When working with powerful machinery designed for precise cutting tasks, it’s essential to have a clear understanding of their individual components and how they interact. A comprehensive layout of the various elements not only enhances the user’s knowledge but also facilitates efficient maintenance and troubleshooting. This approach ensures that users can effectively operate the equipment while minimizing the risk of malfunctions.

By delving into the arrangement of each section, one can gain insights into the functionality and significance of each part. Recognizing how these components fit together allows for better handling and care, ultimately extending the lifespan of the tool. Furthermore, familiarity with the layout aids in identifying potential issues before they escalate, promoting a safer working environment.

In the following sections, we will explore the intricate design of these devices, highlighting the roles of individual elements. Whether you are a seasoned professional or a newcomer to the field, understanding this schematic representation is crucial for optimizing performance and ensuring that every job is completed with precision.

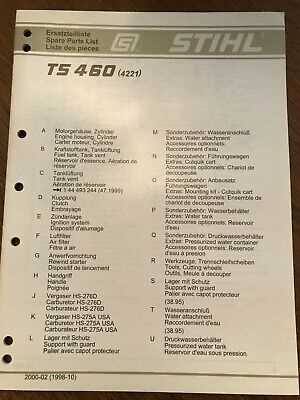

Understanding the Stihl TS 460 Parts

Familiarity with the components of a powerful cutting tool is essential for effective maintenance and operation. Knowing the various elements that make up this machine allows users to troubleshoot issues, perform repairs, and ensure optimal performance over time. This section delves into the essential parts and their functions, providing a clearer understanding of the overall assembly.

| Component | Description |

|---|---|

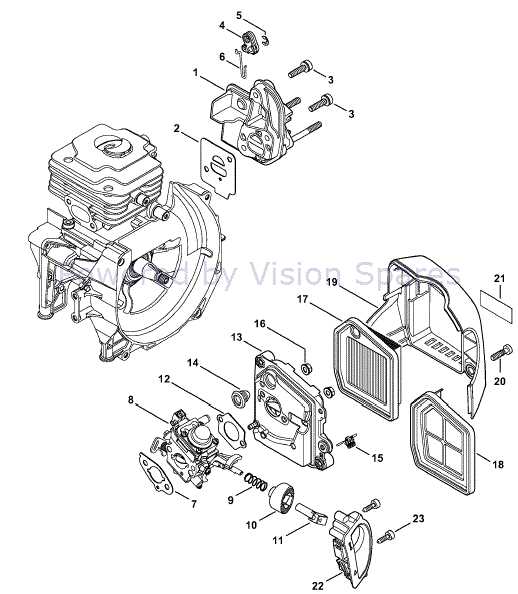

| Engine | The heart of the tool, providing the necessary power to drive the cutting mechanism. |

| Cutter Blade | The primary tool for cutting through materials, available in various sizes and types for different applications. |

| Air Filter | Prevents debris from entering the engine, ensuring clean air intake for efficient combustion. |

| Fuel Tank | Holds the fuel needed for operation, designed for easy refueling and secure storage. |

| Starter Mechanism | Facilitates the initial ignition of the engine, typically operated by a pull cord. |

| Handle | Provides grip and control during operation, designed for comfort and safety. |

Understanding these key elements not only aids in identifying potential issues but also enhances the overall user experience. Regular inspections and familiarity with these components contribute to a longer lifespan and better efficiency of the equipment.

Overview of TS 460 Features

This section explores the various attributes and functionalities of a powerful cutting tool designed for precision and efficiency. Its innovative design combines advanced engineering with user-friendly features, making it a top choice for professionals and DIY enthusiasts alike.

Key Characteristics

The tool boasts a range of impressive characteristics that enhance its performance and usability. Here are some notable features:

| Feature | Description |

|---|---|

| Engine Performance | Equipped with a robust engine that delivers high torque and reliability. |

| Weight | Lightweight design for easy handling and maneuverability. |

| Blade Compatibility | Compatible with a variety of blades for cutting different materials. |

| Vibration Control | Advanced system to minimize vibrations, ensuring user comfort during operation. |

| Safety Features | Incorporates several safety mechanisms to protect the user. |

Ergonomic Design

The ergonomic construction of this tool prioritizes user comfort and efficiency. The well-thought-out handle design allows for extended use without fatigue, while the balanced weight distribution enhances control and stability during operation.

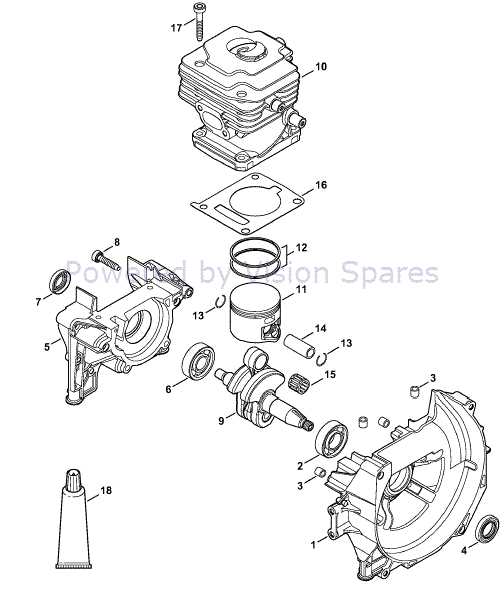

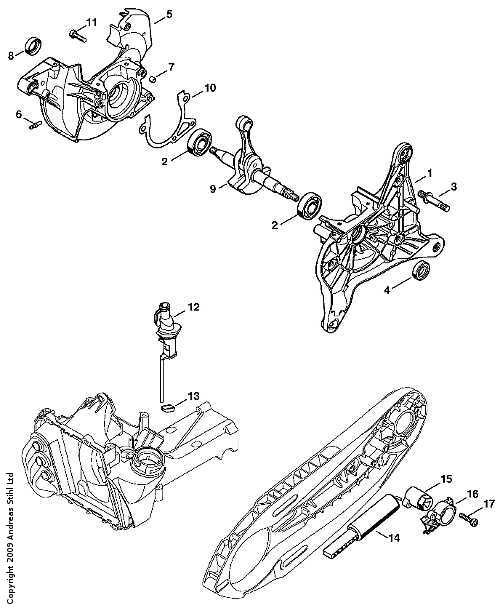

Importance of Parts Diagram

Understanding the structure of machinery is crucial for effective maintenance and repair. A visual representation of components not only simplifies identification but also enhances troubleshooting efficiency. When users can easily reference a detailed layout, it streamlines the process of locating specific elements within the equipment.

Accurate information is vital for ensuring that replacements are compatible and that assembly is correct. This clarity reduces the risk of errors during repairs, ultimately extending the lifespan of the tool. Furthermore, it fosters confidence in users, empowering them to take on maintenance tasks independently.

Access to such visual aids can significantly minimize downtime, as users can quickly pinpoint issues and address them without unnecessary delays. In a professional setting, this efficiency translates to increased productivity and cost savings. Thus, having a comprehensive reference guide is indispensable for anyone involved in the upkeep of machinery.

Common Replacement Parts for TS 460

Regular maintenance and timely replacement of essential components can significantly enhance the performance and longevity of cutting tools. Understanding which elements may require attention helps ensure smooth operation and reliability during use.

| Component | Description |

|---|---|

| Cutter Blade | Key for effective cutting, requiring replacement when dull or damaged. |

| Air Filter | Essential for maintaining airflow and preventing debris from entering the engine. |

| Fuel Filter | Helps to ensure clean fuel supply, preventing clogs and performance issues. |

| Spark Plug | Crucial for ignition; should be replaced periodically for optimal starting and efficiency. |

| Drive Belt | Transmits power from the engine to the cutting mechanism; wear and tear may necessitate replacement. |

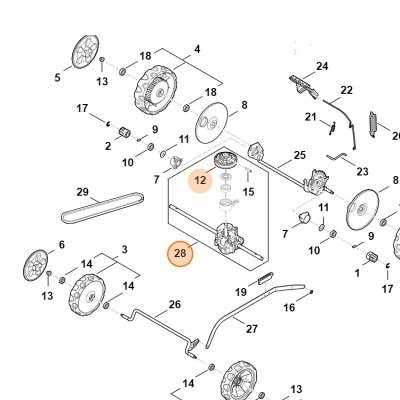

How to Read the Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. This guide will help you navigate the layout, allowing you to identify parts and their relationships clearly.

- Familiarize Yourself: Start by getting accustomed to the overall layout. Look for the main sections and how they connect.

- Identify Symbols: Each element is represented by specific symbols. Refer to the legend or key to understand their meanings.

- Follow Connections: Trace the lines connecting different elements. This will help you grasp how each part interacts with others.

By applying these strategies, you can delve deeper into the representation, enhancing your ability to perform maintenance tasks effectively.

Identifying Parts by Number

Understanding the components of your equipment can significantly enhance maintenance and repair efforts. Each element is typically associated with a unique identification number, making it easier to locate the correct item when needed. Familiarity with these identifiers streamlines the process of sourcing replacements and ensures optimal performance of the machinery.

Importance of Accurate Identification

Accurate identification of components is crucial for effective troubleshooting and repairs. Knowing the specific number associated with each part not only helps in ordering the correct replacements but also aids in understanding compatibility with other elements of the machine. This knowledge can save time and prevent costly errors during maintenance.

How to Use Identification Numbers

To utilize the identification numbers effectively, refer to the user manual or manufacturer’s resources. These documents often provide a comprehensive list of components along with their corresponding numbers. When looking to purchase replacements, using the correct identification ensures that you receive the right item, thus maintaining the efficiency and safety of your equipment.

Maintenance Tips for TS 460

Proper upkeep of your cutting equipment is essential for optimal performance and longevity. Regular maintenance not only enhances efficiency but also ensures safety during operation. Here are some key practices to keep your tool in peak condition.

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Inspect and clean air filter | Every 10 hours | Replace if damaged; ensure it’s free of debris. |

| Check spark plug | Every 20 hours | Clean or replace to maintain efficient ignition. |

| Examine blades for wear | Before each use | Sharpen or replace as necessary for clean cuts. |

| Lubricate moving parts | Every 50 hours | Use appropriate lubricant to prevent rust. |

| Check fuel system | Every 10 hours | Ensure no leaks; use fresh fuel for best performance. |

Where to Find Authentic Parts

Ensuring the longevity and efficiency of your machinery hinges on sourcing genuine components. High-quality replacements not only guarantee optimal performance but also enhance the overall lifespan of your equipment. When searching for reliable sources, it’s essential to consider both the authenticity and the reputation of the supplier.

Authorized Dealers: Start by visiting authorized retailers who specialize in equipment and accessories. These dealers are typically certified to sell original components and provide valuable insights into compatibility and installation.

Official Websites: The manufacturer’s official website is a treasure trove of information. Here, you can find detailed listings of components, along with specifications and recommended distributors. This ensures that you’re purchasing directly from a trustworthy source.

Reputable Online Marketplaces: Certain online platforms are known for their commitment to quality. Look for sellers with high ratings and positive reviews, as they often have stringent policies against counterfeit items.

Local Repair Shops: Consulting with local repair technicians can also be beneficial. They often have access to genuine components and can provide recommendations based on their experience.

Investing time in finding authentic components will pay off in the long run, helping you maintain your equipment in peak condition.

TS 460 Troubleshooting Guide

This section aims to assist users in identifying and resolving common issues that may arise during operation. Effective troubleshooting can enhance performance and prolong the lifespan of your equipment.

- Engine Won’t Start:

- Check the fuel level and ensure it is fresh.

- Inspect the spark plug for wear or damage.

- Verify the choke is in the correct position.

- Excessive Vibration:

- Examine the blade for any signs of damage.

- Ensure all components are securely fastened.

- Look for wear in the dampers or mounts.

- Overheating:

- Check the air filter for clogs.

- Ensure proper fuel mix is being used.

- Inspect the cooling fins for debris.

By following these guidelines, users can effectively diagnose and address various challenges, ensuring optimal functionality.

Comparing TS 460 with Other Models

This section explores the differences and similarities between a specific model and its counterparts in the same category. By examining features, performance, and usability, we aim to provide insights that can help users make informed decisions based on their needs.

Key Features Comparison

| Model | Engine Power | Weight | Cutting Depth |

|---|---|---|---|

| Model A | 3.0 kW | 10.5 kg | 150 mm |

| Model B | 3.2 kW | 11.0 kg | 160 mm |

| Model C | 3.1 kW | 10.8 kg | 155 mm |

User Experience Insights

Feedback from users indicates variations in handling and ease of use among different models. While some may prefer the weight distribution of one model, others might value the power output of another. Such personal preferences often dictate the ultimate choice in a practical setting.

Customer Reviews and Feedback

This section highlights the experiences and opinions of users regarding their recent purchases. Insights gathered from customer feedback can significantly aid potential buyers in making informed decisions.

Overall Satisfaction

Many users express high levels of satisfaction with the product, citing durability and efficiency as major benefits. The performance in various tasks consistently receives praise, with numerous reviews highlighting the reliability of the equipment.

Common Concerns

While most feedback is positive, some customers have noted challenges with assembly and maintenance. It’s essential to consider these aspects when evaluating the overall experience.

| Rating | Comments |

|---|---|

| 5/5 | Exceptional performance and easy to use. |

| 4/5 | Great tool, but assembly instructions could be clearer. |

| 3/5 | Good, but had some issues with parts fitting properly. |