The FS 90 R is a popular tool known for its reliability and performance in various outdoor tasks. Understanding the internal setup of this equipment can greatly enhance maintenance and troubleshooting efforts. By familiarizing yourself with the core elements, you can ensure longevity and efficient operation, saving both time and resources.

In this guide, we will explore the key mechanisms that drive the functionality of this machine. From the engine assembly to the cutting attachments, every part plays a vital role in ensuring smooth performance. Learning about these components can help users maintain the equipment in top condition.

We’ll also cover how each element works together within the system, providing detailed insights to help users optimize its performance. Whether you are a professional or a hobbyist, knowing the internal structure is essent

Understanding the Key Components of FS 90 R

The FS 90 R model is a robust tool designed for demanding tasks, and its efficiency depends on various interconnected elements. Each of these components plays a vital role in ensuring optimal performance. Knowing these essential elements helps in maintaining and troubleshooting your equipment, ensuring long-lasting operation and efficiency.

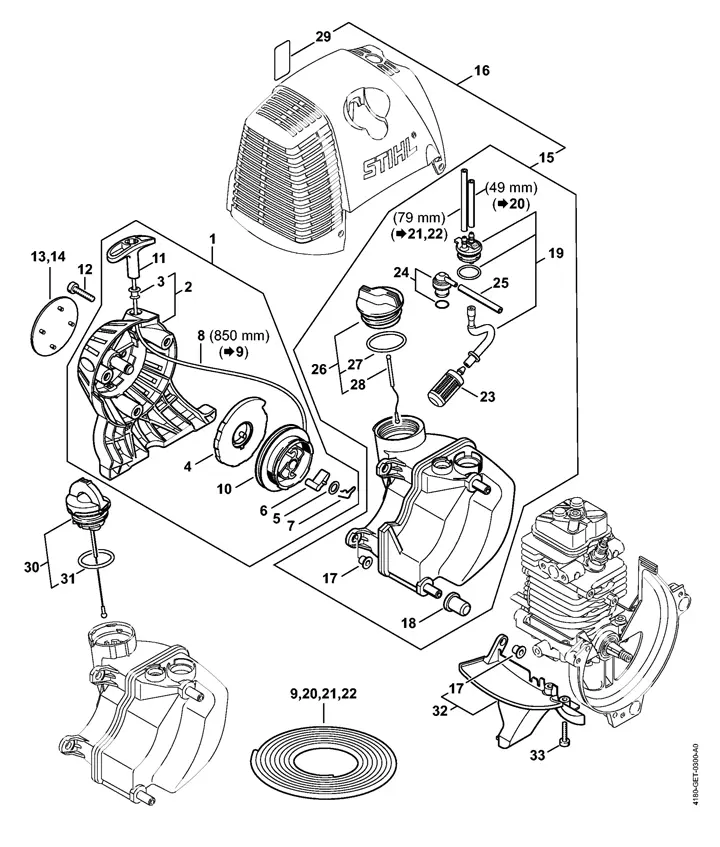

Engine System

At the heart of the FS 90 R is its powerful motor, engineered to deliver consistent power and reliability. This engine is designed for long-term use and requires regular upkeep to maintain performance. The fuel system, air filter, and ignition all work together to ensure smooth operation.

Cutting Mechanism

The cutting system is a crucial part, responsible for trimming vegetation with precision

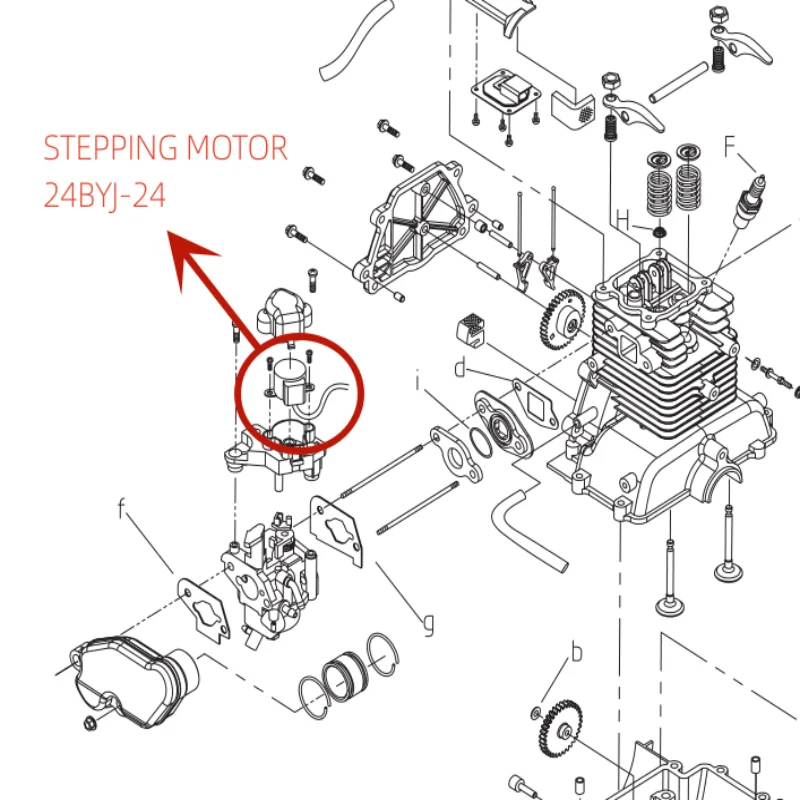

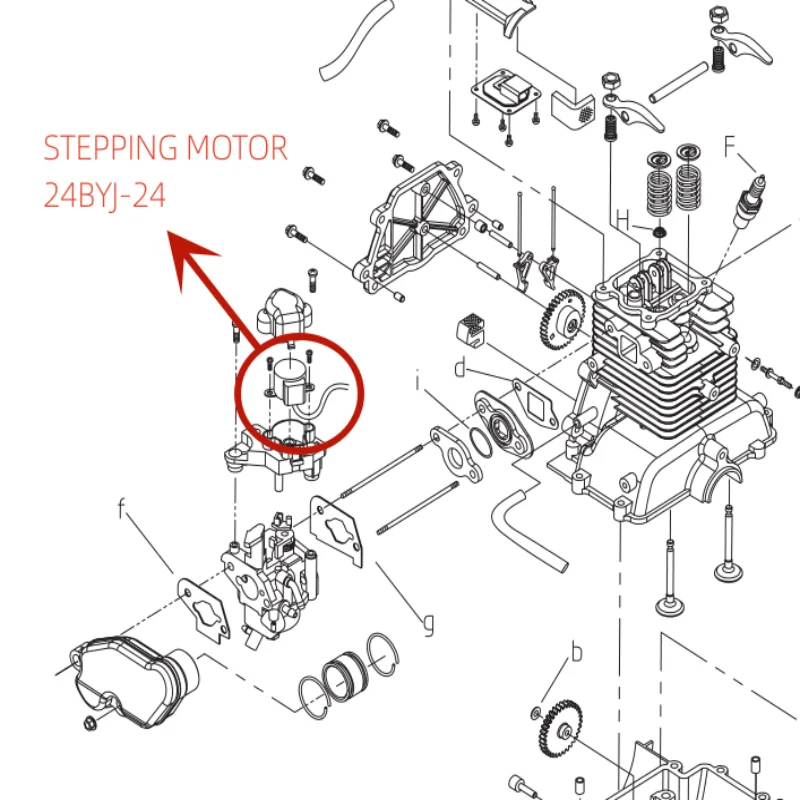

How to Identify and Replace the Carburetor

In this section, we will cover how to recognize when the carburetor needs attention and the process of replacing it. A malfunctioning fuel system can severely affect engine performance, leading to issues such as poor idle, stalling, or difficulty starting. Understanding how to locate and replace this component will help restore optimal functionality.

Recognizing Carburetor Issues

The first signs of a faulty carburetor include irregular engine behavior, such as inconsistent running, sputtering, or a loss of power. If cleaning or adjusting the existing one doesn’t resolve the issue, it may need replacement. Pay close attention to the fuel and air mixture, as improper combustion often points to this area.

Steps to Replace the Carburetor

Step 1: Disconnect the spark plug for safety, ensuring

A Guide to FS 90 R Ignition System

The ignition mechanism plays a pivotal role in ensuring the smooth operation of the FS 90 R trimmer. It is responsible for initiating the combustion process by providing the necessary spark at the right moment, allowing the engine to start and run efficiently. Understanding how this system works can help you maintain and troubleshoot it when necessary.

Key Components of the Ignition Mechanism

The system consists of several crucial elements, each working in harmony to ensure proper engine function. The ignition coil, for instance, generates the high voltage needed to create a spark. This spark, delivered at the right time, ignites the fuel mixture in the combustion chamber. Meanwhile, the flywheel plays a significant role in regulating the timing of this spark, ensuring precision and efficiency.

Maintenance Tips for Optimal Performance

Regular inspection and care of the ignition components are vital for the machine’s longevity. Over time, parts such as the spark plug can wear out, leading

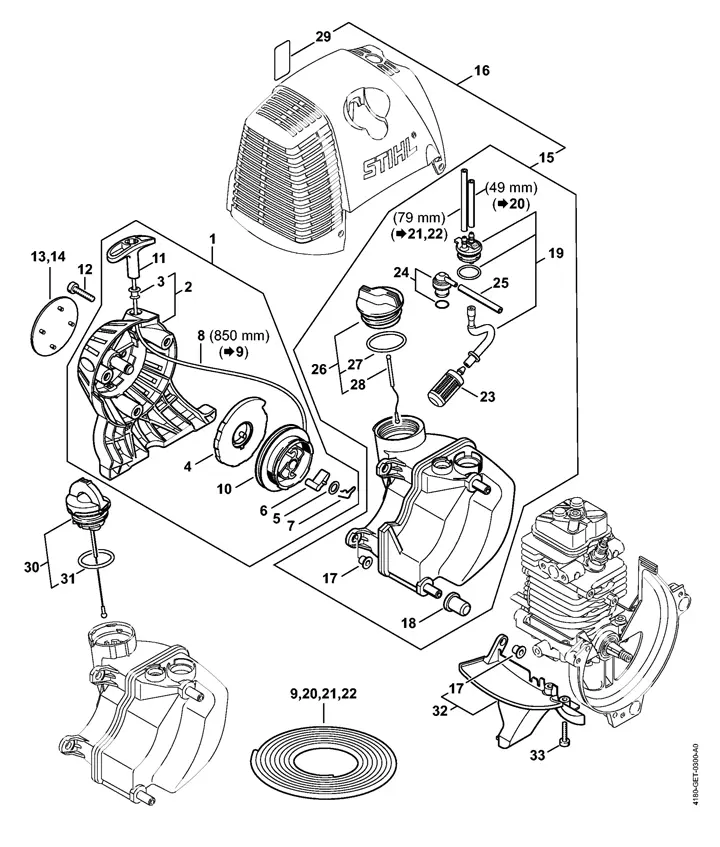

Fuel Tank Assembly Overview and Maintenance Tips

The fuel tank is a crucial component responsible for storing and delivering fuel efficiently. Regular upkeep ensures reliable operation and prevents breakdowns that could arise from common issues like leaks, blockages, or contamination. Proper maintenance prolongs the lifespan of the equipment and reduces the need for frequent repairs.

Key Components of the Fuel Tank

The fuel tank assembly consists of several important elements, each playing a unique role in maintaining fuel flow and system integrity. Below is a summary of the key components and their functions:

| Component |

Function |

| Fuel Cap |

Seals the tank to prevent spillage and maintain

Replacing the Air Filter for Optimal Performance

To ensure smooth operation and prevent damage to your equipment, maintaining the air filter is essential. Over time, dust and debris accumulate, which can reduce efficiency and lead to costly repairs. Regularly replacing the air filter ensures clean airflow, which is crucial for the longevity and overall functionality of your machine.

Why Air Filter Maintenance Matters

The air filter prevents dirt, dust, and other particles from entering the engine, which could cause internal damage. A clogged or dirty filter restricts air intake, making the engine work harder. This increases fuel consumption and reduces power. By keeping the filter clean, you help the engine perform at its best, saving energy and enhancing efficiency.

Steps for Replacing the Air Filter

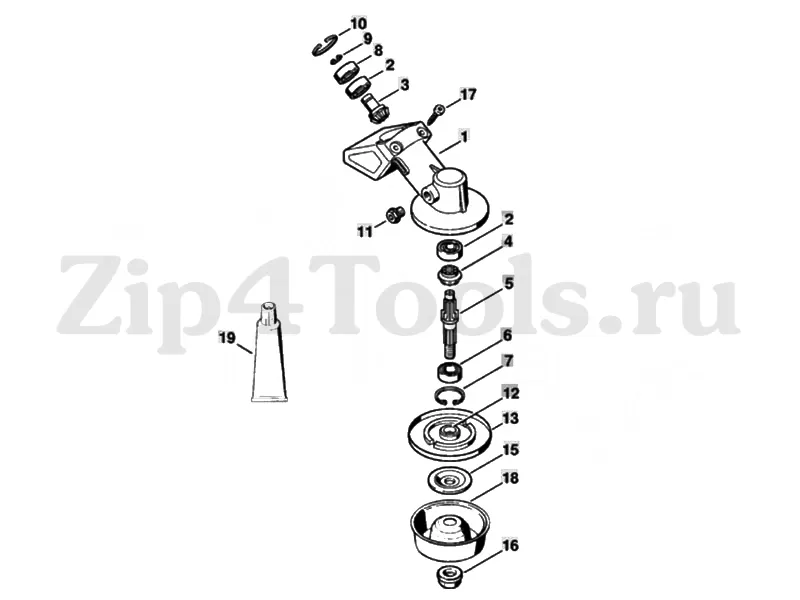

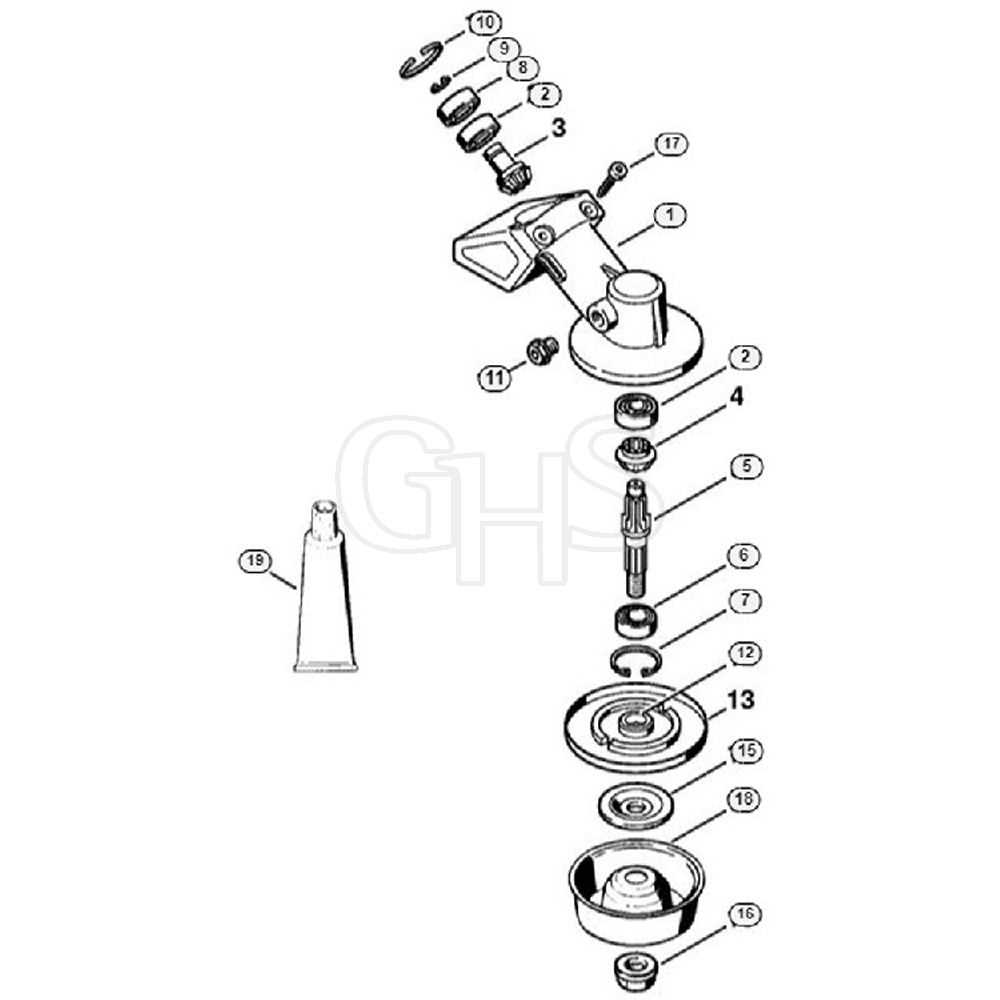

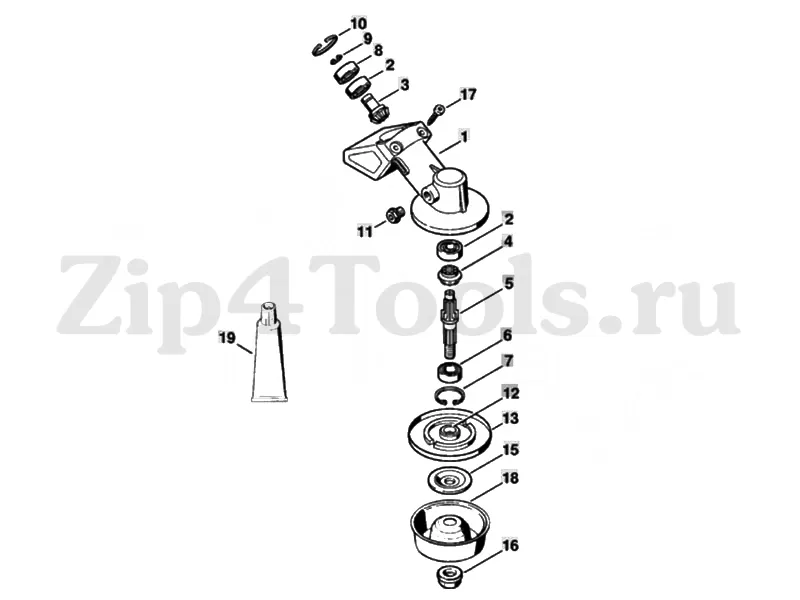

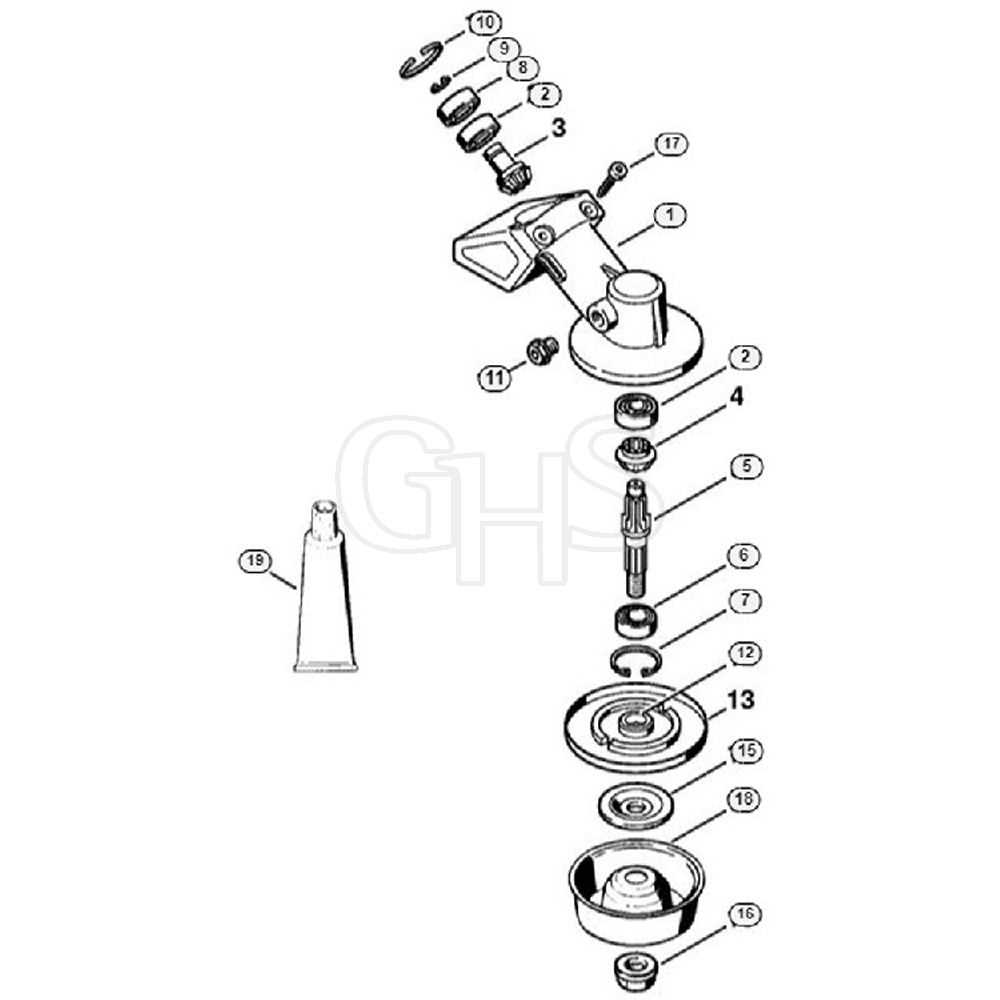

Drive Shaft and Gearbox: Inspection and Repair

Proper maintenance of the internal components is crucial for ensuring long-term reliability and efficiency. The drive shaft and gearbox play essential roles in transmitting power and ensuring smooth operation. Regular checks, cleaning, and timely repairs are important to avoid wear and tear, which can lead to equipment failure.

Inspection Process

Begin by removing the protective covers to access the drive shaft and gearbox. Visually examine the shaft for any signs of bending, corrosion, or damage. Rotate the shaft manually to check for smooth motion and any abnormal noises. Inspect the gearbox by checking for oil leaks or loose fittings, and listen for grinding sounds during rotation.

| Component |

Signs of Damage |

Recommended Action |

| Drive Shaft |

Visible cracks,

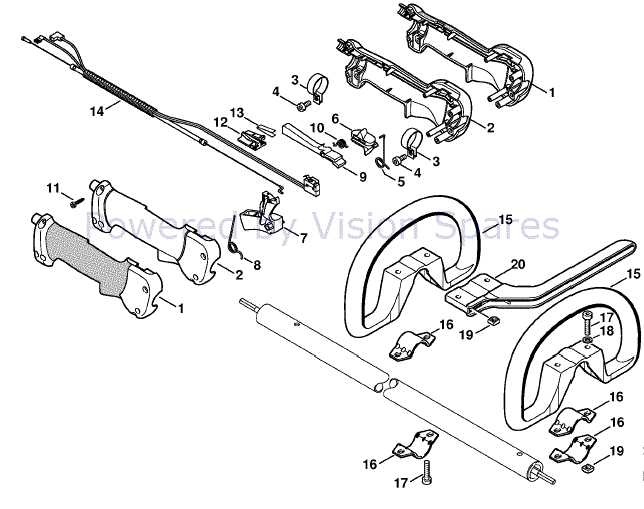

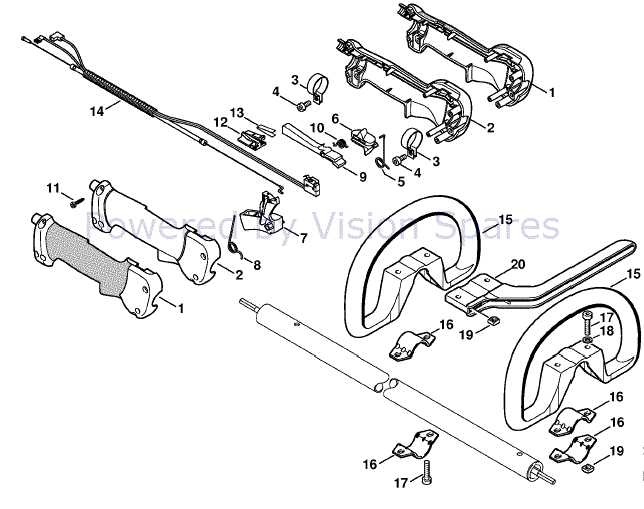

Throttle Trigger and Control Mechanism Explained

The throttle trigger and control system play a crucial role in managing the engine’s power output. These components ensure smooth operation by allowing the operator to control the speed of the machine with precision and efficiency. Understanding how this mechanism functions is essential for maintaining optimal performance and ensuring the equipment responds accurately to user input.

Below, we’ll break down the key parts of the throttle system and how they interact to provide seamless control:

Decoding the FS 90 R Clutch System

The clutch mechanism in the FS 90 R plays a critical role in controlling the power transfer between the engine and the cutting attachment. Its proper functioning ensures that the tool operates smoothly and efficiently under various conditions. Understanding how this component works can help identify issues and perform timely maintenance, extending the lifespan of your equipment.

How It Works: At the core of the clutch is a system designed to engage and disengage based on engine speed. When the engine reaches a certain RPM, the centrifugal force causes the clutch shoes to expand outward, making contact with the drum. This

Handle Assembly Parts and Adjustments

The handle assembly plays a crucial role in the functionality and comfort of outdoor power equipment. Understanding its components and how to properly adjust them ensures optimal performance and user satisfaction. This section delves into the various elements that comprise the handle assembly and highlights key adjustments that can enhance usability and safety.

Components of the Handle Assembly

The handle assembly typically includes several essential components, such as the grip, throttle control, and locking mechanism. The grip provides a comfortable hold, while the throttle control allows for precise speed management. Additionally, the locking mechanism secures the handle in place during operation, preventing any unwanted movement. Familiarity with these elements can facilitate maintenance and troubleshooting when necessary.

Adjustments for Optimal Performance

To achieve the best performance from the handle assembly, periodic adjustments are recommended. Users should regularly check the alignment of the grip to ensure it is securely attached and positioned correctly for ease of use. Moreover, adjusting the throttle control can help maintain consistent power output during operation. Regular inspection and fine-tuning of these components contribute to a safer and more efficient experience.

Tips for Maintaining the Cutting Head

Proper upkeep of the cutting attachment is essential for ensuring optimal performance and longevity of your equipment. Regular maintenance not only enhances cutting efficiency but also reduces the risk of wear and tear, resulting in cost savings over time.

- Regular Inspection: Frequently check the cutting head for any signs of damage or wear. Look for cracks, loose components, or signs of excessive wear.

- Clean After Use: Remove debris, grass, and dirt from the cutting head after each use. A clean attachment functions better and reduces the risk of corrosion.

- Replace Worn Blades: If the blades show signs of dullness or damage, replace them promptly to maintain cutting efficiency.

- Lubricate Moving Parts: Apply the appropriate lubricant to any moving components to ensure smooth operation and prevent rust.

- Check Fasteners: Periodically tighten screws, nuts, and bolts to ensure everything is securely fastened and to prevent any loose parts from affecting performance.

By following these simple maintenance tips, you can prolong the life of your cutting head and ensure it performs at its best for years to come.

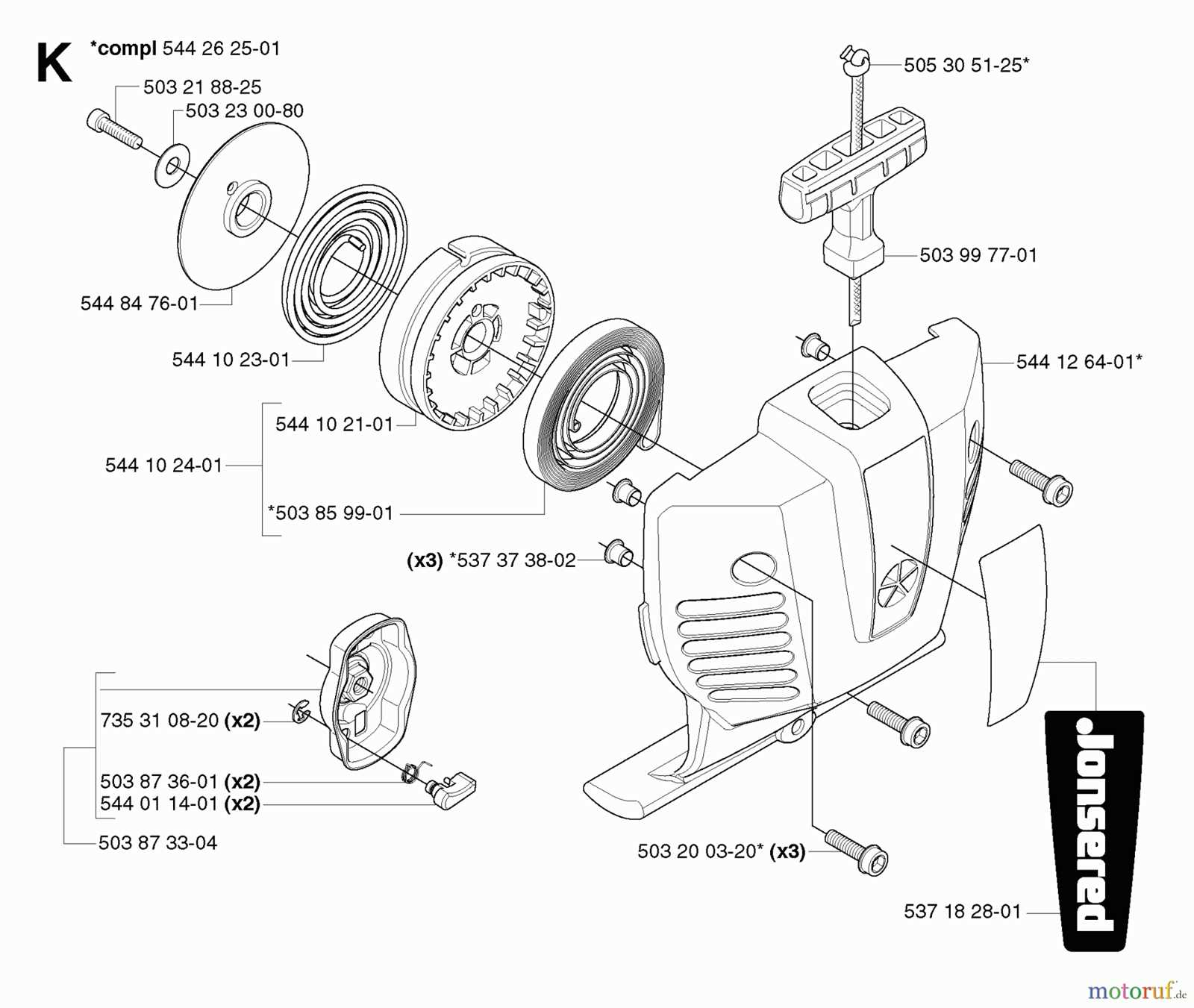

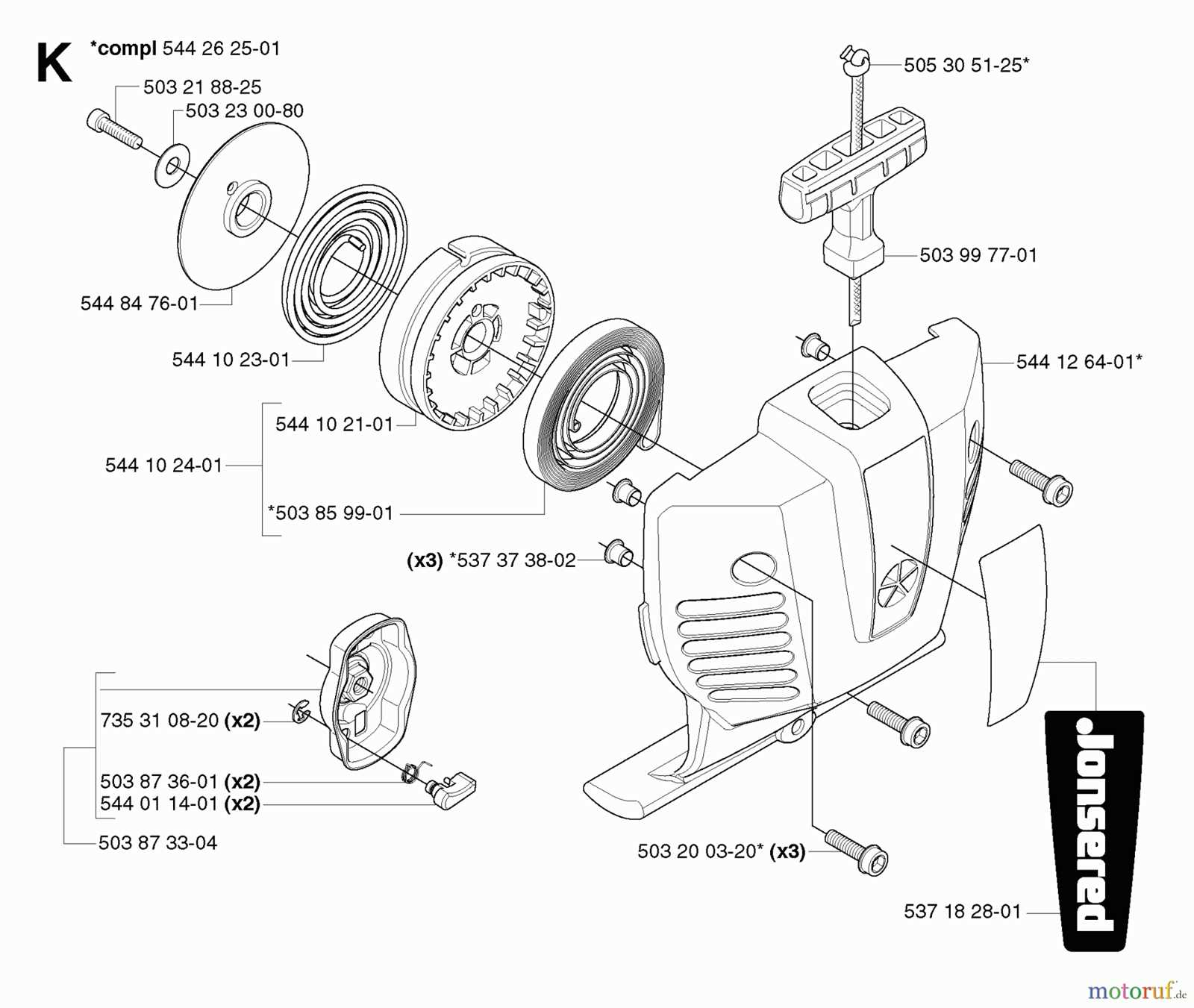

Understanding the Recoil Starter Mechanism

The recoil starter mechanism is a crucial component in many outdoor power equipment, designed to initiate the engine’s operation. This system enables users to effortlessly start their machines by utilizing a simple pull cord. Understanding its functionality is essential for maintenance and troubleshooting, ensuring reliable performance.

At its core, the recoil starter consists of several key elements that work together harmoniously:

- Pull Cord: The user pulls this cord to engage the starter.

- Starter Cup: A circular component that connects with the engine flywheel.

- Spring Mechanism: This part stores energy when the cord is pulled and releases it to turn the engine.

- Return Spring: Responsible for retracting the cord back into the housing after the pull.

When the cord is pulled, the starter cup spins and engages with the engine flywheel, allowing the engine to turn over. The energy stored in the spring mechanism is released, creating a powerful force that initiates the combustion process.

To ensure longevity and reliable performance, regular inspection of the recoil starter components is recommended. This includes checking for:

- Wear and tear on the pull cord.

- Rust or damage on the starter cup.

- Spring tension to ensure proper function.

By understanding the recoil starter mechanism, users can enhance their knowledge of equipment operation, leading to improved maintenance and reduced downtime.

Muffler Assembly: Cleaning and Replacement Tips

The muffler assembly plays a crucial role in maintaining the efficiency and performance of your outdoor power equipment. Proper upkeep is essential to ensure optimal functioning and to extend the lifespan of the machinery. This section provides insights into effective cleaning techniques and replacement guidelines for the muffler assembly.

Cleaning the Muffler Assembly

Regular cleaning of the muffler assembly can help prevent blockages and enhance the machine’s performance. Follow these steps for an effective cleaning process:

- Ensure the engine is cool before starting.

- Disconnect the spark plug to avoid accidental starts.

- Carefully remove the muffler from the engine, taking note of how it is attached.

- Use a wire brush or a soft cloth to clean the exterior surfaces.

- For internal cleaning, spray a suitable cleaner into the muffler and allow it to soak for a few minutes.

- Rinse the muffler with water and dry it completely before reinstallation.

When to Replace the Muffler Assembly

There are specific indicators that suggest it may be time to replace the muffler assembly:

- Visible damage, such as cracks or holes.

- Excessive noise during operation, indicating a malfunction.

- Presence of rust or corrosion affecting performance.

- Unusual exhaust emissions that can signal a problem.

If you notice any of these signs, it is advisable to replace the muffler assembly promptly to maintain the efficiency of your equipment.

Vibration Damp

Vibration dampening systems play a crucial role in enhancing the comfort and safety of equipment operation. By effectively minimizing the transmission of vibrations from the machine to the user, these mechanisms not only reduce fatigue but also prolong the lifespan of the equipment. Understanding the significance of these systems is essential for anyone engaged in maintenance or operation.

Benefits of implementing a reliable vibration dampening solution include decreased wear and tear on components, improved user experience, and enhanced operational efficiency. These features are particularly important in environments where prolonged use is common.

The design of vibration dampers can vary widely, utilizing materials such as rubber, foam, or specialized polymers to absorb shock and reduce oscillation. Each of these materials offers unique properties that can be tailored to specific applications, providing optimal performance and durability.

Regular inspection and maintenance of these systems are vital. Over time, wear may occur, reducing their effectiveness. Ensuring that these components are in good condition will help maintain equipment performance and user safety.

|

|