The intricate structure of small engines is essential for their efficient operation and maintenance. Familiarizing oneself with the arrangement of these elements is crucial for anyone looking to troubleshoot issues or conduct repairs. By gaining insights into how each piece interacts, users can enhance performance and longevity.

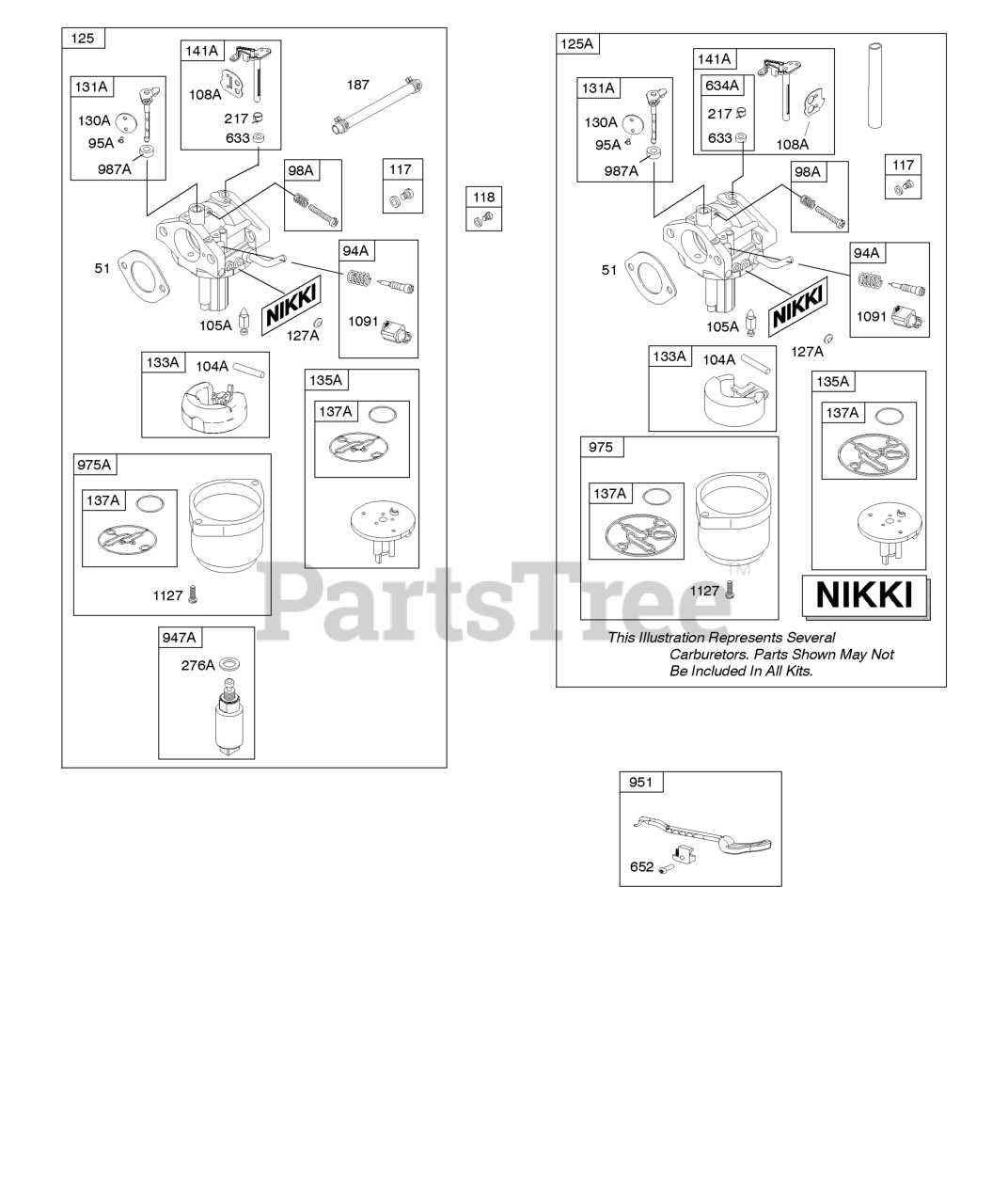

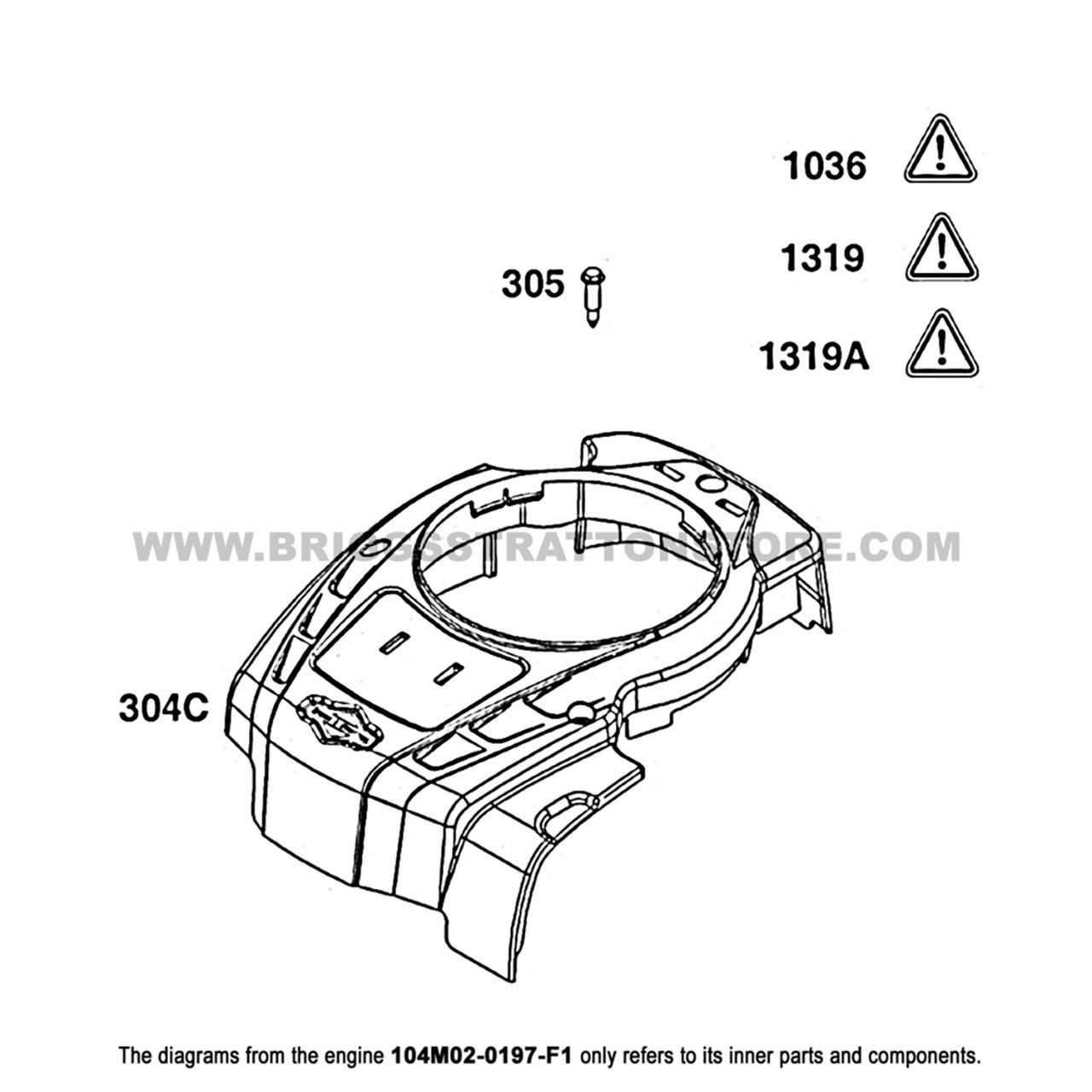

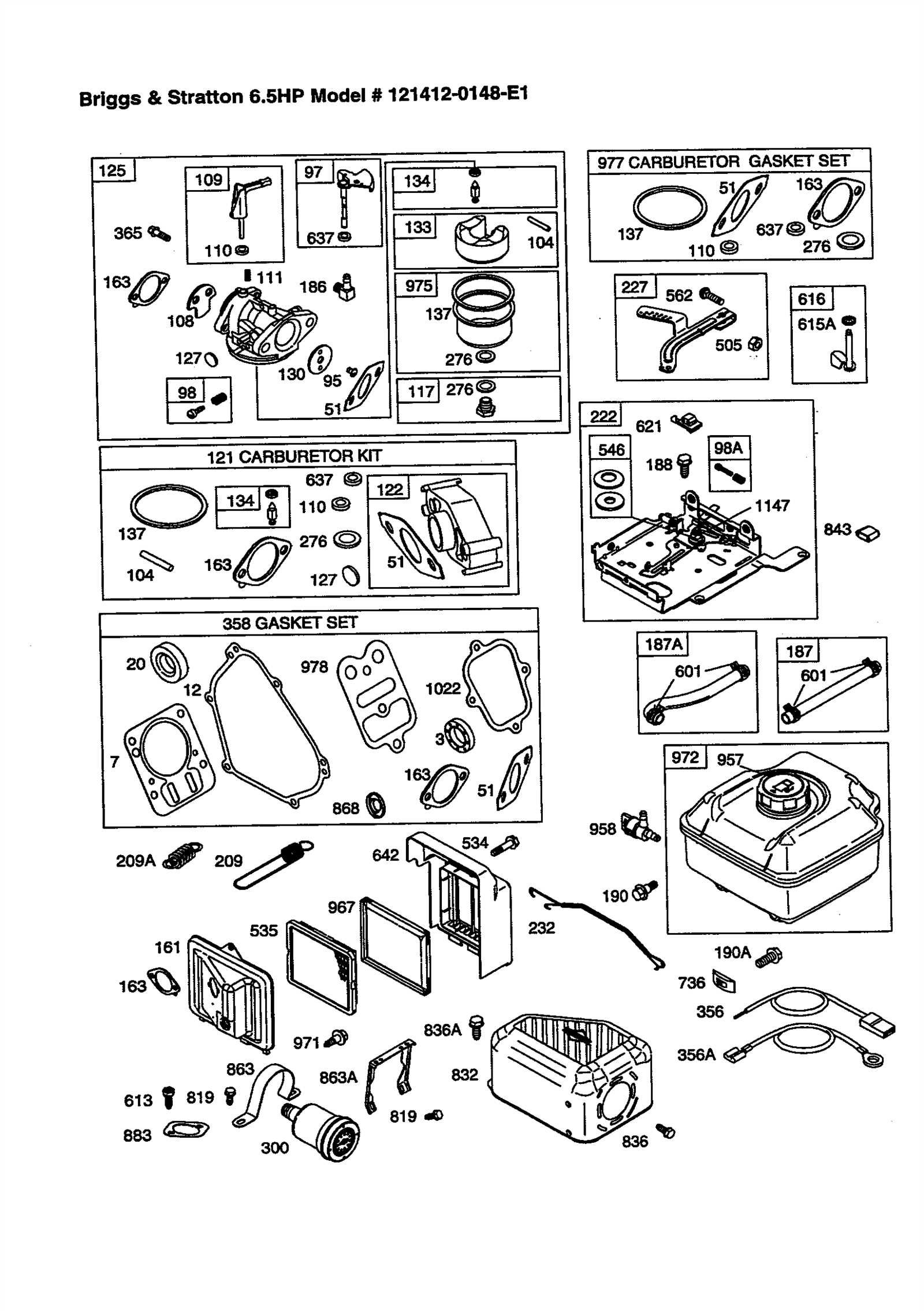

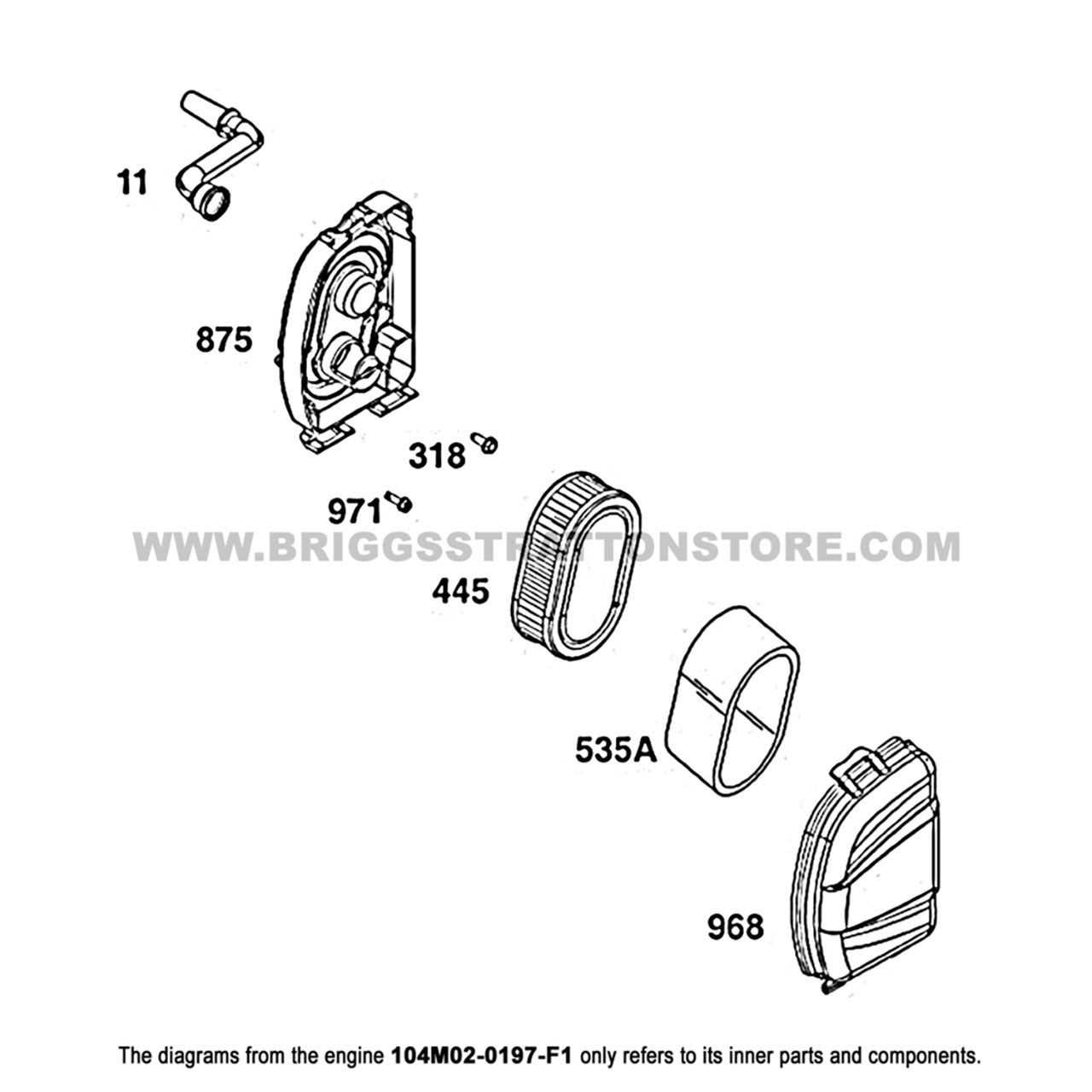

For enthusiasts and mechanics alike, having access to a clear illustration of the various components can make all the difference. Such visual guides not only simplify the identification of specific sections but also provide valuable context for understanding how to effectively address potential malfunctions.

Whether you’re embarking on a restoration project or simply performing routine upkeep, knowing the layout of engine elements empowers users to work with confidence. Engaging with these resources transforms the often daunting task of maintenance into a more approachable and manageable experience.

Understanding Engine Component Functions

Every mechanical system relies on a variety of elements working in unison to achieve optimal performance. In engines, each component plays a vital role in converting fuel into motion, ensuring efficiency and reliability. Recognizing the function of these individual parts helps in understanding how they contribute to the overall operation of the machine.

The cylinder serves as the chamber where fuel combustion occurs, generating the necessary power to drive the pistons. Meanwhile, the crankshaft transforms the linear motion of the pistons into rotational force, which ultimately powers the drivetrain. Additionally, the valve assembly regulates the flow of air and fuel into the cylinder, as well as the expulsion of exhaust gases, playing a crucial role in maintaining engine efficiency.

Moreover, the ignition system ensures the fuel-air mixture ignites at the right moment, significantly impacting performance and fuel efficiency. Components such as the carburetor or fuel injection system manage the mixture of air and fuel, further influencing the combustion process. Understanding these functions provides valuable insight into the intricate workings of engines and highlights the importance of regular maintenance for optimal functionality.

Identifying Key Replacement Parts

When maintaining small engine equipment, recognizing essential components is crucial for ensuring optimal performance and longevity. Familiarity with these vital elements can aid in diagnosing issues and facilitating effective replacements when necessary.

Common elements to focus on include the ignition assembly, air filtration system, and fuel delivery mechanisms. Each of these parts plays a significant role in the engine’s overall functionality. By understanding their locations and functions, users can quickly identify when replacements are needed, ultimately enhancing the efficiency of the machinery.

Regular inspections can help in spotting wear and tear, ensuring timely interventions. It is advisable to refer to comprehensive manuals that detail these components for further clarity. Having this knowledge empowers users to maintain their equipment effectively, reducing downtime and improving productivity.

Exploring Assembly and Disassembly Techniques

Understanding the methods for assembling and disassembling mechanical components is essential for efficient maintenance and repair. Proper techniques not only enhance the longevity of equipment but also ensure safety during the process. This section delves into the fundamental practices and tools required for effective reassembly and disassembly of mechanical systems.

Key Tools for Effective Assembly

Utilizing the right tools can significantly streamline the process. Here’s a list of essential instruments:

| Tool | Purpose |

|---|---|

| Socket Set | Used for fastening and loosening nuts and bolts |

| Screwdrivers | Ideal for driving screws into place or removing them |

| Pliers | Useful for gripping and twisting components |

| Torque Wrench | Ensures bolts are tightened to specified tension |

Steps for Disassembling Components

Disassembling machinery requires a systematic approach to avoid damage and ensure that all parts are accounted for. Follow these general steps:

- Identify and gather necessary tools.

- Carefully document the current configuration for reference during reassembly.

- Remove any covers or protective components.

- Detach parts methodically, starting from the outer components and working inward.

- Store removed pieces in labeled containers to maintain organization.

Common Maintenance Practices for Longevity

Ensuring the extended lifespan of outdoor power equipment requires regular upkeep and attention. By implementing effective maintenance routines, users can enhance performance, reduce wear, and prevent costly repairs. This section highlights essential practices that contribute to the durability of engines and their components.

- Regular Oil Changes: Keeping the lubricant fresh is crucial for optimal operation. Changing the oil according to the manufacturer’s recommendations helps maintain engine health.

- Air Filter Maintenance: A clean air filter ensures proper airflow and engine efficiency. Inspecting and replacing the filter as needed can prevent dirt and debris from entering the engine.

- Spark Plug Inspection: Checking and replacing spark plugs periodically can enhance ignition efficiency and fuel combustion, contributing to smoother operation.

- Fuel System Care: Using high-quality fuel and treating it with stabilizers can prevent corrosion and keep the fuel system clean. Draining fuel when the equipment is not in use for extended periods is also advisable.

- Inspecting Belts and Cables: Regularly examining belts and cables for signs of wear or damage ensures reliable operation. Replacing worn components promptly can avoid breakdowns.

By following these maintenance practices, users can significantly improve the performance and longevity of their equipment, ensuring reliable service for years to come.

Diagnosing Common Mechanical Issues

Identifying prevalent mechanical problems is crucial for maintaining the efficiency and longevity of small engines. Understanding the symptoms and signs can aid in quick troubleshooting and effective repairs, minimizing downtime and preventing further damage.

Typical Symptoms to Watch For

- Difficulty starting the engine

- Unusual noises during operation

- Excessive vibration

- Inconsistent power output

- Leaks of fluids

Steps for Effective Troubleshooting

- Observe the engine while it is running to identify any irregularities.

- Check fluid levels, including oil and fuel, to ensure they are within recommended ranges.

- Inspect for visible damage, such as cracks or loose components.

- Examine the air filter for clogs that might hinder airflow.

- Consult a service manual to understand specific components and their functions.

By systematically analyzing these common indicators, individuals can effectively diagnose issues and implement necessary repairs, ensuring optimal performance and reliability.

Utilizing Diagrams for Accurate Repairs

Employing visual representations can significantly enhance the repair process. These illustrations provide a clear overview of the components and their interconnections, allowing for a better understanding of how everything functions together. When tackling maintenance tasks, having a visual guide can lead to more efficient and precise repairs.

Visual aids not only simplify complex structures but also help in identifying worn or damaged elements that need replacement. By consulting these resources, technicians can ensure that they are working with the correct specifications and avoid common pitfalls associated with misinterpretation. The clarity offered by these guides leads to a more streamlined workflow.

Furthermore, utilizing these visuals can improve the confidence of individuals undertaking repairs. Knowing that a reliable reference is available reduces uncertainty and fosters a more methodical approach. This ultimately leads to a higher quality of workmanship and greater satisfaction with the completed tasks.

Choosing Quality Replacement Components

When it comes to maintaining outdoor equipment, selecting superior replacement elements is crucial for ensuring optimal performance and longevity. Quality components not only enhance the functionality of your machinery but also contribute to its overall reliability. Understanding how to identify and procure these essential items can significantly impact your maintenance efforts.

First and foremost, consider the manufacturer’s reputation. Opt for components produced by well-known brands that have established trust within the industry. Genuine products are often designed to meet specific performance standards, which can be a decisive factor in achieving the best results. Additionally, always check for compatibility with your existing machinery to avoid any issues during installation.

Another aspect to keep in mind is the availability of support and resources. Quality manufacturers typically offer extensive documentation and customer assistance, making it easier to address any concerns that may arise. Investing in quality components will not only save time and effort in the long run but also ensure that your equipment operates efficiently for years to come.

Safety Precautions During Repairs

When undertaking maintenance on machinery, ensuring personal safety is paramount. Observing essential safety measures can prevent accidents and injuries, creating a secure environment for repairs. Understanding and implementing these guidelines is crucial for both novice and experienced technicians.

Essential Safety Guidelines

Adhering to fundamental safety practices can significantly reduce risks during repair activities. Here are key precautions to keep in mind:

| Precaution | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear appropriate gear, including gloves, goggles, and sturdy footwear, to shield yourself from potential hazards. |

| Proper Ventilation | Ensure the workspace is well-ventilated to prevent the buildup of harmful fumes or gases during repair tasks. |

| Tools Inspection | Regularly check tools for damage or wear before use to avoid malfunctions that could lead to injury. |

| Emergency Equipment | Have first aid kits and fire extinguishers accessible and ensure all individuals know their locations. |

Additional Considerations

It is advisable to familiarize yourself with the machinery’s manual to understand specific safety warnings and procedures. Staying alert and focused during repairs can prevent mishaps and ensure a successful maintenance experience.

Accessing Online Parts Resources

In today’s digital age, obtaining essential components for machinery has become more straightforward than ever. The internet offers a wealth of information and tools that can assist enthusiasts and professionals alike in locating the right items for their repairs or upgrades. From manufacturer websites to specialized retailers, there are numerous avenues to explore when searching for specific items.

Manufacturer Websites

One of the most reliable sources for finding replacement components is directly through the official manufacturer’s website. These platforms typically provide comprehensive catalogs that outline available items, including specifications and compatibility details. Users can often search by model or type, ensuring they find the correct piece for their needs.

Online Retailers and Marketplaces

Numerous online retailers and marketplaces have emerged, offering a diverse range of options for those in need of components. These sites often feature user reviews, making it easier to assess the quality and reliability of different offerings. Additionally, many platforms provide helpful filtering tools that allow customers to narrow down their choices based on specific criteria.

Comparing Aftermarket vs. OEM Parts

When it comes to maintaining outdoor power equipment, the choice between original and alternative components can significantly impact performance and longevity. Understanding the nuances of these two options is essential for making informed decisions that align with your specific needs.

Original components are produced by the equipment manufacturer and are designed to meet exact specifications. In contrast, alternative components are made by third-party companies and may vary in quality and compatibility. Here are some key points to consider:

- Quality Control: Original components typically undergo rigorous testing to ensure reliability, while alternative options may lack the same level of scrutiny.

- Cost: Alternative components are often more affordable, making them an attractive option for budget-conscious consumers.

- Availability: Original components can sometimes be difficult to source, whereas alternative options are usually more readily available through various retailers.

- Performance: While original components are designed for optimal performance, some alternative components can offer comparable results, although this is not guaranteed.

Ultimately, the decision between original and alternative components will depend on factors such as budget, availability, and personal preferences regarding quality and performance. Careful consideration of these aspects can help ensure the longevity and efficiency of your equipment.