The intricate design of modern V-type engines showcases a harmonious blend of engineering precision and functionality. Each component plays a pivotal role in ensuring optimal performance, longevity, and reliability. Grasping the layout and interconnections of these essential elements is crucial for anyone involved in maintenance or enhancement of such machinery.

Exploring the various sections reveals how each part contributes to the overall efficiency of the engine. Knowledge of these elements not only aids in troubleshooting but also enhances the capability for customization. Whether you’re a seasoned mechanic or a novice enthusiast, delving into this subject will equip you with the ultimate understanding necessary for effective engine management.

Moreover, familiarity with the specific components allows for informed decisions regarding repairs and upgrades. This knowledge is indispensable for maximizing the potential of your engine, ensuring that it operates smoothly and efficiently. Ultimately, the pursuit of understanding these intricate mechanisms leads to improved performance and satisfaction in your mechanical endeavors.

Understanding Briggs and Stratton V-Twin Engines

This section explores the intricacies of a specific type of engine known for its performance and reliability. These power units are engineered to deliver robust output while maintaining efficiency, making them popular in various applications. By delving into their design and functionality, one can appreciate the craftsmanship involved in creating these machines.

Key Features

The unique architecture of these engines provides enhanced torque and power delivery. With two cylinders operating in a synchronized manner, they offer smoother operation and reduced vibration. Additionally, their compact design allows for versatile installation options, catering to a range of equipment needs.

Maintenance Insights

Key Components of V-Twin Design

The V-engine configuration has become a popular choice for various applications due to its unique characteristics and efficient performance. This design offers a compact structure while delivering powerful output, making it ideal for different types of machinery. Understanding the essential elements of this configuration is crucial for anyone looking to grasp its functionality and maintenance requirements.

| Component | Description |

|---|---|

| Cylinder Blocks | These house the pistons and are crucial for compression and power generation. |

| Crankshaft | This component converts the linear motion of the pistons into rotational motion. |

| Camshaft | It regulates the timing of valve openings and closings, influencing engine performance. |

| Valves | These allow air and fuel into the combustion chamber and expel exhaust gases. |

| Intake Manifold | This directs the air-fuel mixture into the cylinders for combustion. |

| Exhaust Manifold | It channels exhaust gases away from the engine, enhancing efficiency. |

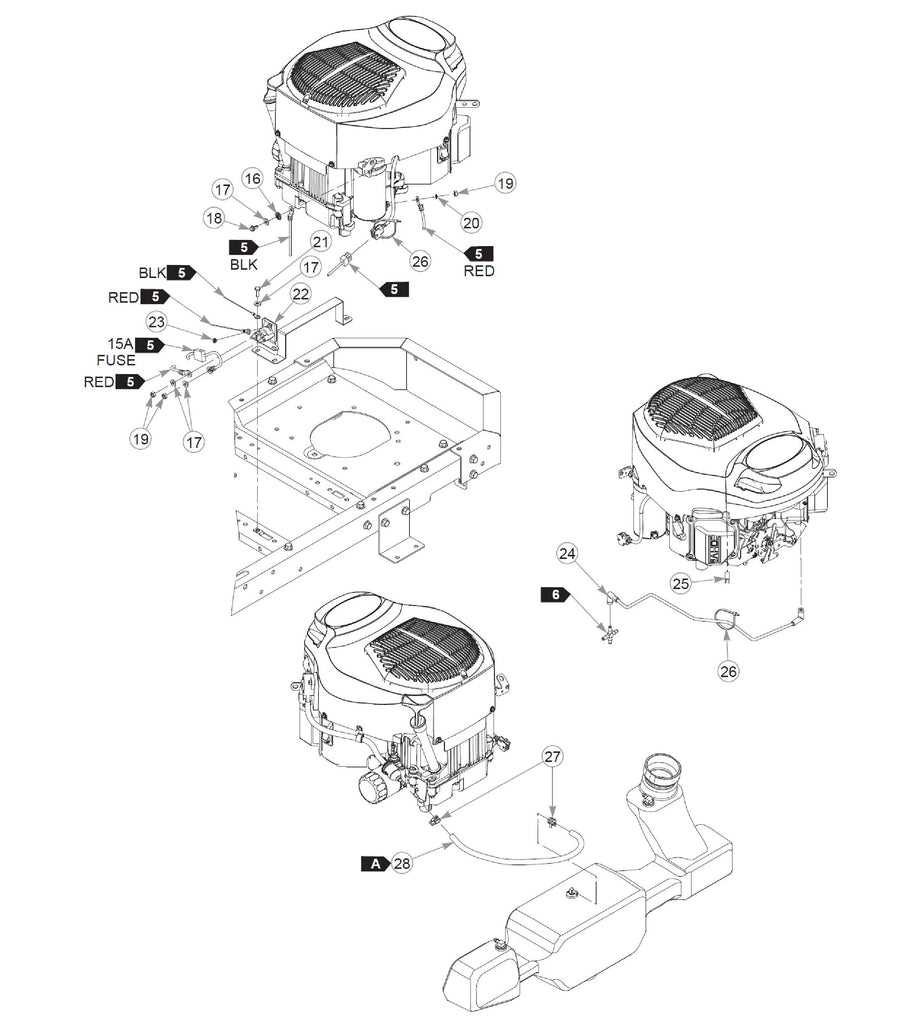

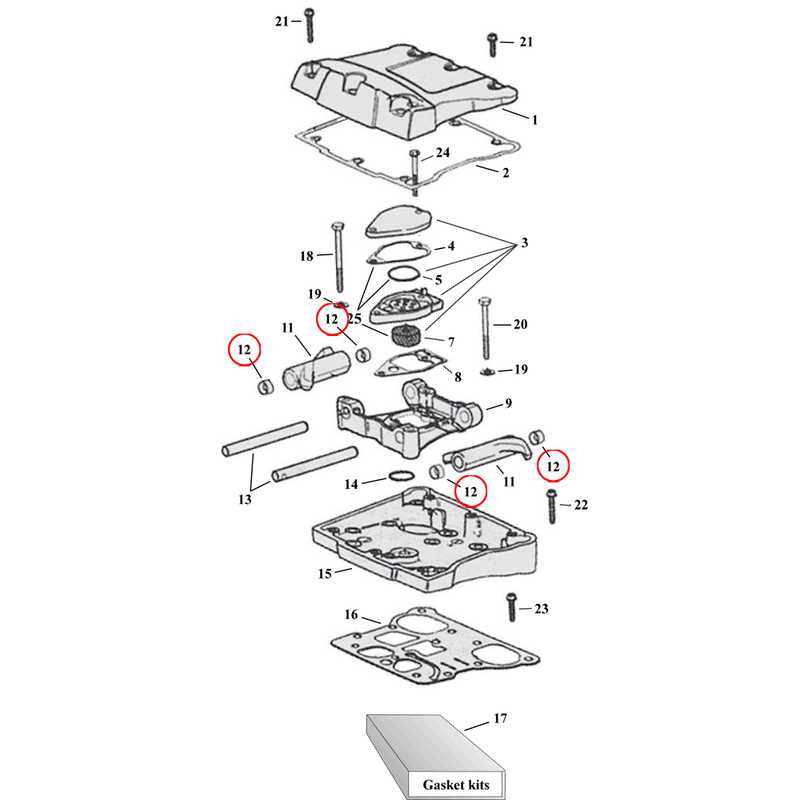

Importance of Accurate Parts Diagrams

Detailed visual representations of components are essential for maintenance and repair tasks. They provide clarity on how each element fits together, reducing confusion and enhancing efficiency. Understanding these illustrations helps technicians and hobbyists alike ensure proper assembly and functionality of machinery.

Enhancing Repair Efficiency

Having precise visual guides can significantly speed up the repair process. Users can quickly identify the required components, minimizing downtime and streamlining workflow.

Avoiding Costly Mistakes

Inaccurate representations can lead to misdiagnosis or incorrect part replacements. This not only wastes time but can also incur additional costs, making reliability crucial for successful repairs.

| Benefit | Description |

|---|---|

| Clarity | Clear visuals prevent confusion during assembly. |

| Efficiency | Speeds up the identification of necessary components. |

| Accuracy | Reduces the risk of errors and incorrect installations. |

How to Interpret Engine Diagrams

Understanding mechanical illustrations is crucial for effective maintenance and repair. These visual aids provide essential information about the structure and components of an engine, enabling users to identify parts and their relationships.

Key Elements to Look For

- Labels: Each component is often labeled for easy identification.

- Lines and Arrows: These indicate connections and the flow of fluids or energy.

- Symbols: Recognizing standard symbols can simplify understanding.

Steps for Interpretation

- Start with the legend to understand symbols and terminology.

- Identify the main components and their functions.

- Trace connections to comprehend how parts interact.

- Refer to manuals for additional context if needed.

Common Issues with V-Twin Engines

V-engine configurations are popular for their power and efficiency, but they can encounter several challenges that may affect performance and longevity. Understanding these common issues can help in maintaining optimal function and ensuring a longer lifespan.

1. Overheating

Overheating is a frequent problem in V-configured engines, often caused by:

- Inadequate coolant levels

- Blocked cooling fins

- Faulty thermostat

- Poor airflow due to debris

Regular checks and maintenance can prevent severe damage.

2. Oil Leaks

Oil leakage can lead to significant issues, such as:

- Increased wear and tear

- Reduced lubrication

- Potential engine failure

Common sources of leaks include worn gaskets, seals, and improperly tightened bolts. Routine inspections are essential to catch these issues early.

Essential Tools for Maintenance

Regular upkeep of machinery requires specific instruments to ensure optimal performance and longevity. These essential implements not only facilitate repairs but also enhance efficiency during routine checks.

Basic Hand Tools

Every maintenance kit should include a range of basic hand tools such as wrenches, screwdrivers, and pliers. These tools are crucial for tightening or loosening components, making adjustments, and performing minor repairs. Quality and durability are vital when selecting these items to withstand frequent use.

Safety Equipment

Ensuring safety while conducting maintenance is paramount. Items like gloves, goggles, and masks protect against potential hazards. Investing in reliable safety gear not only safeguards the technician but also promotes a safe working environment.

Replacement Parts: What to Consider

When seeking components for engine maintenance, it’s crucial to assess various factors that influence both performance and longevity. Selecting the right replacements can significantly enhance functionality and prevent future issues.

Quality vs. Cost

Balancing quality with budget constraints is essential. Investing in high-quality components often leads to better performance and durability, while cheaper alternatives may save money initially but can result in more frequent replacements.

Compatibility

Ensuring that chosen components are compatible with the specific engine model is vital. Always refer to manufacturer specifications to avoid any mismatches that could lead to inefficient operation or damage.

Identifying Genuine vs. Aftermarket Parts

Understanding the differences between authentic components and their alternatives is crucial for optimal performance and longevity of machinery. Recognizing these distinctions can help users make informed decisions, ensuring they select the best option for their specific needs.

Key Characteristics

Genuine components typically exhibit higher quality standards and durability, while aftermarket options may vary widely in performance and reliability. Here are some factors to consider:

| Feature | Genuine Components | Aftermarket Options |

|---|---|---|

| Quality | Consistent, high standards | Variable quality |

| Warranty | Manufacturer’s warranty | Limited or no warranty |

| Fit | Perfect fit and compatibility | May require modifications |

Conclusion

In conclusion, assessing the authenticity of components is essential for ensuring the efficiency and reliability of your equipment. By understanding the key features, users can ultimately make choices that best suit their machinery’s performance requirements.

Steps for Disassembling a V-Twin Engine

Disassembling a V-engine requires careful attention to detail and methodical steps to ensure successful reassembly. Understanding the structure and components is essential for any maintenance or repair work.

Preparation and Tools

Before starting, gather the necessary tools: wrenches, screwdrivers, and a torque wrench. Ensure a clean workspace to avoid losing any small components. Review the manual for specific guidance related to the engine model.

Disassembly Process

Begin by disconnecting the battery and draining fluids. Remove the outer casing and components like the air filter and exhaust system. Label each part as you go to facilitate reassembly. Pay attention to the orientation of each piece, ensuring everything is properly documented for the ultimate reconstruction.

Note: Always consult the manufacturer’s manual for specific instructions and torque specifications.

Tips for Reassembling Your Engine

Reassembling your engine requires careful attention to detail and a systematic approach. By following specific strategies, you can ensure that each component fits perfectly and functions optimally, enhancing the performance and longevity of your machinery.

Preparation Steps

- Gather all necessary tools and components before starting.

- Refer to a detailed manual or guide for reference.

- Clean all parts thoroughly to remove dirt and debris.

Reassembly Process

- Start by organizing components in the order of assembly.

- Apply lubrication to moving parts to reduce friction.

- Double-check all connections and ensure tightness to prevent leaks.

- Test functionality after reassembly before full operation.

Maintenance Schedule for V-Twin Engines

Regular upkeep is essential for the longevity and performance of high-performance engines. Establishing a systematic maintenance plan ensures optimal functionality and reduces the risk of unexpected failures. By adhering to a structured schedule, users can significantly enhance the reliability and efficiency of their machinery.

Daily Checks: Before each use, inspect the oil level and fuel quality. Look for any signs of leaks or unusual noises, which could indicate underlying issues.

Weekly Maintenance: Clean the air filter and check the spark plugs. Replace them if they appear worn or damaged. Also, tighten any loose components to prevent vibrations from causing further wear.

Monthly Tasks: Change the oil and replace the oil filter to ensure proper lubrication. Additionally, inspect the battery terminals and clean them to maintain a good connection.

Seasonal Care: At the beginning of each season, conduct a comprehensive inspection. Check belts, hoses, and other vital components for wear. It’s also advisable to sharpen blades if applicable.

Annual Service: Schedule a professional tune-up at least once a year. This should include a thorough examination of the engine, fuel system, and electrical components to catch any potential issues early.

Following this maintenance schedule will not only prolong the life of the engine but also enhance its overall performance, ensuring that it runs smoothly for years to come.

Resources for Further Learning

Expanding your knowledge on small engine maintenance and repair can significantly enhance your skills and understanding of mechanics. There are numerous resources available that provide valuable insights, tutorials, and detailed information on various engine components and their functions.

Books are an excellent starting point for anyone looking to deepen their expertise. Consider titles that cover engine theory, troubleshooting techniques, and maintenance practices. These can serve as comprehensive guides that you can refer to repeatedly.

Online forums and communities are another great way to connect with experienced mechanics and hobbyists. Participating in discussions can help you gain practical tips and real-world solutions to common challenges.

Video tutorials on platforms like YouTube can provide visual guidance for specific repairs and upgrades. Watching experienced technicians work through problems can clarify complex concepts and techniques.

Finally, manufacturer websites often offer valuable resources, including service manuals and specification sheets. These documents can provide crucial information about assembly and disassembly processes, ensuring that you have the correct details for your projects.

By utilizing these resources, you can build a solid foundation of knowledge that will serve you well in your endeavors with small engines.