The efficient functioning of small machinery relies heavily on its internal mechanisms. An in-depth exploration of these components reveals how each element contributes to overall performance and reliability. Knowledge of the specific roles played by various sections enhances both maintenance practices and operational proficiency.

When examining the structure of a typical small power unit, it becomes clear that familiarity with individual components is essential. This understanding not only aids in troubleshooting issues but also empowers users to perform repairs and enhancements confidently. An organized visual representation can serve as a valuable resource for anyone looking to optimize their machine’s functionality.

By delving into the specific elements that make up these powerful units, one can appreciate the engineering behind them. Whether for professional use or personal projects, having a clear grasp of these intricate designs allows for better decision-making and more effective handling of any necessary adjustments.

Understanding Briggs and Stratton Engines

Exploring the fundamentals of small power units reveals their significance in various applications. These mechanical devices are renowned for reliability and efficiency, serving as the backbone for numerous outdoor tools and machinery. A comprehensive grasp of their components enhances the ability to maintain and troubleshoot, ensuring optimal performance.

The design of these power units often includes a series of vital elements that work cohesively. Each component plays a crucial role, from the ignition system to the fuel delivery mechanism. Familiarity with these aspects allows users to delve deeper into functionality and potential improvements.

Moreover, knowing how these systems operate can lead to the ultimate enhancement of efficiency and longevity. Regular maintenance and an understanding of wear patterns can prevent issues before they arise, promoting a smoother operational experience.

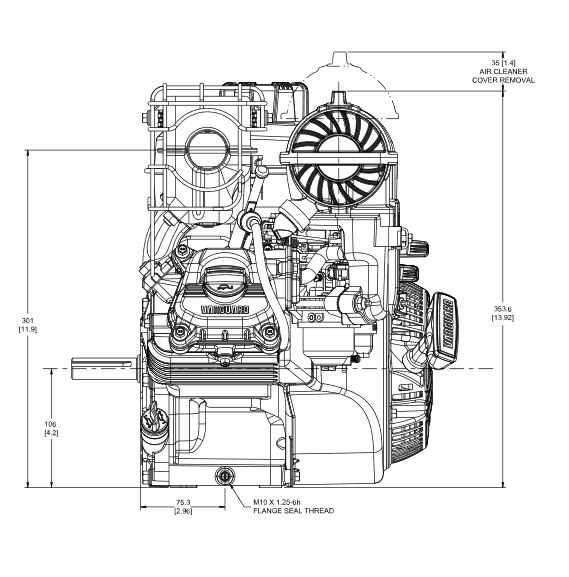

Key Features of 5.5 HP Engine

This section explores the essential characteristics of a compact power unit, highlighting its performance, efficiency, and reliability. Understanding these attributes is crucial for maximizing its potential in various applications.

| Feature | Description |

|---|---|

| Power Output | Delivers robust power suitable for a range of equipment. |

| Fuel Efficiency | Optimized for reduced fuel consumption while maintaining performance. |

| Durability | Constructed with high-quality materials to withstand demanding conditions. |

| Ease of Maintenance | Designed for quick access to key components, simplifying upkeep. |

| Versatility | Compatible with various attachments, enhancing functionality. |

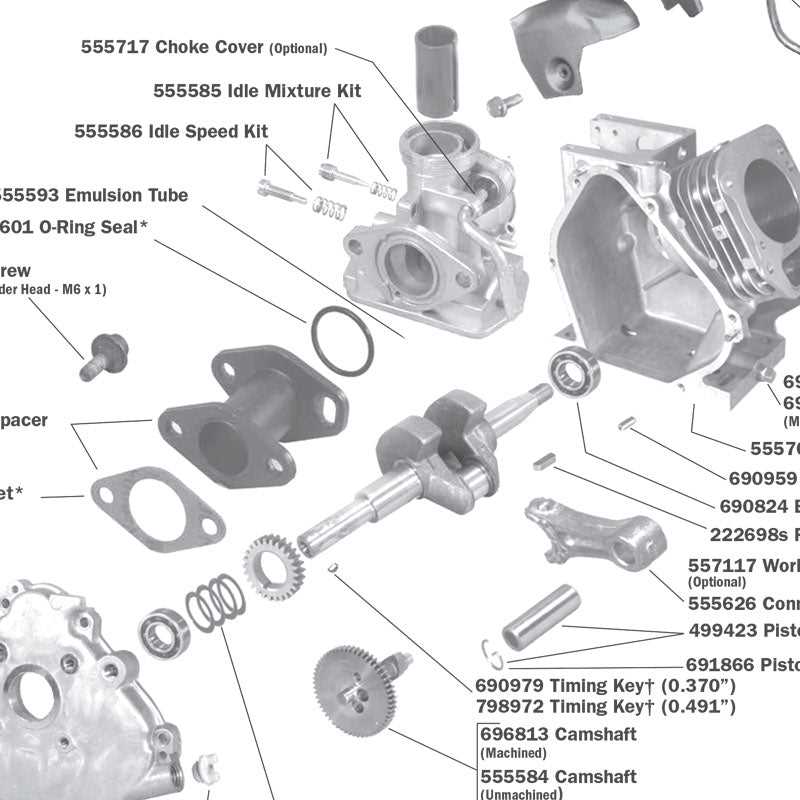

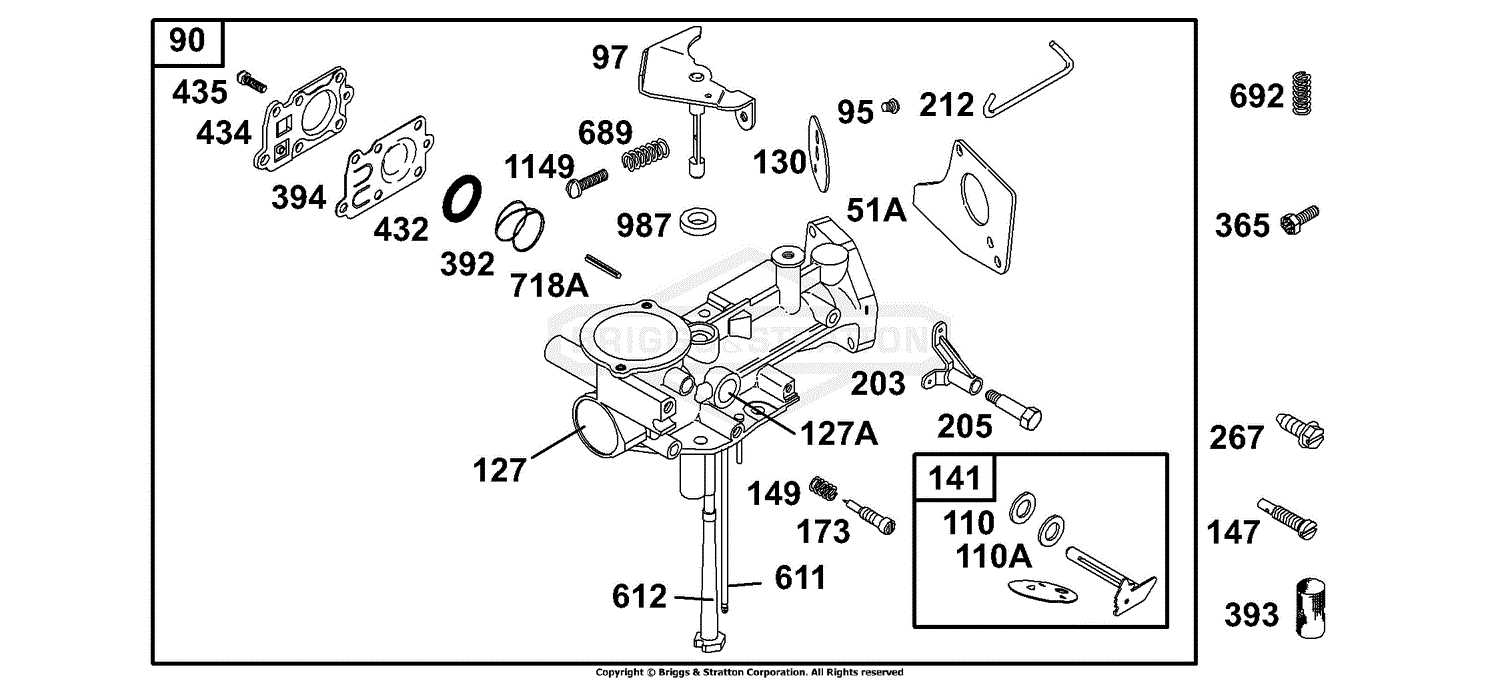

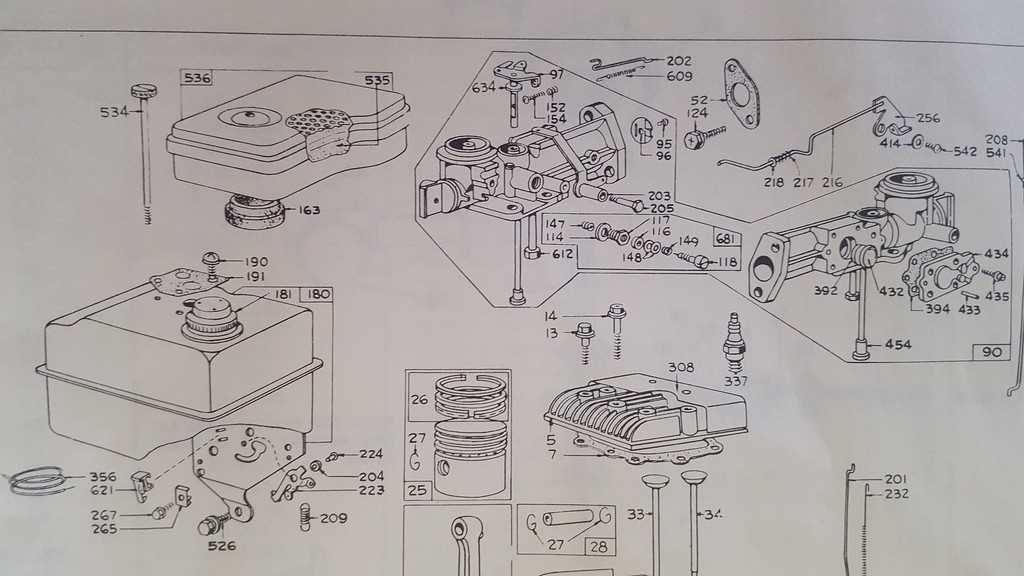

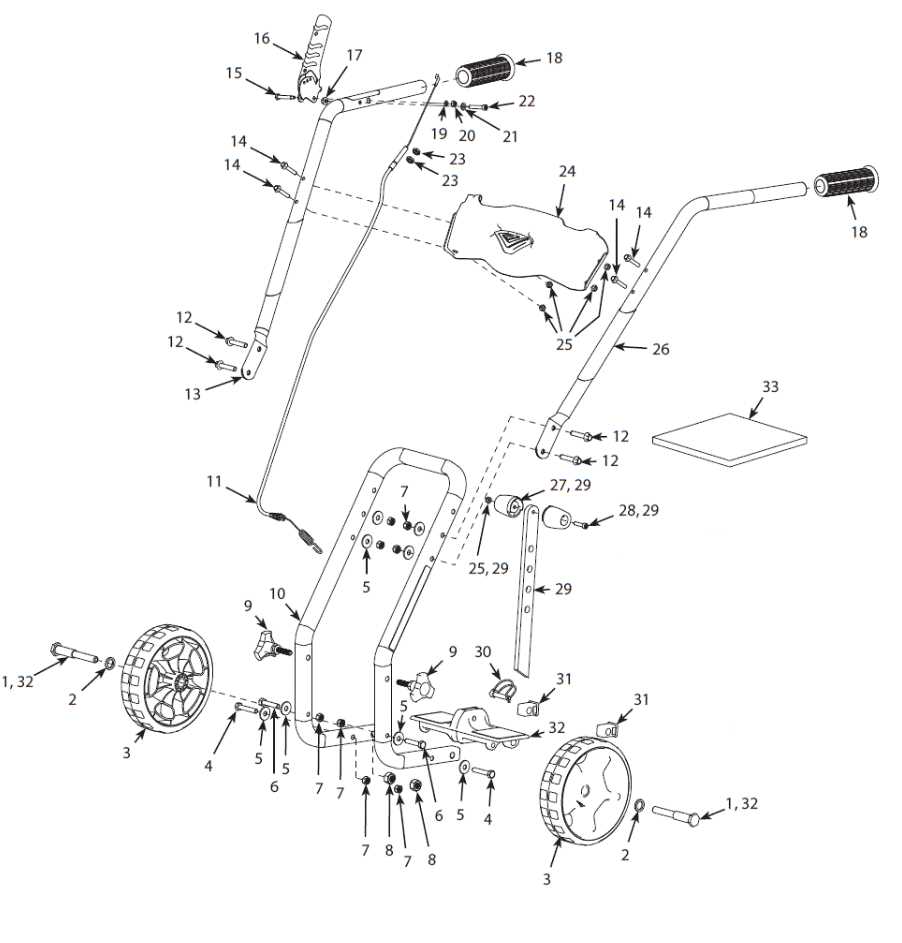

Parts Identification Guide

This section aims to assist users in recognizing essential components of small machinery. Proper identification is crucial for maintenance, repair, and overall performance enhancement.

1. Fuel System: This includes elements that facilitate the delivery of fuel to the combustion chamber, such as the carburetor and fuel lines.

2. Ignition System: Components like the spark plug and ignition coil are vital for initiating combustion within the machine.

3. Cooling Mechanism: This section comprises fans and cooling fins, which help regulate the temperature and prevent overheating.

4. Lubrication System: Parts such as the oil pump and filter ensure that moving elements remain lubricated for smooth operation.

5. Exhaust Components: These include the muffler and exhaust pipe, which direct gases away from the working area, enhancing efficiency.

6. Frame and Mounting: The structure that houses all other components, providing stability and support during operation.

Understanding these critical elements will enable users to effectively maintain their machinery and address any issues that arise.

Common Maintenance Tips

Regular upkeep is essential for optimal performance and longevity of your outdoor machinery. By following a few straightforward practices, you can ensure your equipment runs smoothly and efficiently.

Routine Checks

- Inspect the oil level regularly and change it as recommended.

- Clean or replace the air filter to maintain airflow.

- Examine spark plugs for wear and replace them if necessary.

Seasonal Maintenance

- Before winter storage, drain fuel to prevent degradation.

- Lubricate moving parts to avoid rust and wear.

- Check belts and hoses for signs of damage.

Replacing Engine Components

Maintaining optimal performance in small machinery often requires the replacement of various components over time. Understanding the process involved in swapping out these elements is crucial for ensuring longevity and efficiency. Regular maintenance not only helps in avoiding major breakdowns but also enhances the overall functionality of the unit.

Identifying the Need for Replacement

Recognizing when a component has worn out or is malfunctioning is essential. Common signs include unusual noises, decreased power output, or visible damage. Regular inspections can help identify these issues early, allowing for timely replacements. Additionally, consulting the user manual or a reliable guide can provide insights into typical wear patterns.

Steps to Replace Components

To begin, gather the necessary tools and new components for the task. Safety precautions should always be a priority–ensure the unit is powered off and disconnected. Follow these general steps:

- Remove any covers or shields to access the desired area.

- Carefully detach the old component, noting any connections and positions.

- Install the new part, ensuring it is secured properly.

- Reassemble any removed covers, and conduct a thorough check before restarting.

With attention to detail and adherence to these guidelines, replacing components can be a straightforward task that significantly improves machinery performance.

Tools Required for Repairs

When undertaking maintenance or repair tasks, having the right tools is essential for achieving optimal results. The appropriate equipment not only simplifies the process but also enhances safety and efficiency. Below is a list of essential tools that you may need for various repair tasks.

- Wrenches: A variety of sizes will be necessary to tighten or loosen bolts.

- Screwdrivers: Both flat-head and Phillips types should be on hand for different screws.

- Pliers: Useful for gripping and manipulating small components.

- Socket Set: Ideal for dealing with fasteners in tight spaces.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

In addition to basic tools, some specialized items may enhance your repair experience:

- Gasket Scraper: Helpful for removing old gaskets without damaging surfaces.

- Feeler Gauge: Used for measuring gap widths, particularly in adjustments.

- Oil Filter Wrench: Makes the removal of oil filters easier.

- Multimeter: Essential for diagnosing electrical issues.

- Work Light: Provides adequate illumination in dimly lit areas.

Having these tools readily available will facilitate a smoother repair process, allowing you to focus on the task at hand without unnecessary interruptions.

How to Read a Parts Diagram

Understanding a schematic representation of components is crucial for effective maintenance and repair. These visual guides provide a clear overview of individual elements and their relationships, enabling users to identify necessary replacements or troubleshooting areas efficiently.

Identifying Components

Begin by familiarizing yourself with the symbols and notations used. Each item is typically labeled with a unique identifier, often accompanied by a description. This clarity helps in quickly locating specific elements when seeking replacements.

Understanding Relationships

Pay attention to how components are connected. Lines or arrows often indicate interaction or dependency, giving insight into assembly order or potential failure points. Recognizing these connections is vital for effective repairs.

Troubleshooting Engine Issues

Identifying problems with small power units can be challenging, yet understanding common symptoms and their causes is essential for effective maintenance. This section provides guidance to help users diagnose and resolve typical complications, ensuring optimal performance and longevity.

Common Symptoms

Frequent indicators of malfunction include unusual noises, difficulty starting, or poor performance. These signs often point to underlying issues such as fuel blockages, air leaks, or ignition failures. Regular inspection and awareness of these symptoms can facilitate timely interventions.

Diagnosis and Solutions

Begin troubleshooting by checking fuel levels and quality, as stale or contaminated fuel can cause starting problems. Inspect air filters for clogs and examine spark plugs for wear. A systematic approach can help isolate the issue, allowing for targeted repairs that restore functionality.

Upgrading Your Engine Parts

Enhancing the performance of your machinery can lead to significant improvements in efficiency and longevity. By focusing on the critical components, you can optimize functionality and ensure reliable operation. Whether it’s for recreational use or heavy-duty tasks, upgrading certain elements can yield impressive results.

Identifying the specific areas that require enhancement is essential. Consider factors such as wear and tear, power output, and fuel efficiency. Upgrading components like the carburetor, air filter, or spark plug can provide a noticeable boost. Investing in high-quality replacements can also contribute to smoother operation and reduced maintenance needs.

Additionally, researching compatible enhancements will allow you to make informed decisions. Many aftermarket options provide improved performance over stock elements, tailored for various applications. Before making upgrades, always consult a reliable source to ensure compatibility and effectiveness.

Ultimately, careful consideration and selection of superior components can lead to a more powerful and dependable system, making your tasks easier and more enjoyable. Take the time to evaluate your options and make strategic upgrades for the best possible outcome.

Safety Precautions During Maintenance

Maintaining machinery requires careful attention to safety to prevent accidents and ensure effective operation. Adhering to specific guidelines can significantly reduce the risk of injuries and prolong the lifespan of equipment. Here are essential precautions to consider before beginning any maintenance tasks.

Preparation Steps

- Read the manufacturer’s manual thoroughly to understand the specific requirements.

- Ensure you have all necessary tools and replacement components on hand before starting.

- Work in a well-ventilated area to avoid inhaling fumes or dust.

- Remove any flammable materials from the workspace to reduce fire hazards.

Personal Protective Equipment

- Always wear safety goggles to protect your eyes from debris.

- Use gloves to shield your hands from sharp edges and hazardous substances.

- Wear sturdy footwear to protect your feet from falling objects.

- Consider ear protection if noise levels are high during maintenance activities.

Following these safety measures can help ensure a secure and efficient maintenance process, reducing the likelihood of accidents and enhancing overall productivity.

Where to Buy Genuine Parts

Finding authentic components for your machinery is crucial for maintaining performance and longevity. Whether you are a hobbyist or a professional, sourcing the right replacements ensures that your equipment operates efficiently and safely. Here are some reliable options to consider when looking for original items.

Authorized Dealers

- Visit local dealerships that specialize in outdoor power equipment.

- Check the manufacturer’s official website for a list of certified distributors.

- Ask for recommendations from fellow users or industry professionals.

Online Retailers

- Browse well-known e-commerce platforms that offer a wide selection of authentic components.

- Look for online shops that specialize in replacement items, ensuring they have positive reviews.

- Consider visiting forums or communities focused on machinery to find links to trusted online suppliers.

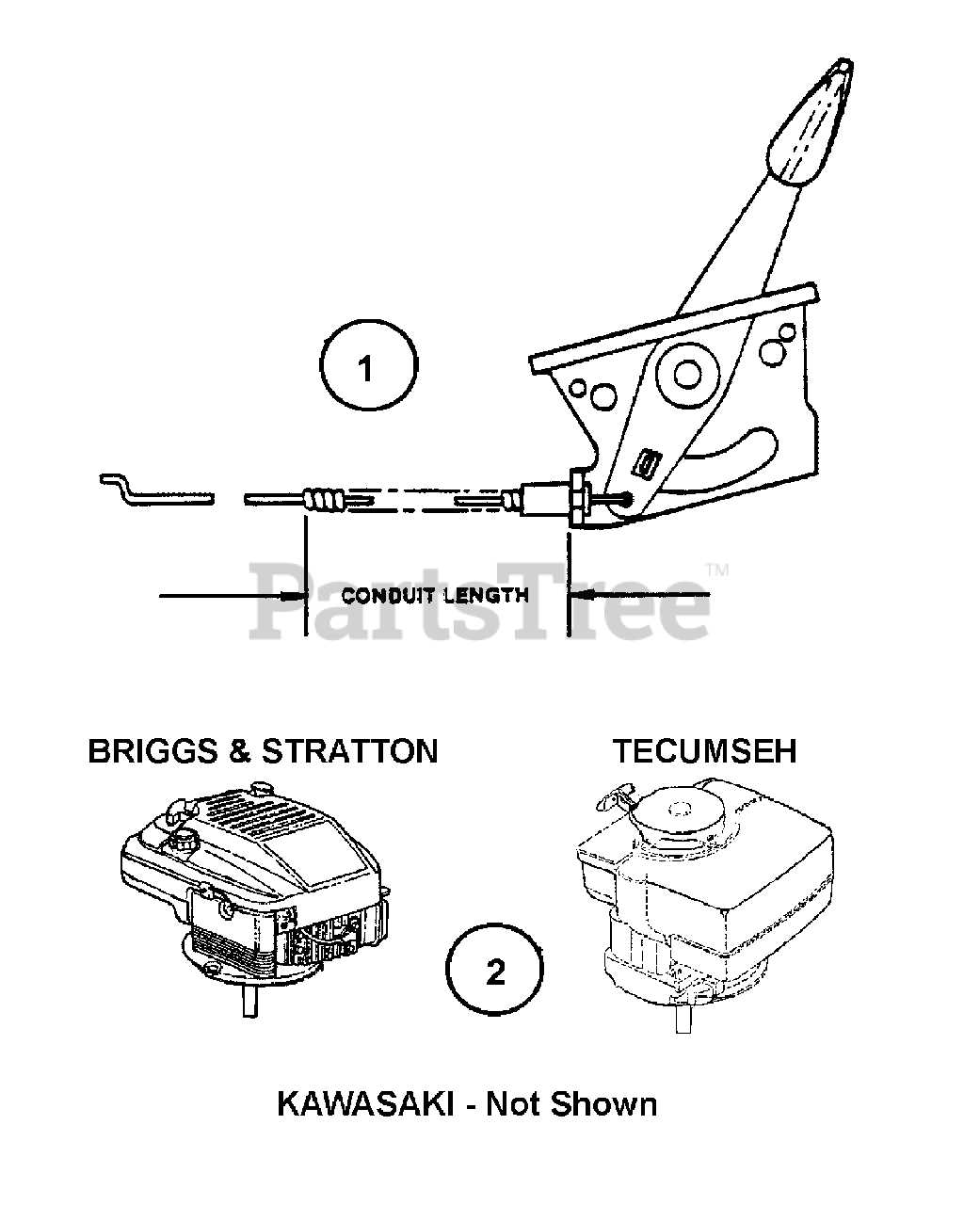

Comparative Analysis of Similar Engines

This section delves into the evaluation of comparable power units that exhibit similar characteristics and functionalities. By examining their design, performance, and application, one can gain insights into their operational efficiencies and suitability for various tasks.

Design Features

The configuration of these power units often includes a variety of components such as cylinders, carburetors, and ignition systems. Each model may adopt a unique arrangement, impacting not only aesthetics but also maintenance ease and durability. The choice of materials used in manufacturing also plays a crucial role in overall longevity and reliability.

Performance Metrics

When analyzing the performance aspects, metrics such as horsepower, torque, and fuel efficiency are essential. Some models may excel in high power output, while others prioritize economical fuel consumption. It is important to consider the intended use case, as this will influence which performance metrics are most relevant.

Application Suitability

Different units are tailored for specific tasks, ranging from residential lawn care to commercial landscaping. The choice of a particular model often hinges on the balance between power and efficiency, alongside the specific requirements of the task at hand. Understanding these nuances can help users select the most appropriate option for their needs.

Conclusion

A comprehensive understanding of these comparable power sources provides valuable guidance for users seeking to make informed decisions. By evaluating design, performance, and application suitability, one can select the ideal unit for their specific requirements.