For enthusiasts and professionals alike, comprehending the intricate layout of engine components is essential for effective maintenance and repairs. Having a clear representation of each element ensures that troubleshooting and replacement processes are seamless and efficient. This guide aims to provide insights into the various segments of a small engine, focusing on its essential features and functions.

By familiarizing oneself with the arrangement and interaction of different components, users can enhance their knowledge of how engines operate. This understanding not only aids in routine upkeep but also empowers individuals to address any issues that may arise during operation. Whether you are a seasoned mechanic or a novice, grasping the overall configuration of engine parts will serve as a valuable resource.

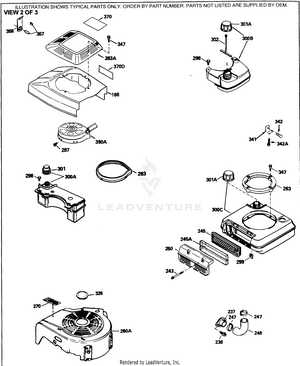

Briggs and Stratton 500E Overview

This section provides an overview of a specific small engine model renowned for its reliability and efficiency. Designed for various outdoor applications, it showcases features that enhance performance and ease of maintenance. The engine is commonly used in lawn care equipment and other similar machinery, making it a popular choice among users seeking durability and power.

Key Features

Among its notable characteristics are a compact design, user-friendly operation, and a variety of power outputs tailored to meet different needs. The engine’s construction emphasizes longevity, with high-quality materials that withstand harsh conditions. Furthermore, it integrates innovative technologies aimed at improving fuel efficiency and reducing emissions, aligning with modern environmental standards.

Applications

This engine model is versatile and finds applications in numerous types of equipment, including lawn mowers, pressure washers, and garden tools. Its adaptability makes it suitable for both residential and commercial use, providing users with a dependable power source for various tasks. Whether tackling routine maintenance or more demanding jobs, this engine stands out for its performance and ease of use.

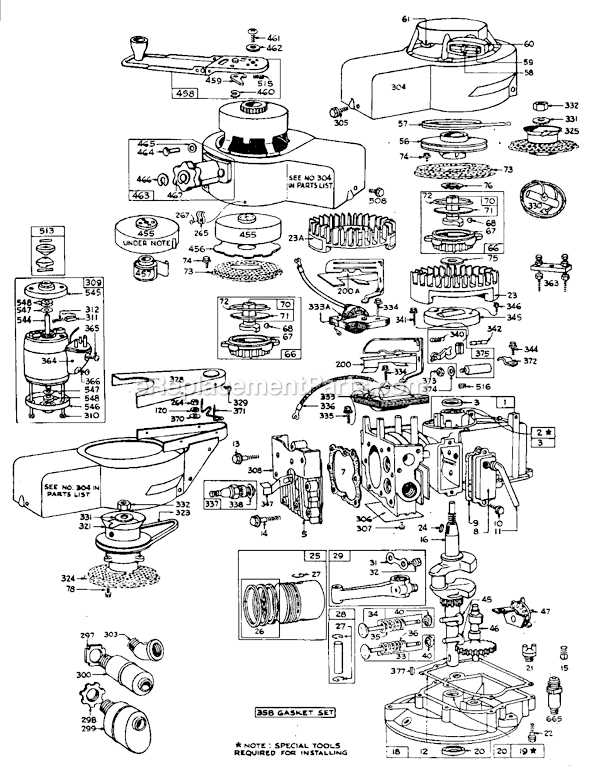

Key Components of the Engine

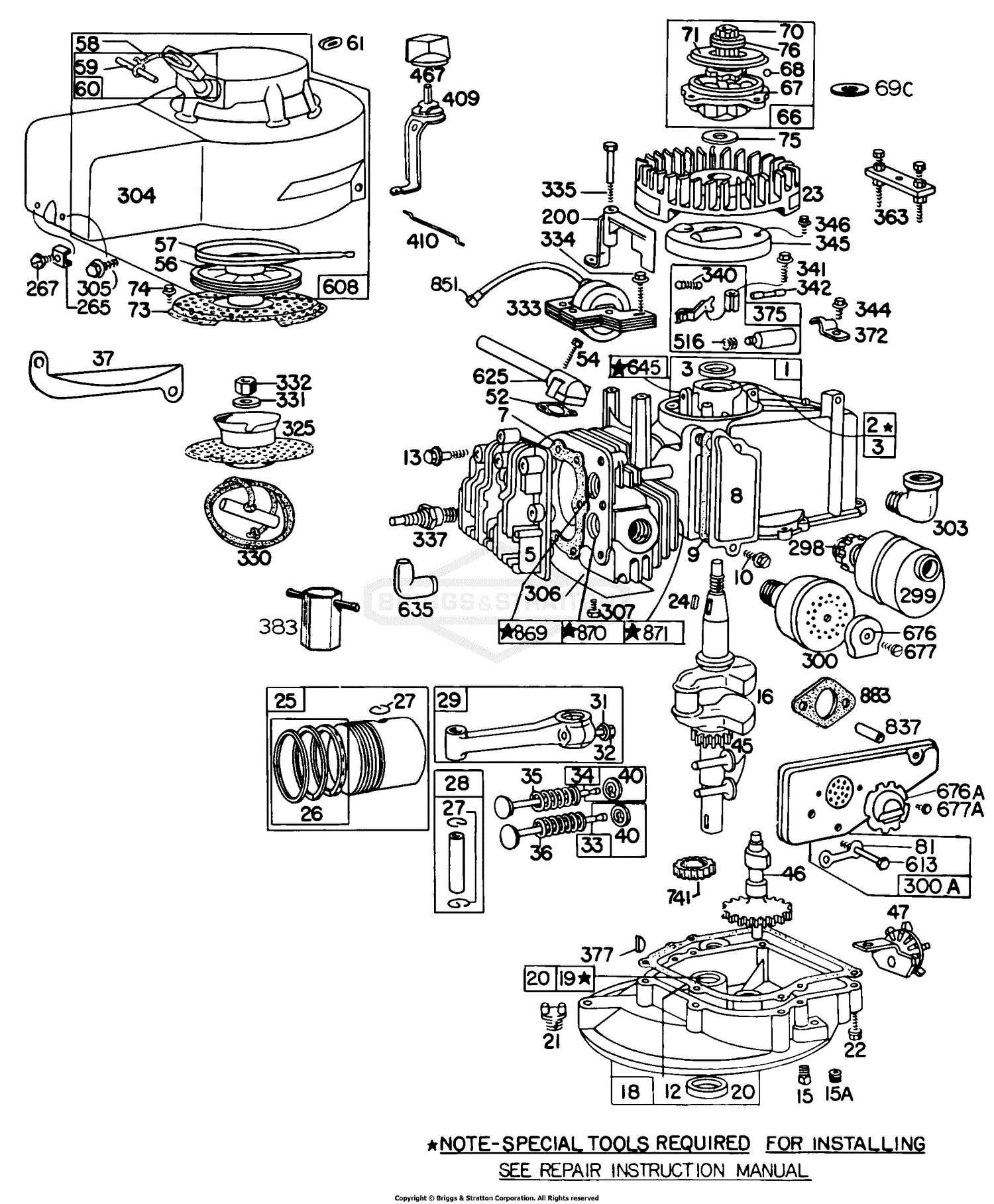

The internal mechanisms of a small motor are crucial for its performance and efficiency. Understanding these essential elements can help in maintenance and troubleshooting. Each part plays a significant role in the overall functionality, contributing to power generation and operational reliability.

Major Parts Overview

The engine consists of various components, each designed to perform specific tasks that ensure smooth operation. The primary elements include the cylinder, piston, crankshaft, and carburetor. Each part interacts harmoniously, creating the necessary conditions for combustion and power delivery.

Functional Role of Each Component

Every part has its own function, contributing to the motor’s performance. The cylinder houses the piston, which moves up and down to compress the air-fuel mixture. The crankshaft transforms this linear motion into rotational energy, driving the output shaft. The carburetor mixes air and fuel in the right proportions for optimal combustion.

| Component | Function |

|---|---|

| Cylinder | Holds the piston and facilitates combustion. |

| Piston | Compresses the air-fuel mixture for ignition. |

| Crankshaft | Converts linear motion into rotational power. |

| Carburetor | Mixes air and fuel for combustion. |

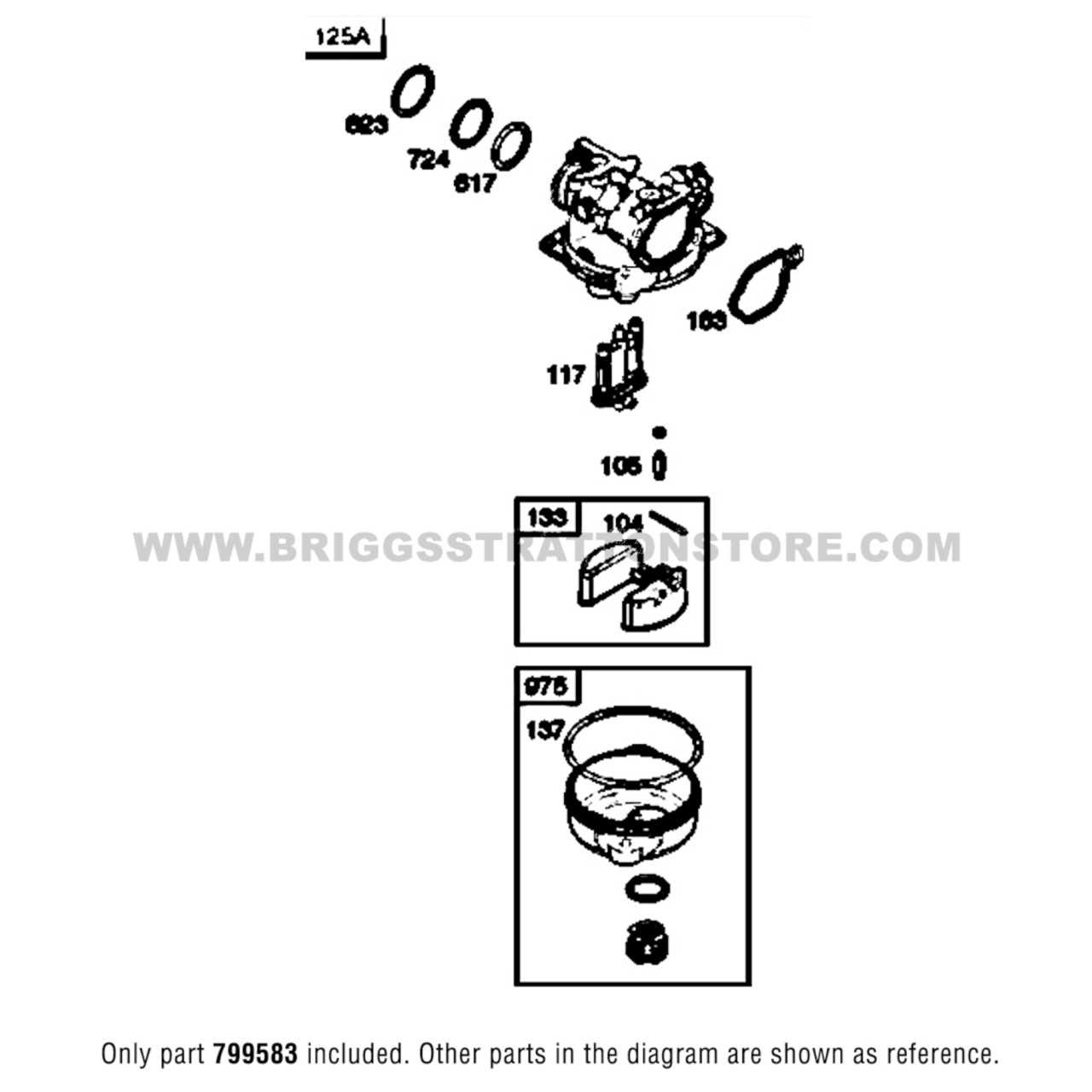

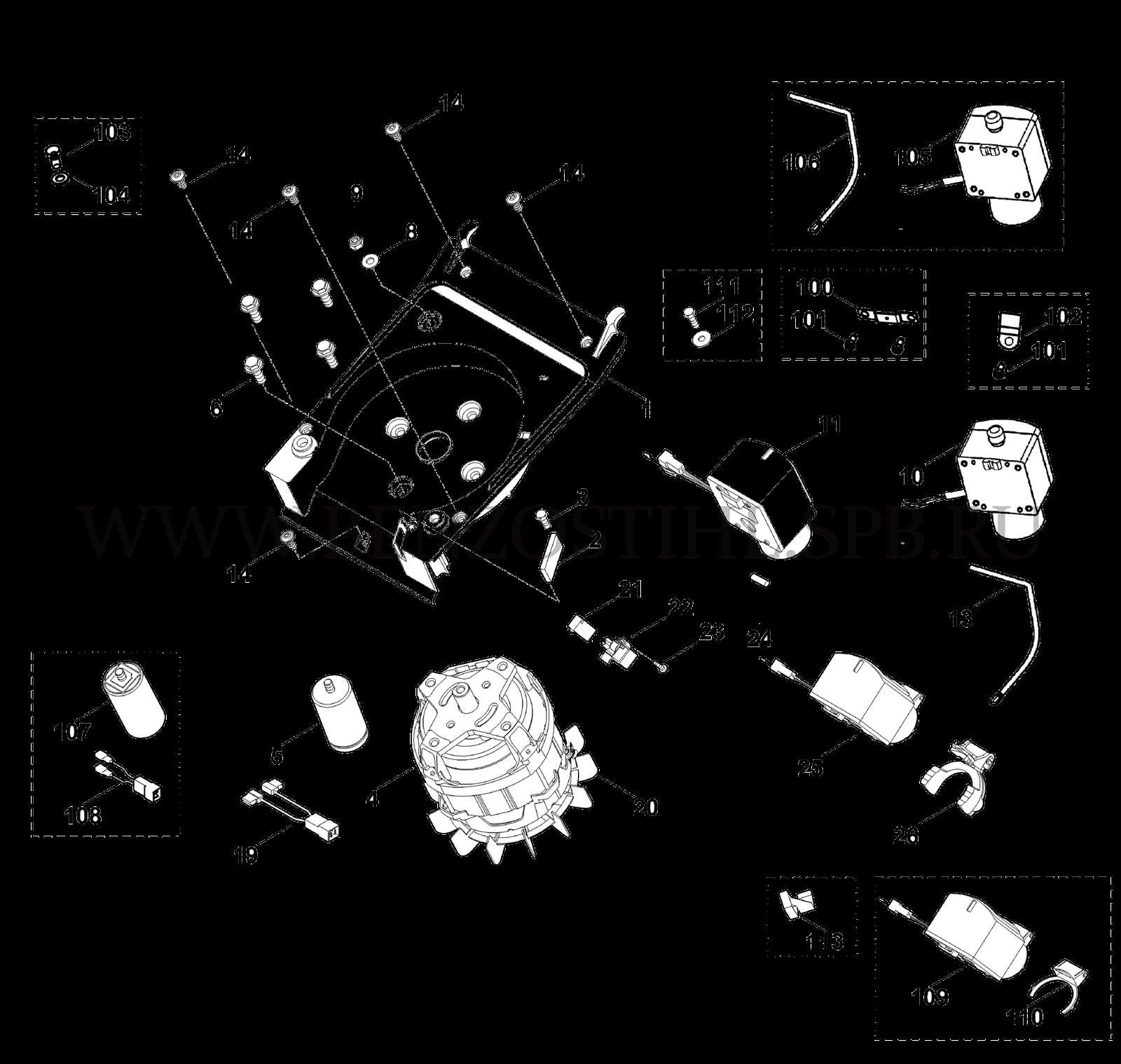

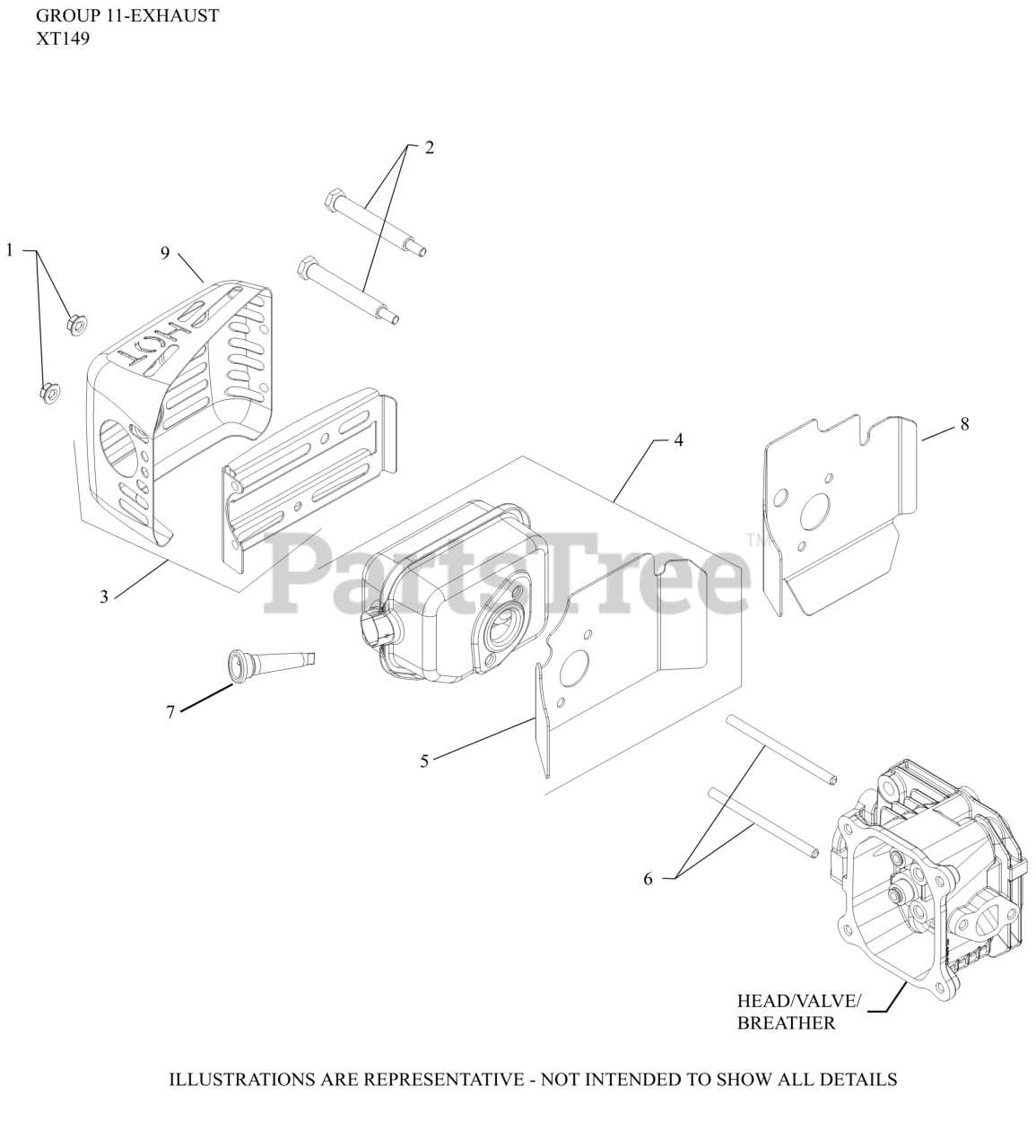

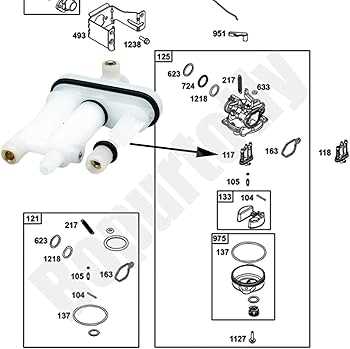

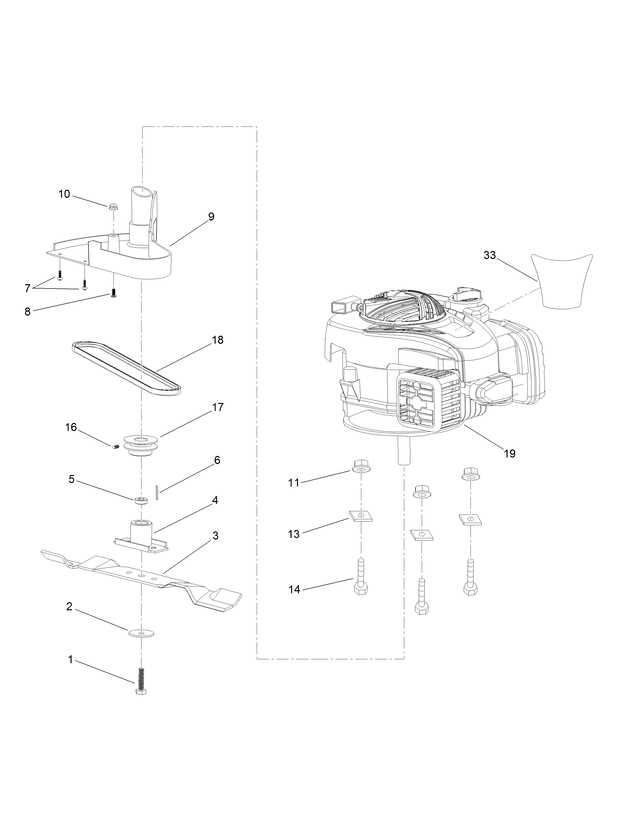

Understanding the Parts Diagram

The visual representation of components within a machine serves as a crucial tool for understanding its functionality. Such illustrations not only depict the individual elements but also highlight their interconnections, allowing for a clearer grasp of the assembly and operation of the device.

Key Components Explained

Each section of the visual representation plays a significant role in the overall performance. Familiarizing yourself with these elements is essential for effective maintenance and troubleshooting. Below are some commonly identified sections:

- Engine: The power unit that drives the entire mechanism.

- Fuel System: Includes components responsible for delivering fuel to the engine.

- Air Filtration: Maintains engine efficiency by ensuring clean air intake.

- Electrical System: Encompasses wiring and components necessary for ignition and operation.

- Starter Mechanism: Facilitates the initiation of the engine.

Benefits of Utilizing the Visual Representation

Understanding the visual representation offers numerous advantages, particularly for those engaged in maintenance or repair tasks:

- Enhances troubleshooting by providing a clear view of potential issues.

- Facilitates ordering the correct components for replacements or upgrades.

- Improves assembly efficiency by offering a reference during reassembly.

By familiarizing yourself with the visual representation of components, you empower yourself to maintain and repair the machinery more effectively.

Common Issues and Solutions

This section addresses frequently encountered challenges with small engines, focusing on identifying common problems and providing effective solutions. Understanding these issues can help ensure proper functionality and prolong the lifespan of the equipment.

Engine Won’t Start

A non-starting engine is a prevalent concern among users. This issue can stem from various factors, including fuel supply, ignition, or battery problems.

| Possible Causes | Solutions |

|---|---|

| Empty fuel tank | Refill with fresh fuel |

| Clogged fuel filter | Replace or clean the fuel filter |

| Faulty spark plug | Inspect and replace if necessary |

| Dead battery | Recharge or replace the battery |

Overheating Issues

Overheating can lead to severe damage if not addressed promptly. It often results from inadequate lubrication, debris buildup, or cooling system failures.

| Possible Causes | Solutions |

|---|---|

| Low oil level | Add oil to the recommended level |

| Blocked air vents | Clear any obstructions |

| Dirty air filter | Clean or replace the air filter |

| Worn out cooling fins | Inspect and replace if damaged |

Maintenance Tips for Longevity

Ensuring the extended lifespan of your outdoor equipment requires regular upkeep and attention to detail. By adopting a few essential practices, you can prevent potential issues and enhance performance. This section highlights effective strategies for maintaining your machinery, contributing to its durability and efficiency.

Regular Cleaning: Keeping your device clean is crucial. Remove debris and dirt after each use to prevent buildup that can affect performance. Pay special attention to air filters and cooling fins, as blockages can lead to overheating.

Fluid Checks: Consistently monitor fluid levels, including oil and fuel. Using the correct type of oil and changing it regularly can significantly improve engine performance and protect against wear. Ensure that fuel is fresh to avoid starting problems.

Inspecting Components: Periodically inspect belts, spark plugs, and filters for wear and tear. Replacing worn parts promptly can prevent further damage and keep your machinery running smoothly. Refer to your equipment’s manual for specific inspection intervals.

Proper Storage: When not in use, store your equipment in a dry and sheltered location. This protects it from harsh weather conditions and reduces the risk of rust and corrosion. Additionally, consider using a cover for extra protection.

By following these maintenance tips, you can enhance the longevity of your machinery and ensure reliable performance for years to come.

Identifying Engine Specifications

Understanding the characteristics of a small engine is crucial for effective maintenance and optimal performance. These specifications provide insights into the engine’s capacity, power output, and operational features, enabling users to make informed decisions when selecting components or performing repairs.

Key specifications typically include engine displacement, which refers to the total volume of all cylinders, and the power rating, often measured in horsepower or kilowatts. Additionally, details such as torque ratings and fuel type are vital for ensuring compatibility with the intended applications. Familiarity with these attributes helps users identify suitable replacements or upgrades for their machinery.

Furthermore, information regarding the cooling system and lubrication requirements plays a significant role in enhancing engine longevity. Regularly consulting these specifications can guide users in maintaining optimal functionality and addressing any potential issues before they escalate.

Replacement Parts Availability

Access to essential components for maintenance and repairs is crucial for ensuring the longevity and efficient performance of small engines. When seeking replacements, it is important to consider various sources and options to obtain the necessary items without delay.

Where to Find Components

Numerous avenues exist for acquiring the needed elements, including:

- Authorized retailers: These establishments often stock genuine items and can provide expert advice.

- Online marketplaces: Websites dedicated to automotive supplies frequently offer a wide range of options, often at competitive prices.

- Local hardware stores: Many carry a selection of commonly required components for various engine models.

- Specialized repair shops: These can be invaluable resources, especially for locating hard-to-find items.

Considerations for Selection

When choosing replacement components, keep in mind the following factors:

- Quality: Opt for high-quality items to ensure optimal performance and longevity.

- Compatibility: Verify that the component matches the specifications of your engine to avoid functionality issues.

- Warranty: Check for warranties or guarantees, as these can provide additional assurance of reliability.

- Cost: Compare prices across various sources to find the best deal without compromising on quality.

Importance of Using Genuine Parts

Utilizing authentic components for maintenance and repairs is crucial for ensuring the longevity and efficiency of any engine. These original elements are designed specifically to meet the exact specifications of the machinery, thereby optimizing its performance and reliability.

Benefits of Authentic Components

Choosing original items offers numerous advantages that can significantly impact overall functionality:

- Quality Assurance: Genuine components undergo rigorous testing to meet high-quality standards, ensuring durability and reliability.

- Compatibility: Original parts are engineered to fit perfectly with the equipment, minimizing the risk of malfunctions or damage.

- Performance Enhancement: Using authentic components helps maintain the original performance levels, leading to better efficiency and power output.

Long-term Cost Savings

Investing in genuine parts may seem more expensive initially, but it can lead to significant savings over time:

- Reduced Repair Costs: Authentic components lower the chances of further damage, minimizing the need for frequent repairs.

- Extended Lifespan: Quality parts enhance the longevity of the machinery, delaying the need for replacements.

- Increased Resale Value: Equipment maintained with original components often retains a higher resale value, making it a wise investment.

Assembly Instructions for DIY Repairs

This section provides essential guidance for individuals interested in performing maintenance or repair tasks on their equipment. Understanding the assembly process is crucial for ensuring that components are correctly fitted and that the device functions optimally. By following these straightforward instructions, even those with minimal experience can successfully complete repairs and extend the lifespan of their machinery.

Preparation Steps

Before starting any assembly work, it is vital to gather all necessary tools and components. Ensure that you have a clean workspace and that you can access all required parts easily. Familiarize yourself with the layout of the components to streamline the assembly process. Below is a checklist of essential items you might need:

| Tool | Purpose |

|---|---|

| Screwdriver | To tighten or loosen screws |

| Wrench | For securing nuts and bolts |

| Pliers | To grip and manipulate small parts |

| Safety Gloves | To protect hands during assembly |

| Flashlight | For illuminating dark areas |

Assembly Process

Begin by referring to the manufacturer’s guidelines to understand the order of assembly. Start with the largest components and work your way down to smaller pieces. Secure each part as you go, ensuring all connections are tight and properly aligned. If any issues arise during assembly, refer back to your checklist to identify any missing items. A careful and methodical approach will ensure successful repairs and enhance the reliability of your equipment.

Tools Required for Maintenance

Proper upkeep of small engines necessitates a set of essential instruments to ensure their efficient operation and longevity. Utilizing the right tools not only simplifies maintenance tasks but also enhances performance and reliability.

Essential Tools

To carry out maintenance effectively, you will need a combination of hand tools and specialized equipment. Commonly required instruments include:

- Socket Wrench Set: Ideal for loosening and tightening bolts and nuts.

- Screwdriver Set: Essential for adjusting and securing various components.

- Pliers: Useful for gripping and bending tasks.

- Fuel Line Pliers: Designed specifically for working with fuel systems.

Maintenance Supplies

In addition to tools, having the right maintenance supplies is crucial. This includes:

- Oil: Ensure you have the correct type and amount for lubrication.

- Air Filter: Regular replacements help maintain optimal airflow.

- Spark Plug: A new spark plug can improve ignition performance.

Having these tools and supplies on hand will facilitate a smoother maintenance process, ensuring that your engine remains in peak condition for years to come.

Safety Precautions During Repairs

Ensuring a safe working environment is crucial when undertaking maintenance tasks on machinery. Adhering to appropriate safety measures not only protects the individual performing the repairs but also prolongs the lifespan of the equipment being serviced. Proper preparation, including the use of safety gear and an organized workspace, can prevent accidents and injuries.

Before commencing any repair work, it is essential to familiarize oneself with the equipment and its components. Taking the time to read relevant manuals and guidelines will enhance understanding and help avoid potential hazards. Here are some key safety precautions to consider:

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use appropriate personal protective equipment, such as gloves, goggles, and ear protection, to minimize risks of injury. |

| Disconnect Power Sources | Before beginning any repair, ensure that the equipment is disconnected from all power sources to prevent accidental activation. |

| Keep Workspace Organized | A tidy workspace reduces the likelihood of accidents. Keep tools and materials well organized to avoid tripping hazards. |

| Use Tools Properly | Utilize the correct tools for each task and ensure they are in good working condition to prevent injuries. |

| Follow Manufacturer Guidelines | Adhere to the manufacturer’s recommendations for repair and maintenance to ensure safe and effective procedures. |

Comparative Analysis with Similar Models

This section delves into a comparative examination of engines in a similar category, focusing on key performance aspects, reliability, and user satisfaction. By analyzing various models, users can make informed decisions regarding which engine best meets their needs and expectations. The similarities and differences highlighted here aim to provide a clearer understanding of how these engines stack up against each other.

Performance Characteristics

When evaluating engines of this type, several performance metrics are essential. These include horsepower output, fuel efficiency, and torque delivery. The following table summarizes the performance specifications of the engine in question and its counterparts:

| Model | Horsepower | Fuel Efficiency (mpg) | Torque (ft-lbs) |

|---|---|---|---|

| Engine A | 5.0 | 25 | 9.0 |

| Engine B | 5.5 | 22 | 10.5 |

| Engine C | 4.8 | 27 | 8.5 |

User Feedback and Satisfaction

Customer reviews play a significant role in understanding the overall satisfaction associated with each model. Users often comment on factors such as ease of maintenance, availability of components, and general reliability. Analyzing these testimonials provides insight into which engines are favored in the market and why. A comparison of user ratings can assist potential buyers in selecting a model that aligns with their preferences and requirements.

Owner Experiences and Recommendations

This section explores the insights and suggestions shared by users of a popular small engine model. Their firsthand accounts provide valuable information for potential owners and those seeking to enhance their experience. By analyzing various reviews and feedback, we aim to highlight common themes and practical advice that can assist others in making informed decisions.

Common Feedback

Users consistently praise the reliability and ease of use associated with this engine. Many appreciate its efficient performance for various outdoor tasks, such as lawn maintenance and light landscaping. A notable aspect highlighted by owners is the simplicity of maintenance, which contributes to the longevity of the engine.

Suggestions for Improvement

While the overall experience has been positive, some users have noted areas for enhancement. Recommendations include upgrading specific components to improve durability and performance. Owners suggest that investing in higher-quality accessories can lead to a more satisfying experience in the long run.

| Common Issues | User Recommendations |

|---|---|

| Difficulty in starting | Regularly check and replace the spark plug |

| Fuel efficiency concerns | Use high-quality fuel and maintain proper levels |

| Wear on components | Consider upgrading to aftermarket parts for enhanced durability |