When it comes to maintaining and servicing your outdoor machinery, having a clear understanding of its components is crucial. Proper knowledge about each element ensures efficient performance and longevity of the device. This section will provide an overview of the different sections and functions within your equipment, offering valuable insights for both beginners and experienced users alike.

Familiarity with the various elements not only aids in troubleshooting common issues but also enhances your ability to perform routine maintenance. Whether you are looking to replace worn-out components or simply want to know how everything fits together, visual aids can be extremely helpful. By examining the intricate details of your machinery, you can ensure that each part is in its optimal state.

In this guide, you will discover detailed illustrations that break down the assembly of your equipment. Each section will highlight the role of individual components and provide tips for ensuring their proper function. Armed with this information, you can approach repairs with confidence, knowing you have the right resources at your disposal.

This section aims to provide an insightful look into the various components of a well-known landscaping tool. Understanding these elements is essential for effective maintenance and repair. By breaking down the different parts, users can enhance their knowledge and ensure optimal performance.

- Essential Components

Each tool consists of vital parts that contribute to its overall functionality. Recognizing these components aids in identifying issues and streamlining repairs.

- Maintenance Tips

Regular upkeep of each element is crucial for longevity. Adopting best practices can prevent common problems and extend the tool’s lifespan.

- Common Issues

Awareness of frequent malfunctions related to specific components allows for quicker troubleshooting. Knowing what to look for can save time and effort during repairs.

- Replacement Options

When parts wear out or become damaged, understanding the available replacement choices is key. This knowledge ensures that users can find suitable substitutes without hassle.

- Assembly Overview

Understanding how different elements fit together aids in proper reassembly after maintenance or part replacement. This comprehension enhances user confidence and ensures correct functionality.

Importance of Accurate Parts Identification

Proper identification of components is crucial for maintaining and repairing machinery effectively. Ensuring that the correct elements are selected not only enhances the performance of the equipment but also prolongs its lifespan. Inaccurate identification can lead to malfunctions and potential damage, which can be costly in both time and resources.

When technicians have access to precise information about the components needed for repairs, they can work more efficiently. This reduces the likelihood of errors and helps in achieving the desired outcomes in a timely manner. Accurate identification supports effective troubleshooting and minimizes downtime, which is vital in both personal and professional settings.

| Key Benefits | Description |

|---|---|

| Efficiency | Streamlined processes lead to quicker repairs. |

| Cost Savings | Reduces the risk of purchasing incorrect components. |

| Enhanced Performance | Ensures machinery operates at optimal levels. |

| Longevity | Prolongs the life of the equipment through proper care. |

Common Issues with Stihl SH56C

Every piece of equipment can encounter problems over time, and handheld blowers are no exception. Users often report various challenges that can affect performance, efficiency, and overall functionality. Understanding these common issues can help in diagnosing and resolving them effectively, ensuring the tool operates at its best.

Performance Problems

One of the most frequently mentioned difficulties involves insufficient power or erratic operation. This can manifest as poor airflow or intermittent functionality. Such issues can stem from several factors, including fuel quality, air filter condition, or spark plug integrity. Regular maintenance checks can alleviate many of these concerns.

Starting Issues

Another prevalent problem is difficulty in starting the equipment. Users may find that the blower fails to ignite or requires multiple attempts to get running. This can often be attributed to issues such as fuel blockage, carburetor malfunction, or ignition system faults. Addressing these components promptly can help restore reliable starting performance.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Power Loss | Poor fuel quality, clogged air filter, worn spark plug | Use fresh fuel, clean or replace air filter, check and replace spark plug if needed |

| Starting Problems | Fuel blockage, carburetor issues, ignition faults | Inspect fuel lines, clean carburetor, check ignition components |

Exploring the Engine Components

The efficiency and performance of a power tool heavily depend on the intricacies of its engine assembly. Understanding the various elements that make up the engine allows for better maintenance, troubleshooting, and ultimately enhances the tool’s longevity. Each component plays a crucial role in ensuring optimal function and can often be the key to resolving operational issues.

Among the essential engine components are the fuel system, ignition system, and various mechanical elements that work in unison. Familiarity with these parts can significantly impact the effectiveness of the machine, as well as help users identify potential problems before they escalate.

| Component | Function |

|---|---|

| Cylinder | Houses the combustion process where fuel and air mix and ignite. |

| Piston | Moves up and down within the cylinder, converting fuel energy into mechanical work. |

| Crankshaft | Transforms the linear motion of the piston into rotational motion to power the tool. |

| Ignition Coil | Generates the spark needed to ignite the fuel-air mixture. |

| Fuel Tank | Stores fuel that powers the engine, ensuring a steady supply during operation. |

Understanding the Fuel System Design

The design of a fuel system is crucial for the efficient operation of any power tool. It ensures that the engine receives the appropriate mixture of fuel and air to facilitate optimal combustion. This intricate system involves various components that work together seamlessly to deliver energy where it is needed.

A typical fuel system consists of a tank, fuel lines, a filter, and a carburetor. The tank holds the fuel, while the lines transport it to the engine. The filter removes impurities, ensuring that only clean fuel reaches the carburetor, where the air and fuel mix occurs. This combination is essential for starting the engine and maintaining its performance during operation.

Understanding how each component interacts within the fuel system can help in troubleshooting issues related to power loss, starting difficulties, or inefficient fuel consumption. Regular maintenance and awareness of the system’s design can enhance the longevity and functionality of the equipment.

Key Features of the Blower Assembly

The blower assembly is a crucial component designed to optimize airflow and enhance performance in outdoor cleaning tasks. Understanding its key features helps users appreciate its efficiency and versatility in various applications.

Powerful Airflow Generation

One of the standout attributes of the blower assembly is its ability to generate powerful airflow. This is essential for effectively clearing leaves, debris, and other unwanted materials from outdoor spaces.

- High airspeed for efficient clearing.

- Adjustable power settings for tailored use.

- Ergonomic design for comfortable handling.

Durability and Maintenance

Durability is another significant feature, ensuring longevity and consistent performance even in challenging conditions. Regular maintenance practices contribute to the assembly’s extended life and reliability.

- Robust construction materials for weather resistance.

- Simple disassembly for easy cleaning and maintenance.

- Minimal wear and tear, enhancing operational lifespan.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and performance of your outdoor power equipment. Proper maintenance not only extends the lifespan of the machine but also enhances its efficiency and reliability. Following a consistent care routine can prevent costly repairs and keep your equipment in peak condition.

Essential Maintenance Practices

Implementing a few basic maintenance practices can greatly enhance the longevity of your equipment. These practices include regular cleaning, inspection, and timely replacement of worn-out components. Keeping the equipment free from debris and dirt will ensure optimal performance and prevent overheating.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Clean Air Filter | Every 25 hours | Replace if damaged or excessively dirty. |

| Inspect Spark Plug | Every 50 hours | Clean or replace as needed. |

| Check Fuel Lines | Monthly | Look for cracks or leaks. |

| Sharpen Blades | Every 10 hours of use | Ensure clean cuts for better performance. |

Seasonal Care Recommendations

In addition to regular tasks, seasonal care is crucial for maintaining optimal function. Before storing the equipment for winter, ensure that it is thoroughly cleaned and the fuel system is stabilized. Conversely, spring maintenance should focus on inspecting components for wear and preparing the machine for the busy season ahead.

How to Replace Common Parts

Maintaining your equipment is essential for optimal performance and longevity. This section provides guidance on replacing frequently used components, ensuring that your machinery operates smoothly. Understanding the replacement process can save time and enhance functionality.

To begin, gather the necessary tools and replacement components. It is advisable to consult the manufacturer’s recommendations for specific items. Once you have everything ready, disconnect the power source to ensure safety while working on the unit.

Start with the most accessible components. Remove any coverings or casings carefully to expose the area you need to work on. For instance, if you are changing filters or other easily replaceable elements, follow the designated steps to remove the old part and install the new one. Ensure that all connections are secure and that no debris is left behind.

For more complex replacements, like motors or larger assemblies, consult the manual for detailed instructions. If available, refer to online resources for visual aids that can assist you in understanding the assembly. Always ensure you have the correct tools for the job, as this will make the process more efficient.

After completing the replacements, double-check all connections and secure any covers that were removed. Finally, reconnect the power source and perform a test run to confirm that everything is functioning correctly. Regularly replacing worn or damaged components will prolong the life of your equipment and maintain its performance.

Tools Required for Repairs

When it comes to maintaining outdoor power equipment, having the right tools is essential for ensuring effective repairs and longevity of the machine. Each task may require specific implements that enhance the efficiency of the repair process. This section outlines the essential tools needed for effective maintenance and troubleshooting.

Basic Hand Tools

Start with a set of basic hand tools, including screwdrivers, wrenches, and pliers. These are crucial for loosening and tightening various components, making them indispensable for any repair task. A comprehensive toolkit ensures that you can tackle most repairs without delay.

Specialized Equipment

In addition to basic hand tools, consider investing in specialized equipment. For instance, socket sets can provide the necessary torque for certain bolts, while cleaning brushes help maintain performance by removing debris. Having these tools readily available will facilitate a smoother repair process and enhance overall functionality.

Benefits of Genuine Stihl Parts

Using authentic components for your equipment is essential for maintaining optimal performance and longevity. These high-quality items are specifically designed to fit perfectly and work seamlessly with your machinery, ensuring that you get the best possible results during operation.

Enhanced Performance

When you choose original components, you are investing in superior performance. These items are engineered to meet precise specifications, which means they function efficiently under various conditions. This leads to better efficiency, allowing your machinery to operate at its full potential.

Increased Durability

Authentic components are built to withstand the rigors of use, providing a longer lifespan than their aftermarket counterparts. This durability not only saves you money on replacements but also reduces downtime, allowing you to focus on your tasks without interruptions.

Where to Find Replacement Parts

When your equipment requires new components, locating the right replacements is essential for maintaining its performance and longevity. There are various avenues to explore, ensuring you can find the necessary items with ease.

Here are some reliable sources to consider:

- Authorized Dealers: Visiting an official dealer ensures that you obtain high-quality components specifically designed for your equipment.

- Online Retailers: Numerous e-commerce platforms offer a wide selection of replacements, often at competitive prices. Make sure to check customer reviews for reliability.

- Local Hardware Stores: Many local shops stock essential components for various tools and equipment. It’s worth checking their inventory for quick solutions.

- Manufacturer’s Website: The official website often features a catalog of available components and direct purchasing options.

- Second-Hand Market: Websites that specialize in second-hand goods may have listings for pre-owned components, which can be a cost-effective option.

Always verify the compatibility of the components with your specific model to ensure optimal performance. Taking the time to find the right replacements will enhance the efficiency and lifespan of your equipment.

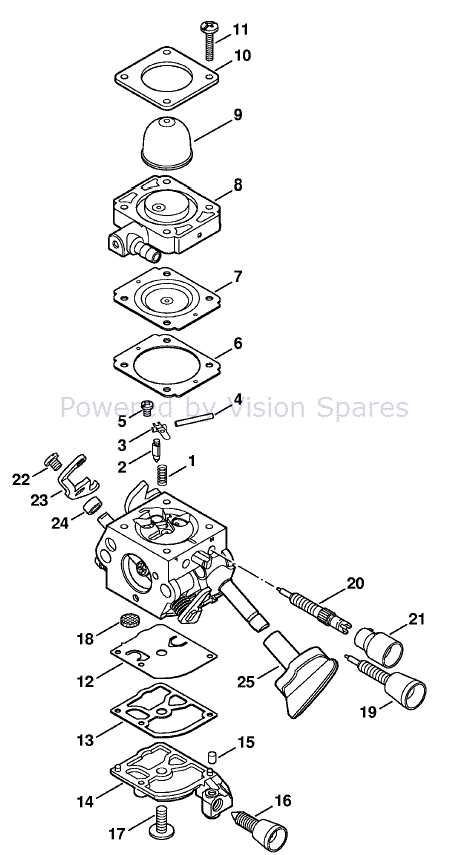

Illustrated Parts Breakdown Guide

This section provides a comprehensive overview of various components associated with your equipment, focusing on their functionalities and interrelationships. Understanding these elements is crucial for maintenance and repairs, ensuring optimal performance.

The following outlines key components and their roles:

- Engine Assembly: The heart of the machine, responsible for power generation.

- Fuel System: Includes the tank, lines, and filter, essential for delivering fuel efficiently.

- Air Filtration: Helps maintain air quality for combustion, preventing debris from entering the engine.

- Exhaust System: Directs harmful gases away from the operator and the machine.

- Starter Mechanism: Initiates the engine, ensuring reliable operation.

In addition to these, several smaller elements contribute to the overall functionality:

- Gaskets and Seals

- Fasteners and Bolts

- Control Cables

- Housing and Frame

Each component plays a vital role in the machine’s operation, and familiarity with them can greatly assist in troubleshooting and repair tasks.

Customer Support and Resources

Access to reliable support and resources is essential for users seeking to maintain and troubleshoot their equipment effectively. Whether you require assistance with operational issues or need guidance on obtaining components, various channels are available to provide the necessary help. Utilizing these resources can enhance your overall experience and ensure the longevity of your equipment.

Online Resources

The internet offers a wealth of information for users looking for guidance. Official websites often feature comprehensive manuals, FAQs, and troubleshooting guides that can address common concerns. Engaging with online communities and forums can also yield valuable insights from fellow users who share their experiences and solutions.

Customer Service

For personalized assistance, reaching out to customer support representatives is highly recommended. Many companies provide multiple contact options, including phone support, email, and live chat. These channels enable users to ask specific questions and receive tailored advice based on their unique situations.