When it comes to maintaining outdoor power equipment, having a clear grasp of its inner workings is essential. This knowledge not only enhances performance but also extends the lifespan of the machinery. By exploring the essential elements that comprise your device, you can ensure it operates smoothly and efficiently.

Each component plays a crucial role, contributing to the overall functionality of the equipment. Whether it’s the engine, the collection system, or the cutting mechanism, understanding how these parts interact is vital for effective troubleshooting and maintenance. With this insight, you can address issues proactively and avoid costly repairs.

In this guide, we will delve into the intricate relationships between various elements, providing you with a comprehensive overview. By examining these components, you’ll gain the ultimate advantage in optimizing your tool’s performance and achieving your gardening goals.

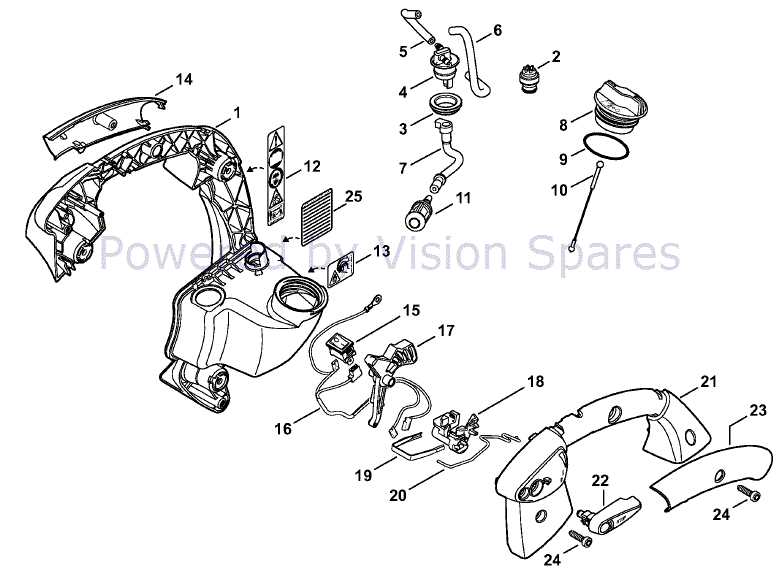

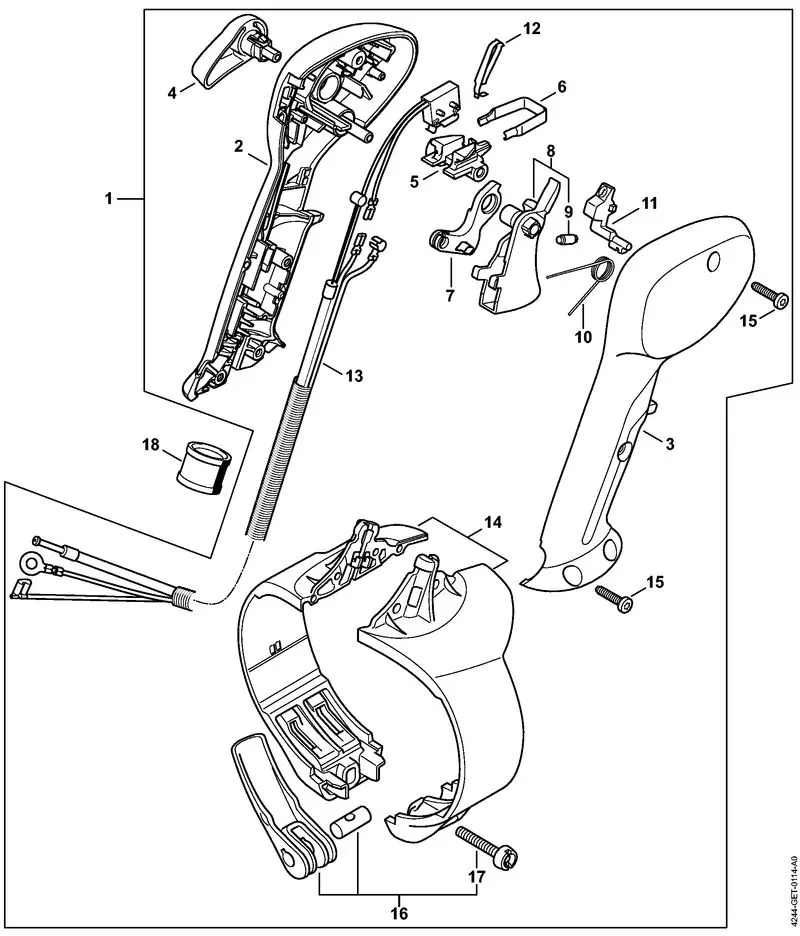

Understanding Stihl SH86C Components

Comprehending the individual elements of a powerful gardening tool is essential for optimal performance and maintenance. Each component plays a vital role in ensuring efficiency and longevity. By familiarizing yourself with these parts, you can enhance your understanding and ability to care for the equipment effectively.

Main Elements

- Engine: The heart of the machine, providing the necessary power for operation.

- Blower Tube: Directs airflow to efficiently move debris.

- Intake Filter: Prevents dirt and particles from entering the engine, ensuring smooth operation.

- Fuel Tank: Stores the fuel mixture, crucial for engine performance.

Additional Features

- Control Handle: Offers ease of operation and maneuverability.

- Vacuum Kit: Allows for collecting debris, enhancing versatility.

- Support Frame: Provides stability and structural integrity to the device.

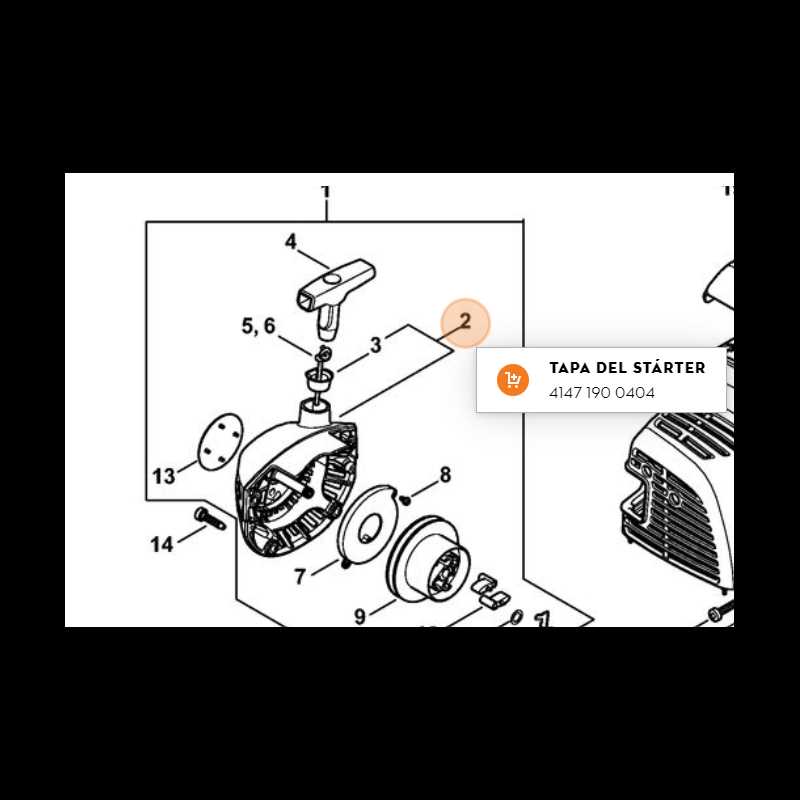

- Start Mechanism: Facilitates quick and reliable ignition of the engine.

By understanding these key components, users can make informed decisions regarding maintenance, troubleshooting, and upgrades. This knowledge is invaluable for achieving the best results in landscaping tasks.

Importance of Parts Diagrams

Understanding the assembly and functionality of machinery is crucial for effective maintenance and repair. Visual representations of components enhance comprehension and facilitate efficient troubleshooting. By providing a clear overview, these illustrations enable users to identify necessary elements and understand their interactions, ultimately leading to better performance.

Moreover, having access to such visuals minimizes the risk of errors during reassembly. Users can confidently source and replace specific components without guesswork, ensuring that repairs are done accurately. This clarity not only saves time but also extends the lifespan of the equipment by promoting proper handling.

In addition, these visual aids serve as invaluable references for training purposes. New users can quickly learn about the machinery, gaining insights into its structure and function. This foundational knowledge fosters a deeper understanding of the equipment, empowering users to troubleshoot issues effectively and maintain optimal operation.

Key Features of Stihl SH86C

This section explores the distinctive characteristics of a powerful outdoor tool designed for efficient maintenance tasks. Its engineering ensures high performance, reliability, and ease of use, catering to both professionals and enthusiasts.

| Feature | Description |

|---|---|

| Powerful Engine | Equipped with a robust engine that delivers exceptional performance for various outdoor tasks. |

| Multi-Functional | Designed to handle multiple functions, including vacuuming and shredding, enhancing versatility. |

| Lightweight Design | Engineered for ease of handling, reducing user fatigue during extended use. |

| Easy Start System | Incorporates an innovative starting mechanism that simplifies the ignition process. |

| High Collection Efficiency | Features an advanced collection system that maximizes debris intake, ensuring a tidy workspace. |

Common Replacement Parts Overview

Understanding the essential components of outdoor power tools is crucial for maintaining optimal performance and longevity. This section focuses on frequently needed replacements that enhance functionality and ensure reliability during operation. By familiarizing yourself with these elements, you can make informed decisions and keep your equipment in peak condition.

Key Components

Among the vital elements are air filters, spark plugs, and fuel lines. Regularly replacing these items helps to maintain efficiency and prevent potential damage. Each plays a significant role in the overall operation, contributing to better performance and ease of use.

Maintenance Tips

Routine inspections and timely replacements are essential for sustaining equipment health. Keeping a checklist of these components can streamline the maintenance process, ensuring that your tool remains ready for any task at hand.

How to Read Parts Diagrams

Understanding technical illustrations can greatly enhance your ability to service and maintain equipment. These visuals provide a comprehensive overview of components, helping you identify each piece and its function within the assembly.

Here are some key points to consider when interpreting these illustrations:

- Identify the Legend: Most diagrams include a legend or key that explains the symbols and notations used. Familiarize yourself with these to decode the information effectively.

- Follow the Flow: Pay attention to how parts connect and interact. This will help you grasp the overall structure and functionality.

- Locate Part Numbers: Each component is typically assigned a unique identifier. Make note of these numbers for easy reference when ordering replacements.

- Examine the Scale: Understanding the scale of the illustration can help you gauge the size and proportions of each element, which is crucial for proper installation.

- Refer to Additional Resources: If available, consult accompanying manuals or guides for detailed explanations and context regarding the visual.

By following these guidelines, you can efficiently navigate technical visuals, ensuring that you have the knowledge needed to perform repairs and maintenance confidently.

Tools Required for Maintenance

Proper upkeep of outdoor equipment is essential for ensuring optimal performance and longevity. A well-prepared toolkit not only streamlines the maintenance process but also enhances safety and efficiency. Below are key instruments that facilitate routine checks and repairs.

Essential Instruments

For effective servicing, a screwdriver set is crucial for adjusting or replacing various components. Additionally, a wrench set allows for securing and loosening fasteners as needed. These basic tools provide a solid foundation for most maintenance tasks.

Advanced Equipment

To delve deeper into specific repairs, having plumbing pliers and a spark plug wrench is beneficial. These specialized tools ensure that more intricate parts can be accessed and handled correctly. Maintaining a well-stocked toolkit is the ultimate way to ensure your equipment runs smoothly.

Identifying Wear and Tear Signs

Recognizing the indicators of degradation is crucial for maintaining equipment efficiency and safety. Various components may exhibit specific symptoms that suggest they are reaching the end of their useful life. Regular inspections can help in detecting these issues before they lead to more significant problems.

Common signs include unusual noises during operation, reduced performance, and visible damage such as cracks or excessive wear. Components like blades and filters often show physical deterioration that can affect functionality. Pay attention to any changes in vibration or operational smoothness, as these can also signal underlying issues.

Neglecting these signs can result in decreased performance and potentially costly repairs. Therefore, it’s essential to conduct routine checks and replace any worn parts promptly to ensure optimal operation.

Step-by-Step Disassembly Guide

This section provides a comprehensive guide for carefully dismantling your equipment, ensuring that each component is accessed and handled with precision. Following these steps will facilitate effective maintenance and repair, allowing you to keep your machine running smoothly.

- Gather necessary tools: a screwdriver, wrench set, and pliers.

- Disconnect the power source for safety.

- Remove any attachments or accessories.

- Unscrew the outer casing using the screwdriver.

- Carefully take off the casing, noting any clips or fasteners.

- Identify and label internal components for easier reassembly.

- Remove screws holding the main assembly in place.

- Gently detach components, ensuring no wires are snagged.

By following this guide, you will be able to delve into the inner workings of your device, ensuring a thorough understanding of each part and its function.

Where to Find Genuine Parts

When maintaining outdoor equipment, sourcing authentic components is crucial for optimal performance and longevity. Genuine items ensure reliability and compatibility, providing peace of mind for users. Here are some effective ways to locate these essential elements.

Authorized Dealers

- Visit local authorized retailers for trusted options.

- Check online platforms affiliated with certified distributors.

- Inquire about warranty and return policies for added security.

Manufacturer’s Website

- Explore the official site for an extensive catalog of available items.

- Utilize online tools to assist in finding the right match for your equipment.

- Look for promotions or discounts directly from the source.

Comparing OEM and Aftermarket Options

When considering replacement components for equipment, users often face the choice between original manufacturer offerings and alternative solutions. Each category presents distinct advantages and potential drawbacks that can influence performance, longevity, and overall satisfaction.

Advantages of OEM Parts

Original equipment manufacturer parts are designed specifically for certain models, ensuring compatibility and reliability. These components often come with warranties and are crafted to meet high-quality standards, which can provide peace of mind for users concerned about performance.

Benefits of Aftermarket Alternatives

Aftermarket options can often be more affordable and may provide a wider variety of choices. Many manufacturers focus on enhancing performance or durability, appealing to those looking to optimize their equipment beyond standard specifications.

| Factor | OEM | Aftermarket |

|---|---|---|

| Quality | High | Variable |

| Cost | Generally Higher | Usually Lower |

| Warranty | Often Included | Varies by Manufacturer |

| Compatibility | Perfect Fit | Potential Issues |

Maintenance Tips for Longevity

Proper upkeep of your outdoor power equipment is essential for maximizing its lifespan and ensuring optimal performance. Regular attention to maintenance tasks can prevent costly repairs and extend the life of your tools.

Regular Cleaning

Cleaning your equipment after each use is crucial. Remove debris, dirt, and clippings to prevent buildup that can hinder performance. Pay special attention to air filters and cooling fins, ensuring they remain unobstructed.

Routine Inspections

Conduct routine inspections to identify wear and tear early. Check components such as spark plugs, fuel lines, and cutting edges. Addressing minor issues promptly can prevent major failures down the line.

Troubleshooting Common Issues

This section focuses on identifying and resolving frequent problems encountered with outdoor power tools. Understanding these issues can enhance performance and extend the lifespan of your equipment.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Engine won’t start | Out of fuel, clogged filter, spark plug issues | Refill fuel, check and clean the filter, inspect or replace spark plug |

| Excessive vibrations | Worn components, unbalanced attachments | Inspect for wear, balance attachments properly |

| Poor performance | Dirty air filter, dull blades | Clean or replace air filter, sharpen or replace blades |

| Overheating | Low oil level, blocked cooling vents | Add oil, clear any obstructions from vents |

Ordering Parts Online: Best Practices

When seeking components for your equipment, navigating the online marketplace can be both convenient and overwhelming. To ensure a smooth transaction and receive quality items, it’s essential to follow some effective strategies that will help you make informed decisions.

Research Reputable Suppliers

Before placing an order, take the time to explore various vendors. Look for customer reviews and ratings to gauge their reliability. A trustworthy supplier will often provide detailed information about the items they offer and have a clear return policy.

Verify Compatibility

Ensure the items you intend to purchase are compatible with your specific model. Check product specifications carefully and, if needed, reach out to customer support for confirmation. This diligence can save you time and money in the long run.