When delving into the intricate world of marine machinery, having a clear overview of the essential components is crucial. This section focuses on the configuration and organization of various elements that contribute to the overall functionality of the engine. By grasping how these pieces interrelate, one can enhance both maintenance and performance.

Visualizing the arrangement of engine components allows enthusiasts and professionals alike to identify specific parts more easily. With an organized layout, it becomes simpler to understand the operational mechanisms and troubleshoot potential issues that may arise during usage.

Furthermore, familiarizing oneself with the individual elements can lead to improved efficiency in repairs and upgrades. Knowing the exact location and role of each component empowers users to make informed decisions regarding maintenance and replacements, ultimately contributing to the longevity of the machinery.

Overview of Suzuki DF115 Components

This section explores the essential elements of an outboard motor, emphasizing their significance and functionality. Understanding these components aids in maintaining optimal performance and ensuring longevity.

Main Components

- Powerhead: The core of the engine, responsible for generating thrust.

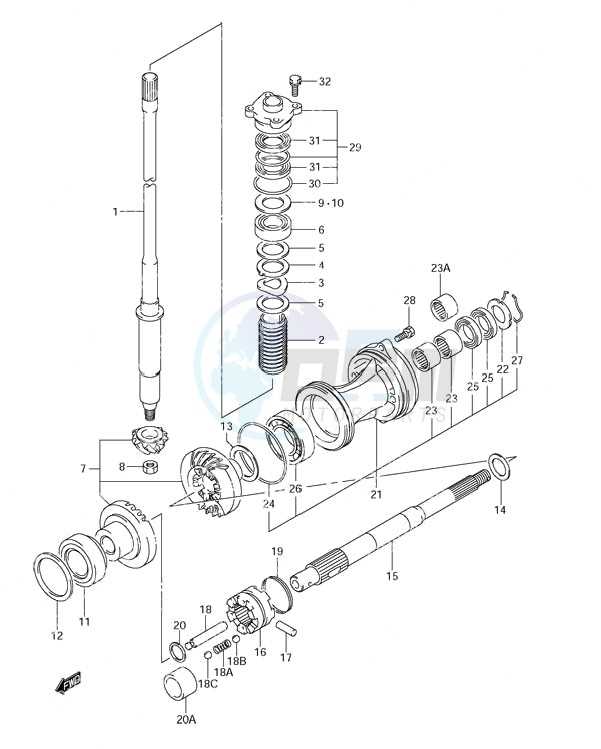

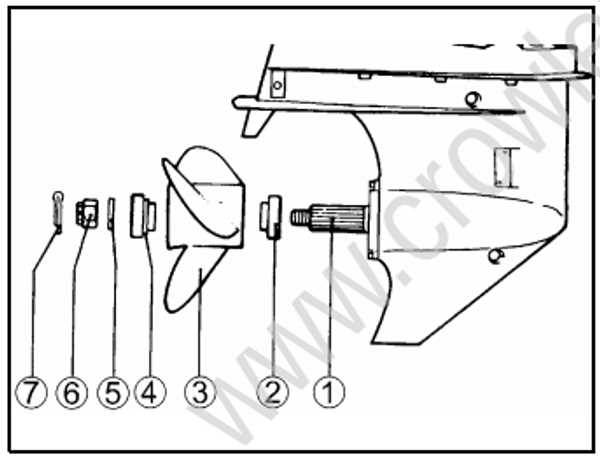

- Lower Unit: Houses the gears and propeller, facilitating movement through water.

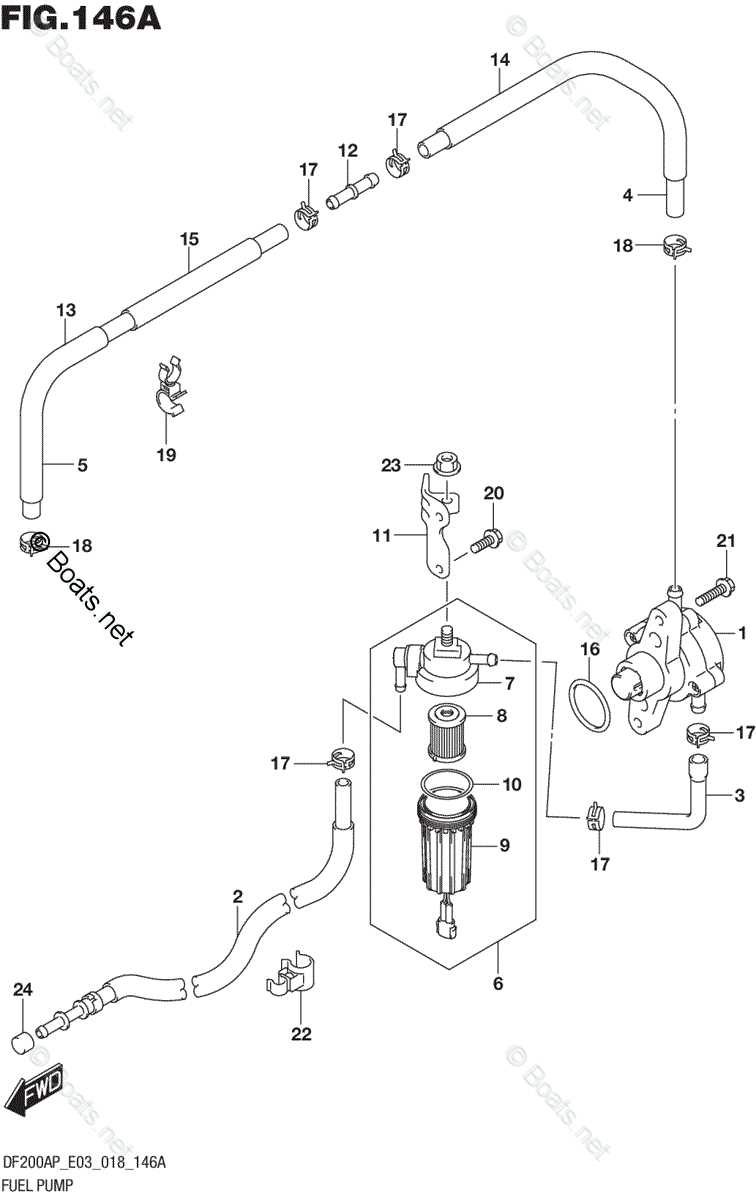

- Fuel System: Ensures proper delivery of fuel to the engine for efficient operation.

- Cooling System: Maintains optimal engine temperature to prevent overheating.

Additional Features

- Ignition System: Initiates combustion, crucial for engine performance.

- Steering Mechanism: Allows for directional control while navigating.

- Control Panel: Displays vital information and controls various functions.

Understanding the Parts Diagram

The schematic representation of components is essential for comprehending how various elements interact within a mechanism. This visual aid facilitates a clearer understanding of the assembly and functionality of the system.

Importance of Component Representation

Recognizing each element’s position and role contributes significantly to effective maintenance and troubleshooting. Here are some key benefits:

- Enhances knowledge of the assembly structure.

- Assists in identifying compatible replacements.

- Streamlines the repair process by providing clarity.

How to Read the Schematic

Interpreting the schematic involves a few straightforward steps:

- Identify the key symbols representing different components.

- Note the connections and pathways between elements.

- Refer to the accompanying legend for additional information.

By following these steps, one can gain a comprehensive understanding of how each part contributes to the overall operation.

Key Features of DF115 Engine

The engine in focus boasts a range of impressive characteristics that enhance its performance and reliability. Designed for optimal efficiency, it delivers a powerful output while maintaining fuel economy.

Advanced Technology: Incorporating innovative engineering, this motor features electronic fuel injection that ensures precise fuel delivery, resulting in reduced emissions and improved throttle response.

Durability: Crafted from high-quality materials, the structure of this engine provides long-lasting performance, even in challenging environments. Its robust design helps withstand the rigors of marine conditions.

Maintenance-Friendly: The layout promotes easy access to critical components, simplifying routine inspections and servicing. This feature is essential for maintaining peak operational efficiency.

Lightweight Design: Its compact and lightweight construction not only enhances maneuverability but also contributes to better overall vessel handling, making it an excellent choice for various applications.

Identifying Replacement Parts

When maintaining and repairing marine engines, understanding how to locate suitable components is essential for ensuring optimal performance and longevity. This process involves recognizing specific elements that may need substitution and knowing where to find appropriate replacements.

Begin by familiarizing yourself with the engine’s assembly. A comprehensive overview can help you pinpoint which components are prone to wear or damage.

- Review the manufacturer’s specifications to understand recommended replacements.

- Consult service manuals or technical documents for detailed illustrations and descriptions of various elements.

- Utilize online forums or communities where enthusiasts share insights and recommendations regarding compatible components.

Additionally, consider the following tips when sourcing replacements:

- Verify compatibility with your engine’s model and specifications.

- Opt for high-quality components to ensure durability and reliability.

- Keep a record of previous replacements to track maintenance history.

By taking these steps, you can effectively identify and source the necessary components for your marine engine, ensuring it operates smoothly and efficiently.

Maintenance Tips for DF115

Regular upkeep is essential for ensuring optimal performance and longevity of your marine engine. By following specific guidelines, you can enhance reliability and efficiency while minimizing potential issues.

- Check Fluid Levels: Regularly inspect oil and coolant levels to prevent overheating and engine damage.

- Inspect Fuel System: Ensure that fuel filters are clean and replace them as needed to avoid clogging.

- Clean Air Filters: Keep air intake systems clear to promote efficient combustion.

Following these steps not only preserves the engine’s functionality but also helps identify minor issues before they escalate into major repairs.

- Schedule regular professional inspections to ensure comprehensive checks.

- Keep the exterior clean to prevent corrosion and other environmental damage.

- Utilize high-quality lubricants and fuels to enhance engine performance.

Common Issues and Solutions

In the realm of marine engines, various challenges can arise that may affect performance and reliability. Understanding these common problems and their corresponding remedies is essential for maintaining optimal functionality.

- Overheating: This issue often stems from insufficient coolant flow or a blocked cooling system. Regular maintenance and inspections can help prevent this.

- Fuel System Problems: Clogged filters or fuel lines can lead to poor engine performance. Ensure regular replacement of filters and check for any blockages.

- Electrical Failures: Issues with the ignition system or battery can result in starting difficulties. Regularly inspect electrical connections and battery condition.

Implementing preventive measures can significantly reduce the occurrence of these issues. Regular check-ups and maintenance routines are vital to ensuring longevity and efficiency.

Performance Enhancements for DF115

Improving the performance of outboard engines can significantly enhance overall boating experiences. Various modifications can optimize efficiency, increase power output, and improve fuel consumption. Here are several strategies to achieve better performance from your engine.

- Upgrade the Propeller: Selecting the right propeller can make a substantial difference in acceleration and top speed. Consider materials and pitch that suit your specific needs.

- Adjust the Engine Trim: Proper trimming can maximize speed and fuel efficiency. Experiment with different angles to find the optimal setting for various conditions.

- Engine Tuning: Regular maintenance and tuning can ensure the engine runs smoothly. Check ignition timing and fuel mixture for optimal performance.

- Enhanced Fuel System: Upgrading fuel filters and injectors can improve fuel flow and combustion efficiency, leading to better performance.

- Weight Reduction: Minimizing the load on the vessel can enhance speed and responsiveness. Remove unnecessary items and consider lightweight materials for essential gear.

Implementing these enhancements can lead to noticeable improvements in speed, handling, and overall engine performance. Regular assessment and fine-tuning are key to achieving the best results.

Installing Aftermarket Accessories

Adding aftermarket components to your marine vessel can significantly enhance its performance and functionality. Whether you’re looking to improve navigation, increase comfort, or boost aesthetic appeal, a variety of options are available to suit your needs.

Before proceeding with the installation, it’s crucial to ensure that the selected accessories are compatible with your existing setup. Research the specifications and read user reviews to gauge their effectiveness and reliability. Proper installation is essential for optimal performance and longevity, so consider consulting professional guidelines or manuals when necessary.

Once compatibility is confirmed, gather the required tools and equipment for installation. Taking your time during the process can prevent mistakes and ensure that all components are securely attached. Following the manufacturer’s instructions will help you achieve the best results, allowing you to enjoy the benefits of your new additions with confidence.

Importance of Genuine Parts

Using authentic components in any mechanical system is crucial for optimal performance and longevity. These original elements are specifically designed to fit and function seamlessly within the machine, ensuring reliability and efficiency. Their quality significantly impacts the overall operation, reducing the risk of malfunctions and costly repairs.

When selecting replacements, it’s essential to consider the advantages of genuine options over generic alternatives. Authentic items not only offer superior durability but also often come with warranties that provide additional peace of mind. Here’s a comparison that highlights the key benefits:

| Feature | Genuine Components | Generic Alternatives |

|---|---|---|

| Quality | High | Variable |

| Compatibility | Perfect Fit | May Not Fit Properly |

| Durability | Long-lasting | Shorter Lifespan |

| Warranty | Yes | No |

Investing in authentic components ultimately ensures that the machinery operates at its best, preserving its value and functionality for years to come.

Visual Guide to DF115 Layout

This section provides an insightful overview of the configuration of a specific outboard motor, emphasizing its key components and their arrangements. Understanding this layout is essential for effective maintenance and repairs.

- Engine Block: The heart of the unit, housing critical mechanisms.

- Fuel System: Includes injectors and fuel lines essential for operation.

- Cooling System: Comprises water intake and cooling passages to regulate temperature.

- Ignition System: Encompasses spark plugs and wiring crucial for starting the engine.

- Gearcase: Houses the propeller and related components for propulsion.

Each part plays a vital role in the overall functionality, making a comprehensive understanding of the layout invaluable for anyone involved in maintenance or repair tasks.