Every tool requires an intricate network of elements working harmoniously to ensure optimal performance. Recognizing the structure and functionality of these individual components is essential for both maintenance and efficient operation. This knowledge not only aids in troubleshooting but also enhances the overall longevity of the equipment.

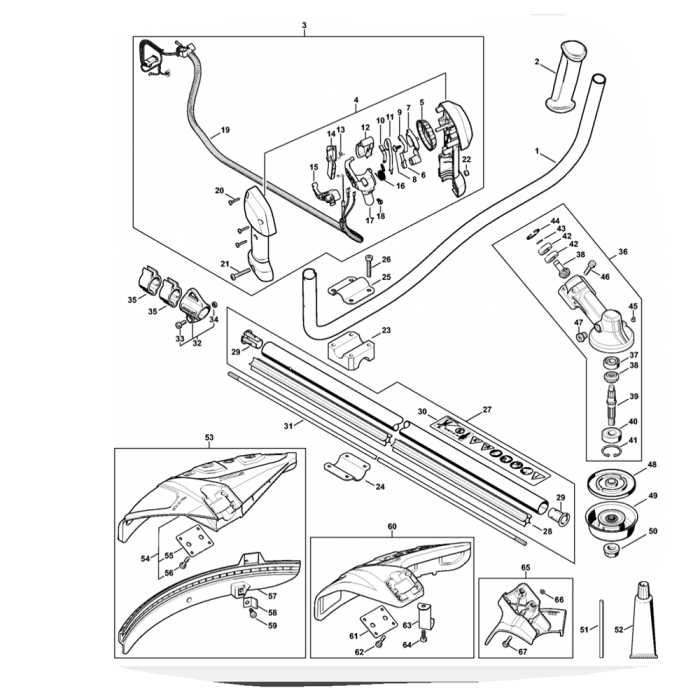

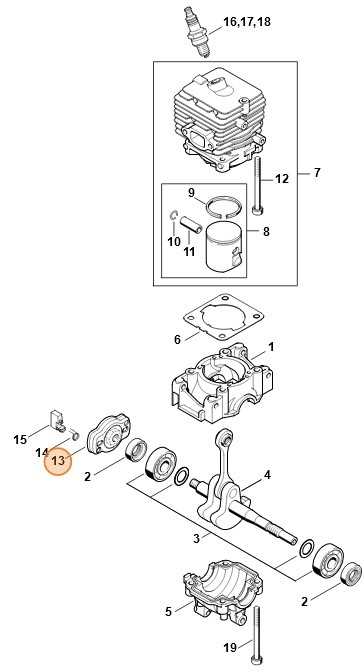

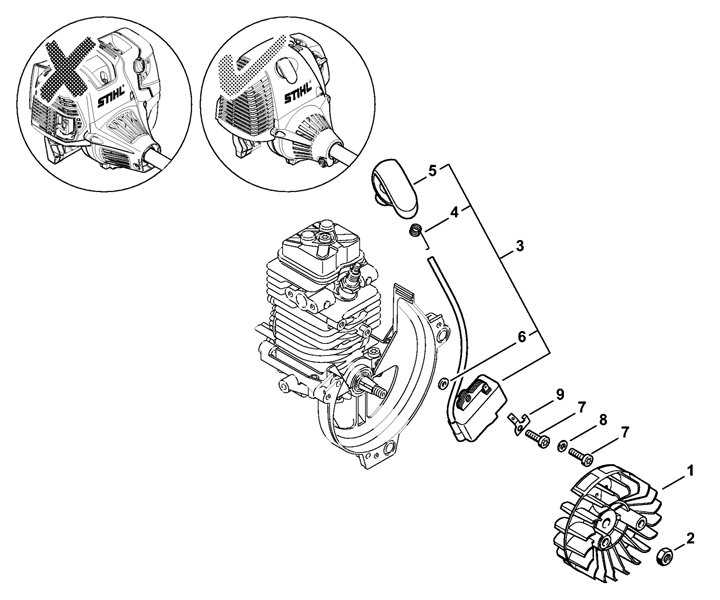

When faced with the need for repairs or replacements, having a clear visual reference can significantly simplify the process. A well-organized schematic representation serves as a valuable guide, illustrating the relationships and positioning of each piece. Whether you are a seasoned professional or a DIY enthusiast, familiarizing yourself with these visuals can empower you to tackle any issues that may arise.

Additionally, understanding the various parts and their specific roles allows for informed decisions regarding upgrades or modifications. This approach not only optimizes functionality but also ensures that the equipment remains at peak performance. Embracing this knowledge fosters a deeper appreciation for the intricacies of the machinery you rely on.

Understanding the Stihl FS94R Components

When it comes to the efficient operation of outdoor power equipment, a thorough comprehension of its individual elements is essential. Each component plays a significant role in ensuring the machine functions smoothly and effectively. By familiarizing oneself with these parts, users can enhance their maintenance skills and address any issues that may arise during operation.

In this exploration, we will delve into the various sections of the device, highlighting their functions and interrelationships. Understanding how these elements work together can lead to improved performance and longevity of the equipment. This knowledge is invaluable for anyone looking to maximize the effectiveness of their outdoor machinery.

Additionally, recognizing common components such as the engine assembly, cutting tools, and control mechanisms will provide insights into the assembly’s overall design. Each part contributes to the machine’s capability to tackle a variety of tasks, from trimming to clearing, making this understanding crucial for optimal use.

Finally, being aware of the typical wear and tear associated with these elements can aid in proactive maintenance, ensuring that the equipment remains in top condition and is ready for any job. Overall, gaining insight into the intricate workings of these components equips users with the tools necessary for successful operation and care.

Overview of Stihl FS94R Features

This section provides a comprehensive look at the remarkable attributes of a particular lightweight outdoor power tool designed for grass trimming and clearing tasks. Its innovative design and powerful functionality make it a preferred choice among professionals and homeowners alike, offering efficiency and ease of use in various landscaping applications.

Key Specifications

The tool boasts several notable specifications that contribute to its overall performance. These features ensure that users can handle a wide range of tasks effectively while maintaining comfort and control.

| Feature | Description |

|---|---|

| Engine Type | Powerful two-stroke engine for enhanced cutting efficiency. |

| Weight | Lightweight construction allows for easy maneuverability. |

| Handle Design | Ergonomically designed handles to reduce user fatigue. |

| Cutting Width | Generous cutting width for faster trimming and clearing. |

Safety Features

In addition to performance attributes, this tool includes several safety mechanisms to protect users during operation. These features are essential for preventing accidents and ensuring a secure working environment.

| Safety Feature | Description |

|---|---|

| Throttle Lock | Prevents accidental engine engagement. |

| Protective Guard | Shielding around the cutting area to minimize debris projection. |

| Vibration Dampening | Reduces vibrations for a more comfortable grip. |

Identifying Key Replacement Parts

Understanding the essential components of your equipment is crucial for maintaining its performance and longevity. Recognizing which elements may require replacement can help ensure smooth operation and prevent potential breakdowns. This section will guide you in identifying the primary elements that may need to be replaced over time.

Here are the main categories to consider when examining your equipment:

- Engine Components: These include parts that contribute to the overall functionality and power of the engine.

- Cutting Tools: Sharp blades and attachments that are vital for effective operation and performance.

- Fuel System: Elements related to fuel delivery, which are essential for the proper functioning of the machinery.

- Electrical Components: Wiring and connectors that ensure proper electrical flow and ignition.

- Housing and Body: Outer structures that protect internal mechanisms and ensure safety during use.

Identifying these categories can simplify the process of locating specific components that may need to be replaced. Regular inspections and maintenance will help prolong the life of your equipment and enhance its efficiency.

Benefits of Using Original Parts

Utilizing authentic components in equipment maintenance ensures optimal performance and longevity. Original components are engineered specifically for certain models, offering compatibility and reliability that aftermarket alternatives may lack. By choosing genuine items, users can enhance the overall efficiency and safety of their machines, ultimately leading to better results in their tasks.

Enhanced Performance

Original components are designed to meet precise specifications, ensuring that the equipment operates at its best. This attention to detail helps maintain the integrity of the machinery, preventing potential malfunctions or inefficiencies that can arise from using subpar alternatives. As a result, users experience smoother operation and improved output.

Long-Term Cost Savings

While original components may come at a higher initial cost, they often lead to long-term savings. By reducing the likelihood of breakdowns and extending the lifespan of the equipment, authentic items minimize the need for frequent replacements or repairs. This proactive approach ultimately saves time and money, providing greater value for the investment.

How to Access Parts Diagrams

Finding detailed illustrations of components for your equipment is essential for maintenance and repairs. These resources provide a visual representation of each element, making it easier to identify and order necessary replacements. Accessing these materials can streamline your repair process and ensure that you have the right tools for the job.

Online Resources

Many manufacturers offer online platforms where you can view comprehensive illustrations. Simply visit the official website and navigate to the support or service section. Look for links to manuals or component breakdowns, often available in digital formats. Using the model number can expedite your search, ensuring you find the correct visual aids quickly.

Local Dealerships

If online resources do not yield the desired results, consider visiting or contacting local dealers. They often have physical copies of these resources and can provide guidance on locating the specific components you need. Inquire about printed materials or digital access that they might offer to enhance your repair experience.

Common Issues and Solutions

This section addresses frequent challenges that users may encounter with their outdoor power equipment. Understanding these common problems and their respective solutions can enhance performance and extend the lifespan of the machinery.

| Issue | Description | Solution |

|---|---|---|

| Engine Won’t Start | The engine may not ignite due to fuel issues or spark plug problems. | Check the fuel level, ensure it’s fresh and properly mixed, and inspect the spark plug for wear or damage. |

| Loss of Power | A significant drop in performance can hinder efficiency. | Clean or replace the air filter, and examine the fuel lines for clogs. |

| Overheating | Excessive heat can lead to equipment failure. | Allow the machine to cool, check for blockages in the cooling system, and ensure adequate airflow. |

| Vibration Issues | Excessive vibrations can affect handling and comfort. | Inspect for loose screws or components, and ensure that cutting attachments are balanced and correctly fitted. |

| Fuel Leakage | Leaks can occur due to damaged seals or hoses. | Identify the source of the leak and replace any worn parts promptly to prevent hazards. |

Maintenance Tips for Longevity

Proper upkeep of your equipment is essential for ensuring its durability and optimal performance over time. Regular care not only enhances efficiency but also helps prevent costly repairs and prolongs the lifespan of the machinery. Adopting a consistent maintenance routine will yield significant benefits and keep your tools functioning effectively.

Begin by routinely checking and cleaning the air filter to ensure proper airflow, which is crucial for engine performance. Replace or clean the filter as needed to prevent debris from entering the system. Additionally, inspect the spark plug regularly; a clean spark plug facilitates easier starting and better fuel efficiency. If the plug shows signs of wear or damage, replacing it promptly will contribute to smoother operation.

Lubrication is another critical aspect of maintenance. Regularly oil moving parts to reduce friction and wear, which can lead to premature failure. Follow the manufacturer’s guidelines for the correct type of lubricant and application frequency. Furthermore, inspect and tighten any loose screws or bolts, as vibrations during use can lead to these components becoming loose over time.

Finally, store the equipment in a dry, sheltered location to protect it from harsh environmental factors. If the machine will not be used for an extended period, consider draining the fuel system to avoid deterioration and blockages. By following these simple yet effective practices, you can enhance the longevity of your tools and ensure reliable performance for many years to come.

Tools Needed for Part Replacement

Replacing components in machinery requires specific tools to ensure efficiency and safety. Proper equipment not only facilitates the process but also helps maintain the integrity of the unit being serviced. This section outlines essential tools that will assist in the successful replacement of various elements in your equipment.

Essential Hand Tools

Basic hand tools are crucial for any maintenance task. A set of screwdrivers, including flathead and Phillips, is necessary for loosening or tightening screws. Additionally, a wrench set will be needed for nuts and bolts, allowing for secure fittings. Plier sets are useful for gripping and manipulating smaller components, ensuring precise adjustments during the replacement process.

Power Tools for Efficiency

In many cases, using power tools can significantly speed up the replacement procedure. A cordless drill is invaluable for driving screws quickly and efficiently, while a socket wrench can facilitate the removal of larger fasteners with ease. Having a reliable torque wrench on hand is also advisable, as it ensures that components are tightened to the manufacturer’s specifications, preventing potential damage or failure.

Where to Buy Stihl Parts

When seeking components for outdoor power equipment, it’s essential to know where to find reliable sources. Whether you’re looking to replace a worn-out element or upgrade your machinery, having access to quality suppliers can make all the difference in maintaining performance and longevity.

Here are some excellent avenues to explore when searching for high-quality components:

- Authorized Dealers: Visiting an authorized retailer ensures that you receive genuine parts that are specifically designed for your equipment. These dealers often have knowledgeable staff who can assist you in finding the right replacements.

- Online Marketplaces: Websites like Amazon, eBay, and specialized online stores provide a vast selection of components. Make sure to check the seller’s reputation and read reviews to avoid counterfeit items.

- Local Repair Shops: Many local mechanics or repair shops specialize in outdoor machinery. They often have a stock of commonly needed items and can order specific components if necessary.

- Manufacturer’s Website: Many manufacturers offer direct sales through their websites. This option guarantees that you are getting authentic parts directly from the source.

- Second-Hand Stores: Thrift shops or specialized second-hand stores may have older models of equipment and parts available. This can be a cost-effective solution for those looking to save money.

Always prioritize quality and compatibility when selecting components, as this can significantly affect your equipment’s performance and durability.

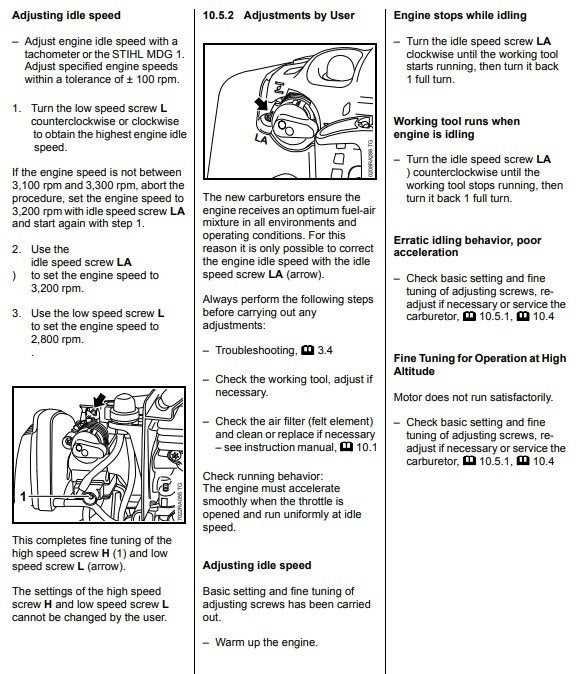

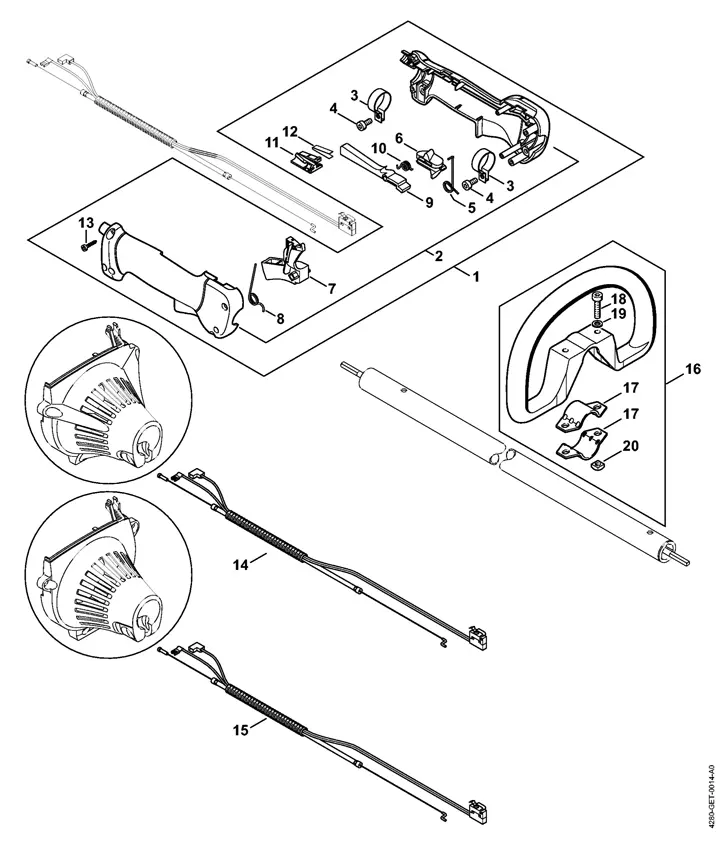

Interpreting the Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repair tasks. This illustration serves as a guide, providing a comprehensive overview of the various elements and their relationships within the machinery. By familiarizing yourself with this visual aid, you can enhance your troubleshooting skills and ensure the proper functioning of your equipment.

Key Components and Their Functions

The visual representation typically highlights individual components, each with a specific role in the overall operation. Recognizing these elements helps in identifying any potential issues that may arise during use. Take note of the labels and annotations that accompany the illustration, as they provide valuable information regarding the assembly and arrangement of each part.

Utilizing the Illustration for Repairs

When undertaking repair tasks, refer to the visual guide to locate the necessary components accurately. This will streamline the process, allowing for efficient replacements or adjustments. A clear understanding of the layout ensures that you can perform maintenance activities with confidence, minimizing the risk of errors and enhancing the longevity of your machinery.

Frequently Asked Questions

This section addresses common inquiries related to maintenance equipment and their components. Understanding these aspects can help users make informed decisions about repairs and replacements, ensuring optimal performance and longevity of their tools.

What should I do if I need to replace a specific component?

If a particular element of your equipment is worn or damaged, consult the manufacturer’s reference materials for guidance on compatible replacements. It’s crucial to select high-quality parts that meet the specifications to maintain functionality.

How can I locate a repair manual for my tool?

To find a detailed guide for your equipment, visit the manufacturer’s official website or authorized dealers. These resources typically offer downloadable manuals that contain crucial information about maintenance, assembly, and troubleshooting.

User Manual Insights

This section provides valuable insights into the operational guide for a popular model of outdoor equipment. It emphasizes the importance of understanding the user’s manual for optimal performance and safety while using the machine. Familiarity with the instructions can significantly enhance the user experience and ensure proper maintenance over time.

The manual typically includes various sections that cover setup, safety precautions, operation guidelines, and troubleshooting tips. Each part is essential for both novice and experienced users to maximize efficiency and extend the life of the equipment.

| Section | Description |

|---|---|

| Introduction | An overview of the equipment, including features and benefits. |

| Safety Information | Critical safety guidelines to prevent accidents and injuries during operation. |

| Setup Instructions | Step-by-step guidance on how to assemble and prepare the equipment for use. |

| Operating Procedures | Detailed instructions on how to use the equipment effectively and safely. |

| Maintenance Guidelines | Recommendations for routine maintenance to ensure longevity and reliability. |

| Troubleshooting | Common issues and solutions to help users resolve problems quickly. |

Engaging with the operational guide equips users with knowledge, promoting confident handling of the equipment. Understanding each component and its function fosters a safer and more effective working environment.

Warranty and Service Information

This section provides essential details regarding the coverage and maintenance options available for your equipment. Understanding warranty terms is crucial for ensuring that your investment is protected against defects and malfunctions, allowing you to use your device with confidence.

Typically, warranties cover specific components for a designated period, ensuring that repairs or replacements are carried out without additional costs. It’s advisable to familiarize yourself with the conditions that apply, including any maintenance requirements that must be adhered to in order to maintain warranty validity.

For servicing, authorized centers offer professional assistance, ensuring that your equipment is maintained to optimal performance standards. Regular servicing not only extends the lifespan of your device but also guarantees that it operates efficiently and safely. Always refer to the manufacturer’s guidelines for recommended service intervals and procedures.

Should you experience issues, it’s vital to contact customer support promptly. They can provide guidance on troubleshooting steps and facilitate any necessary repairs. Keeping records of your purchase and service history can also be beneficial in managing your warranty claims effectively.