Understanding the intricate layout of various mechanical systems is essential for maintaining and repairing machinery. When working with complex machines, having a clear visualization of each component and its function can significantly enhance the troubleshooting and repair process. This section will provide valuable insights into the structure and role of various elements in a well-designed machine.

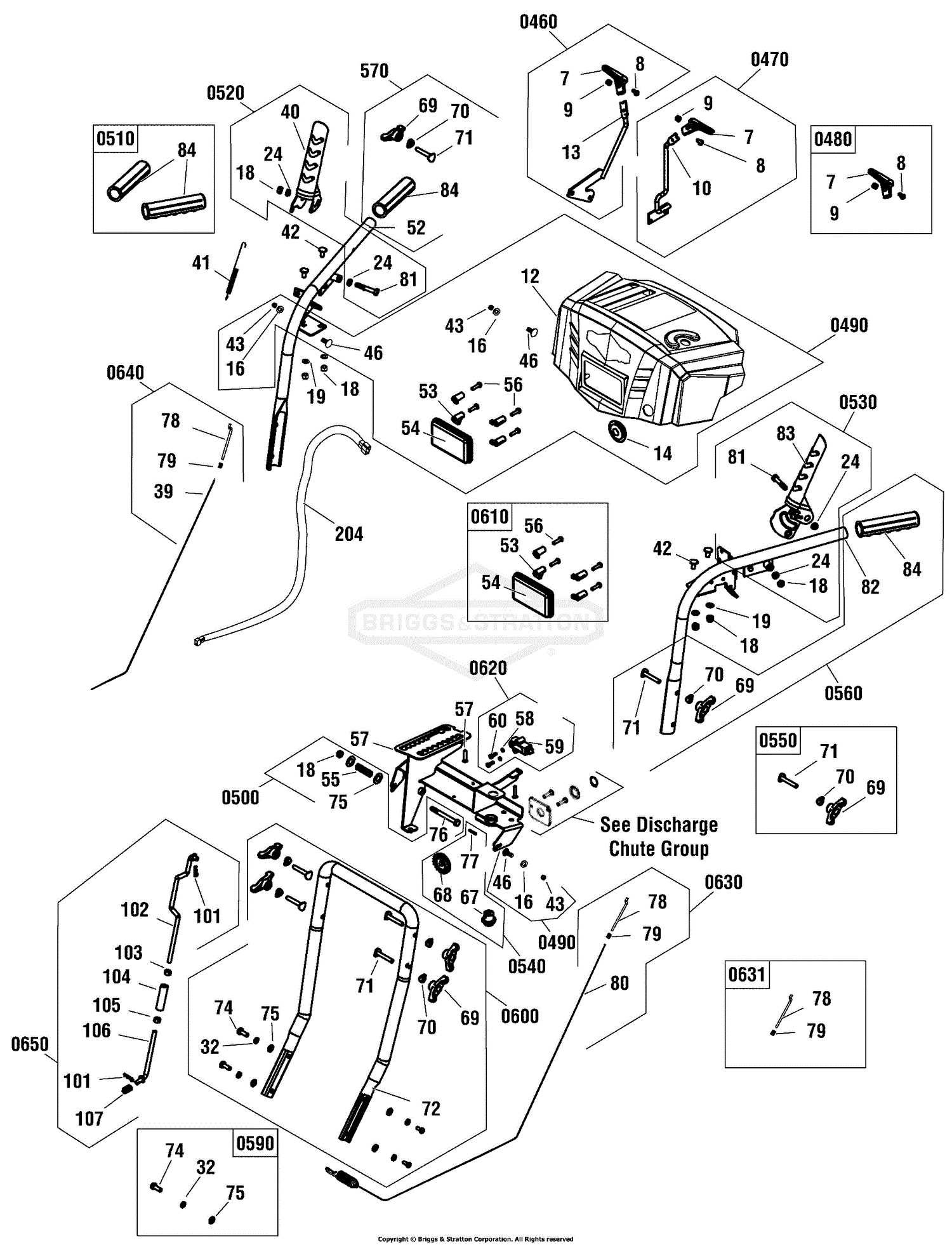

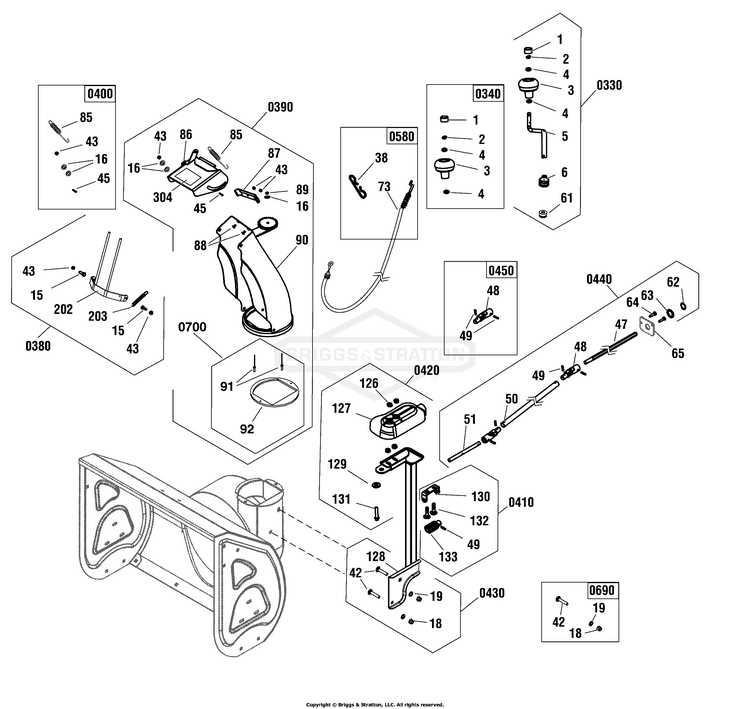

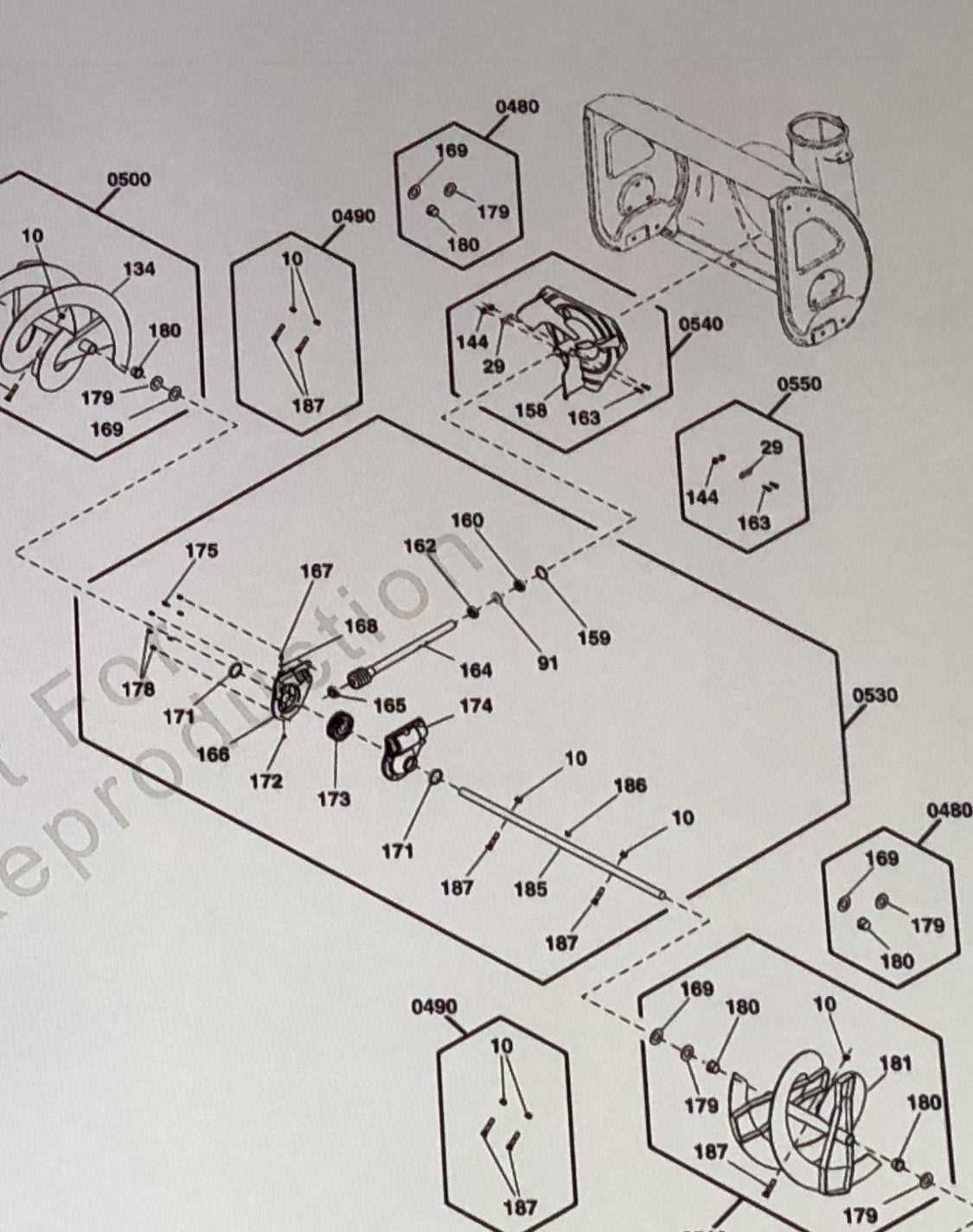

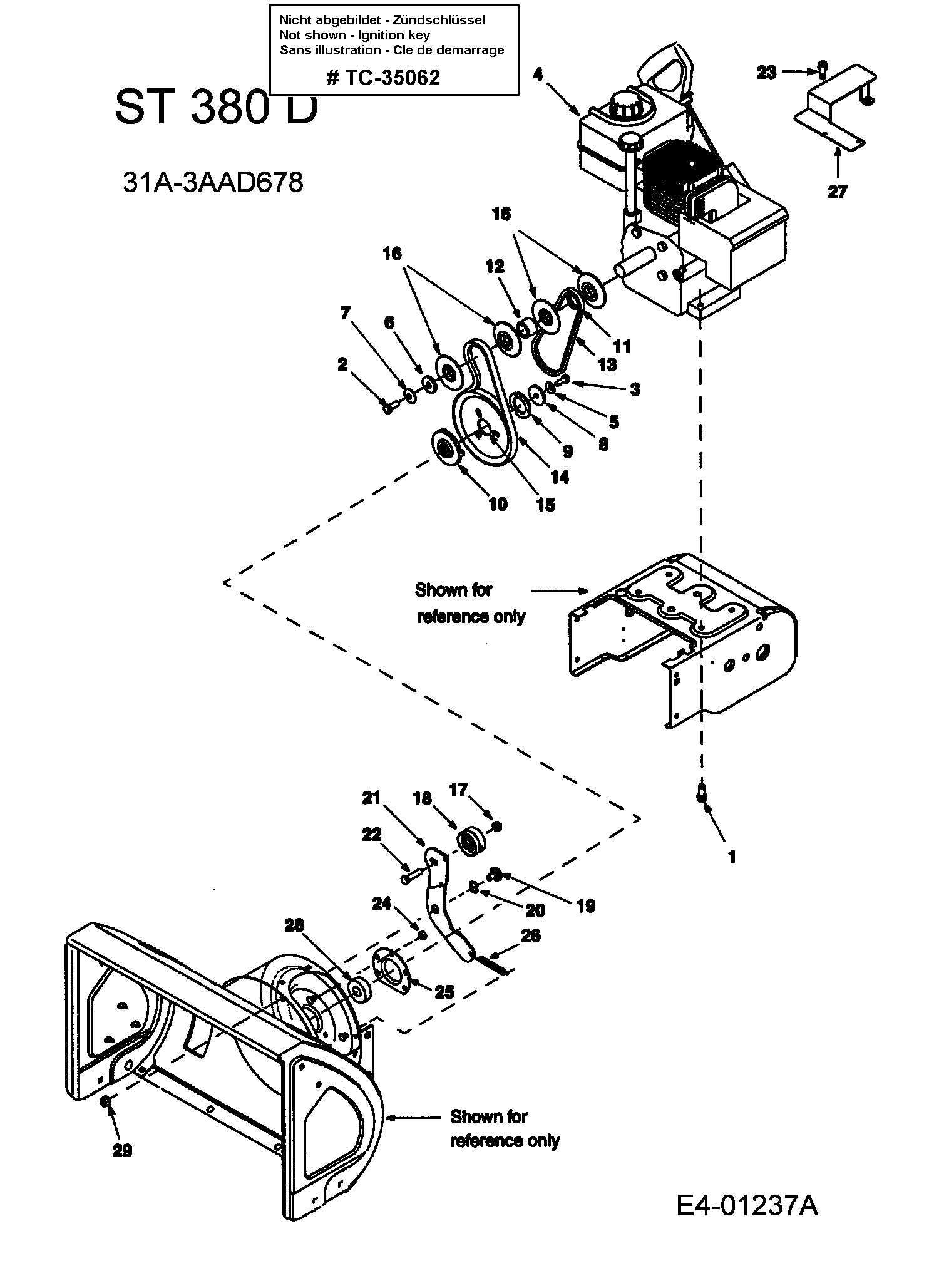

Exploring the mechanical arrangement helps to decode the relationships between different elements, ensuring a smooth workflow during maintenance. Identifying each key piece and its connection to others allows for quicker and more efficient repairs. This information is crucial for anyone aiming to enhance their technical knowledge and machine-handling skills.

By focusing on the arrangement of key elements, this guide will support you in developing a deeper understanding of how machines are assembled and how each component contributes to the overall functionality of the system. Whether you’re an expert or a novice, these details are indispensable for ensuring the longevity and performance of your equipment.

Briggs and Stratton 1024MD Overview

This model of outdoor power equipment stands out for its durability and efficiency. Designed for performance in tough conditions, it delivers reliable service over time. The machine is known for its advanced features that enhance both ease of use and operational capacity.

Key Features

- High power output for demanding tasks

- Efficient fuel consumption for extended use

- Built-in safety mechanisms for operator protection

Advantages of the Model

- Robust construction ensures long-term reliability

- Easy maintenance due to accessible components

- Versatile performance suitable for a variety of applications

Main Components of 1024MD Engine

The core structure of this engine relies on several essential elements that ensure smooth operation and long-lasting performance. Each component plays a critical role in maintaining the overall functionality and durability of the system.

Cylinder and Piston Assembly

- Cylinder: The engine’s main housing where combustion occurs, driving the piston.

- Piston: Moves up and down inside the cylinder, transferring energy generated from combustion to the crankshaft.

Fuel and Exhaust Systems

- Fuel Injector: Delivers the precise amount of fuel into the combustion chamber.

- Exhaust Valve: Releases exhaust gases after the fuel is burned, allowing fresh air to enter for the next cycle.

Understanding the 1024MD Fuel System

The fuel system is a critical component responsible for ensuring the proper flow of gasoline to the engine. It manages the transportation of fuel from the tank, its filtering, and the eventual delivery to the combustion chamber. By keeping this system in optimal condition, you can ensure efficient engine operation and prolong its lifespan.

- The fuel tank stores gasoline, ready for use.

- A filter is responsible for removing impurities before the fuel enters the engine.

- The fuel line connects the tank to the carburetor, ensuring a steady flow of gasoline.

- The carburetor mixes air with fuel in the right ratio for combustion.

- From there, the fuel enters the engine to power the machine.

Regular maintenance of these components is essential for smooth operation and optimal engine performance. Cleaning the filter, checking the fuel line for leaks, and ensuring the carburetor is properly adjusted are key tasks to keep in mind.

Exhaust System Parts Breakdown

The exhaust system plays a crucial role in directing gases away from the engine while maintaining efficiency and reducing noise. It consists of several key components that work together to ensure smooth operation and proper ventilation of exhaust fumes. Understanding the breakdown of these elements helps in maintaining the engine’s performance and prolonging its lifespan.

Main Components of the Exhaust System

- Muffler: This component reduces the noise produced by the engine’s exhaust gases.

- Exhaust Pipe: Channels the gases from the engine to the tailpipe, helping to maintain proper flow.

- Manifold: Collects exhaust gases from the engine cylinders and directs them into the exhaust system.

- Gaskets: Seals the joints between the various components to prevent leaks and maintain efficiency.

Additional Elements

- Heat Shields: Protect other engine components from excessive heat generated by the exhaust.

- Clamps and Mounts: Secure the exhaust components in place to prevent movement and maintain system integrity.

Maintaining thes

Ignition System: Key Parts and Functions

The ignition system plays a critical role in ensuring a smooth engine start and optimal performance. It is responsible for generating the necessary spark to ignite the air-fuel mixture, enabling the engine to operate efficiently. This section will explore the main components involved in the process and their respective functions.

Main Components of the Ignition System

- Spark Plug: The device that delivers the electrical spark to ignite the fuel mixture.

- Ignition Coil: A transformer that converts the battery’s low voltage into a higher voltage needed to create the spark.

- Flywheel Magnet: This part helps generate the magnetic field needed for the ignition coil to work.

How the Ignition System Works

- The flywheel magnet rotates, generating a magnetic field.

- The ignition coil amplifies the voltage, sending it to the spark plug.

- The spark plug creates a spark that ignites the fuel mixture in the combustion chamber, powering the engine.

Air Filter Assembly and Maintenance

The air filter assembly plays a crucial role in ensuring optimal performance of your engine by preventing dirt and debris from entering the combustion chamber. Regular maintenance of this component is essential to prolong the lifespan of the engine and enhance its efficiency. Proper care includes periodic inspection and timely replacement of the filter element to maintain clean airflow.

Inspection and Cleaning

Regularly checking the air filter for signs of dirt buildup is vital. If the filter appears excessively dirty or clogged, it is advisable to clean or replace it. For reusable filters, use a gentle wash with mild soap and water, allowing it to dry completely before reinstallation. Ensuring a clean air filter promotes better air intake, leading to improved engine performance.

Replacement Guidelines

When replacing the air filter, refer to the manufacturer’s specifications for the correct size and type. Installation should be straightforward, with a focus on securing the filter properly to avoid any gaps that may allow unfiltered air into the engine. Following replacement, always run the engine for a short period and check for any unusual sounds or performance issues.

Oil System: Components and Replacement Tips

The lubrication system is a crucial element in ensuring optimal performance and longevity of your engine. It plays a vital role in reducing friction between moving parts, thereby preventing wear and tear. Regular maintenance and timely replacements of key components are essential to keep the system functioning efficiently.

Key Components: The main elements of the lubrication system include the oil pump, oil filter, oil sump, and various hoses. The oil pump circulates the lubricant throughout the engine, while the oil filter removes impurities and contaminants. The oil sump acts as a reservoir, holding the necessary fluid for the system to operate effectively.

Replacement Tips: When replacing components, always refer to the manufacturer’s recommendations for compatible parts. Ensure that the oil filter is changed regularly, typically with every oil change, to maintain a clean lubrication system. Additionally, check for any leaks in the hoses and connections, and replace any damaged or worn parts promptly to prevent oil loss and maintain proper pressure.

Drive System: Gears and Linkages Explained

The drive mechanism is a critical component of machinery, ensuring efficient transfer of power from the engine to the wheels or other moving parts. This section delves into the essential elements that make up this system, including the various gears and linkages that facilitate motion and control. Understanding these components helps in diagnosing issues and optimizing performance.

Understanding Gears

Gears play a vital role in converting rotational motion into usable torque. Different types of gears, such as spur, bevel, and worm, are utilized to achieve specific mechanical advantages and facilitate various speed ratios. The arrangement and interaction of these gears determine how effectively power is transmitted through the system.

Linkages and Their Functions

Linkages are the connective structures that transmit motion between components. These mechanisms can include rods, levers, and chains, all designed to maintain the alignment and movement of various parts. Properly functioning linkages ensure smooth operation, enabling the machinery to respond effectively to user inputs.

| Component | Function | Common Issues |

|---|---|---|

| Gear | Transmits power and adjusts speed | Wear and tear, misalignment |

| Linkage | Connects and transfers motion | Slippage, breakage |

| Lever | Provides control and adjustment | Stiffness, lack of response |

Electrical Components and Their Role

Electrical elements are vital for the proper functioning of small engines, providing the necessary power and control for operation. These components work together to ensure the engine starts smoothly and operates efficiently. Understanding the significance of each part helps in maintaining and troubleshooting issues that may arise during use.

Key Electrical Elements

Several essential electrical elements contribute to the overall performance of the engine. Each part plays a specific role in the ignition, power distribution, and regulation of the engine’s operation.

| Component | Function |

|---|---|

| Ignition Coil | Generates high voltage for the spark plug to ignite the fuel-air mixture. |

| Spark Plug | Ignites the fuel-air mixture, allowing the engine to start and run. |

| Battery | Stores electrical energy to power the ignition system and other components. |

| Starter Motor | Engages the engine to initiate the combustion process during startup. |

Importance of Proper Functionality

Ensuring that all electrical components function correctly is crucial for optimal engine performance. Regular checks and maintenance can prevent potential failures, leading to smoother operation and extended lifespan.

1024MD Cooling System: Parts and Purpose

The cooling mechanism in small engines is crucial for maintaining optimal performance and preventing overheating. This system comprises various components, each serving a specific function to ensure efficient heat dissipation. Understanding the roles of these elements can enhance maintenance practices and promote longevity in engine operation.

Key Components of the Cooling Mechanism

The primary elements involved in this cooling setup include the radiator, fan, and thermostat. The radiator dissipates heat from the engine coolant, while the fan circulates air to enhance cooling efficiency. The thermostat regulates the coolant temperature, ensuring that the engine operates within its ideal thermal range.

Functionality and Importance

Each component contributes significantly to the engine’s overall efficiency. The radiator absorbs heat from the coolant and releases it into the atmosphere, preventing the engine from overheating. The fan plays a vital role in increasing airflow over the radiator, particularly during low-speed operation or when the vehicle is stationary. The thermostat ensures that the engine reaches the optimal temperature quickly, improving fuel efficiency and reducing emissions.

Maintaining these components in good condition is essential for ensuring the smooth operation of the engine and preventing costly repairs associated with overheating.