In this section, we delve into the intricate configuration details of a specific marine engine component. Understanding the arrangement and functionality of these intricate elements is crucial for both maintenance and repair purposes.

Unveiling the Inner Mechanisms: Delving deep into the internal workings unveils a network of interconnected parts that harmoniously contribute to the overall functionality.

Identifying Key Components: By scrutinizing each critical element’s placement and role, we gain a comprehensive understanding of how they interact within the larger system.

Suzuki DF6 Parts Diagram Article Outline

This section will provide a detailed framework for understanding the key components of a marine engine. The focus will be on breaking down each crucial element to offer clarity on their functions and how they contribute to the overall performance of the system. Through this breakdown, readers will gain insights into how the individual parts interact to ensure smooth operation.

To begin, we’ll categorize the parts into logical groups, each representing a specific area of the engine. These categories will help readers navigate through the technical details with ease. The layout will also offer a clear, structured approach to understanding how the various parts connect and work together efficiently.

| Category | Key Components | Description |

|---|---|---|

| Engine Components | Cylinder, Piston, Crankshaft | These parts are responsible for generating and converting energy into mechanical movement. |

| Fuel System | Carburetor, Fuel Lines, Fuel Filter | The fuel system ensures the correct delivery of fuel to the engine for combustion. |

| Cooling System | Water Pump, Cooling Hoses, Thermostat | Maintains optimal operating temperature by circulating coolant throughout the engine. |

| Electrical System | Ignition Coil, Spark Plug, Battery | Provides the necessary electrical power for ignition and other functions. |

Understanding the Suzuki DF6 Outboard Engine Components

The power system of a small boat engine consists of a variety of key elements that work together to ensure efficient performance and reliability. Each component plays a crucial role in powering the engine and maintaining smooth operation. A clear understanding of these elements can help boat owners perform basic maintenance, identify potential issues, and enhance the overall performance of their vessels.

The most essential components include:

- Propulsion Mechanism: The unit responsible for transferring the engine’s power to the water, enabling movement.

- Cooling System: A system designed to regulate the temperature of the engine by circulating coolant and expelling heat.

- Fuel Delivery System: Consists of parts responsible for ensuring that fuel reaches the engine in the correct manner and ratio for optimal combustion.

- Ignition System: Responsible for creating the spark that ignites the fuel mixture inside the engine, starting the power cycle.

- Exhaust System: Manages the release of exhaust gases produced during the combustion process, ensuring the engine runs smoothly and safely.

Each of these systems is designed to perform a specific function, and a failure in any one can result in poor performance or complete malfunction. Maintaining these components is key to ensuring long-term reliability and efficiency of the engine.

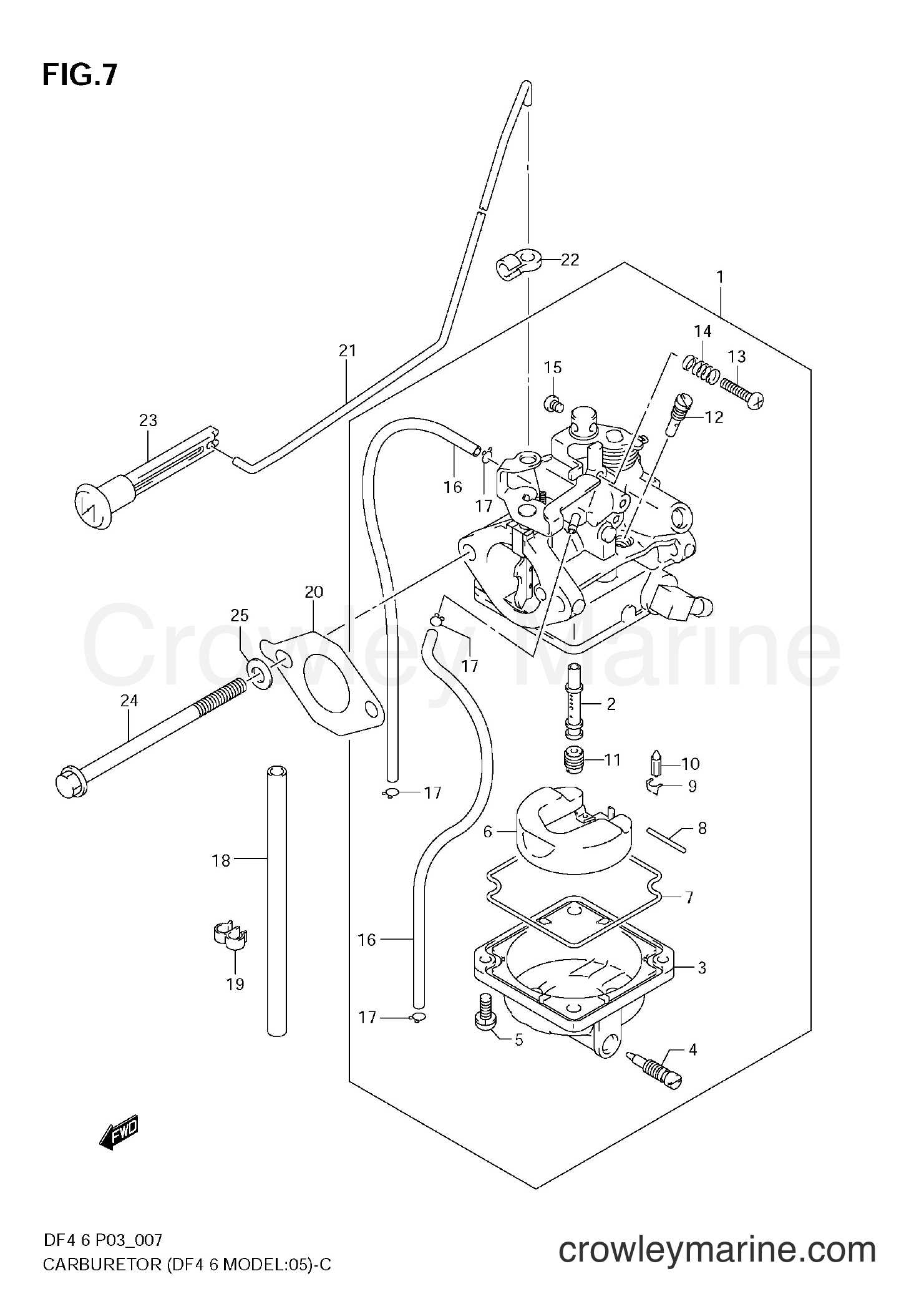

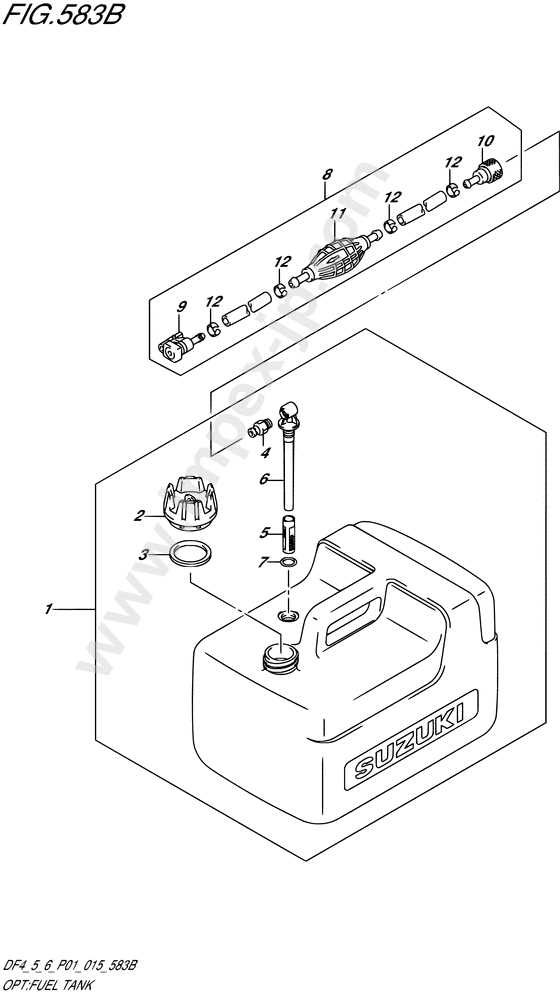

Exploring the Fuel System in the Suzuki DF6

The fuel delivery system in small outboard engines plays a crucial role in ensuring smooth operation and efficient performance. A well-designed fuel system ensures proper fuel flow, clean combustion, and reliable starting. Understanding the components and their functions helps in optimizing the engine’s performance and maintaining its longevity.

Key Components of the Fuel Mechanism

The system typically consists of several interconnected parts that work together to transfer fuel from the tank to the engine’s combustion chamber. These include a fuel pump, fuel filter, carburetor, and fuel lines. Each component has a specific function, such as ensuring fuel cleanliness, preventing blockages, and maintaining the correct fuel pressure for optimal engine operation.

Maintenance and Optimization Tips

Regular maintenance is essential to keep the fuel system in good condition. This includes cleaning or replacing filters, checking fuel lines for leaks or cracks, and ensuring that the pump operates efficiently. Additionally, using high-quality fuel and proper storage methods can prevent common fuel-related issues, like clogging and poor engine performance.

Analyzing the Electrical System of the Suzuki DF6

The electrical components of small marine engines play a crucial role in their overall performance. Understanding how these systems operate ensures proper maintenance and optimization. Key elements include wiring, power distribution, and the connections that control critical functions like ignition and battery charging.

In this section, we will delve into the various electrical components and their interactions within the engine. By examining the layout and functionality of these parts, it becomes possible to diagnose potential issues and improve the efficiency of the power system. Electrical wiring serves as the backbone, connecting the power source to vital systems, while the ignition components ensure smooth starting and running operations.

Additionally, we will explore how the power is regulated and distributed, including the role of voltage regulators and their impact on the engine’s longevity. Proper understanding of these elements helps in maintaining the engine’s electrical health, reducing the risk of malfunctions.

Examining the Cooling System Components

Understanding the essential parts responsible for temperature regulation in marine engines is crucial for optimal performance. The cooling mechanism plays a vital role in maintaining safe operational temperatures, preventing overheating, and ensuring longevity. Key elements within this system work together to regulate the engine’s heat levels, ensuring smooth functioning even under strenuous conditions.

Key Components and Their Roles

The primary components of the temperature regulation system include the pump, thermostat, and heat exchanger. The pump circulates water through the engine to dissipate heat, while the thermostat monitors and controls water flow based on temperature readings. The heat exchanger ensures that the engine receives adequate cooling by transferring excess heat to the surrounding water efficiently.

Ensuring Efficiency and Longevity

Proper maintenance of these parts is essential for preventing damage caused by improper temperature regulation. Regular inspections of the cooling system, along with the use of high-quality components, help maintain system efficiency and extend the engine’s lifespan. Regular cleaning of the heat exchanger and replacing the thermostat at the recommended intervals ensures continuous optimal performance.

Detailing the Propeller and Gearbox Assembly

This section focuses on the essential components responsible for generating propulsion and transferring power in marine engines. The propeller and gearbox are two key elements that work together to drive the vessel forward, ensuring both efficiency and reliability in various water conditions. Understanding their construction and interaction is crucial for maintaining optimal performance.

The assembly consists of several interconnected parts, each playing a vital role in the overall functionality:

- Propeller Blades: These are responsible for converting engine power into thrust. They are typically made from durable materials to withstand harsh marine environments.

- Hub: The central part of the propeller that connects the blades to the gearbox. It houses the mechanism that transmits rotational force.

- Gearbox Housing: This protective casing encloses the gears that regulate the speed and direction of the propeller’s movement.

- Gears: A series of interlocking components that transfer rotational force from the engine to the propeller. They adjust the speed and torque for optimal movement.

- Propeller Shaft: The shaft transmits power from the engine to the propeller. It is crucial for maintaining alignment and preventing vibrations during operation.

Regular inspection and maintenance of these components are essential for preserving the efficiency of the propulsion system. Proper lubrication, alignment checks, and the replacement of worn-out parts can prevent mechanical failure and enhance overall durability.

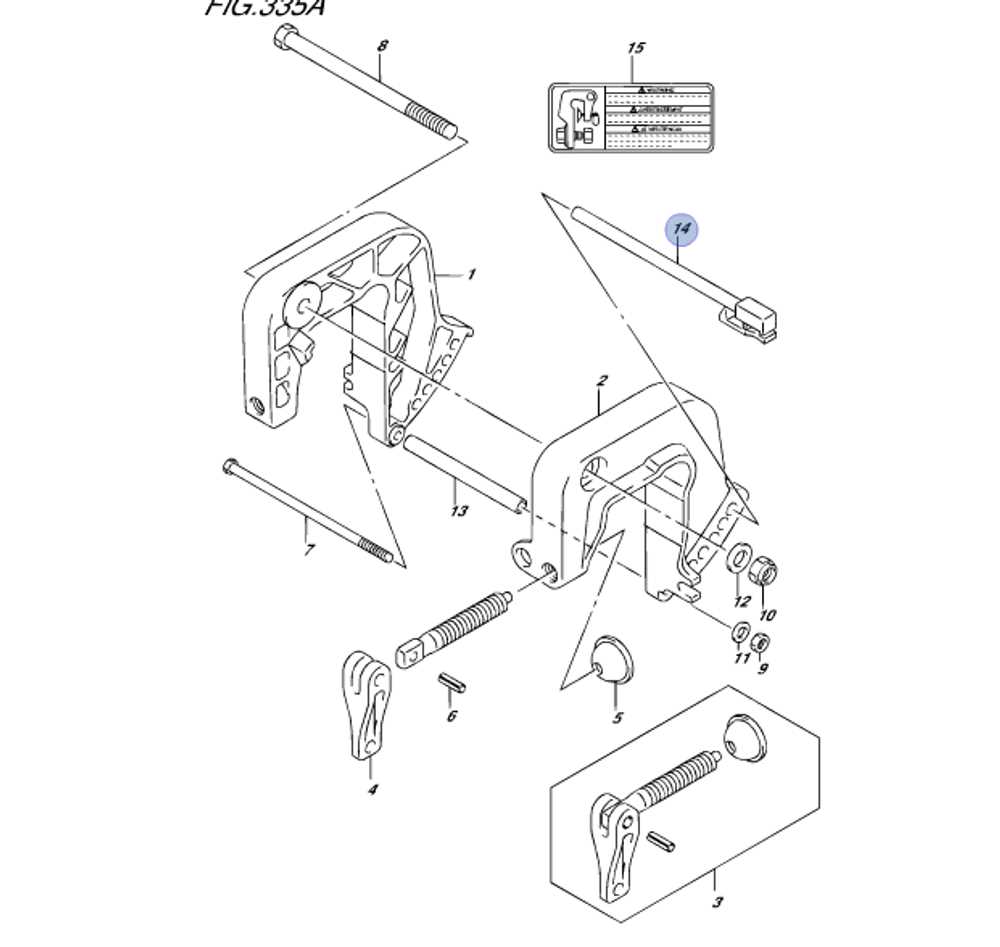

Insight into the Steering Mechanism of the DF6

The steering system of this compact watercraft engine is designed to provide smooth, responsive control, ensuring maneuverability even under challenging conditions. It consists of several interconnected components that work together to translate the operator’s inputs into precise movement of the propulsion unit.

The key to its functionality lies in the integration of the helm and the rotating mechanism, allowing for effortless directional adjustments. Leveraging a balance of mechanical and hydraulic forces, this arrangement enhances the overall efficiency, providing better handling with minimal effort.

Understanding how these components interact can significantly improve the user’s experience. By maintaining the integrity of the steering linkage and ensuring proper lubrication, the system ensures consistent performance and longevity.

Overview of the Ignition System

The ignition system plays a crucial role in ensuring the proper functioning of an engine. It is responsible for generating the spark necessary to ignite the air-fuel mixture within the combustion chamber, allowing the engine to start and run smoothly. This system involves a series of components that work together to produce the high voltage required for ignition and distribute it efficiently to the engine’s cylinders.

Main Components

- Ignition Coil: Converts low voltage from the battery to high voltage that is needed to create the spark.

- Spark Plug: The final point where the high voltage is released, creating a spark that ignites the fuel mixture.

- Flywheel: Contains magnets that generate the necessary power to trigger the ignition system.

- Points or CDI Unit: Controls the timing of the ignition process, ensuring the spark occurs at the right moment.

- Wiring: Transports electrical signals between the components, ensuring the ignition process is synchronized.

Working Mechanism

The process begins when the flywheel generates power, sending electrical signals to the ignition coil. The ignition coil then transforms this energy into a high voltage that is directed to the spark plug. Once the high voltage reaches the spark plug, a spark is created, which ignites the fuel-air mixture in the engine’s cylinder. The timing of this spark is crucial, and it is controlled either by mechanical points or a modern CDI unit. This entire cycle occurs rapidly, and the system must operate in perfect harmony for the engine to perform efficiently.

Identifying Key Components in the Exhaust System

The exhaust system of a small marine engine plays a critical role in ensuring efficient operation and minimizing harmful emissions. Understanding its key elements can help in both maintenance and troubleshooting, ensuring that all components are functioning as intended.

- Exhaust Manifold: The manifold collects exhaust gases from the engine cylinders and directs them into the exhaust system. It is an essential part of the engine’s ability to expel gases effectively.

- Silencer: This component reduces noise levels produced by exhaust gases, ensuring a quieter operation. Its role is crucial in maintaining a smooth sound profile during engine use.

- Exhaust Pipe: The pipe channels the gases from the silencer to the outside environment. The material and diameter of the pipe are important factors in reducing backpressure and ensuring optimal engine performance.

- Water Jacket: Often integrated into the exhaust system, the water jacket helps cool the exhaust gases, preventing overheating and damage to the components.

Recognizing the function of each of these elements ensures a better understanding of how the exhaust system contributes to the overall performance of the engine.

Explaining the Lubrication System in the DF6 Engine

The lubrication system plays a crucial role in maintaining the performance and longevity of an engine. It ensures that all moving parts are adequately supplied with oil, reducing friction, minimizing wear, and preventing overheating. This process is vital for the engine’s efficiency, as it aids in cooling, cleaning, and sealing the internal components.

Key Components of the Lubrication System

- Oil Pump: Responsible for circulating the oil throughout the engine, ensuring it reaches all necessary areas.

- Oil Filter: Removes contaminants and impurities from the oil, maintaining its cleanliness and effectiveness.

- Oil Cooler: Helps regulate the temperature of the oil, preventing it from becoming too hot during engine operation.

- Oil Sump: Stores the oil when it is not circulating through the engine, providing a reservoir for future use.

How the Lubrication System Works

The system operates by using a pump to draw oil from the sump and distribute it through various engine components. The oil then passes through the filter to remove any debris or contaminants. After circulating through critical engine parts, such as pistons and bearings, the oil returns to the sump to be reused. This continuous cycle ensures that the engine operates smoothly and without unnecessary wear.

Understanding Maintenance Tips for Suzuki DF6 Parts

Proper upkeep of any mechanical equipment is crucial for ensuring its longevity and optimal performance. Regular maintenance helps in identifying and addressing potential issues before they become significant problems. This section highlights key considerations and practices to maintain your equipment in top condition.

Routine Inspections and Cleaning

Frequent inspections are essential to detect wear and tear. Regularly check components for any signs of corrosion or damage. Keeping the system clean by removing dirt, debris, and saltwater build-up will prevent malfunctions and increase efficiency. A soft cloth and non-abrasive cleaning solutions are recommended for sensitive parts.

Lubrication and Fluid Levels

Lubricating moving parts ensures smooth operation and prevents friction-related damage. Make sure to use the recommended type of oil and lubricants. Also, monitor fluid levels to prevent overheating or internal damage. Proper fluid management can significantly enhance the overall performance of your equipment.

Tip: Always use quality lubricants and fluids for the best protection and efficiency.

Note: Always refer to the manufacturer’s guidelines for specific maintenance instructions tailored to the model.