevity

To ensure the drive shaft assembly operates efficiently, regular cleaning and lubrication are essential. Proper maintenance not only prolongs the lifespan of the assembly but also enhances the overall performance of the machine. Additionally, replacing worn components promptly can prevent more significant damage and costly repairs.

Ignition System

The ignition mechanism is a critical component in ensuring optimal engine performance. It is responsible for initiating the combustion process, allowing the engine to operate efficiently. A well-functioning ignition system guarantees smooth starts and reliable operation under various conditions.

This assembly typically consists of several key elements, including the ignition coil, spark plug, and electronic control unit. Each part plays a vital role in generating and delivering the necessary spark to ignite the fuel-air mixture. Regular maintenance and timely replacements of these components are essential to prevent operational issues and extend the lifespan of the equipment.

Understanding the intricacies of the ignition assembly can aid users in troubleshooting common problems. Symptoms of a malfunctioning system may include difficulty starting, erratic idling, or a noticeable decrease in power. By recognizing these signs early, users can take appropriate measures to resolve issues and maintain the efficiency of their equipment.