When working with powerful cutting machines, comprehending their individual elements is crucial for maintenance and effective operation. A thorough grasp of these essential components not only enhances performance but also ensures longevity. This guide aims to unravel the complexities of a particular model’s structure, aiding both enthusiasts and professionals alike in navigating the intricacies of their tool.

By breaking down the various sections and mechanisms, users can gain valuable insights into how each part contributes to the overall functionality. Understanding these connections can empower users to troubleshoot issues effectively and make informed decisions regarding repairs or upgrades. An in-depth exploration of the machinery allows for a more intuitive handling experience, which is vital in any demanding environment.

Equipped with this knowledge, operators can approach their tasks with confidence, knowing they have a clear picture of how everything works together. Whether you are a seasoned expert or a newcomer, delving into the specifics of these components can significantly enhance your operational efficiency and safety.

Understanding the Stihl MS 362 C Model

This section explores the intricacies of a high-performance cutting tool, highlighting its essential components and functionality. Designed for efficiency and durability, this model caters to various applications, making it a favorite among professionals and enthusiasts alike.

| Feature | Description |

|---|---|

| Engine Power | Delivers robust performance for demanding tasks. |

| Weight | Lightweight design enhances maneuverability. |

| Fuel Efficiency | Ultimate efficiency minimizes operational costs. |

| Safety Features | Equipped with advanced safety mechanisms. |

Key Features of MS 362 C Chainsaw

The chainsaw model offers a blend of performance and efficiency, catering to both professional and casual users. Its design emphasizes user comfort while ensuring powerful operation, making it a reliable tool for various cutting tasks.

Powerful Engine

Equipped with a high-performance engine, this model delivers exceptional cutting power, enabling it to tackle demanding jobs with ease. The efficient fuel consumption allows for longer operation times, reducing the need for frequent refueling.

Lightweight and Ergonomic Design

The innovative construction of this chainsaw ensures a lightweight profile, facilitating ease of handling during extended use. Comfortable grips and an anti-vibration system further enhance user experience, minimizing fatigue and increasing precision in cutting tasks.

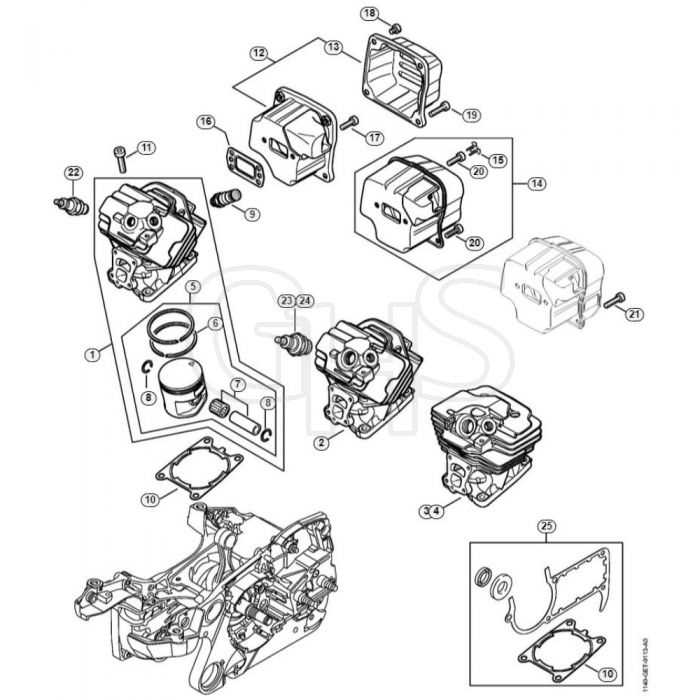

Importance of Parts Diagrams

Understanding the components of a machine is essential for effective maintenance and repair. Visual representations serve as invaluable tools, simplifying the identification and organization of each element within the assembly. This clarity aids technicians and users alike in ensuring optimal functionality and longevity of their equipment.

Benefits of Visual Representations

- Enhances comprehension of the assembly process

- Facilitates accurate troubleshooting and repairs

- Streamlines inventory management for replacements

Utilizing Visual Aids Effectively

- Refer to the illustration during disassembly and reassembly.

- Keep the visual guide accessible for quick reference.

- Use it as a training tool for new users and technicians.

How to Read a Parts Diagram

Understanding the layout of an assembly visual is essential for effective maintenance and repairs. These illustrations provide a clear representation of the various components, their arrangement, and how they interact within the overall system. Familiarizing yourself with this type of visual can save time and reduce frustration when working on equipment.

To begin, locate the reference numbers associated with each element. These identifiers often correspond to a list that details specifications or replacement options. Pay close attention to how the components are grouped, as this can indicate assembly order and highlight critical areas that require careful handling.

It’s also important to note any specific notations that may indicate the orientation or alignment of certain elements. Arrows and labels can provide crucial information about how parts fit together and function, guiding you through the repair process with confidence.

By practicing these skills, you’ll enhance your ability to interpret these visuals, leading to more efficient repairs and a better understanding of your equipment’s design.

Common Parts for Stihl MS 362 C

This section focuses on essential components commonly found in a well-regarded chainsaw model. Understanding these elements is crucial for maintenance and ensuring optimal performance. Each component plays a significant role in the functionality and longevity of the equipment.

| Component | Description |

|---|---|

| Chain | Vital for cutting, this item must be sharp and well-lubricated for efficiency. |

| Bar | The elongated piece that guides the chain and aids in stability during operation. |

| Air Filter | Prevents debris from entering the engine, ensuring proper airflow and performance. |

| Fuel Filter | Filters out impurities from fuel, protecting the engine and enhancing performance. |

| Spark Plug | Ignites the fuel-air mixture, playing a crucial role in starting and running the engine. |

Maintenance Tips for Chainsaw Longevity

Proper upkeep of your cutting tool is essential for ensuring its efficiency and extending its lifespan. Regular maintenance not only improves performance but also enhances safety during operation. Here are some vital tips to keep your device in top shape.

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Clean the Air Filter | Every 5 hours of use | Remove and gently wash with soapy water; ensure it’s completely dry before reinstallation. |

| Sharpen the Chain | After every 5-10 cuts | Use a file or sharpener specifically designed for your model to maintain optimal cutting efficiency. |

| Check Bar and Chain Tension | Before each use | Ensure proper tension to prevent damage; adjust if the chain feels loose or too tight. |

| Inspect Fuel Mixture | Regularly | Use the correct ratio of oil to fuel to avoid engine problems; consider using fresh fuel every month. |

| Examine Spark Plug | Every 25 hours of use | Replace if worn or dirty; check for proper gap to ensure efficient ignition. |

| Lubricate the Bar | After every use | Apply oil to the guide bar and chain to minimize friction and wear. |

By following these maintenance steps, you can ensure your cutting tool remains reliable and performs efficiently for many years to come.

Identifying Replacement Parts Easily

Understanding how to locate components for your equipment can significantly enhance maintenance and repair efficiency. By familiarizing yourself with the structure and layout of your machinery, you can quickly pinpoint what you need. This not only saves time but also ensures you obtain the right items for optimal performance.

Visual aids such as schematics can be invaluable in this process. They provide a clear overview of the various elements, making it easier to identify what requires replacement. Taking the time to study these resources can prevent costly mistakes and enhance your confidence in managing repairs.

Additionally, utilizing online platforms dedicated to equipment maintenance can streamline your search. Many websites offer comprehensive guides, enabling users to delve into specifics and understand the compatibility of different components. With the right tools and information, finding what you need becomes an ultimate goal within reach.

Where to Find Authentic Stihl Parts

Finding genuine components for your outdoor power equipment is essential for maintaining performance and longevity. Ensuring that you source these items from reputable suppliers will not only enhance the durability of your machinery but also ensure safety during operation. Here are some reliable avenues to explore when searching for authentic items.

Authorized Dealers

One of the most reliable options is to visit authorized dealers. These establishments are certified to sell original equipment and provide expert advice. They often have a comprehensive selection of components and can assist with identifying the right parts for your specific model.

Online Retailers

Another convenient option is reputable online retailers that specialize in outdoor power tools. Look for websites that guarantee authenticity and provide detailed descriptions and images of the items. Additionally, read customer reviews to ensure the credibility of the seller. Websites that focus on original merchandise often offer return policies, which adds an extra layer of security to your purchase.

Remember: Always prioritize quality over cost. Investing in genuine components will pay off in the long run, enhancing both performance and safety.

Tools Needed for Assembly and Repair

Proper assembly and maintenance of equipment require a set of essential tools to ensure effective and safe handling. Having the right instruments at your disposal not only streamlines the process but also enhances the overall performance of the machine. Below is a comprehensive list of necessary tools for effective assembly and repair tasks.

- Screwdrivers: A variety of screwdrivers, including flat-head and Phillips, are crucial for tightening and loosening screws.

- Wrenches: Both adjustable and fixed wrenches are needed to manage nuts and bolts securely.

- Socket Set: A socket set allows for easy access to fasteners in tight spaces, providing efficiency in repairs.

- Pliers: Needle-nose and regular pliers are useful for gripping, twisting, and cutting wires or small components.

- Torque Wrench: This tool is essential for applying a specific torque to fasteners, ensuring they are tightened to the manufacturer’s specifications.

- Hex Key Set: Also known as Allen wrenches, these are necessary for assembling components that use hexagonal screws.

- Fuel Mixing Container: For proper fuel preparation, a container with measurement markings is important to ensure the correct mixture ratios.

- Safety Gear: Personal protective equipment such as gloves, goggles, and ear protection should always be used to ensure safety during repairs.

Utilizing these tools effectively will facilitate a smoother assembly and maintenance experience, allowing you to keep your equipment in optimal condition.

Safety Guidelines for Chainsaw Use

Operating a cutting tool requires careful consideration and adherence to safety measures to prevent accidents and injuries. Proper knowledge of equipment, protective gear, and safe practices is essential for a secure working environment.

| Safety Measure | Description |

|---|---|

| Wear Protective Gear | Always use helmets, gloves, eye protection, and chainsaw chaps to safeguard against potential hazards. |

| Inspect Equipment | Before use, check the tool for any damage or wear, ensuring all components function correctly. |

| Maintain Proper Stance | Position yourself securely with feet shoulder-width apart for stability while operating the equipment. |

| Be Aware of Surroundings | Ensure the area is clear of people, animals, and obstacles to prevent accidents during operation. |

| Follow Operating Instructions | Always adhere to the manufacturer’s guidelines and safety recommendations for optimal performance. |

Comparative Analysis with Other Models

This section explores how specific tools compare with other models in terms of performance, design, and functionality. Understanding these differences can help users make informed decisions based on their unique needs.

When examining similar devices, several key factors emerge:

- Power Output: Different models may offer varying levels of engine performance, impacting efficiency and cutting speed.

- Weight and Ergonomics: The balance and weight distribution can significantly affect user comfort during extended use.

- Durability: Construction materials and design choices can influence the longevity and maintenance needs of the equipment.

- Fuel Efficiency: Variations in fuel consumption can determine overall operational costs and environmental impact.

Ultimately, comparing these aspects allows for a deeper understanding of how each model caters to specific tasks and user preferences.