When it comes to maintaining and repairing outdoor machinery, having a clear visual representation of the various elements involved is essential. An insightful breakdown of the individual components can enhance understanding and facilitate effective troubleshooting. This guide aims to provide a comprehensive overview of the intricate relationships between the different parts of a specific machine.

Every piece of equipment is composed of numerous sections, each serving a unique function. By familiarizing oneself with these segments, users can not only perform routine maintenance more efficiently but also tackle repairs with confidence. A well-structured representation can demystify complex assemblies, allowing operators to navigate their machinery with ease.

In the following sections, readers will discover a detailed examination of the essential components, complete with visual aids that illustrate their arrangement. This knowledge will empower users to optimize performance and extend the longevity of their equipment, ensuring it operates at peak efficiency.

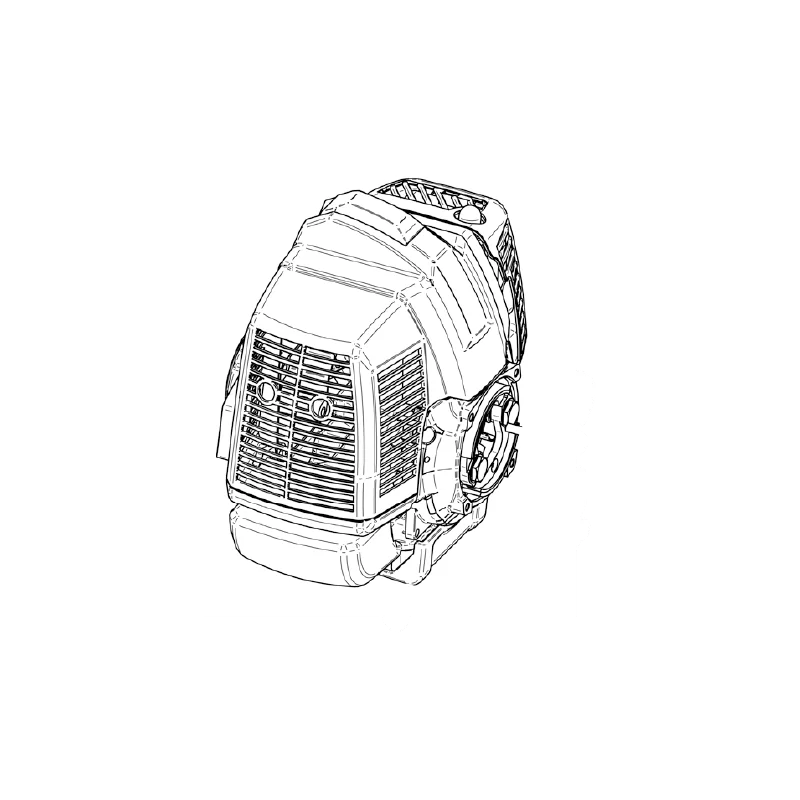

Understanding Stihl FS130 Components

When working with outdoor power equipment, a solid grasp of its individual elements is essential for effective operation and maintenance. Each component plays a crucial role in the overall functionality and efficiency of the machine. Familiarity with these parts can help users troubleshoot issues and ensure optimal performance.

The motor serves as the heart of the machinery, providing the necessary power for operation. Coupled with this, the cutting attachment is vital for executing tasks such as trimming and mowing. Additionally, the fuel system, including the tank and lines, must be regularly checked to maintain proper performance and prevent fuel-related issues.

Other significant components include the handle, which provides user control and comfort, and the safety features designed to protect the operator during use. Understanding the interplay of these various elements not only enhances the user experience but also contributes to the longevity of the equipment.

Regular inspection and maintenance of each part will help prevent wear and tear, ensuring that the machine remains reliable over time. By taking the time to understand these components, users can maximize efficiency and achieve better results in their outdoor tasks.

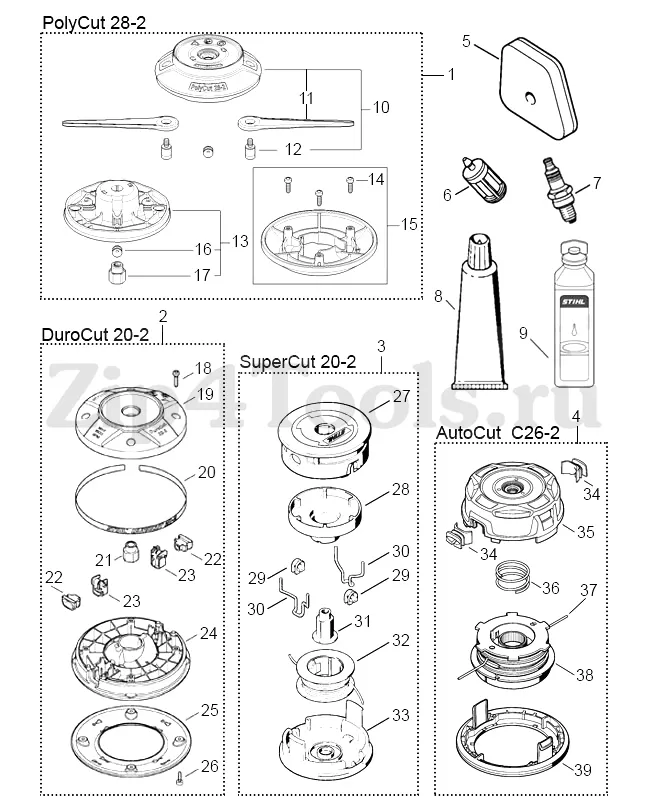

Overview of the Parts Diagram

This section provides a comprehensive look at the visual representation of components for a specific model of outdoor equipment. Understanding the layout and organization of these elements is essential for efficient maintenance and repair. A well-structured illustration not only aids in identifying individual parts but also highlights their interconnections, facilitating a clearer understanding of how the entire assembly functions.

The illustration typically includes various segments, each detailing specific components and their respective functions. The clarity of the visual representation is crucial for both novice users and seasoned technicians, enabling them to quickly locate the necessary elements for servicing or replacement.

| Component | Description | Function |

|---|---|---|

| Engine | Power unit that drives the machine | Provides the necessary energy for operation |

| Cutter Head | Rotating part that performs the cutting | Trims grass and weeds efficiently |

| Handle | Grip for user control | Allows for maneuverability and ease of use |

| Fuel Tank | Container for the energy source | Holds fuel for the engine |

| Throttle Control | Regulates engine speed | Enables adjustment of power output |

By familiarizing oneself with this visual guide, users can enhance their understanding of the equipment, leading to improved functionality and longevity of the machine. Knowing where each component fits in the overall scheme promotes effective troubleshooting and minimizes downtime during maintenance tasks.

Essential Features of FS130

This section explores the key characteristics that define this powerful tool, highlighting what makes it stand out in its category. From its robust design to advanced functionality, each feature contributes to a reliable and efficient performance in various outdoor tasks.

- Engine Power: Equipped with a high-performance engine, it offers exceptional torque and cutting speed, making it ideal for heavy-duty jobs.

- Weight and Balance: The ergonomic design ensures optimal weight distribution, reducing user fatigue during extended periods of use.

- Cutting Attachments: Compatible with a variety of cutting heads, enhancing versatility for different applications, from trimming grass to clearing dense underbrush.

- Vibration Control: Innovative technology minimizes vibrations, ensuring a comfortable grip and reducing strain on the user.

- Fuel Efficiency: Designed for low fuel consumption, it allows for longer operation times without frequent refueling.

These features not only enhance performance but also contribute to user satisfaction, making it a valuable addition to any outdoor toolkit.

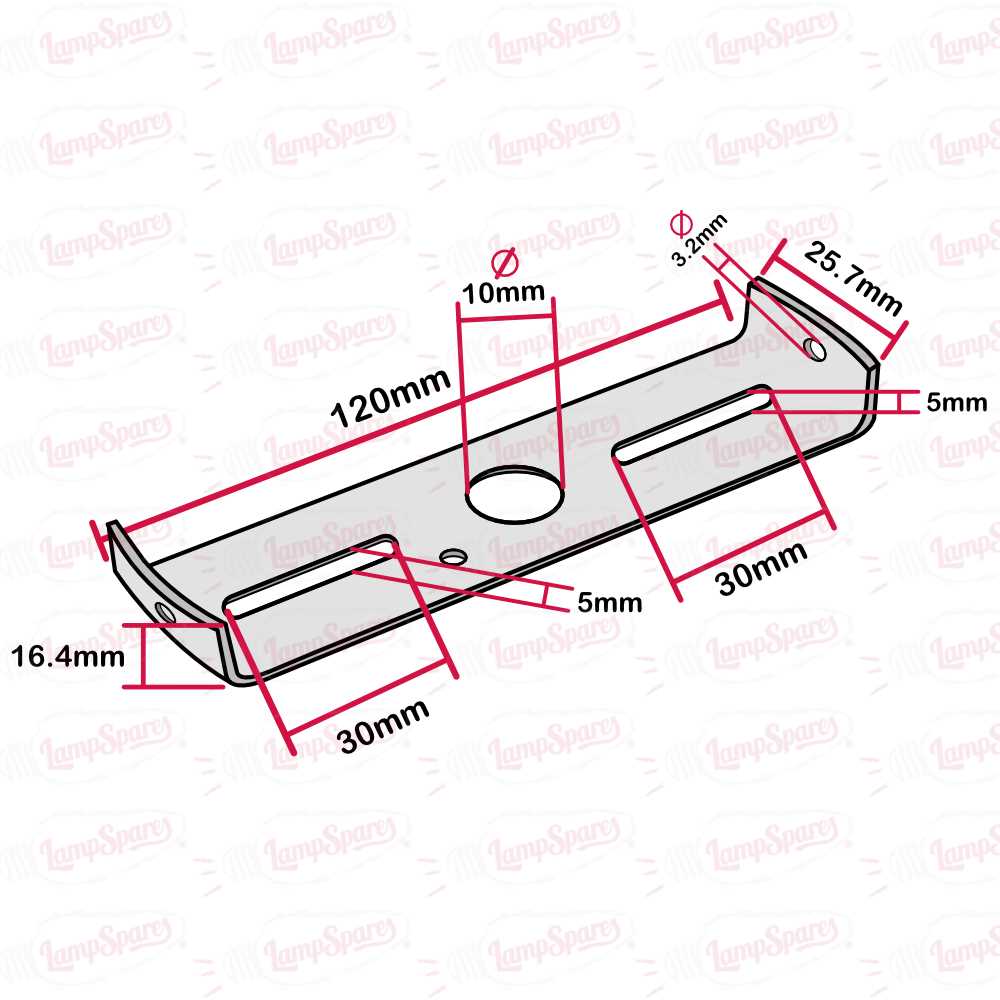

Common Replacement Parts Explained

When maintaining outdoor power equipment, understanding the key components that often require attention can enhance performance and longevity. Knowing which elements are most prone to wear and tear is essential for effective upkeep.

Fuel Filters are crucial for ensuring clean fuel reaches the engine. Over time, these filters can become clogged with debris, leading to reduced efficiency. Regular replacement is recommended to maintain optimal performance.

Trimmer Lines are another frequently replaced item. They wear down with use, impacting cutting effectiveness. Choosing the right thickness and material can make a significant difference in the quality of trimming tasks.

Blades should be monitored regularly, as dull or damaged edges can hinder performance. Sharpening or replacing them as needed is vital for maintaining cutting precision.

Spark Plugs play a key role in engine performance. Worn or fouled plugs can lead to starting issues and inefficient combustion. Checking and replacing these components periodically ensures reliable operation.

Air Filters protect the engine from dust and debris. A clean filter promotes better airflow and enhances fuel efficiency. It’s advisable to inspect and change air filters according to usage conditions.

By focusing on these commonly replaced components, users can ensure their equipment operates smoothly and efficiently, ultimately extending its lifespan and enhancing productivity.

Importance of Accurate Diagrams

Precise visual representations play a crucial role in maintenance and assembly tasks. They provide users with a clear understanding of how components fit together, ensuring efficient repairs and replacements. When individuals rely on these illustrations, they can avoid common pitfalls that lead to improper installations or malfunctions.

Furthermore, accurate depictions facilitate effective communication among technicians, making it easier to share knowledge and troubleshoot issues. The clarity offered by well-detailed visuals can significantly reduce errors and enhance overall productivity.

| Benefits | Description |

|---|---|

| Clarity | Helps users comprehend complex assemblies easily. |

| Efficiency | Reduces the time spent on repairs by providing straightforward guidance. |

| Communication | Enables effective sharing of information among team members. |

| Error Reduction | Minimizes the risk of mistakes during assembly or maintenance. |

Maintenance Tips for Stihl FS130

Proper upkeep of your outdoor power equipment is essential for optimal performance and longevity. Regular maintenance not only enhances efficiency but also ensures safety during operation. Here are some crucial tips to keep your device running smoothly.

Regular Cleaning: After each use, make sure to clean the exterior components. Removing dirt, grass, and debris prevents corrosion and helps maintain visibility of critical parts.

Air Filter Inspection: A clean air filter is vital for engine efficiency. Check it regularly and replace it as necessary to ensure proper airflow and reduce strain on the motor.

Fuel System Care: Use fresh fuel and consider adding a fuel stabilizer to prevent degradation. Regularly inspect fuel lines for leaks or wear, and replace them if you notice any signs of damage.

Blade Maintenance: Keep blades sharp for effective cutting. Dull blades not only decrease performance but also increase wear on the engine. Sharpen or replace blades as needed.

Inspect Cables and Connections: Periodically check all cables and electrical connections for signs of wear or fraying. Tighten loose connections and replace any damaged components to ensure safe operation.

Storage Practices: When not in use, store your equipment in a dry, sheltered location. Consider using a protective cover to prevent dust accumulation and environmental damage.

By following these maintenance guidelines, you can extend the lifespan of your equipment and enhance its performance, ensuring that it remains a reliable tool for all your outdoor tasks.

Identifying Parts by Diagram

Understanding the components of your equipment is crucial for effective maintenance and repairs. By utilizing a visual representation, you can easily recognize individual elements, ensuring that you select the correct ones for replacement or servicing. This approach not only enhances your knowledge but also streamlines the overall upkeep process.

Visual guides serve as valuable tools, breaking down complex machinery into manageable sections. Each part is typically labeled, allowing you to quickly pinpoint specific items. This method is especially beneficial when dealing with intricate systems where details matter significantly.

To enhance your experience, take the time to familiarize yourself with the layout and nomenclature used in these illustrations. Recognizing these features will empower you to navigate your equipment with confidence, ultimately leading to better performance and longevity.

Tools Needed for Repairing FS130

When maintaining and fixing outdoor equipment, having the right tools is essential for efficient and effective repairs. Each task may require specific instruments to ensure safety and precision. Below is a comprehensive list of necessary tools to aid in the repair process.

Essential Tools

- Wrench set

- Screwdriver set (flat and Phillips)

- Pliers (needle-nose and standard)

- Torque wrench

- File or sandpaper

Optional Tools

- Multimeter for electrical diagnostics

- Cleaning brush

- Protective gloves and goggles

- Oil can or lubricant

- Workbench or sturdy surface

Ordering Stihl FS130 Parts Online

In today’s digital age, acquiring components for your outdoor equipment has never been easier. With just a few clicks, you can find the necessary replacements to keep your machinery running smoothly. Online platforms provide a vast selection of items, enabling you to choose the exact pieces you need without the hassle of visiting physical stores.

Steps to Follow for a Smooth Purchase

- Research Reliable Retailers

- Identify the Specific Components Required

- Compare Prices and Availability

- Add Items to Your Cart

- Review Your Order Before Checkout

- Complete Payment and Provide Shipping Details

Tips for a Successful Online Experience

- Check Customer Reviews for Trustworthiness

- Look for Warranty Information on Items

- Ensure the Site Has a Secure Payment Method

- Consider Shipping Times and Costs

- Contact Customer Support for Queries

Following these guidelines will help ensure that you receive the right components efficiently, allowing you to maintain your equipment in optimal condition.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring a safe working environment is paramount. Following proper safety measures not only protects the individual performing the repairs but also safeguards the equipment and surrounding area.

Wear Protective Gear: Always use appropriate safety equipment, including gloves, goggles, and ear protection, to shield yourself from potential hazards.

Work in a Well-Lit Area: A brightly lit workspace helps you clearly see what you are doing, reducing the risk of accidents and errors.

Disconnect Power Sources: Before starting any repairs, ensure that all power sources are turned off and disconnected to prevent accidental activation.

Keep Tools Organized: Maintain a tidy workspace by keeping tools organized. This reduces the risk of tripping and ensures that you can quickly access what you need.

Follow Manufacturer Guidelines: Always consult the user manual for specific instructions and safety recommendations related to the equipment you are working on.

By adhering to these precautions, you can create a safer environment and effectively mitigate risks during repair tasks.

Comparing FS130 to Similar Models

This section focuses on examining a specific model in relation to other comparable tools in the market. By analyzing various features, performance metrics, and overall design, users can gain a clearer understanding of how this model stands against its peers.

| Model | Engine Power (cc) | Weight (lbs) | Cutting Width (in) | Fuel Efficiency (mpg) |

|---|---|---|---|---|

| Model A | 30 | 11.5 | 16 | 120 |

| Model B | 28 | 10.5 | 15 | 110 |

| Model C | 31 | 12 | 18 | 115 |

| Model D | 29 | 11 | 17 | 130 |

In comparing these models, it becomes evident that the selected tool offers a unique blend of power and efficiency, making it suitable for a variety of tasks. Consideration of weight and cutting width also plays a crucial role in determining the best fit for individual needs.

Frequently Asked Questions About Parts

This section aims to address common inquiries related to components and their functions, ensuring users have a clear understanding of what to consider when seeking replacements or maintenance items. Knowledge of these aspects can enhance the longevity and efficiency of your equipment.

What should I look for when selecting a replacement component?

When choosing a new item, ensure it matches the specifications of your existing one. Look for quality materials, compatibility with your equipment, and reviews from other users to guide your decision.

How often should I replace essential components?

Regular maintenance is crucial. Inspect items frequently and replace them based on usage, wear signs, or manufacturer recommendations to maintain optimal performance.