In the realm of small engine maintenance, grasping the arrangement of various components is essential for efficient repair and servicing. Each element plays a pivotal role in the overall functionality, ensuring that the machinery operates smoothly. A clear representation of these parts not only aids in identification but also enhances the repair process, making it more intuitive.

By exploring the intricate relationships between components, one can achieve a deeper comprehension of how to effectively manage issues that may arise. This knowledge empowers users to tackle repairs with confidence, reducing downtime and extending the lifespan of the equipment.

Furthermore, having a visual reference can simplify the understanding of assembly and disassembly, guiding users through complex procedures. Ultimately, mastering this layout transforms the maintenance experience into a more manageable and rewarding endeavor.

Understanding the Briggs and Stratton 1450 Engine

This section aims to provide insight into a widely used small power unit, known for its reliability and efficiency. Its design principles and functionality make it a preferred choice for various applications, ranging from lawn care to light machinery. Understanding its components and how they work together is crucial for anyone looking to maintain or troubleshoot the engine.

Key Features

The engine boasts several notable characteristics that enhance its performance. Among these are its robust construction, user-friendly maintenance, and adaptability to different tasks. Familiarity with these features can significantly aid in optimizing its use.

Essential Components

Each component of this power unit plays a vital role in its operation. Below is a table summarizing the primary elements and their functions:

| Component | Function |

|---|---|

| Cylinder | Houses the combustion process, converting fuel into mechanical energy. |

| Piston | Moves up and down within the cylinder, facilitating the intake and exhaust cycles. |

| Crankshaft | Transforms the linear motion of the piston into rotational motion. |

| Ignition System | Ignites the fuel-air mixture, starting the combustion process. |

| Fuel System | Supplies the necessary fuel to the engine for operation. |

Key Components of the 1450 Model

This section delves into the essential elements that make up this particular engine model. Understanding these components is crucial for maintenance and performance optimization.

- Engine Block: The core structure housing various internal parts, providing stability and durability.

- Cylinder Head: Plays a vital role in the combustion process, sealing the top of the cylinder and containing the valves.

- Crankshaft: Converts linear motion into rotational motion, driving the output power.

- Piston: Moves up and down within the cylinder, essential for the engine’s cycle.

- Fuel System: Includes the carburetor and fuel lines, responsible for delivering the air-fuel mixture for combustion.

- Ignition System: Generates a spark to ignite the fuel, crucial for starting and running the engine efficiently.

- Exhaust System: Directs gases away from the engine, reducing emissions and enhancing performance.

Each of these components contributes to the overall efficiency and functionality of the engine, making them important for anyone involved in its upkeep or operation.

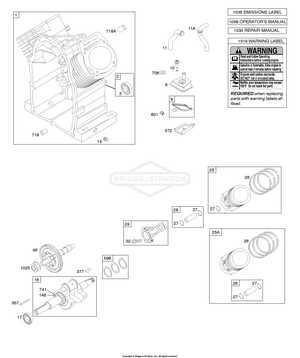

Parts Diagram Overview

This section provides a comprehensive look at the essential components that make up a specific engine model. Understanding these elements is crucial for effective maintenance and repairs, ensuring optimal performance over time.

Key Components

Each unit consists of various crucial elements, including the fuel system, ignition components, and mechanical parts. Familiarity with these segments aids in troubleshooting and enhances overall functionality.

Importance of Understanding Components

Knowledge of individual parts contributes significantly to the longevity and efficiency of the engine. Identifying and recognizing each component allows for informed decisions during servicing and repairs.

Importance of Accurate Diagrams

Precise illustrations play a crucial role in understanding complex machinery. They serve as essential tools for users, helping to identify components and their arrangements. This clarity aids in maintenance and troubleshooting, ultimately enhancing efficiency and performance.

Furthermore, well-crafted visuals prevent misinterpretations, reducing the risk of errors during assembly or repairs. By providing a clear reference, these illustrations streamline the process, ensuring that every piece fits together seamlessly. This accuracy not only saves time but also minimizes potential damage to equipment.

In essence, reliable visuals are invaluable for anyone looking to delve deeper into mechanical systems. They empower users with the knowledge necessary to make informed decisions, leading to improved longevity and functionality of their equipment.

Common Repairs and Replacements

This section explores typical maintenance tasks and component swaps that are essential for optimal functionality. Understanding these common issues can enhance performance and prolong the lifespan of your equipment.

- Air Filter: Regular replacement ensures clean airflow and efficient operation.

- Spark Plug: A worn spark plug can lead to starting difficulties and poor performance.

- Oil Change: Frequent oil changes prevent engine wear and maintain lubrication.

- Fuel Filter: Replacing the fuel filter keeps the fuel system clean and effective.

- Belt Replacement: Worn belts can affect performance; regular checks are advisable.

Identifying these areas will help maintain your machinery and prevent larger issues down the line.

Where to Find Replacement Parts

Finding components for your equipment can be a straightforward process if you know where to look. Various resources are available to help you locate the necessary items, ensuring your machinery remains in optimal working condition.

Online Retailers: Many websites specialize in selling components for engines and machinery. These platforms often provide a wide selection and detailed descriptions, making it easier to identify the right item for your needs. Be sure to check for customer reviews to gauge reliability.

Local Hardware Stores: Many physical stores stock essential items for engines and related equipment. Visiting a nearby shop allows you to consult with knowledgeable staff who can assist you in finding the exact component required.

Manufacturer’s Website: The official site of the equipment’s manufacturer usually offers a catalog of components. You can often find a search feature that helps you locate specific items based on model numbers or categories.

Specialized Forums and Communities: Engaging with online communities dedicated to machinery can provide valuable insights. Enthusiasts often share links to suppliers or may even have spare components available for sale or trade.

Second-Hand Markets: Consider checking platforms that specialize in used goods. Many individuals sell excess or unused components, offering a cost-effective alternative to purchasing new items.

Utilizing these resources can help ensure you find the right items to keep your equipment functioning smoothly.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires consistent care and attention. By following a few essential practices, you can significantly extend the life of your machinery while maintaining optimal performance.

Regular Cleaning: Keep your equipment clean from dirt, debris, and oil buildup. Regularly inspecting and cleaning vital components helps prevent corrosion and wear.

Oil Changes: Frequent oil changes are crucial for smooth operation. Use high-quality lubricants and adhere to the recommended intervals to keep internal parts well-protected.

Filter Maintenance: Replace air and fuel filters periodically. Clogged filters can lead to inefficiency and increased strain on the engine, which may shorten its lifespan.

Inspect Belts and Hoses: Regularly check belts and hoses for signs of wear or damage. Replace them as necessary to avoid unexpected breakdowns and ensure reliable operation.

Proper Storage: When not in use, store your equipment in a dry, sheltered area. This practice protects it from harsh weather conditions that can cause premature deterioration.

Follow Manufacturer Guidelines: Always refer to the manufacturer’s manual for specific maintenance recommendations. Adhering to these guidelines ensures that your machinery remains in peak condition.

Identifying Parts by Model Number

Recognizing components by their model identifiers is crucial for maintenance and repair tasks. Accurate identification ensures you procure the right elements, enhancing efficiency and performance. This process can significantly simplify troubleshooting and replacements, leading to prolonged equipment life.

Why Model Numbers Matter

Model numbers serve as unique identifiers for machinery and equipment. Here are key reasons for their importance:

- Precision: Ensures you select the exact components required.

- Compatibility: Confirms that parts will fit seamlessly within your machinery.

- Availability: Aids in locating suppliers and stockists with the correct inventory.

- Guidance: Helps in consulting manuals and online resources specific to your model.

How to Find Your Model Number

Finding the model number is a straightforward process. Follow these steps:

- Check the product label or sticker, typically located on the frame or base.

- Refer to the owner’s manual, which usually includes the model number in the specifications section.

- Look for any engraved numbers on the equipment itself.

Once you have the model number, use it to access detailed information about compatible components and maintenance guidelines, ensuring optimal functionality of your equipment.

Visual Guides for Assembly

Effective assembly is crucial for ensuring optimal performance and longevity of machinery. Utilizing visual references can significantly simplify the process, allowing users to quickly identify components and their arrangement. This approach not only enhances understanding but also minimizes errors during the reassembly of equipment.

Illustrative Diagrams

Illustrative diagrams provide clear representations of each component, showcasing their placement and connections. These visuals can help both novice and experienced individuals navigate complex assemblies with ease. By following these guides, users can gain confidence and clarity in their assembly tasks.

Step-by-Step Instructions

Accompanying each visual guide with step-by-step instructions ensures a comprehensive understanding of the assembly process. These instructions should be concise yet detailed, outlining necessary tools and any precautions to take. Together with diagrams, this format creates a cohesive resource for efficient assembly.

DIY Repair Techniques Explained

Engaging in self-repair can be both rewarding and cost-effective. Understanding various methods can empower individuals to tackle mechanical issues with confidence. This section will explore effective techniques that simplify the repair process and enhance your skills.

Essential Tools for Home Repairs

Having the right tools is crucial for any repair task. A quality toolkit should include wrenches, screwdrivers, pliers, and safety equipment. Properly organized tools not only streamline your efforts but also improve efficiency.

Step-by-Step Approach to Troubleshooting

A systematic approach is vital when diagnosing problems. Begin by identifying symptoms, gathering information, and isolating the issue. Documenting each step can help you delve deeper into the root cause and facilitate a more effective resolution.

Compatibility with Other Engines

Understanding how components can interchange between various motor types is essential for maintenance and repairs. This compatibility not only saves time but also reduces costs associated with sourcing specific parts.

When considering the interchangeability of components, factors to evaluate include:

- Physical dimensions

- Connection types

- Performance specifications

- Mounting arrangements

Many users find that certain models share similarities, allowing for effective replacements. Here are some common points of compatibility:

- Engine sizes within the same power range

- Similar fuel systems

- Identical ignition setups

Always consult with technical documentation to ensure proper fitment and functionality before proceeding with any modifications or replacements.

Customer Support Resources Available

Accessing effective assistance is crucial for users seeking help with their equipment. Various resources are designed to provide guidance, ensuring that every customer can find the information they need quickly and efficiently.

Online Resources: Websites often feature comprehensive FAQs, troubleshooting guides, and forums where users can share experiences and solutions. These platforms serve as valuable repositories of knowledge.

Contact Options: Many manufacturers offer direct communication channels, including phone support and email assistance. This ensures personalized help for specific inquiries, enhancing user satisfaction.

Local Service Centers: Authorized repair shops can provide hands-on support. Customers can consult professionals for repairs, maintenance, and expert advice on their machinery.

User Manuals: Detailed manuals often accompany products, filled with essential information regarding operation and maintenance. Referring to these documents can resolve many common issues.

Community Forums: Engaging with fellow users through dedicated online communities can foster connections and provide practical tips and solutions based on collective experiences.