In the world of small engine machinery, comprehending the intricate layout of its various elements is essential for maintenance and repair. Each component plays a crucial role in the overall functionality, ensuring that the machine operates smoothly and efficiently. By gaining insights into these individual sections, users can enhance their troubleshooting skills and streamline their repair processes.

Whether you’re a seasoned technician or a DIY enthusiast, familiarizing yourself with the internal organization of a specific engine model can significantly simplify your maintenance tasks. This exploration delves into the essential elements, offering clarity on how they interact to create a seamless operating system. Understanding these connections not only aids in resolving issues but also empowers users to undertake their repairs with confidence.

Furthermore, having access to a clear reference for these components can serve as a valuable tool in the repair process. It allows individuals to identify any worn-out or malfunctioning parts, thereby facilitating informed decisions regarding replacements or adjustments. Ultimately, this knowledge contributes to prolonging the life of the engine and optimizing its performance.

The 44P777 variant represents a significant innovation in small engine design, characterized by its efficiency and reliability. This model is widely recognized for its robust performance and versatility, making it suitable for various applications in outdoor equipment. Understanding its components and functionalities is essential for optimal maintenance and operation.

Key Features

- Compact and lightweight construction

- Enhanced fuel efficiency

- Durable materials for extended longevity

- Easy accessibility for routine checks

Applications

- Lawn mowers

- Generators

- Pressure washers

- Garden tillers

Familiarity with the various elements of this engine model ensures users can effectively troubleshoot issues, perform maintenance tasks, and achieve peak performance across diverse scenarios.

Key Components of the Engine

The functionality of an engine relies on a variety of essential elements that work together to produce power and efficiency. Understanding these key components is crucial for effective maintenance and troubleshooting.

Primary Elements

- Crankshaft: This component converts linear motion into rotational motion, playing a pivotal role in the engine’s operation.

- Piston: Moving within the cylinder, it compresses the fuel-air mixture, essential for the combustion process.

- Camshaft: Regulating the opening and closing of the intake and exhaust valves, this part ensures proper airflow within the engine.

- Fuel System: This includes various components such as the fuel tank, fuel pump, and carburetor, which work together to deliver the correct mixture of fuel to the engine.

- Ignition System: Responsible for initiating the combustion process, this system includes spark plugs and ignition coils.

Supporting Structures

- Engine Block: The main structure housing many of the engine’s components, providing durability and support.

- Cooling System: This system prevents overheating by circulating coolant, typically comprising a radiator, hoses, and a water pump.

- Exhaust System: Directs exhaust gases away from the engine, including components like mufflers and pipes.

Familiarity with these fundamental parts enables users to better understand their engine’s performance and aids in troubleshooting potential issues.

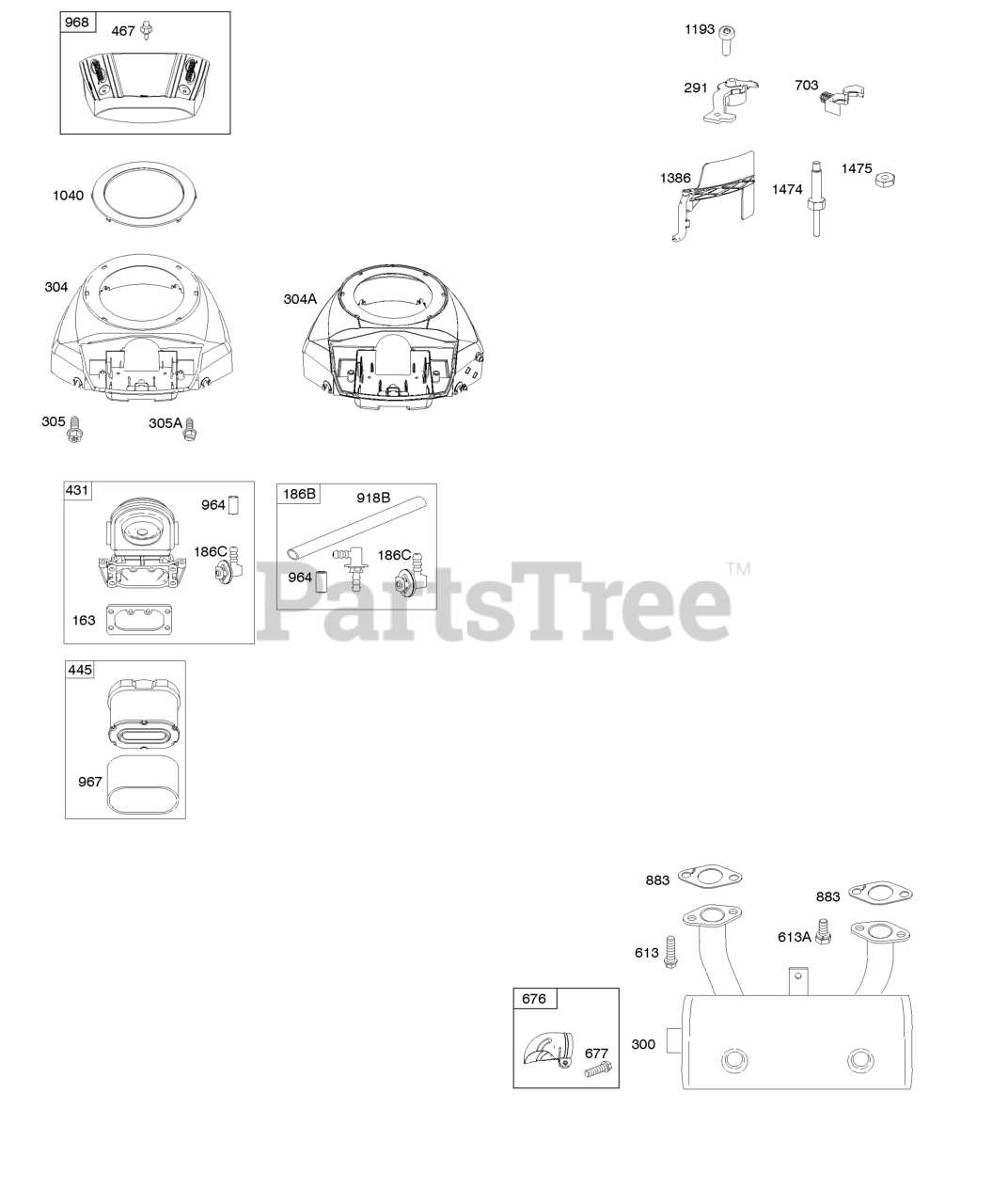

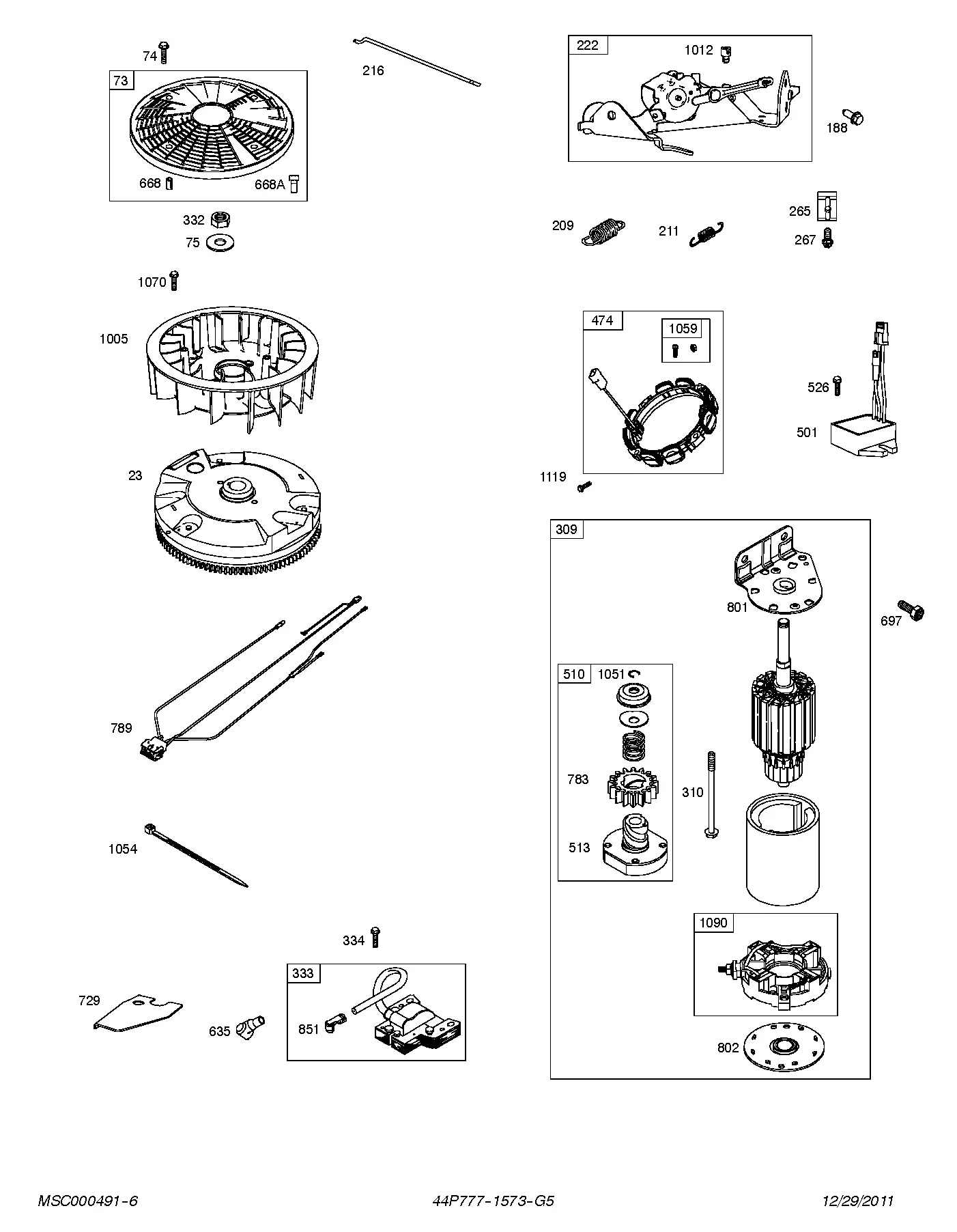

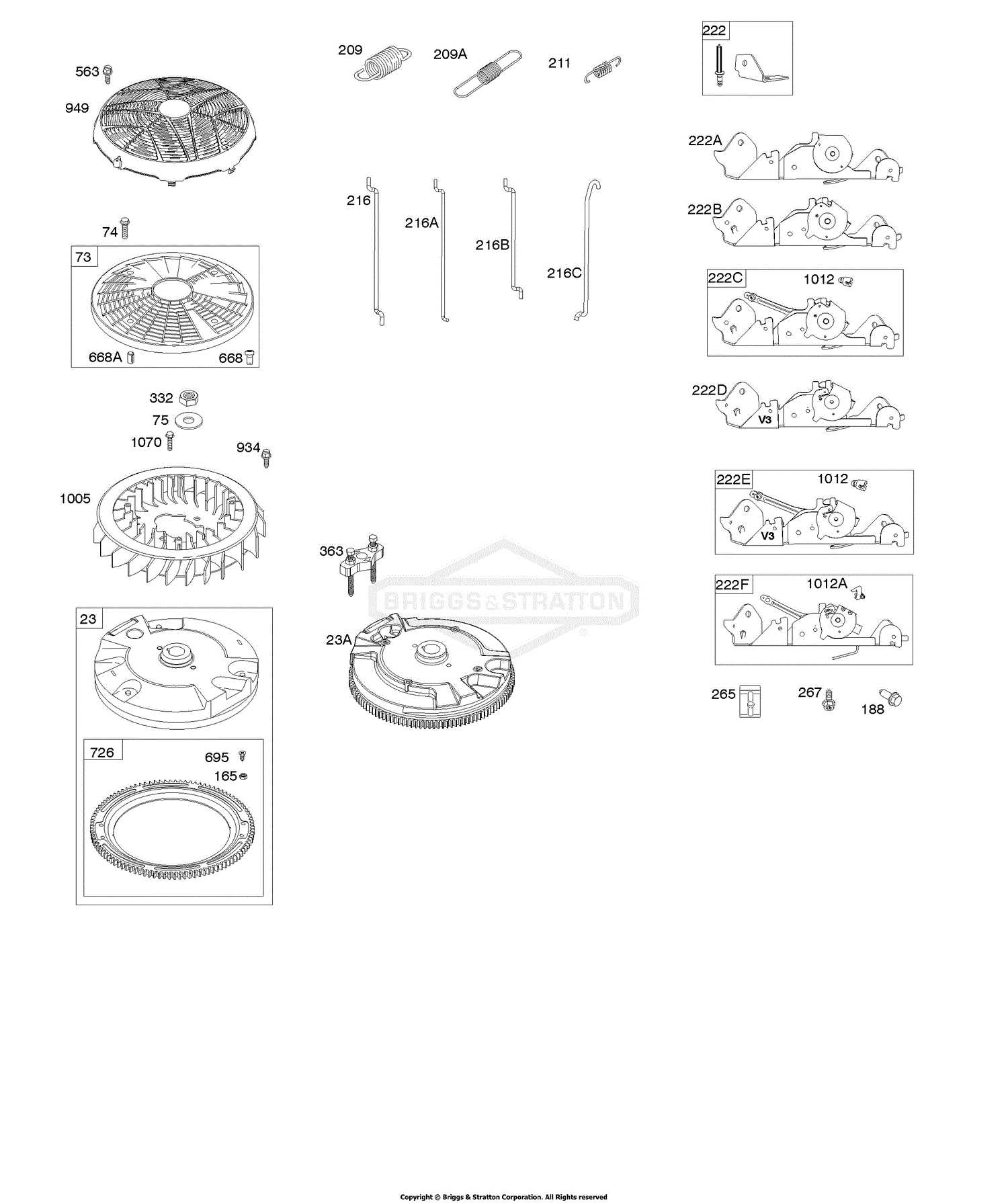

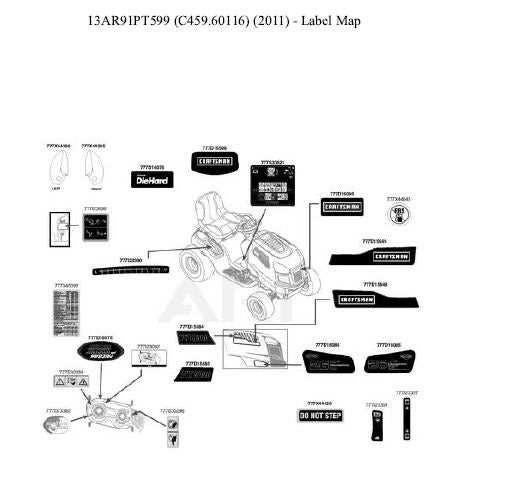

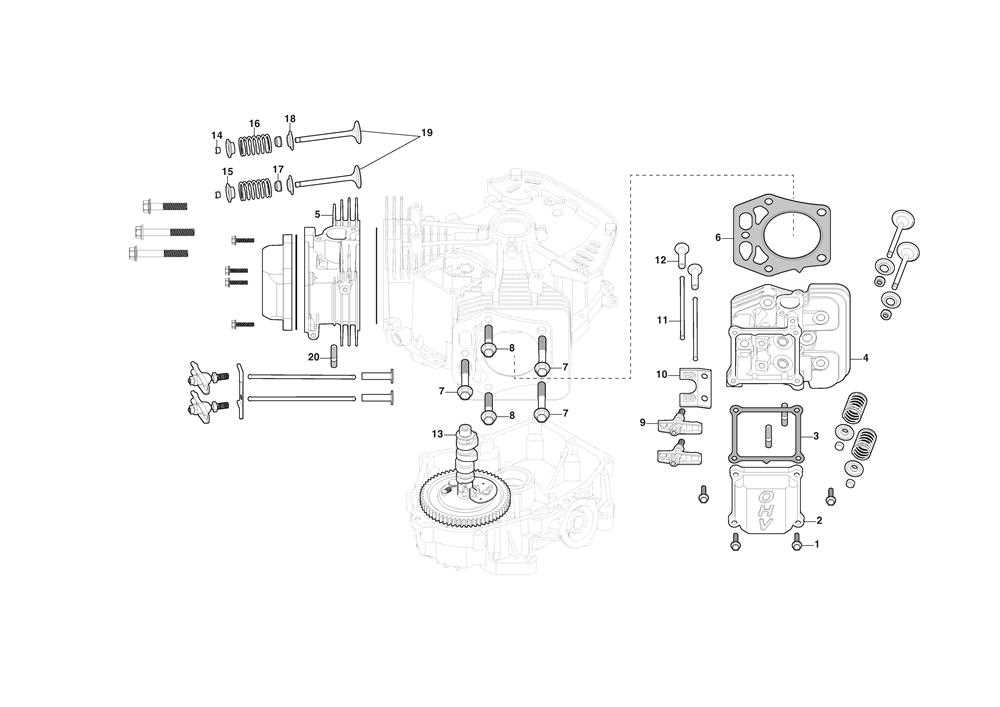

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the intricate details of machinery. They provide clarity and facilitate effective maintenance, assembly, and troubleshooting, ensuring that users can effectively navigate complex systems.

Enhanced Understanding

By illustrating the arrangement and function of various elements, these visual aids help users grasp how each component interacts within the overall system. This understanding is vital for:

- Identifying components quickly

- Facilitating repairs and replacements

- Improving overall efficiency in maintenance tasks

Streamlined Maintenance Process

Utilizing visual aids simplifies the maintenance process, allowing users to:

- Locate specific elements without confusion

- Ensure all necessary components are accounted for

- Reduce the likelihood of errors during assembly or disassembly

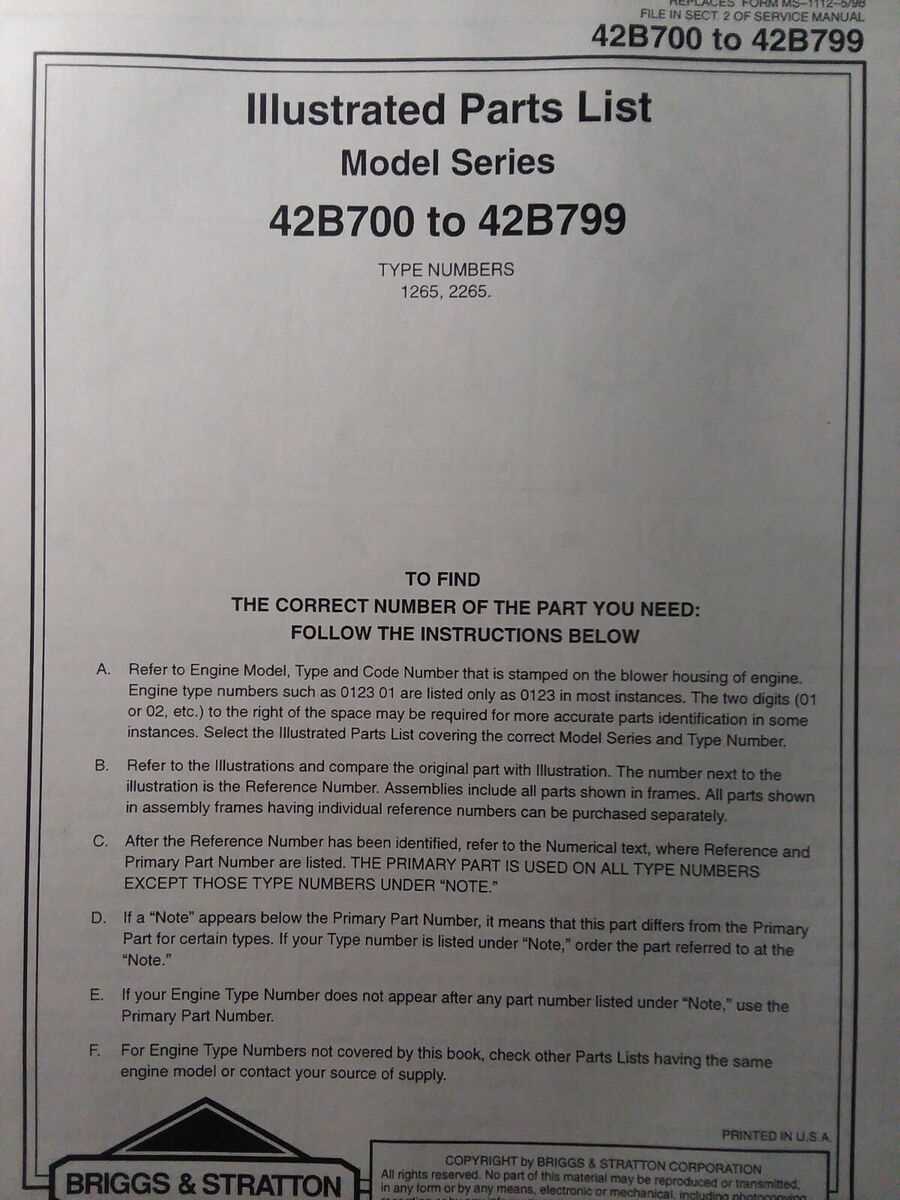

How to Read a Parts Diagram

Understanding an assembly illustration is essential for effective maintenance and repair tasks. These visual aids provide a clear representation of components, their relationships, and how they fit together in a mechanical system. Familiarizing yourself with these graphics can significantly enhance your ability to identify, source, and replace necessary elements.

Key Elements to Consider

- Labels: Each component is typically marked with a unique identifier, making it easier to find specific items.

- Groupings: Parts are often categorized into sections based on their function, helping to streamline the identification process.

- Numbers: Sequential numbering can indicate the order of assembly or the sequence in which parts should be installed.

Steps for Effective Interpretation

- Start by reviewing the legend or key, which explains symbols and identifiers.

- Identify the main assembly sections and their components.

- Cross-reference each part number with a catalog or retailer to ensure compatibility.

- Take note of any notes or special instructions provided in the illustration.

Common Issues with 44P777 Engine

Engines of this model may experience a variety of common challenges that can affect performance and reliability. Understanding these issues can help users take preventive measures and ensure optimal functionality. Below are some frequent problems encountered with this particular engine type.

1. Starting Difficulties

One prevalent issue is the difficulty in starting the engine. This can be attributed to several factors, including fuel-related problems or ignition failures. Regular maintenance of the fuel system and checking the spark plug can help mitigate this issue. Ensuring that the battery is fully charged is also crucial for smooth ignition.

2. Overheating

Another common concern is overheating. This often occurs due to insufficient lubrication or a clogged cooling system. To prevent overheating, it is important to regularly check the oil levels and clean any debris from the cooling fins. Additionally, using the correct oil type can enhance the engine’s efficiency.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your engine requires consistent upkeep and attention to detail. Regular maintenance not only enhances performance but also prevents costly repairs down the line. By adhering to a structured maintenance routine, you can enjoy reliable operation and efficiency.

Here are some essential practices to keep in mind:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours of operation | Replace old oil with fresh oil to ensure proper lubrication and prevent engine wear. |

| Air Filter Inspection | Every 25 hours of operation | Check and clean or replace the air filter to ensure optimal airflow and engine efficiency. |

| Spark Plug Replacement | Every 100 hours of operation | Inspect and replace spark plugs to maintain reliable ignition and smooth engine operation. |

| Fuel System Cleaning | As needed | Use fuel stabilizers and clean the fuel system periodically to prevent clogging and ensure proper fuel flow. |

| Belt Inspection | Every 50 hours of operation | Examine belts for wear and proper tension to ensure smooth operation and prevent breakdowns. |

By implementing these maintenance strategies, you can maximize the functionality and lifespan of your engine. Regular attention to these details will contribute to long-lasting performance and reliability.

Where to Find Replacement Parts

Locating suitable components for your small engine can be straightforward if you know where to look. Various resources offer quality items that ensure optimal functionality and longevity of your equipment.

Online Retailers: A plethora of online stores specialize in engine components. Websites dedicated to outdoor power equipment often have a comprehensive selection, enabling you to browse and compare options from the comfort of your home. Make sure to read customer reviews to assess product quality.

Local Dealers: Visiting nearby retailers that focus on engine maintenance can yield valuable results. Knowledgeable staff can assist you in identifying the right components, and you may also benefit from their expertise in installation.

Salvage Yards: Salvage yards or recycling centers can be treasure troves for those seeking budget-friendly alternatives. You might discover functional parts at a fraction of the cost, helping you save money while still achieving the desired repairs.

Manufacturer’s Website: The official website of the manufacturer often provides detailed information on compatible components. Accessing this resource can help ensure that you select high-quality items specifically designed for your engine’s model.

With these options in mind, finding the necessary components for maintenance and repair becomes much easier, allowing you to keep your equipment in excellent working condition.

Tools Required for Repairs

Effective maintenance and restoration tasks necessitate a specific assortment of implements to ensure optimal performance. Having the right tools on hand not only streamlines the process but also enhances the accuracy of the repairs. This section outlines essential equipment that facilitates efficient servicing of the engine.

Basic Hand Tools

For any mechanical repair, a collection of fundamental hand tools is indispensable. These typically include wrenches, screwdrivers, and pliers. Each tool serves a distinct purpose, allowing for the disassembly and assembly of various components with precision. It is advisable to select high-quality tools to withstand repeated use and provide reliability.

Specialized Equipment

In addition to basic tools, specialized equipment may be necessary for more intricate tasks. Items such as torque wrenches and spark plug sockets are essential for specific functions that require exact measurements and fit. Utilizing the correct specialized tools ensures that every aspect of the repair is handled properly, contributing to the longevity of the machinery.

Step-by-Step Repair Process

Repairing small engine machinery involves a systematic approach to ensure that each component is addressed effectively. By following a structured method, you can enhance the longevity of the equipment and restore its functionality. Below is a detailed guide to assist you in executing repairs proficiently.

Preparation for Repair

- Gather necessary tools: Ensure you have all required instruments, including wrenches, screwdrivers, and pliers.

- Review the owner’s manual: Familiarize yourself with the specifications and recommendations for the model in question.

- Create a clean workspace: Clear any clutter to avoid losing small components during the process.

Repair Steps

- Disconnect the power source: Always begin by ensuring the equipment is powered off to prevent accidents.

- Inspect the external condition: Check for visible wear and tear or damage that may affect performance.

- Disassemble components: Carefully remove the necessary parts, taking note of their arrangement for reassembly.

- Examine internal parts: Look for signs of damage or malfunction within the engine.

- Replace faulty components: Use high-quality replacements to maintain the integrity of the machinery.

- Reassemble the equipment: Follow your earlier notes to ensure that all parts are reattached correctly.

- Test the machinery: Once reassembled, reconnect the power source and conduct a trial run to verify functionality.

Following these steps will aid in successfully restoring the equipment to optimal working condition. Regular maintenance and timely repairs can significantly extend the lifespan of your machinery.

Safety Precautions During Repairs

When undertaking maintenance tasks on machinery, it is essential to prioritize safety to prevent accidents and injuries. Proper precautions can create a secure working environment and ensure effective repairs. This section outlines crucial guidelines to follow during the repair process.

General Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear.

- Work in a well-ventilated area to minimize exposure to harmful fumes.

- Keep your workspace organized to prevent trips and falls.

- Ensure all tools are in good condition and suitable for the task.

Specific Precautions

- Disconnect the power source before starting any repair work to avoid electrical hazards.

- Follow the manufacturer’s instructions closely to ensure proper handling and avoid damage to components.

- Never attempt repairs on hot or running equipment; allow sufficient time for cooling.

- Be cautious of sharp edges and moving parts during disassembly and reassembly.

Resources for Further Assistance

When seeking additional support for your machinery, various sources can provide valuable insights and guidance. Utilizing these resources can enhance your understanding and improve maintenance practices, ensuring optimal performance.

Below is a table summarizing useful references:

| Resource Type | Description | Website |

|---|---|---|

| Manufacturer Website | Official site offering manuals, troubleshooting tips, and part lists. | Visit |

| Online Forums | Community-driven platforms where users share experiences and solutions. | Visit |

| Instructional Videos | Visual guides demonstrating repair techniques and maintenance practices. | Visit |

| Local Repair Shops | Professional services offering assistance and expert advice. | Visit |