Exploring the intricate workings of small power units reveals a fascinating world of machinery. Each segment plays a crucial role in the overall performance, and recognizing these elements can enhance both maintenance and functionality. Enthusiasts and professionals alike benefit from a comprehensive grasp of these systems.

Visual representations of these components facilitate a deeper appreciation of their arrangement and function. By examining detailed schematics, one can identify how various pieces interconnect to produce optimal results. This knowledge empowers users to troubleshoot and maintain their machinery effectively.

In the quest for ultimate efficiency, understanding each component’s role becomes essential. Whether for repairs or enhancements, being well-informed allows individuals to make sound decisions regarding their equipment. Let’s delve into the specifics of these vital elements.

Understanding the Briggs and Stratton Engine

Exploring the inner workings of a small power unit can greatly enhance your appreciation of its capabilities. This type of machinery plays a crucial role in various applications, from gardening tools to recreational vehicles. Grasping the fundamentals of how these mechanisms function can lead to better maintenance practices and improved performance.

Key Components in these machines are designed to work harmoniously, each fulfilling a specific role in the overall operation. Familiarity with these elements allows for quicker troubleshooting and effective repairs. Recognizing the significance of parts such as the fuel delivery system, ignition setup, and cooling mechanisms can prevent common issues that may arise during use.

Moreover, understanding the maintenance requirements of these units is vital for longevity. Regular checks and timely replacements of essential components can avert costly repairs and ensure optimal functionality. Learning about the best practices for upkeep can transform your experience, enabling you to tackle tasks with confidence.

In summary, diving into the intricacies of these small power units reveals a wealth of knowledge that enhances both user experience and technical proficiency. Whether you are a hobbyist or a professional, mastering the components and care of this machinery is invaluable.

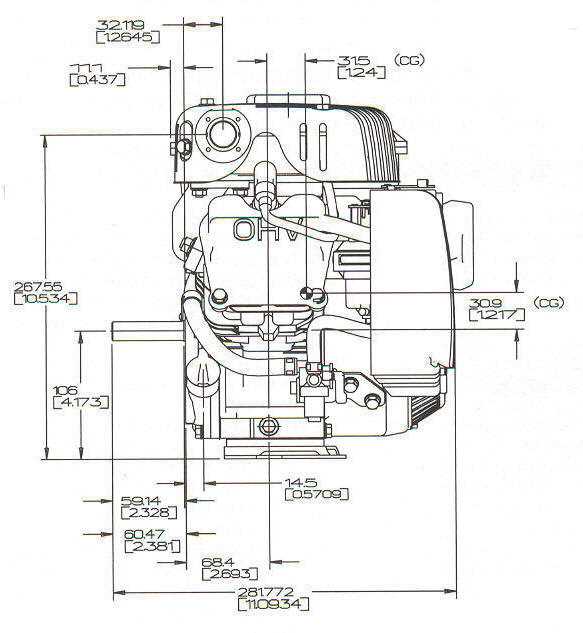

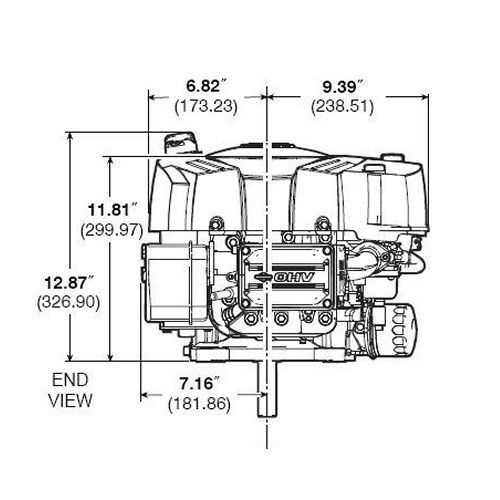

Key Features of 15.5 HP Engines

This section highlights the essential characteristics of compact power units designed for various applications. These robust machines offer reliability and efficiency, making them suitable for both residential and commercial use.

| Feature | Description |

|---|---|

| Power Output | Delivers sufficient horsepower for demanding tasks. |

| Durability | Constructed with high-quality materials to ensure longevity. |

| Fuel Efficiency | Optimized for lower fuel consumption, enhancing performance. |

| Maintenance | Designed for easy access to components, simplifying upkeep. |

| Versatility | Can be used in a wide range of applications, from lawn care to construction. |

Importance of Engine Maintenance

Regular upkeep of machinery plays a crucial role in ensuring optimal performance and longevity. Neglecting this essential practice can lead to various issues that may compromise functionality and efficiency.

Benefits of Consistent Upkeep

- Enhances performance and reliability.

- Reduces the likelihood of costly repairs.

- Increases fuel efficiency.

- Extends the lifespan of components.

Key Maintenance Practices

- Regularly check and change fluids.

- Inspect filters and replace when necessary.

- Clean or replace spark plugs periodically.

- Examine belts and hoses for wear.

Common Issues with Briggs and Stratton

Many small power units experience a variety of challenges that can affect performance and reliability. Understanding these common problems can help users troubleshoot effectively and maintain their equipment.

- Starting difficulties: Often caused by fuel issues, battery problems, or ignition failures.

- Overheating: Typically results from low oil levels or clogged cooling fins.

- Power loss: Can stem from dirty air filters, fuel lines, or carburetors.

- Excessive vibration: May indicate imbalanced components or worn mounts.

- Fuel leakage: Often due to faulty gaskets or damaged lines.

By addressing these common issues, users can enhance the lifespan and efficiency of their machinery.

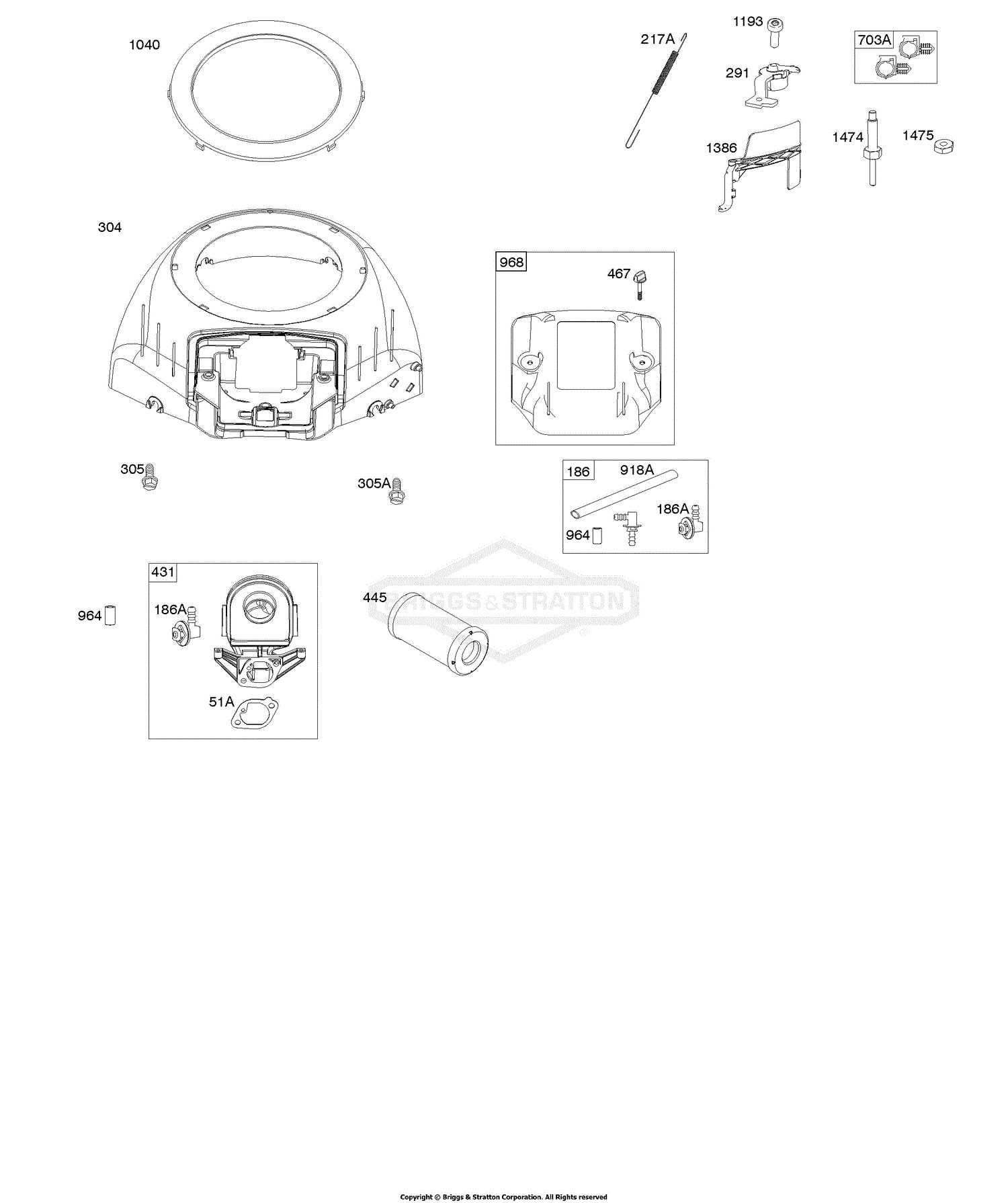

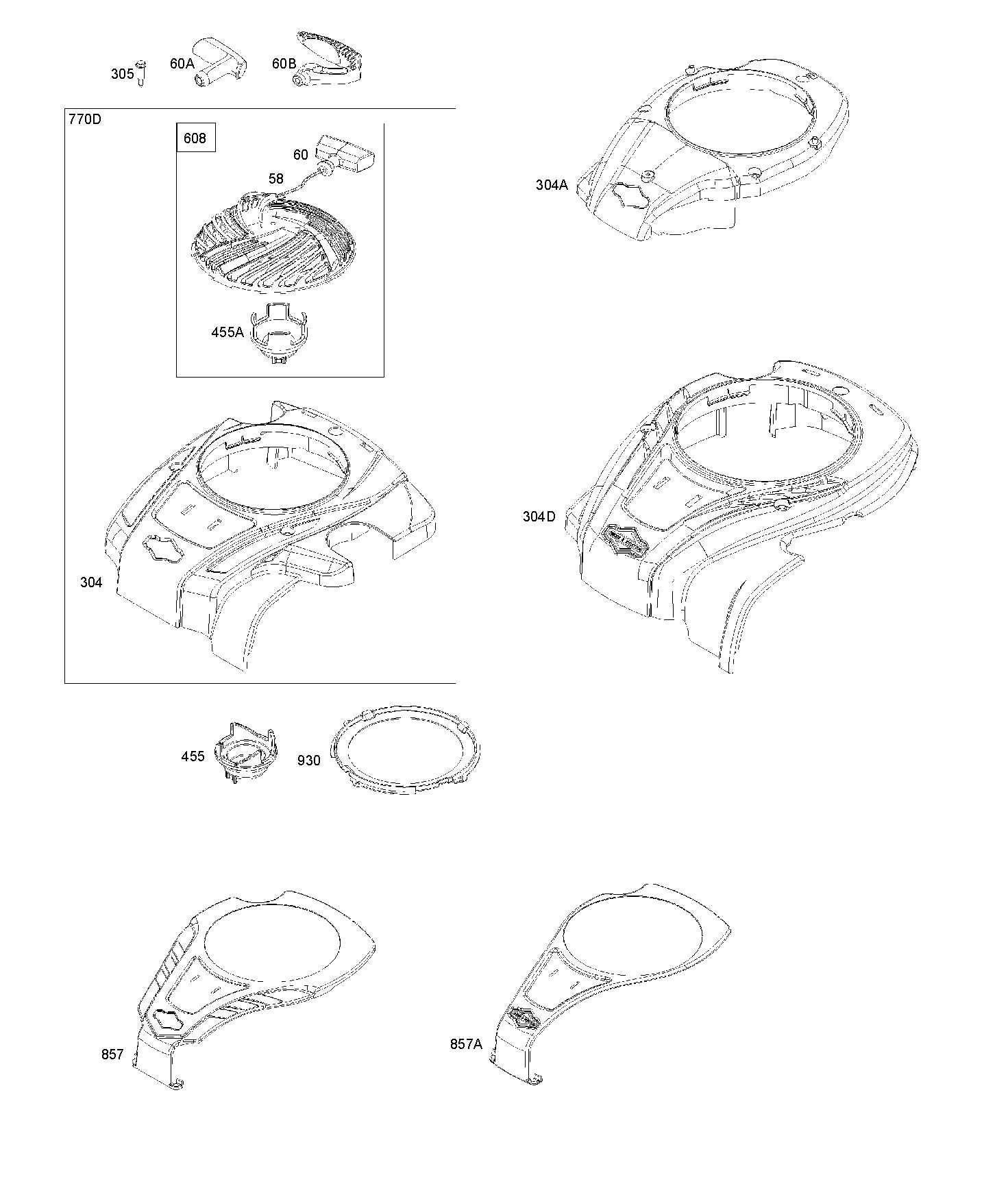

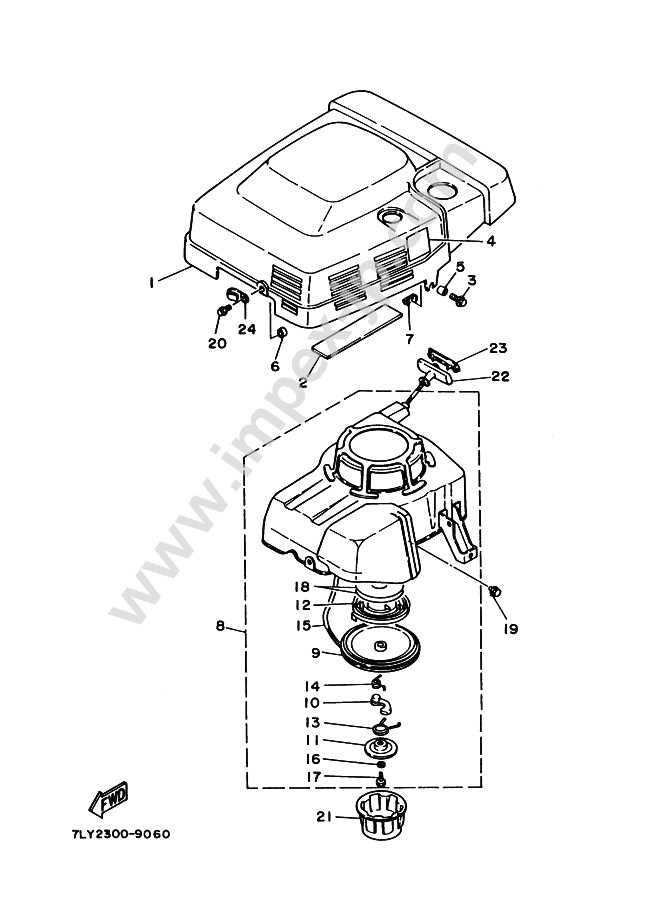

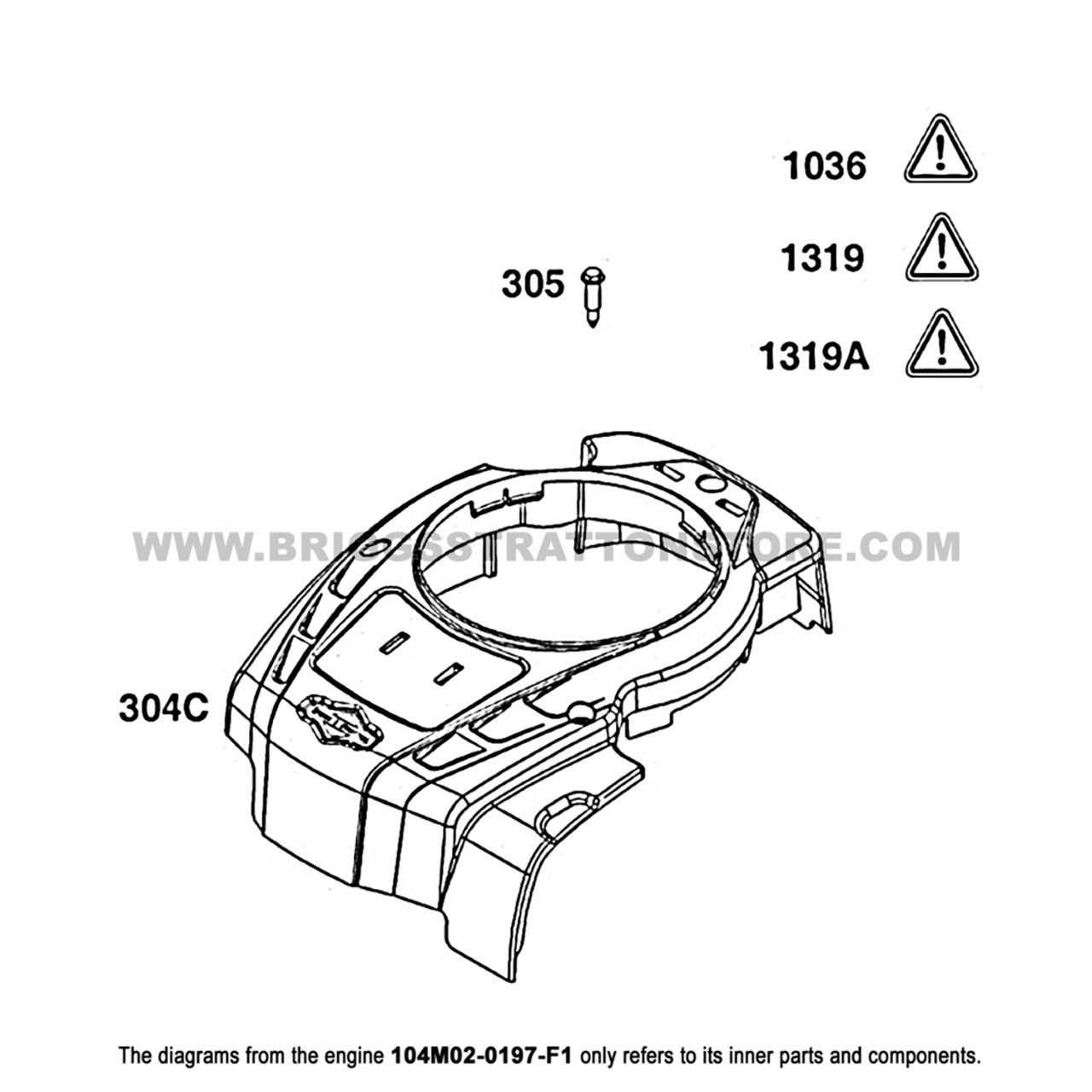

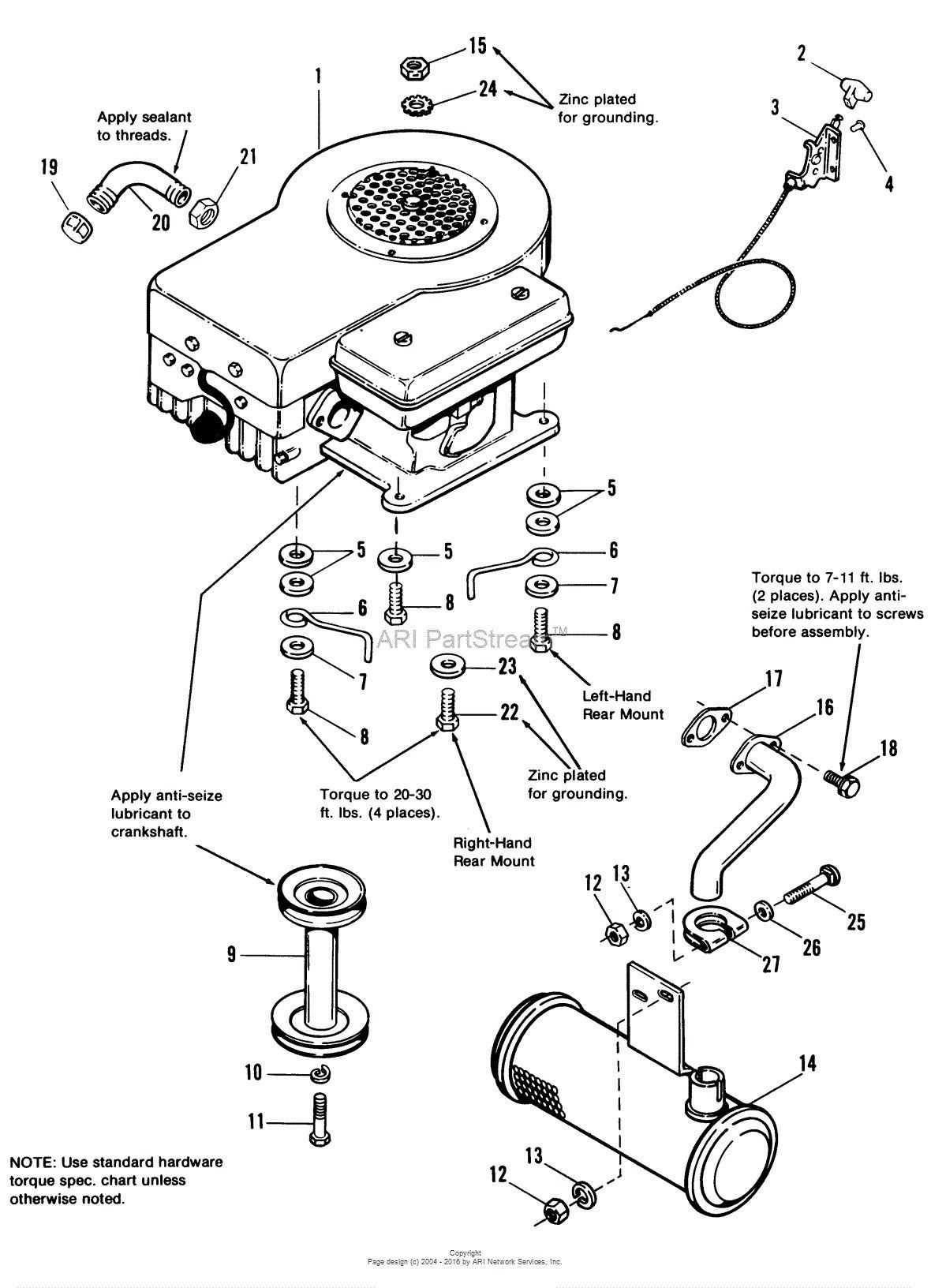

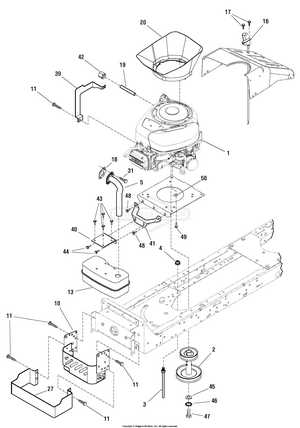

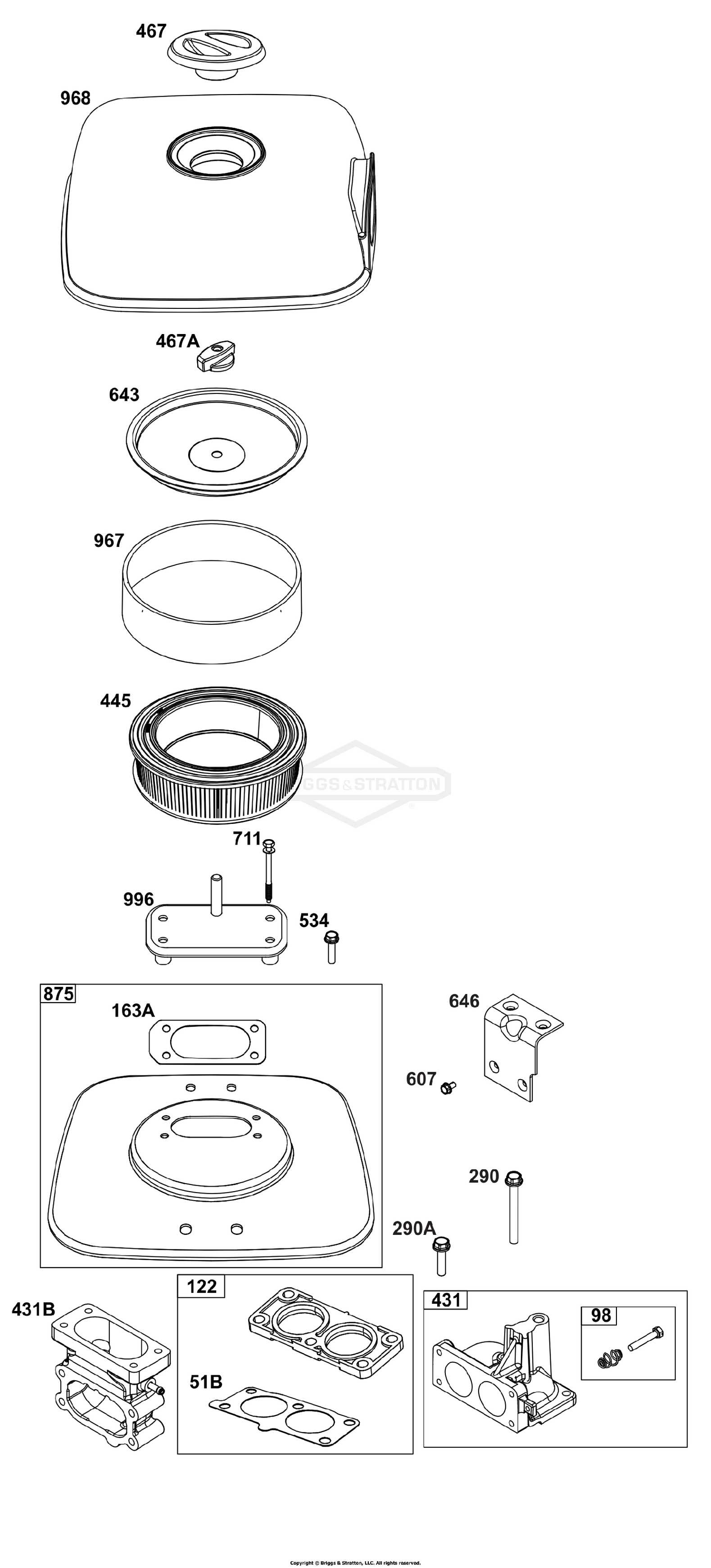

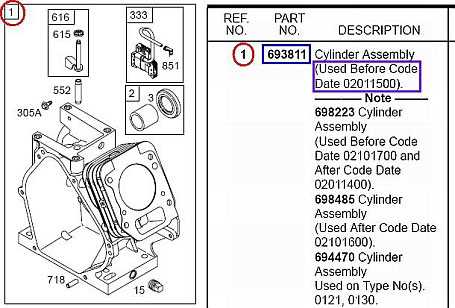

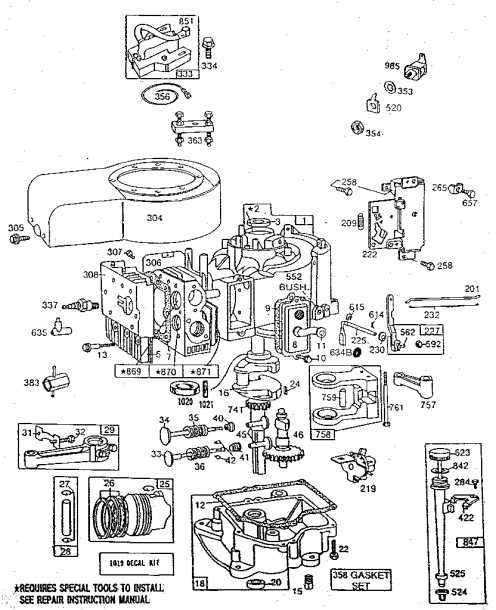

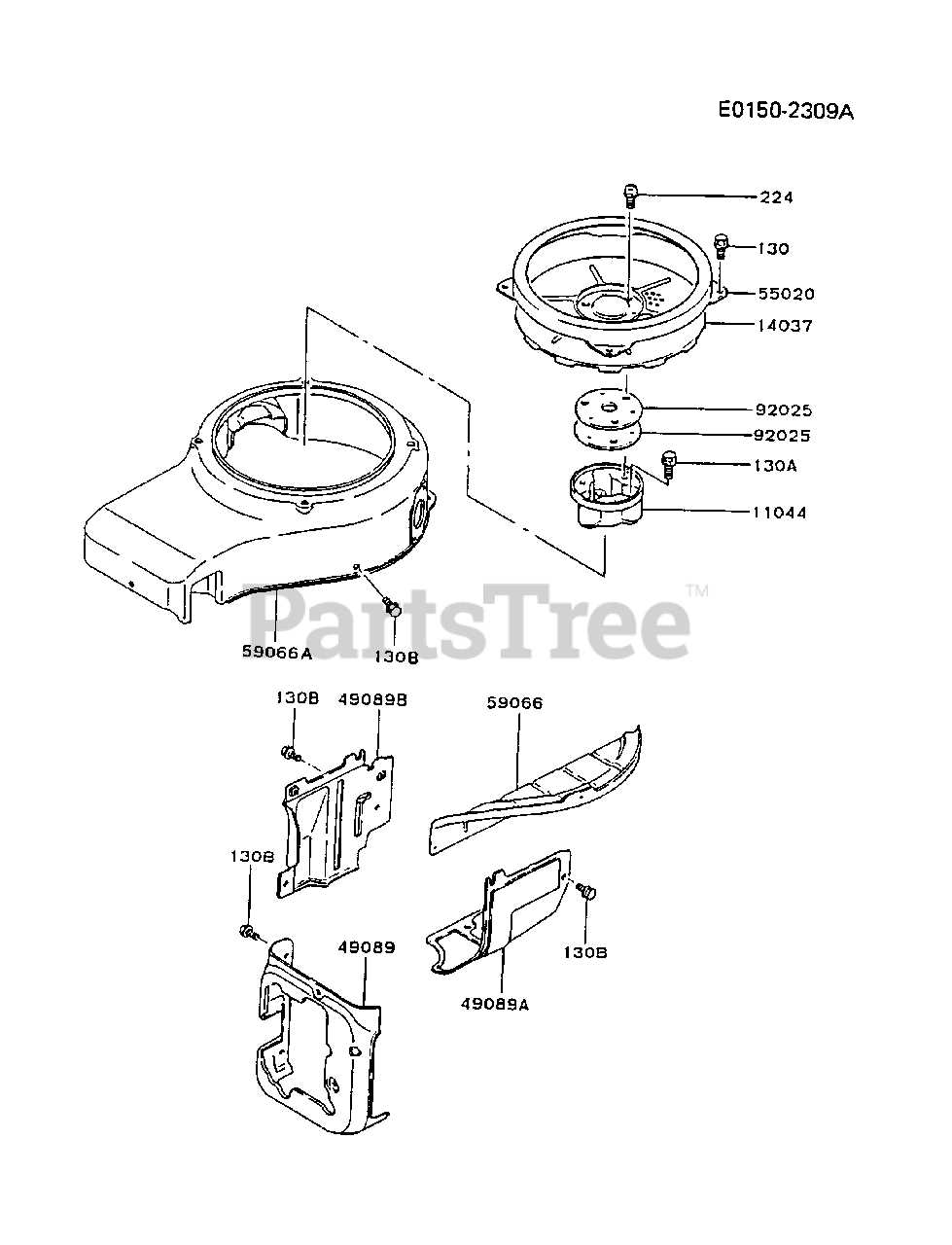

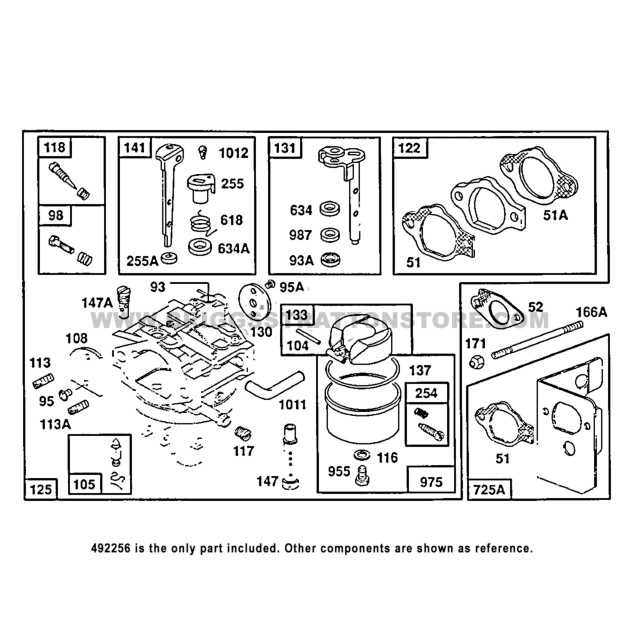

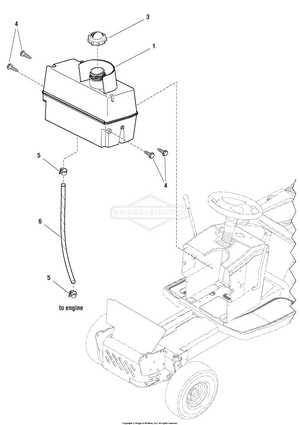

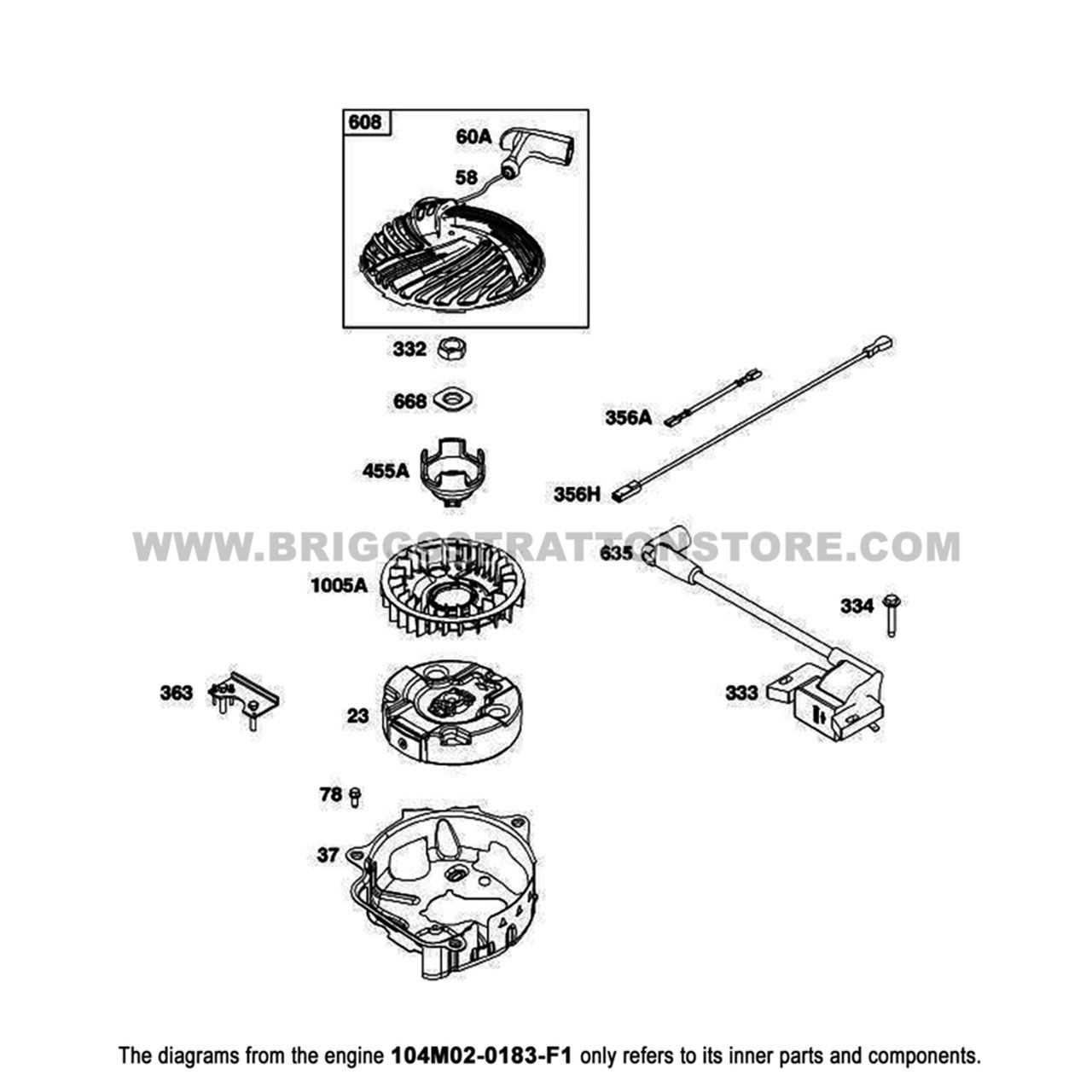

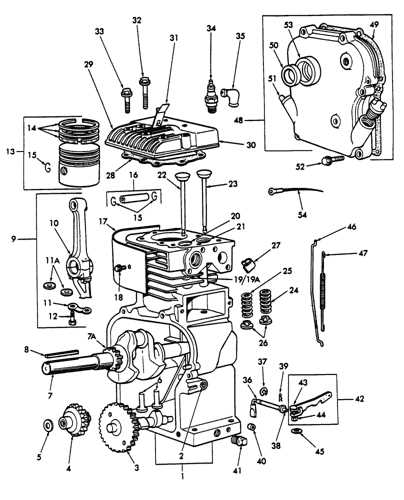

Parts Breakdown for Repair and Replacement

Understanding the various components of your machine is essential for effective maintenance and repair. A comprehensive breakdown of individual elements allows for easier identification of issues and the selection of suitable replacements. This guide aims to provide clarity on the necessary components, ensuring that any repairs can be executed smoothly and efficiently.

Common Components include the fuel system, ignition system, and cooling mechanisms. Each of these plays a vital role in the overall functionality. Knowing the specifics of these sections will enable you to address any malfunctions effectively.

Replacement Parts should be chosen based on quality and compatibility. Using OEM (Original Equipment Manufacturer) items is often recommended, as they ensure a perfect fit and reliability. Additionally, understanding how to disassemble and reassemble these components will save time and effort during repairs.

Overall, having a clear understanding of the layout and function of each element will empower you to tackle any maintenance task with confidence.

Tools Needed for Engine Repairs

To effectively maintain and restore small machinery, having the right instruments is crucial. This ensures not only efficiency but also safety during the process. Various tools can help diagnose issues, facilitate repairs, and enhance overall performance.

Essential items typically include wrenches, screwdrivers, pliers, and sockets, each serving specific functions. A torque wrench is vital for achieving proper fastening, while a multimeter aids in electrical diagnostics. Additionally, cleaning supplies like brushes and degreasers are important for maintaining a pristine working environment.

Investing in quality tools can ultimately save time and effort, leading to successful repairs and prolonged equipment lifespan. Regularly inspecting your toolkit ensures you are always prepared for any challenges that may arise.

Step-by-Step Repair Process

This section outlines a comprehensive approach to fixing a small motor, ensuring that each phase is executed efficiently. Following these steps will enhance your understanding and proficiency in maintenance tasks.

Preparation

- Gather all necessary tools and materials.

- Ensure the work area is clean and well-lit.

- Review the repair manual for specific guidelines.

Disassembly

- Begin by disconnecting the power source for safety.

- Carefully remove the outer casing and components.

- Organize parts systematically to ease reassembly.

Identifying Engine Components Easily

Recognizing various elements of machinery can greatly enhance your maintenance and repair skills. Whether you are a seasoned technician or a novice enthusiast, understanding the key components involved is essential for troubleshooting and improving performance. This section will guide you in distinguishing these parts effortlessly.

Common Components to Recognize

- Fuel System: Responsible for delivering fuel to the combustion chamber.

- Ignition System: Initiates combustion by creating a spark.

- Cooling System: Regulates temperature to prevent overheating.

- Lubrication System: Ensures smooth operation by reducing friction.

- Air Intake: Supplies the necessary air for combustion.

Tips for Easy Identification

- Familiarize yourself with the layout of each system.

- Use color coding or labels to mark each component.

- Refer to manuals or online resources for detailed diagrams.

- Engage in hands-on practice to reinforce your understanding.

- Join forums or communities for shared experiences and advice.

By applying these strategies, you will gain confidence in identifying and understanding the crucial elements of machinery, making maintenance and repairs a more manageable task.

Where to Find Genuine Parts

Finding authentic components for your machinery is crucial for maintaining performance and longevity. Various reliable sources provide quality items that ensure optimal functionality. Here are some options to consider:

| Source | Description |

|---|---|

| Authorized Dealers | Official retailers guarantee authenticity and offer expert assistance. |

| Manufacturer’s Website | Direct purchases from the brand ensure you receive original components. |

| Local Repair Shops | Professionals often stock genuine items and can provide valuable advice. |

| Online Marketplaces | Reputable platforms may offer genuine components; always check reviews. |

Upgrading Your Engine for Better Performance

Enhancing the capabilities of your power unit can significantly improve its efficiency and output. By focusing on specific components, you can achieve remarkable upgrades that elevate overall functionality and responsiveness.

Key Components to Consider

- Air Intake: A high-performance filter can boost airflow, promoting better combustion.

- Exhaust System: Upgrading the exhaust can reduce back pressure and improve engine flow.

- Fuel System: Consider a high-flow fuel pump to ensure adequate fuel delivery during demanding tasks.

Benefits of Upgrading

- Increased Power: Improved airflow and fuel delivery lead to enhanced horsepower.

- Enhanced Efficiency: Optimized components contribute to better fuel consumption.

- Longer Lifespan: Quality upgrades can reduce wear and tear on internal parts.

DIY vs. Professional Repairs

When it comes to maintaining and fixing machinery, individuals often face the choice between tackling repairs themselves or hiring an expert. Both options have their merits and drawbacks, making it essential to consider factors such as skill level, cost, and time investment before making a decision. Understanding these aspects can help in choosing the most suitable approach for any specific situation.

Benefits of DIY Repairs

Taking on repairs independently can be rewarding. It allows for a hands-on experience and a deeper understanding of the mechanics involved. Additionally, DIY enthusiasts can save on labor costs and take their time to ensure that every detail is addressed. Access to online resources, tutorials, and community forums further empowers individuals to tackle various challenges effectively.

Advantages of Professional Services

On the other hand, hiring a specialist brings expertise and efficiency to the table. Professionals often have the necessary tools and experience to diagnose and resolve issues quickly, minimizing downtime. For complex problems or when safety is a concern, relying on a trained technician can provide peace of mind and guarantee that repairs are performed correctly.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring personal safety and the protection of others is paramount. Familiarity with essential guidelines can significantly reduce risks associated with mechanical work. Adopting a cautious mindset not only safeguards physical well-being but also enhances the overall efficiency of repair activities.

Always wear appropriate personal protective equipment, such as gloves, goggles, and steel-toed boots. These items provide crucial defense against potential hazards, including sharp components and heavy objects. Additionally, maintaining a clean and organized workspace minimizes the likelihood of accidents, allowing for a smoother workflow.

Before beginning any repair, disconnect power sources to prevent accidental starts. This simple yet effective step is vital for avoiding injuries. Moreover, familiarize yourself with the specific machinery involved, as understanding its operation can lead to safer handling practices.

Finally, ensure proper ventilation in your working area, especially when dealing with fuels or chemicals. This practice not only promotes safety but also contributes to a healthier working environment, allowing you to delve into your tasks with confidence.

Resources for Further Learning

Exploring additional materials can significantly enhance your understanding of small motor mechanics. Accessing diverse sources provides insights into maintenance, troubleshooting, and performance optimization.

Online Tutorials: Numerous websites offer step-by-step guides that delve into specific aspects of motor upkeep. Video tutorials can visually demonstrate techniques, making them easier to grasp.

Forums and Community Groups: Engaging with enthusiasts in online communities allows for sharing experiences and advice. These platforms often feature discussions that tackle common challenges faced by users.

Manufacturer Manuals: Reviewing official documentation can yield valuable specifications and guidelines. These resources are ultimate references for understanding your machinery’s design and functionality.

Books and E-books: Consider investing in literature focused on small engine maintenance. Comprehensive texts can provide a deep dive into the principles and practices of motor care.