In the realm of small engine maintenance, having a clear understanding of the fuel delivery system is essential. This intricate assembly plays a pivotal role in ensuring optimal performance and efficiency. Knowledge of each component within this system can aid in troubleshooting issues, enhancing overall engine reliability, and extending its lifespan.

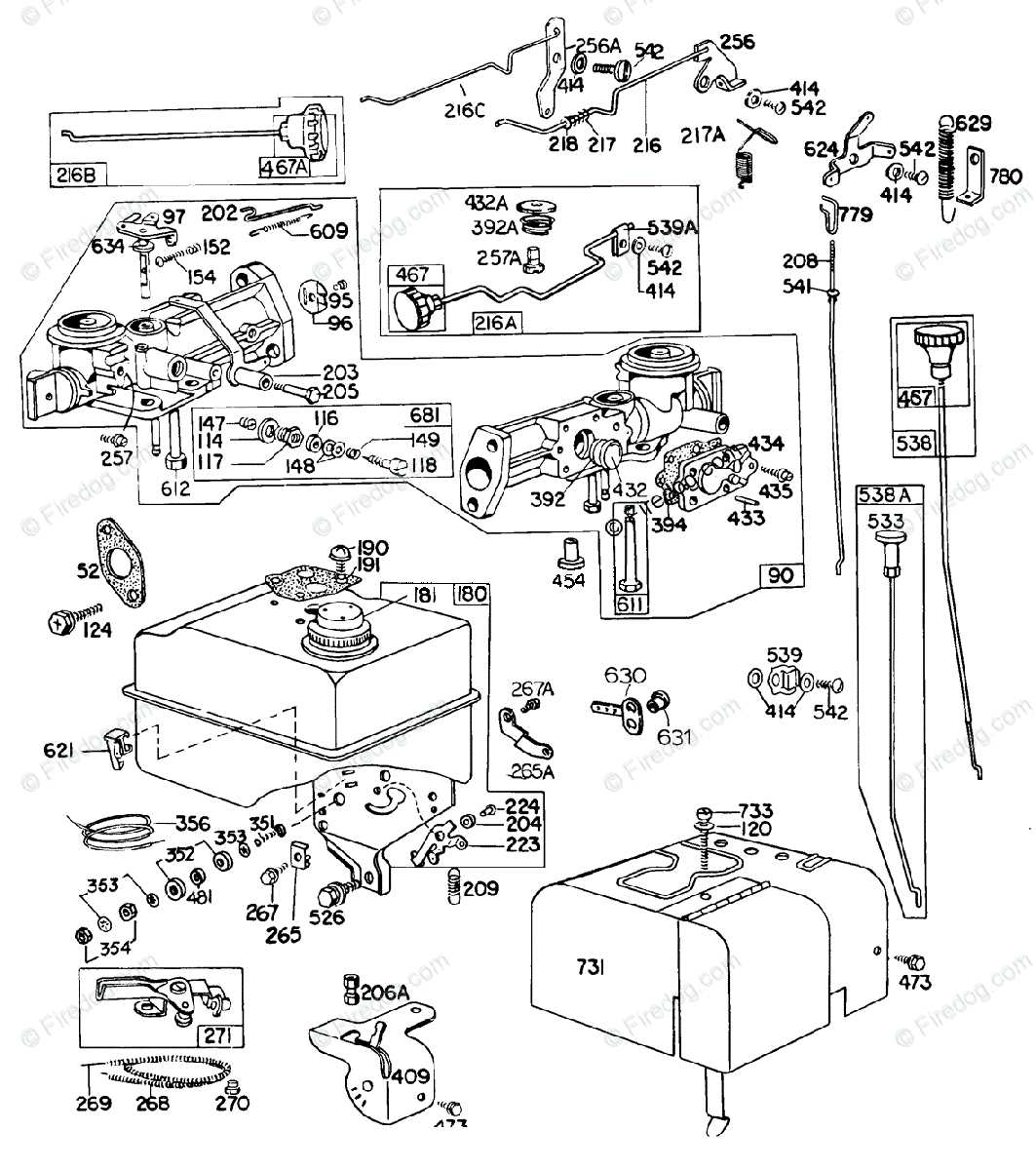

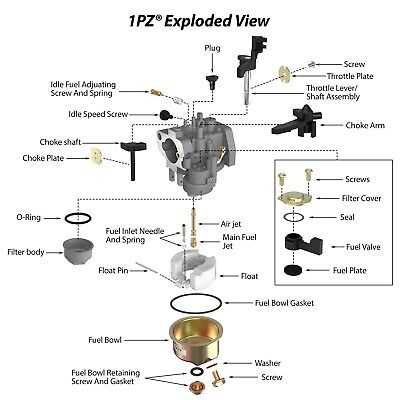

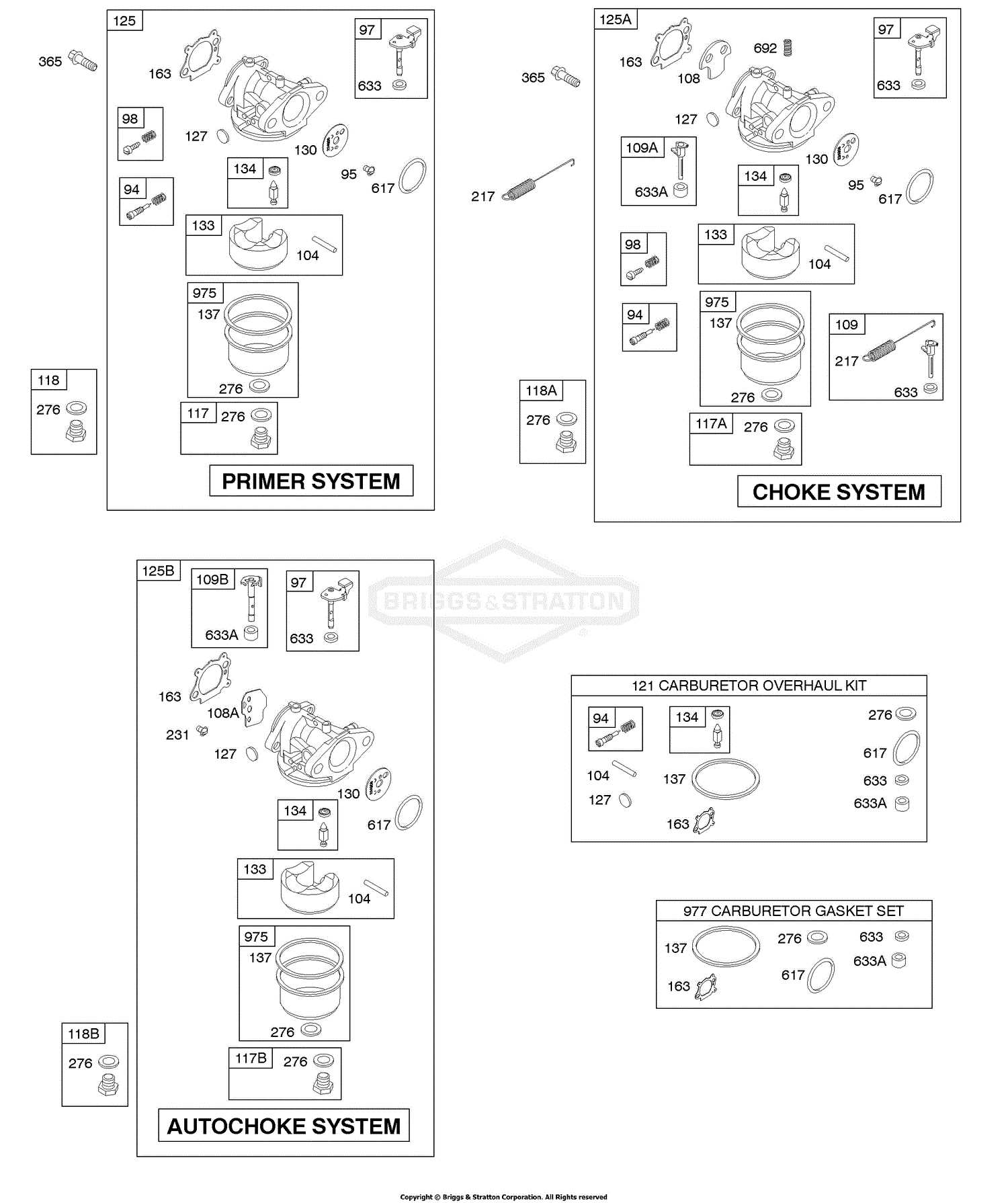

Visual representations of these components provide invaluable insights, allowing enthusiasts and technicians alike to identify individual elements and their functions. By familiarizing oneself with these illustrations, one can easily locate potential problem areas and understand how various pieces interact within the assembly. This familiarity not only promotes efficient repairs but also empowers users to make informed decisions regarding upgrades and replacements.

Moreover, recognizing the significance of each element contributes to a deeper appreciation of the engineering involved in these machines. Whether for a hobbyist or a professional, the ability to navigate through the intricate world of fuel delivery enhances the experience of operating and maintaining small engines. With this understanding, anyone can embark on a journey towards greater mechanical knowledge and proficiency.

Briggs and Stratton Carburetor Overview

This section provides an insight into the fuel mixing mechanism that plays a crucial role in the performance of small engines. Understanding this essential component helps in appreciating how air and fuel are blended to create the ideal mixture for efficient combustion. A well-functioning assembly is vital for optimal operation, ensuring smooth starts and reliable power delivery.

Key Functions: The primary responsibility of this mechanism is to regulate the flow of fuel and air into the combustion chamber. By adjusting the ratio of these elements, it ensures that the engine operates efficiently under varying conditions. This assembly typically includes various components such as float chambers, jets, and adjusting screws, each contributing to its overall functionality.

Maintenance Considerations: Regular inspection and servicing are essential to maintain peak performance. Over time, dirt and debris can clog the fuel passages, leading to poor engine performance. Cleaning or replacing components as needed can significantly enhance the longevity and reliability of the assembly.

Key Components of Carburetor Assembly

The assembly responsible for mixing air and fuel in an engine consists of several essential elements that work together to ensure optimal performance. Understanding these components is crucial for effective maintenance and troubleshooting. Each part plays a specific role in regulating the flow of air and fuel, impacting the engine’s efficiency and power output.

One of the primary components is the throttle valve, which controls the amount of air entering the system. By adjusting the airflow, it influences the engine’s speed and power. Another significant element is the fuel inlet, which allows the proper supply of gasoline into the mixing chamber. This chamber is where the air and fuel blend before entering the combustion area.

Additionally, the float assembly plays a vital role in maintaining the correct fuel level within the mixing chamber. It rises and falls with the fuel level, regulating the flow to ensure consistent performance. The needle and seat assembly work in conjunction with the float, sealing the fuel inlet when the desired level is reached.

Furthermore, the choke mechanism assists in starting the engine by enriching the fuel mixture when cold. This component temporarily restricts airflow, promoting a richer fuel supply until the engine warms up. Lastly, the main jet, responsible for metering fuel flow, ensures the correct fuel-to-air ratio under various operating conditions.

Understanding Fuel Delivery Mechanism

The process of supplying fuel to an engine is a vital aspect of its functionality. This mechanism ensures that the correct amount of fuel is mixed with air to achieve efficient combustion. Understanding how this system operates is essential for maintenance and troubleshooting.

Key Components of Fuel Delivery

- Fuel Tank: Stores the fuel until needed.

- Fuel Pump: Transfers fuel from the tank to the engine.

- Fuel Filter: Removes impurities to protect the engine.

- Intake System: Mixes air with fuel for optimal combustion.

- Choke: Regulates the air-fuel mixture during startup.

Functionality of the System

The operation begins when the fuel pump activates, drawing fuel from the tank. The fuel is then pushed through a filter to eliminate any contaminants. Once purified, the fuel reaches the intake system, where it combines with air. The choke plays a crucial role by adjusting the air-fuel ratio, particularly during cold starts. This well-coordinated sequence is vital for the engine’s performance and longevity.

Common Carburetor Issues Explained

Understanding the typical problems that can arise with fuel delivery systems is essential for maintaining optimal engine performance. These systems play a crucial role in mixing air and fuel, ensuring that combustion occurs efficiently. This section outlines some prevalent difficulties that users may encounter, helping to identify symptoms and potential solutions.

Fuel Blockage

Blockages can occur within the fuel delivery mechanism, leading to insufficient fuel flow. This issue often results from dirt, debris, or varnish build-up, which can obstruct fuel passages. Regular maintenance and cleaning can help prevent this complication, ensuring that fuel flows freely and the engine runs smoothly.

Air Leaks

Another common challenge involves air leaks in the system, which can lead to a lean fuel mixture. This condition may cause the engine to run poorly, exhibit rough idling, or even stall. Checking for loose connections and worn gaskets is essential for addressing this issue. Ensuring a tight seal can help maintain proper air-fuel ratios and enhance engine performance.

Tools Needed for Maintenance

Proper upkeep of your small engine equipment requires a selection of essential implements. These tools ensure that every component is serviced efficiently and effectively, leading to optimal performance and longevity. Familiarity with the necessary instruments will facilitate a smoother maintenance process.

To begin with, a set of screwdrivers is indispensable for loosening and tightening various fasteners. Both flathead and Phillips types will be needed to accommodate different screws found throughout the assembly. Additionally, a quality wrench set will enable you to address nuts and bolts of varying sizes, ensuring a snug fit and preventing any potential leaks.

Another crucial tool is a socket set, which provides versatility in reaching confined spaces. This allows for easy access to hard-to-reach areas where standard wrenches may not suffice. Furthermore, a pair of pliers is helpful for gripping, twisting, and cutting, making it a valuable addition to your toolkit.

Lastly, having a clean workspace with organization aids, such as a parts tray or magnetic bowl, will assist in keeping small components secure during maintenance tasks. By equipping yourself with these basic tools, you will be well-prepared to tackle any upkeep challenges that may arise.

Step-by-Step Repair Guide

This section outlines a comprehensive process for restoring the functionality of a specific engine component. Following these instructions carefully will help you navigate through the necessary steps, ensuring that the assembly is efficient and effective.

Gather Your Tools and Materials

Before starting the repair, it is essential to collect all necessary tools and materials. This includes wrenches, screwdrivers, a clean workspace, and replacement components. Having everything on hand will streamline the repair process and prevent interruptions.

Disassembly and Cleaning

Begin by carefully disassembling the assembly to access the internal mechanisms. Take note of the arrangement of each piece, as this will aid in reassembly. Once disassembled, clean all parts thoroughly using a suitable solvent. Pay special attention to any areas that may have accumulated debris or residue, as this can impact performance.

Reassembly should follow the reverse order of disassembly. Ensure that each component is securely fastened and positioned correctly. Before testing, double-check that all connections are tight and that no tools or materials have been left behind.

Finally, after reassembling the unit, conduct a test run to ensure everything functions smoothly. If issues persist, revisit the previous steps to identify any overlooked components or connections.

Importance of Gasket and Seals

Gaskets and seals play a crucial role in the proper functioning of small engine systems. These components are essential for maintaining the integrity of various assemblies, preventing leaks and ensuring optimal performance. Their primary function is to create a barrier between different surfaces, which is vital for the overall efficiency of the engine.

Role in Preventing Leaks

One of the most significant functions of these components is to prevent the escape of fluids and gases. Effective seals ensure that fuel and air mixtures remain contained within the engine, preventing loss of power and efficiency. Without reliable gaskets and seals, the risk of leaks increases, which can lead to performance issues and potential engine damage.

Enhancing Engine Performance

In addition to preventing leaks, gaskets and seals contribute to the overall performance of the engine. They help maintain the proper pressure and temperature, allowing the engine to operate smoothly. This optimization leads to better fuel efficiency and reduced emissions, making it not only beneficial for the engine but also for the environment.

Cleaning Tips for Optimal Performance

Regular maintenance is essential for ensuring that your equipment operates at peak efficiency. A thorough cleaning process not only enhances performance but also extends the lifespan of various components. By following a systematic approach to upkeep, you can prevent common issues and maintain smooth operation.

Essential Cleaning Steps

Begin by disconnecting any power sources to ensure safety. Carefully remove any accessible components to gain better access to the internal sections. Use a soft brush or compressed air to eliminate dirt and debris from crevices. Pay close attention to the fuel system, as blockages can hinder functionality. A suitable cleaning solvent can be applied to stubborn residues, but ensure that all surfaces are dry before reassembling.

Regular Maintenance Schedule

Implementing a regular cleaning schedule is vital. Aim to inspect and clean critical components after every few uses or as recommended in the user manual. Seasonal maintenance checks can prevent buildup over time, leading to improved reliability. Keeping a log of your cleaning activities can help track when the last service was performed, making it easier to stay on top of maintenance needs.

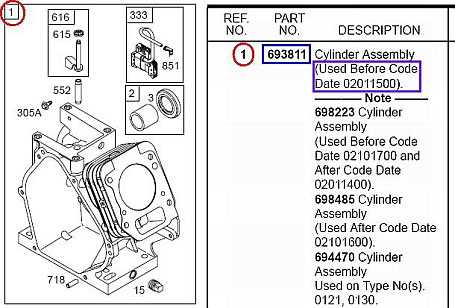

Replacement Parts: When to Buy

Understanding when to acquire new components for your engine system is essential for maintaining optimal performance. Regular inspection and awareness of signs indicating wear and tear can help prevent unexpected breakdowns and ensure smooth operation. Below are some key factors to consider before making a purchase.

| Signs of Wear | Recommended Action | Timing |

|---|---|---|

| Frequent stalling or poor fuel efficiency | Consider replacing the affected components | Immediately |

| Visible cracks or damage | Purchase replacements as soon as possible | Urgently |

| Difficulty starting or unusual noises | Inspect and replace as necessary | Within the next maintenance cycle |

| Old or worn components based on service history | Schedule replacements | At the next scheduled service |

Keeping track of these indicators will help you decide when it’s time to invest in new elements for your engine system, ensuring reliability and efficiency in operation.

Adjusting Air-Fuel Mixture Settings

Tuning the balance between air and fuel is crucial for optimal engine performance. This adjustment impacts combustion efficiency, affecting power output, fuel consumption, and overall functionality. Ensuring the correct proportions can lead to smoother operation and prolong the lifespan of the equipment.

To achieve the desired mixture, one must locate the adjustment screws typically found on the assembly. Turning these screws clockwise generally decreases the fuel flow, resulting in a leaner mixture, while counterclockwise increases fuel, making it richer. It’s essential to make these adjustments in small increments and test the engine’s response after each change to identify the most effective setting.

Monitoring engine performance during adjustments can help detect signs of an imbalanced mixture. If the engine sputters or runs erratically, it may indicate a need for further tuning. Conversely, a smooth-running engine is a good sign that the air-fuel mixture is appropriately set. Regular maintenance and fine-tuning can enhance performance and ensure the equipment runs efficiently for years to come.

Diagnosing Starting Problems

When facing difficulties in initiating a small engine, it is essential to identify the underlying issues that may be preventing proper operation. This process involves systematically examining various components and systems to determine the root cause of the problem. A thorough understanding of the mechanisms at play can significantly aid in effective troubleshooting and resolution.

Common Issues to Check

Several factors can contribute to starting challenges. First, ensure that fuel is reaching the engine and that it is fresh and free from contaminants. Examine the ignition system, as a faulty spark plug or ignition coil can hinder starting efforts. Additionally, inspect the air intake for any blockages that might restrict airflow, impacting combustion efficiency.

Steps for Effective Troubleshooting

Begin by checking the fuel supply, making sure that the tank is filled and the fuel lines are unobstructed. Next, test the ignition components to confirm they are functioning correctly. A spark tester can help determine if the ignition system is delivering a strong spark. Lastly, evaluate the overall condition of the engine, looking for signs of wear or damage that may necessitate repair or replacement of parts.

Resources for Troubleshooting Techniques

Effective problem-solving requires access to a variety of tools and information sources. By utilizing these resources, individuals can identify issues more efficiently and implement appropriate solutions. Here, we explore several valuable avenues that can assist in diagnosing common mechanical challenges.

- Online Forums: Engaging with communities dedicated to repair and maintenance can provide insights from experienced users. These platforms often feature discussions on common problems and their solutions.

- Manufacturer Manuals: Comprehensive guides from manufacturers often contain troubleshooting sections that outline symptoms and corrective measures. These documents serve as crucial references for understanding specific equipment.

- Video Tutorials: Visual learners can benefit greatly from instructional videos that demonstrate step-by-step processes for resolving issues. Platforms like YouTube host a wealth of content from various creators.

- Technical Support Hotlines: Reaching out to customer support can provide direct assistance from trained professionals who can guide users through specific challenges.

- Diagnostic Tools: Investing in specialized tools can streamline the troubleshooting process. Equipment designed for testing performance can quickly reveal underlying issues.

By leveraging these resources, users can enhance their troubleshooting abilities, ensuring they can address mechanical issues effectively and maintain optimal performance.