Exploring the intricate workings of small engines is essential for maintenance and repair. Knowing how each component interacts within the system can significantly enhance performance and longevity. A clear representation of these elements allows for easier identification and troubleshooting, leading to efficient servicing.

Visual aids serve as a valuable tool for both novice and experienced mechanics. They simplify the process of understanding complex machinery by breaking down the engine into manageable sections. This approach not only aids in locating specific components but also highlights the relationship between different parts, ensuring a more comprehensive grasp of the overall function.

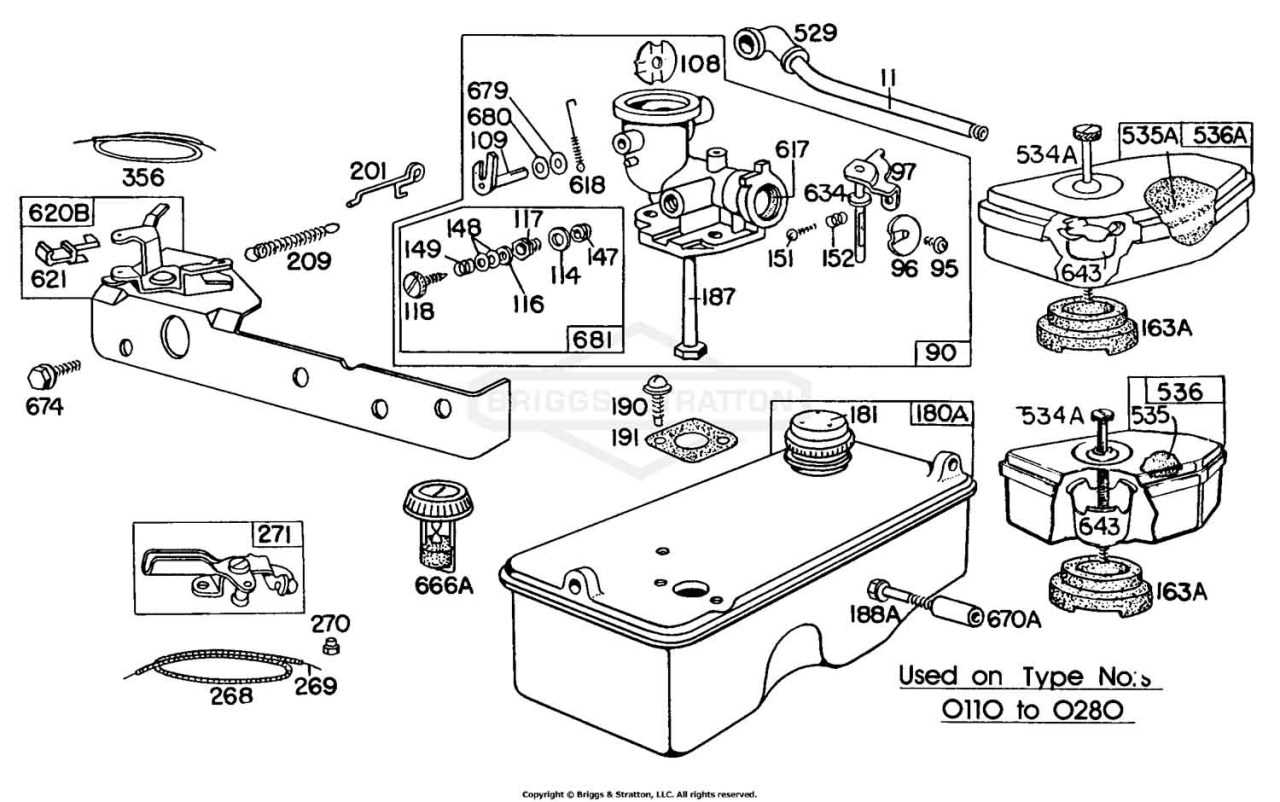

In this discussion, we delve into an illustrative guide that captures the essential elements of a particular engine model. By focusing on the configuration and positioning of each piece, we empower users to tackle repairs with confidence. Gaining insight into these layouts will ultimately lead to more informed decisions during maintenance tasks.

Understanding Briggs and Stratton Sprint 375

This section aims to provide insights into a well-known small engine model commonly utilized in various outdoor equipment. Recognizing its components and their functions is essential for effective maintenance and optimal performance. By familiarizing yourself with this engine, you can enhance its longevity and efficiency.

The model features a robust design that ensures reliability during operation. Its engine specifications cater to a variety of applications, making it a versatile choice for users. Knowledge of its inner workings can significantly aid in troubleshooting and repairs.

Additionally, understanding the assembly can lead to better handling and fewer operational issues. Whether you’re a novice or experienced user, mastering the key elements of this engine will ultimately improve your overall experience.

Components of Sprint 375 Engine

The engine’s functionality relies on a variety of integral elements that work together harmoniously. Each component plays a crucial role in ensuring optimal performance and reliability, forming a well-coordinated system designed for efficiency.

1. Cylinder Head: This component houses the valves and plays a vital role in the combustion process. It facilitates the flow of air and fuel into the combustion chamber while allowing exhaust gases to escape.

2. Crankshaft: Serving as the heart of the engine, the crankshaft converts linear motion into rotational force, enabling the engine to generate power. Its design is essential for minimizing vibrations and ensuring smooth operation.

3. Carburetor: This part is responsible for mixing air and fuel in the correct ratio, which is crucial for efficient combustion. The carburetor’s adjustments directly impact engine performance and fuel efficiency.

4. Ignition System: A reliable ignition system initiates the combustion process by creating a spark at precisely the right moment. This timing is critical for maximizing power output and minimizing emissions.

5. Governor: The governor regulates the engine’s speed by adjusting the fuel flow based on the load demands. This ensures consistent performance under varying operational conditions.

Understanding these essential elements provides insight into the overall mechanics and engineering behind a high-performing engine, showcasing the complexity and precision involved in its design.

Identifying Essential Parts in Diagrams

Understanding the key components within technical illustrations is crucial for effective maintenance and repair. These visuals serve as valuable resources, enabling users to pinpoint various elements and their functions with clarity. By familiarizing oneself with the layout and symbols used, one can streamline the process of identifying specific items necessary for tasks.

Each illustration typically categorizes components into distinct sections, allowing for easier navigation. Recognizing common shapes and notations enhances comprehension, facilitating a more efficient approach to troubleshooting. Mastery of these elements ultimately empowers individuals to take confident steps toward successful interventions.

Common Issues and Replacement Parts

When dealing with small engine machinery, certain challenges may frequently arise, necessitating the replacement of specific components. Understanding these common problems can help ensure optimal performance and longevity of the equipment. Below are some prevalent issues encountered, along with suggestions for corresponding replacements.

Frequent Problems

Users often report difficulties related to starting, irregular operation, or power loss. These issues can stem from several underlying causes such as fuel system malfunctions, ignition failures, or wear and tear of essential components. Identifying these problems early can prevent more extensive damage and costly repairs.

Recommended Replacements

Addressing the common issues often requires replacing key elements. The following table outlines typical problems along with their suggested replacements:

| Issue | Replacement Component |

|---|---|

| Engine won’t start | Spark Plug |

| Inconsistent power output | Air Filter |

| Excessive vibration | Mounting Grommets |

| Fuel leakage | Fuel Line |

| Overheating | Cooling Fins |

By addressing these common issues and replacing the necessary components, users can maintain the efficiency and reliability of their small engine machinery.

Maintenance Tips for Sprint 375

Ensuring longevity and optimal performance of your equipment requires regular upkeep and attention. By following a few key practices, you can enhance efficiency and prevent common issues that may arise over time.

Regularly check and clean air filters to maintain airflow and engine performance. Replace them as needed to prevent blockages that can hinder operation. Additionally, change the oil at recommended intervals to keep the internal components lubricated and functioning smoothly.

Inspect spark plugs periodically; cleaning or replacing them can lead to better ignition and fuel efficiency. Furthermore, examining fuel lines for leaks or damage ensures safe operation and reduces the risk of engine failure.

Finally, always store your machine in a dry, protected area to prevent rust and deterioration. Seasonal checks can help identify potential problems early, allowing for timely interventions and ensuring your equipment remains in peak condition.

Tools Needed for Repairs

Effective maintenance and repairs require the right equipment to ensure efficiency and accuracy. Utilizing appropriate tools not only simplifies the process but also enhances the quality of the work. Whether you are a novice or an experienced technician, having the necessary instruments at hand is crucial for successful repairs.

Essential Instruments

Among the basic instruments, a socket set is vital for loosening and tightening various components. Additionally, screwdrivers of different sizes, pliers, and wrenches are fundamental for manipulating parts effectively. A reliable multimeter can also help diagnose electrical issues, ensuring a thorough examination of the machine.

Safety Equipment

Safety should always be a priority. Protective eyewear and gloves are essential to safeguard against potential hazards during repairs. Moreover, having a sturdy workbench can provide a secure and organized workspace, making the repair process more efficient.

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repair. These illustrations provide a detailed overview of individual elements, their arrangement, and how they interconnect within a machine. Mastering the ability to interpret these graphics can significantly enhance your troubleshooting skills and facilitate smoother repairs.

Key Components of Visual Representations

When examining a visual layout, it’s essential to recognize the various sections and notations used. Each symbol or line typically corresponds to a specific piece, indicating its function and position. Here are some common elements you may encounter:

| Symbol | Description |

|---|---|

| Circle | Represents a component that is removable or replaceable. |

| Arrow | Indicates the direction of movement or flow within the system. |

| Dashed Line | Shows optional components or alternate configurations. |

Interpreting the Information

To effectively utilize these illustrations, focus on the accompanying legends or annotations that provide additional context. Often, these notes will explain part numbers, specifications, or assembly sequences, making it easier to locate and replace components as needed. Familiarizing yourself with these representations can save time and improve the accuracy of your repairs.

Finding Genuine Replacement Components

Ensuring optimal performance and longevity of your equipment hinges on sourcing authentic replacement parts. Utilizing high-quality components not only guarantees compatibility but also maintains the integrity of the machinery.

Identifying genuine components involves thorough research and verification of suppliers. Look for authorized dealers or reputable retailers that specialize in your specific model. Check reviews and seek recommendations to avoid counterfeit options that may compromise performance.

Furthermore, keeping an eye on product packaging and documentation can provide additional assurance of authenticity. Always cross-reference part numbers and specifications with trusted sources to ensure you’re making the right choice.

Steps for Engine Reassembly

Reassembling a small engine requires careful attention to detail and methodical steps to ensure optimal performance. This process is crucial for restoring functionality and extending the life of the equipment.

1. Organize Components: Begin by sorting all the components to have a clear view of what needs to be reassembled. Use labeled containers to keep similar parts together.

2. Inspect Each Part: Examine all elements for wear and damage. Replace any worn components to avoid future issues.

3. Follow Manufacturer’s Instructions: Refer to the assembly manual for the specific sequence and torque specifications. This ensures that each component is installed correctly.

4. Apply Lubrication: Use appropriate lubricants on moving parts to facilitate smooth operation and reduce friction.

5. Assemble in Reverse Order: Reassemble the engine by following the disassembly steps in reverse. This approach helps to avoid missing any parts.

6. Double-Check Connections: Ensure all bolts, screws, and connections are tightened properly. A loose part can lead to serious mechanical failures.

7. Perform a Final Inspection: Before closing up, conduct a thorough inspection to confirm that everything is in place and correctly aligned.

8. Test the Engine: Once reassembly is complete, start the engine to test functionality. Listen for any unusual noises and check for leaks.

Upgrading Sprint 375 Performance

Enhancing the efficiency of your engine can lead to improved power output and better overall functionality. By focusing on specific modifications, you can achieve a noticeable boost in performance without extensive overhauls.

Improving Airflow

One effective way to elevate performance is by optimizing airflow. Upgrading the air filter to a high-flow variant allows for increased air intake, enhancing combustion efficiency. Additionally, considering a performance exhaust can reduce back pressure, further improving the engine’s output.

Tuning the Fuel System

Adjusting the fuel system is crucial for maximizing performance. Replacing the carburetor with a more efficient model can significantly improve fuel delivery. Pair this with a premium fuel blend to ensure your engine runs smoothly and efficiently, providing that ultimate power boost.

Resources for Further Learning

Exploring additional materials can greatly enhance your understanding of small engine components and maintenance. Whether you are a novice or an experienced technician, a variety of resources are available to deepen your knowledge and skills.

Online Forums: Participating in communities where enthusiasts share tips and experiences can provide practical insights and troubleshooting advice.

Instructional Videos: Visual guides on platforms like YouTube offer step-by-step demonstrations that can clarify complex processes.

Manufacturer Manuals: Accessing official documentation helps in understanding specific models and their unique features, ensuring proper maintenance.

Books and eBooks: Many publications focus on engine repair and maintenance, offering detailed explanations and illustrations to support learning.

Workshops and Courses: Enrolling in hands-on training sessions can provide direct experience, allowing you to delve into engine repair techniques with expert guidance.