When it comes to maintaining your outdoor machinery, a clear comprehension of its construction is essential. Knowing how various components interact ensures optimal performance and longevity. Whether you are a hobbyist or a professional, familiarizing yourself with the intricate layout can enhance your repair and maintenance skills.

Every tool comprises distinct elements, each serving a unique function. By exploring the arrangement of these pieces, you can identify potential issues and carry out effective troubleshooting. An organized overview allows users to tackle repairs with confidence, streamlining the entire process.

Moreover, grasping the connection between different components not only aids in resolving problems but also empowers you to make informed upgrades. This knowledge ultimately leads to a more efficient and reliable experience, ensuring that your machinery performs at its best.

Understanding Stihl FS44 Overview

This section provides an insightful look into a specific model of outdoor power equipment, highlighting its essential components and operational mechanisms. With a focus on efficiency and user-friendliness, this tool is designed for a variety of gardening tasks, making it a popular choice among enthusiasts and professionals alike.

Key Features

Among its many attributes, this model boasts a powerful engine, lightweight construction, and ergonomic design, all contributing to superior performance. Its versatility allows users to tackle different jobs effectively, whether trimming or edging.

Maintenance and Care

Proper upkeep is crucial for longevity. Regular checks of the fuel system, air filter, and cutting attachments will ensure optimal functioning. Understanding these elements is vital for anyone looking to maximize the tool’s potential and efficiency.

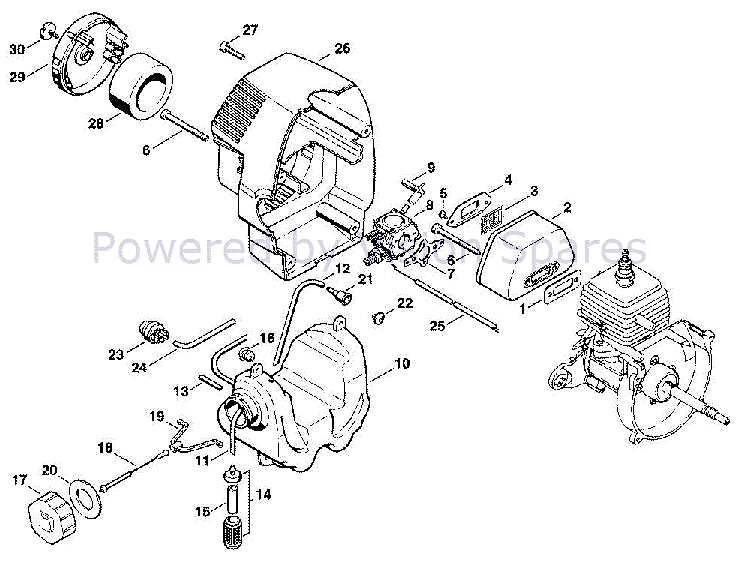

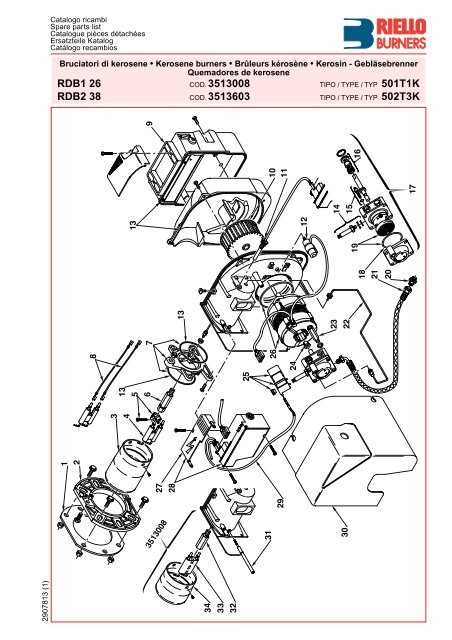

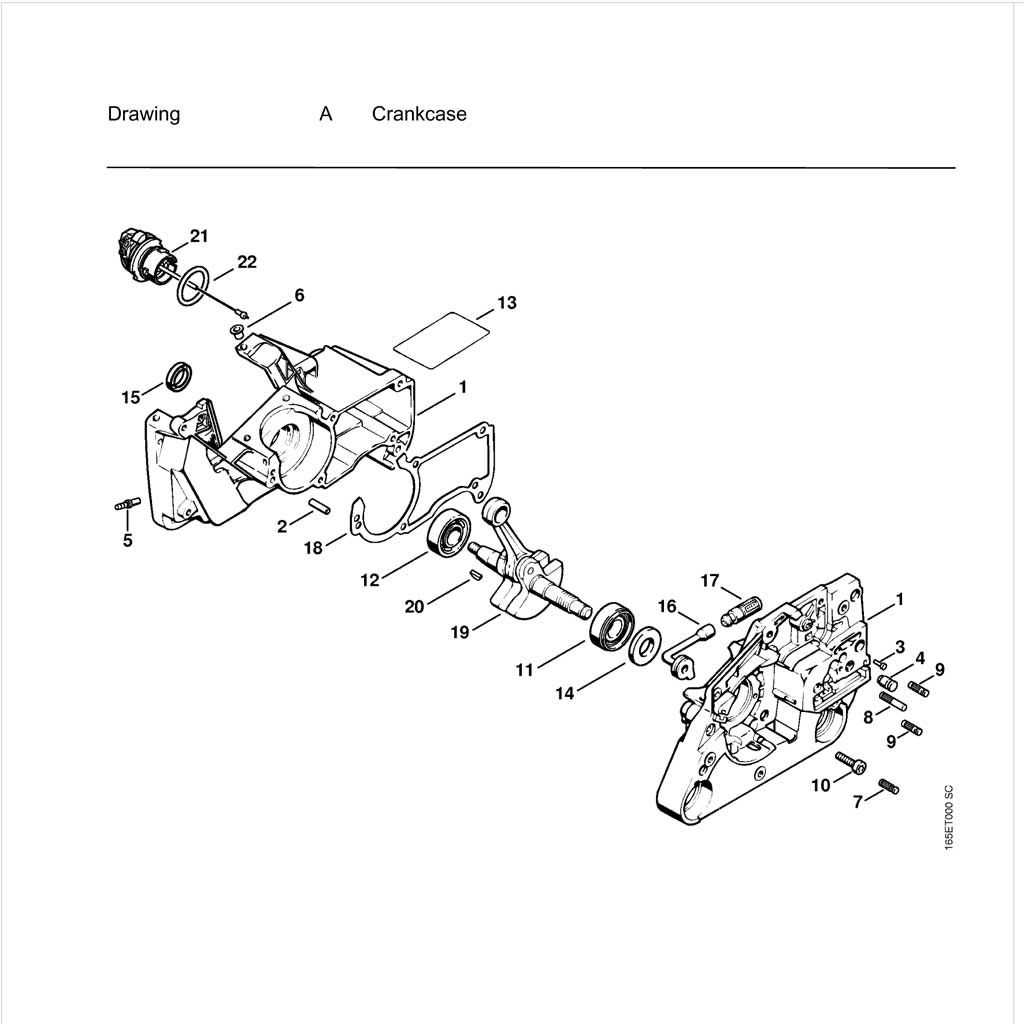

Key Components of FS44 Model

This section explores the essential elements that contribute to the efficient operation of this cutting tool. Each component plays a vital role in enhancing performance and ensuring longevity, making it crucial for users to understand their functions and interactions.

Engine Assembly

The engine assembly serves as the heart of the machine, providing the necessary power for various tasks. Its robust design ensures reliable performance, while features such as the fuel system and ignition contribute to optimal efficiency.

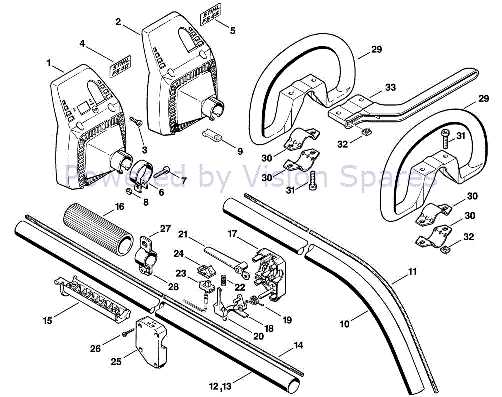

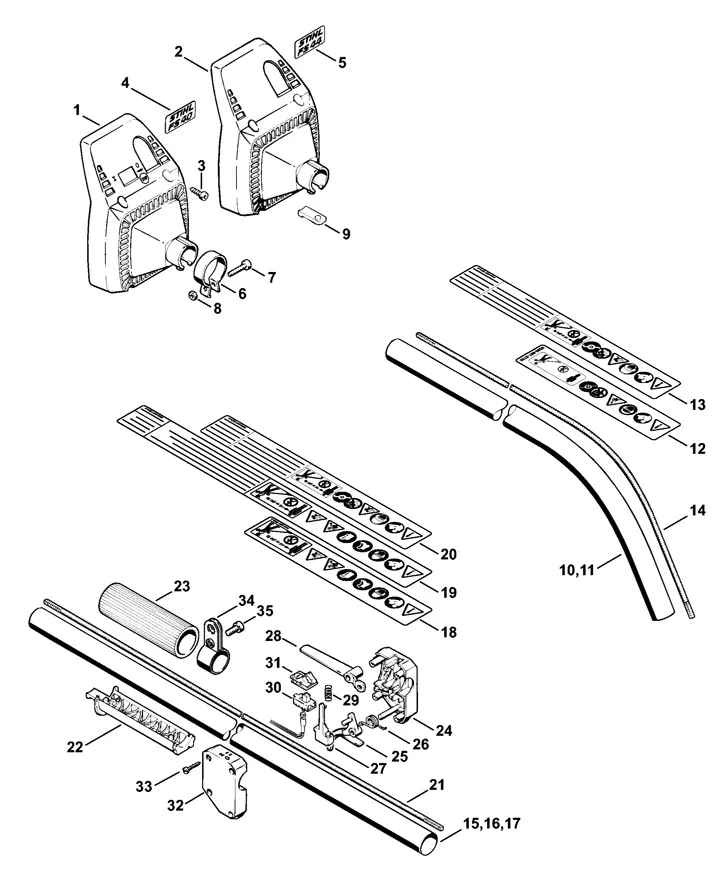

Cutting Head Mechanism

The cutting head mechanism is pivotal for effective trimming and edging. This component includes the blade attachment and drive shaft, which work together to deliver precision and ease of use. Regular maintenance of this area is essential for achieving the best results.

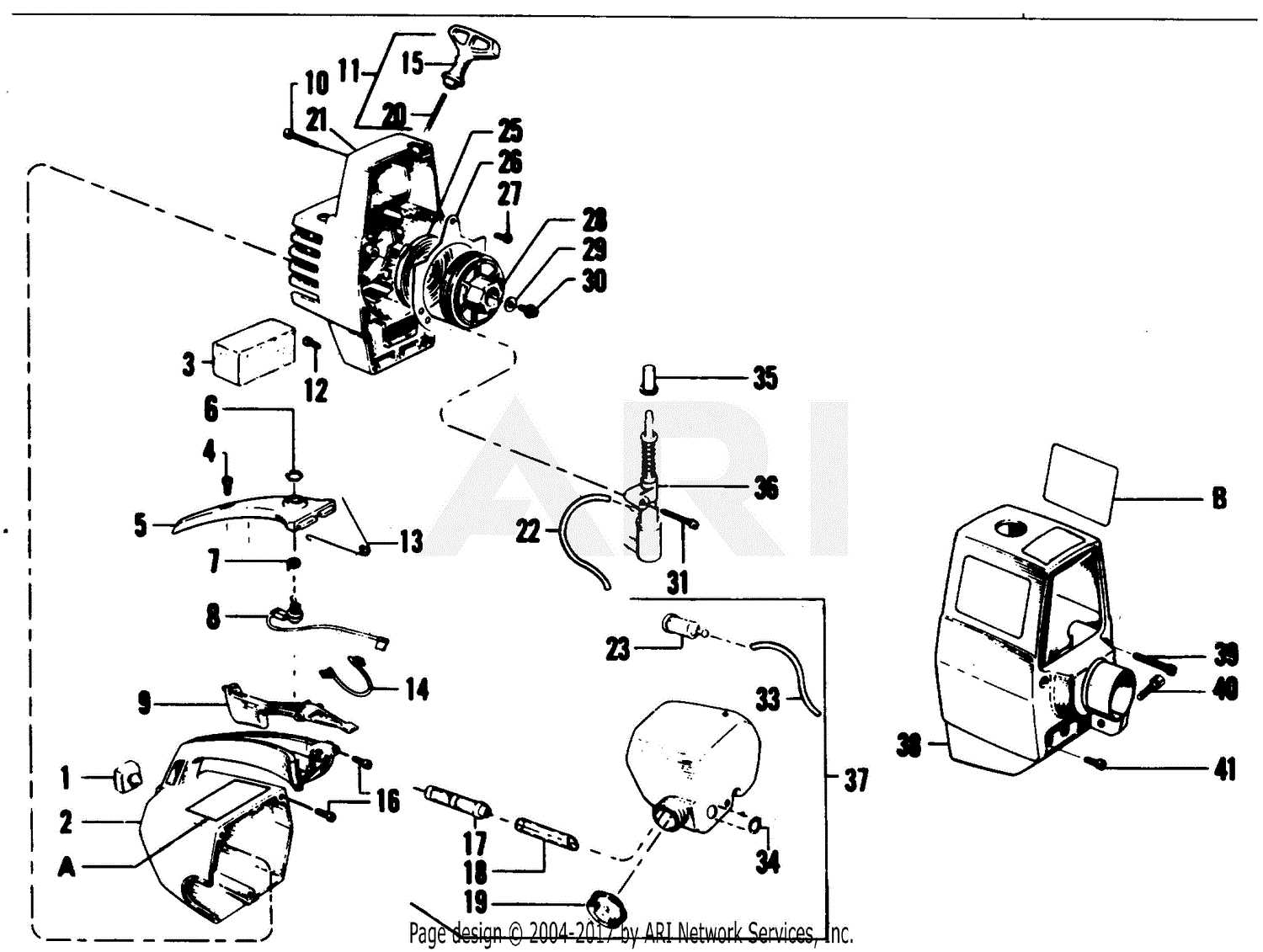

Importance of Parts Diagrams

Understanding the layout and functionality of components within machinery is crucial for effective maintenance and repair. Visual representations serve as invaluable resources, enabling users to identify individual elements and comprehend their relationships within the system. This knowledge not only streamlines the repair process but also enhances the overall efficiency of the equipment.

Facilitating Troubleshooting

Having access to a visual guide simplifies the identification of issues. When users can easily locate specific components, they can more effectively diagnose malfunctions and implement solutions. This leads to reduced downtime and prolongs the life of the equipment.

Streamlining Maintenance

Regular upkeep is essential for optimal performance. Visual aids assist users in recognizing which parts require attention or replacement, ensuring that maintenance tasks are conducted efficiently. By fostering a clear understanding of the machinery’s construction, these guides empower users to perform maintenance with confidence.

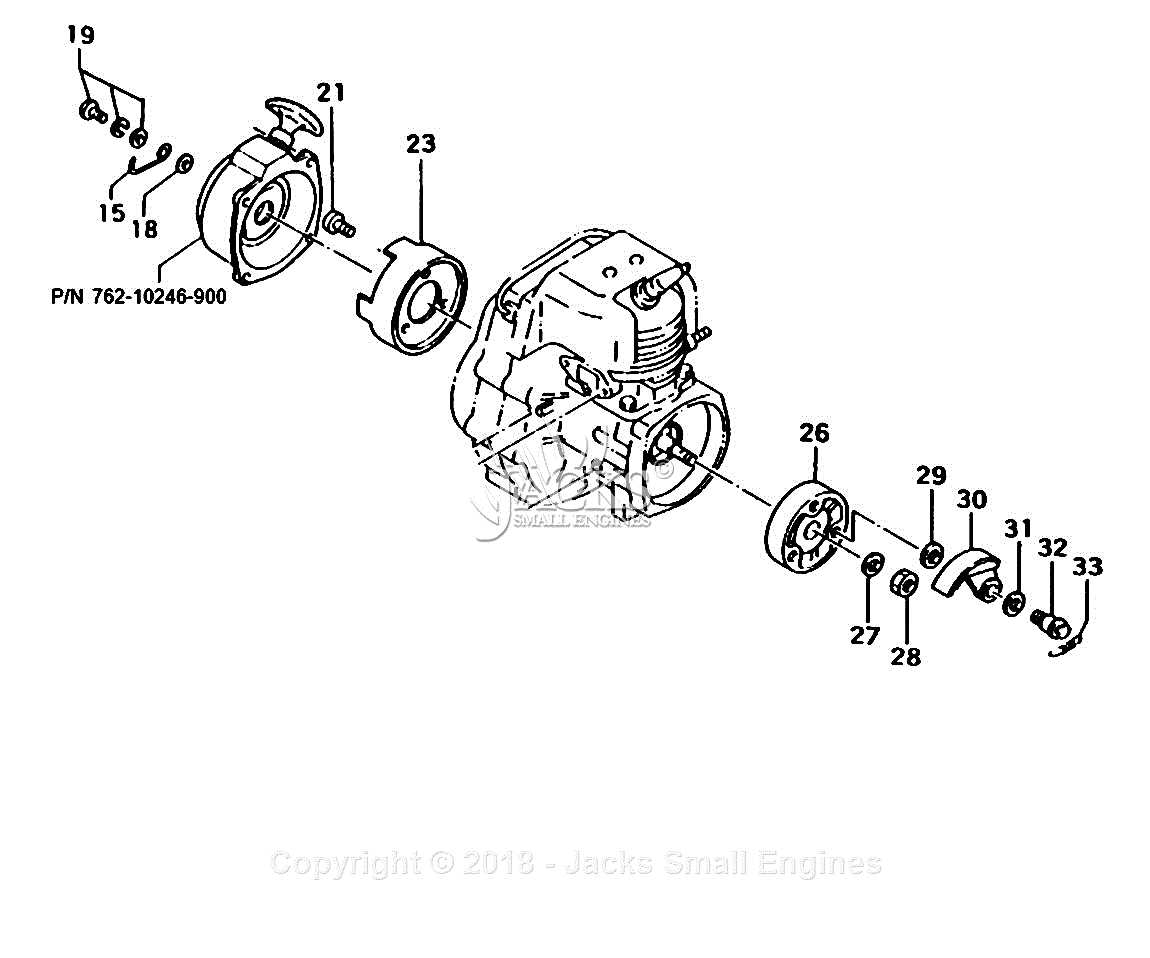

How to Read Parts Diagrams

Understanding visual representations of components can significantly enhance your ability to identify and acquire necessary items for maintenance or repair. These illustrations serve as a guide, breaking down complex machinery into manageable sections, making it easier to locate specific elements.

Key Elements to Look For

- Labels: Each component is usually accompanied by a label or number, indicating its position and function within the assembly.

- Sections: Diagrams are often divided into sections, each focusing on a particular part of the equipment, allowing for more straightforward navigation.

- Legend: A legend may be included to explain symbols or color codes used throughout the illustration.

Tips for Effective Interpretation

- Start by familiarizing yourself with the overall layout before diving into specific components.

- Cross-reference the numbers or labels with your equipment manual to confirm the correct identification of each part.

- Take notes on any components that require replacement or maintenance, ensuring you gather all necessary information.

Common Issues with FS44 Parts

When using outdoor power equipment, various components can encounter frequent challenges that affect performance and reliability. Understanding these common problems can help users maintain their tools effectively.

Wear and Tear: Over time, certain elements may experience significant wear, leading to reduced efficiency. Regular inspections can identify these issues before they become critical.

Fuel System Problems: Blockages or leaks in the fuel delivery system can hinder operation. Keeping the fuel lines clean and ensuring proper seals are essential for optimal functionality.

Ignition Failures: Issues with the ignition components often result in starting difficulties. Checking the spark plug and ignition coil regularly can prevent these setbacks.

Mechanical Damage: Physical impacts or exposure to harsh conditions can cause damage to various mechanisms. Protective measures can help mitigate these risks and prolong the lifespan of the equipment.

Vibration Effects: Excessive vibrations can loosen connections and cause misalignments. Regular tightening and maintenance can reduce these occurrences significantly.

Where to Find Replacement Parts

When it comes to maintaining outdoor power tools, sourcing high-quality components is essential for ensuring optimal performance and longevity. Whether you’re looking for specific items or general supplies, several reliable avenues exist for obtaining what you need.

Authorized Dealers: One of the most reliable options is to visit authorized retailers. These outlets often carry a comprehensive selection of original components, ensuring compatibility and quality. Additionally, staff members can provide expert advice on suitable items for your equipment.

Online Marketplaces: Numerous e-commerce platforms specialize in outdoor tool supplies. These websites typically feature extensive catalogs, allowing users to search for specific components easily. Always check for seller ratings and reviews to ensure you’re purchasing from reputable sources.

Local Repair Shops: Local maintenance centers can also be a valuable resource. Not only do they sell individual items, but they may also offer repair services. This can be particularly beneficial if you require assistance in selecting the right components for your equipment.

Manufacturer Websites: Many manufacturers have official websites where you can browse available items directly. These sites often include detailed specifications and compatibility information, making it easier to find the right fit for your needs.

Exploring these options can help you efficiently locate the necessary components to keep your outdoor tools in excellent working condition.

Comparing FS44 to Other Models

This section explores the differences and similarities between a specific model and other similar devices in its category. Understanding these variations can help users make informed decisions based on their needs and preferences.

Key aspects to consider include:

- Power output

- Weight and portability

- Ease of use

- Maintenance requirements

- Durability

When examining alternatives, users might find:

- Model A: Offers higher power but is heavier.

- Model B: Lighter and more portable, yet less powerful.

- Model C: Features advanced technology for ease of operation.

Ultimately, the choice will depend on individual preferences and specific usage scenarios.

Maintenance Tips for FS44 Users

Proper upkeep of your gardening equipment is essential for ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also minimizes the risk of unexpected breakdowns. By following a few key practices, users can keep their tools in excellent condition and ready for any task.

Regular Inspection and Cleaning

Frequent checks for wear and tear are crucial. Inspect all components for signs of damage or deterioration. Clean the equipment after each use to remove debris and prevent rust. Pay special attention to the air filter and spark plug, as these can significantly impact performance if neglected.

Lubrication and Fuel Quality

Using the right type of lubricant is vital for moving parts. Ensure that bearings and joints are adequately greased to reduce friction. Additionally, always use high-quality fuel, as poor fuel can lead to engine problems and decreased efficiency. Consider adding a fuel stabilizer if you plan to store the equipment for an extended period.

Tools Needed for Repairs

Proper maintenance and repair of outdoor equipment require specific tools to ensure efficiency and effectiveness. Having the right instruments at hand can significantly simplify the repair process, allowing for quicker diagnosis and resolution of issues. Below is a list of essential tools you should consider for successful repairs.

Essential Hand Tools

- Screwdrivers: A set of both flathead and Phillips screwdrivers is crucial for loosening and tightening various screws.

- Wrenches: Adjustable wrenches or a complete set of combination wrenches are necessary for bolts and nuts of different sizes.

- Pliers: Needle-nose pliers and standard pliers help in gripping and manipulating small components.

- Torque Wrench: Ensures that screws and bolts are tightened to the manufacturer’s specifications.

Power Tools and Equipment

- Drill: Useful for making holes or driving screws when manual methods are insufficient.

- Impact Driver: Ideal for loosening stubborn fasteners that may be difficult to remove with a regular screwdriver.

- Multimeter: Essential for diagnosing electrical issues by measuring voltage, current, and resistance.

- Clean-up Tools: A vacuum or air compressor is useful for removing debris and ensuring a clean workspace.

Having these tools readily available will help streamline the repair process, allowing you to efficiently address any issues that may arise with your equipment.

Safety Precautions During Repairs

When conducting maintenance on outdoor power tools, ensuring safety is paramount. Proper precautions not only protect the individual performing the task but also prolong the lifespan of the equipment. Adhering to recommended guidelines can prevent accidents and enhance the repair experience.

| Precaution | Description |

|---|---|

| Personal Protective Equipment | Always wear gloves, safety goggles, and sturdy footwear to protect against debris and sharp components. |

| Work Area | Ensure the workspace is clean, well-lit, and free from distractions to minimize the risk of accidents. |

| Tool Inspection | Regularly check tools for wear and damage to avoid malfunctions during repairs. |

| Disconnect Power Source | Always disconnect the power supply before beginning any repair work to prevent accidental starts. |

| Follow Manufacturer Guidelines | Refer to the manufacturer’s instructions for specific safety measures and repair procedures. |

Frequently Asked Questions about FS44

This section aims to address common inquiries related to a specific model of outdoor equipment, focusing on maintenance, operation, and troubleshooting. Here, you’ll find concise answers to enhance your understanding and usage of this tool.

General Inquiries

- What type of fuel should be used?

- How often should maintenance be performed?

- What are the common signs of wear?

Troubleshooting Tips

- What should I do if the engine won’t start?

- How can I fix a clog in the line?

- What to check if it runs inconsistently?

Customer Reviews and Experiences

This section explores the thoughts and insights of users who have engaged with this particular outdoor equipment. Their feedback provides valuable perspectives on performance, reliability, and overall satisfaction, helping potential buyers make informed decisions.

User Satisfaction

- Many users appreciate the ease of use and lightweight design.

- Performance during prolonged tasks is frequently highlighted as a positive aspect.

- Customers often commend the durability and longevity of the equipment.

Common Concerns

- Some users report occasional issues with specific components.

- A few customers express the need for clearer assembly instructions.

- Price point is a topic of discussion, with some considering it higher than competitors.

Tips for Troubleshooting FS44 Problems

When dealing with equipment issues, a systematic approach can save time and frustration. By understanding common malfunctions and their potential causes, you can effectively diagnose and resolve problems. This guide offers insights to help you identify and address typical challenges that may arise during operation.

1. Check Fuel Quality: Ensure that the fuel used is fresh and free from contaminants. Old or dirty fuel can lead to starting difficulties and poor performance. Always use the recommended fuel mixture for optimal results.

2. Inspect the Spark Plug: A worn or fouled spark plug can hinder ignition. Remove the plug and examine it for carbon buildup or damage. Cleaning or replacing the spark plug may restore proper functionality.

3. Examine the Air Filter: A clogged air filter restricts airflow, affecting engine performance. Regularly clean or replace the filter to maintain adequate air supply.

4. Check for Fuel Leaks: Inspect the fuel lines and connections for any signs of leakage. Leaks can lead to inefficient operation and pose safety risks.

5. Review Operating Procedures: Sometimes, issues stem from incorrect usage. Ensure you’re following the manufacturer’s guidelines for operation, maintenance, and safety.

6. Listen for Unusual Sounds: Uncommon noises can indicate mechanical problems. Pay attention to any changes in sound during operation, and investigate accordingly.

7. Consult the Manual: The owner’s manual is a valuable resource for troubleshooting. Refer to it for specific guidance on maintenance and common issues.

By following these tips, you can enhance your troubleshooting skills and ensure your equipment operates smoothly, allowing you to complete tasks efficiently.