When it comes to maintaining marine machinery, having a clear overview of the various elements involved is crucial. This knowledge empowers enthusiasts and professionals alike to ensure their vessels operate at peak performance. Navigating through the intricate network of components can seem daunting, yet it offers insights into the engineering behind watercraft.

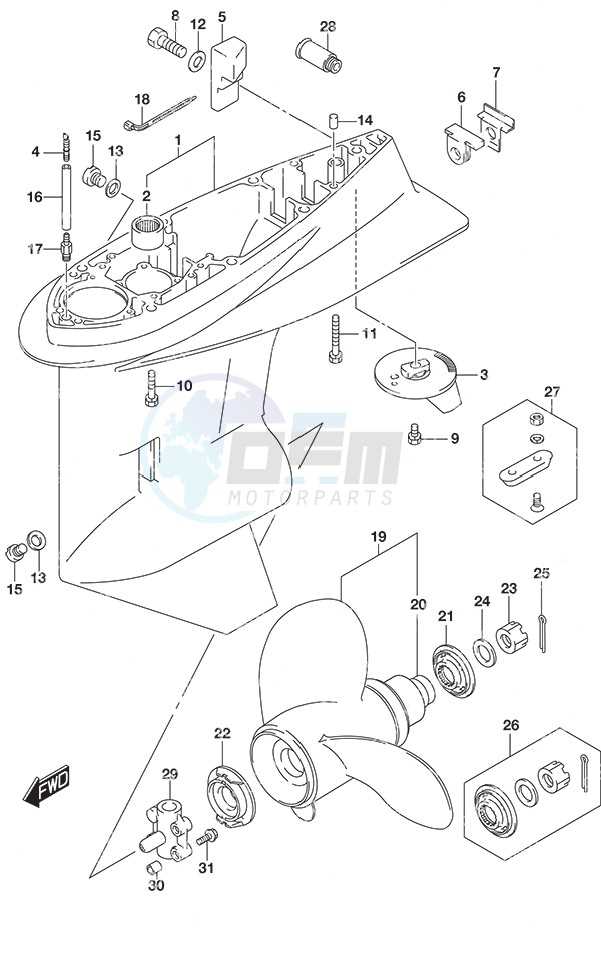

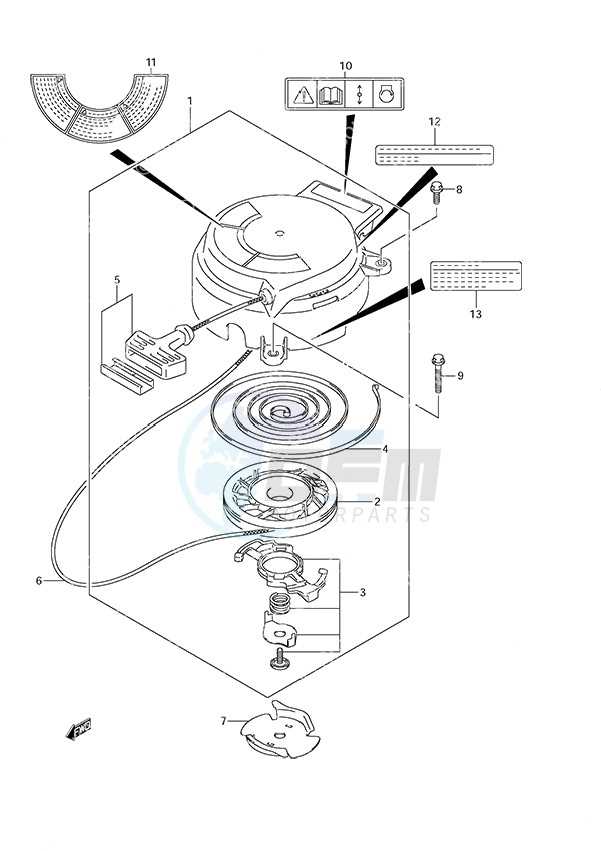

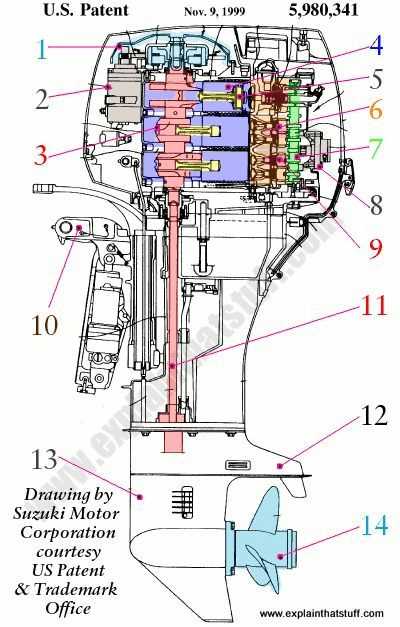

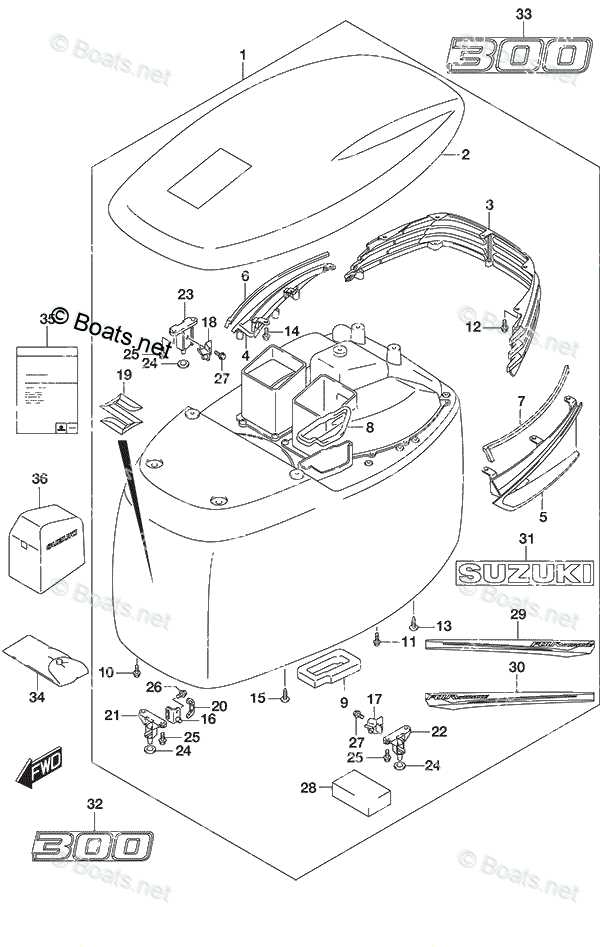

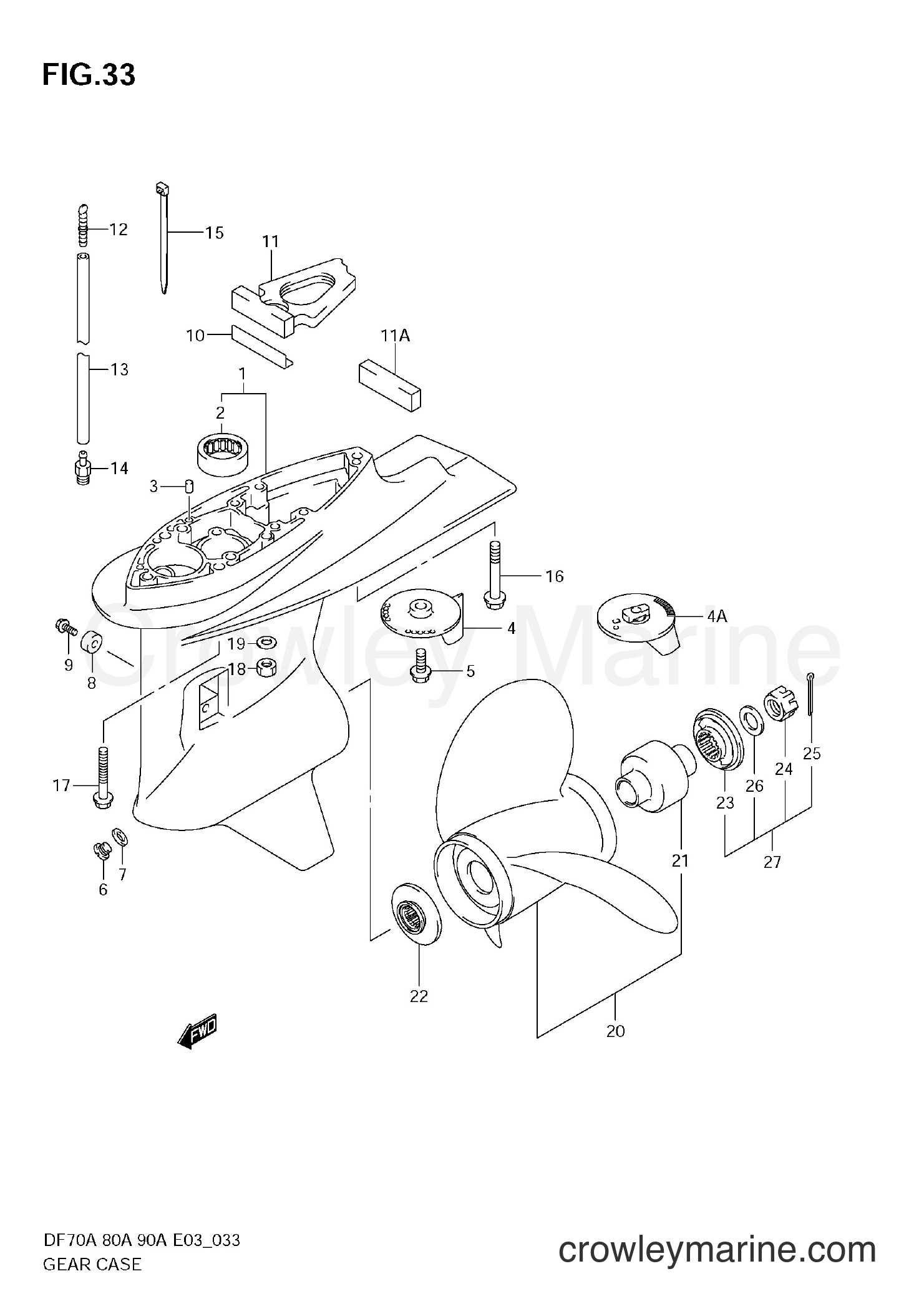

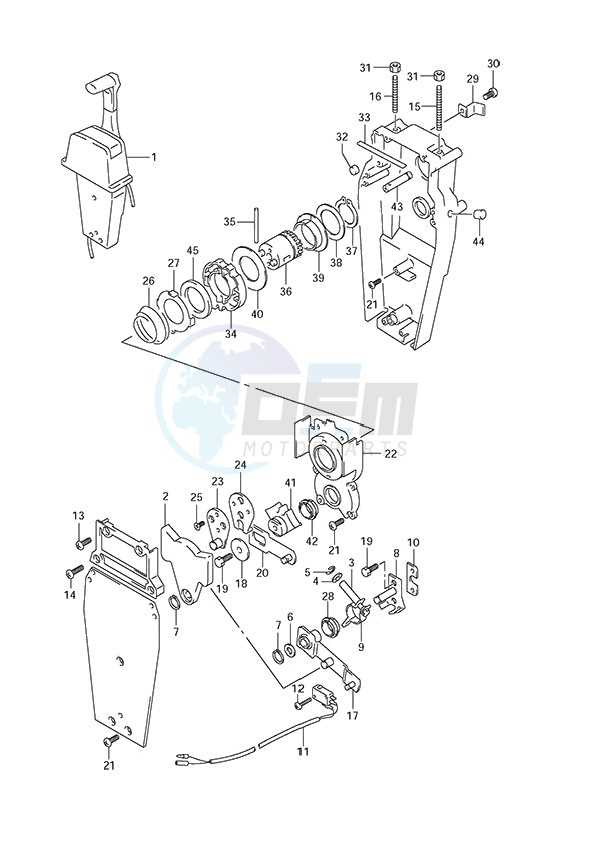

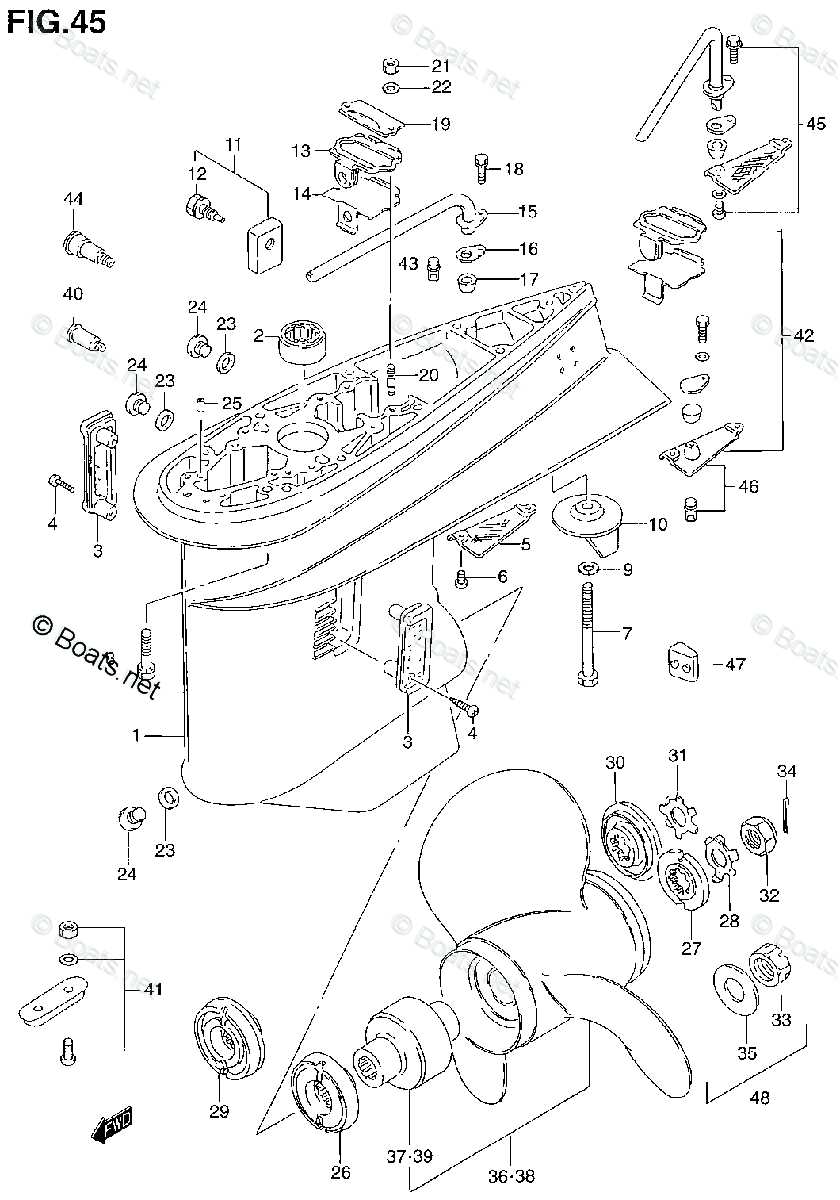

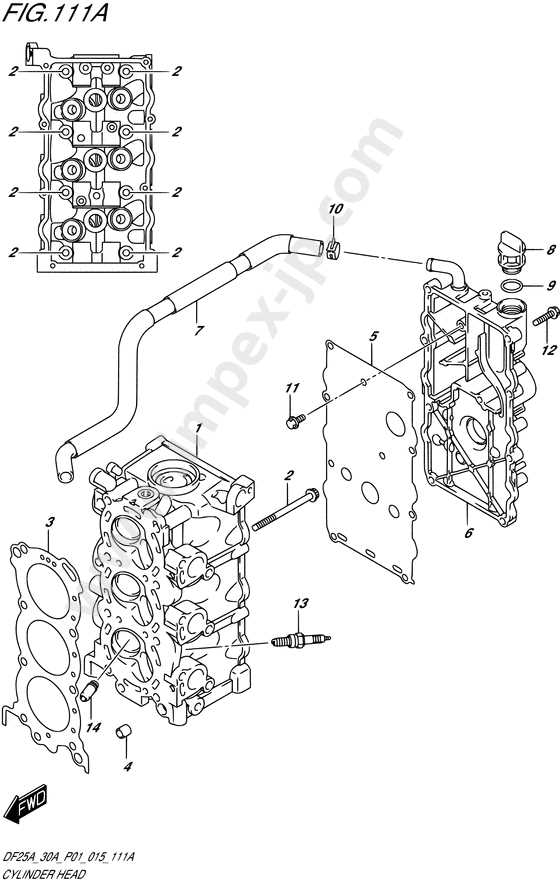

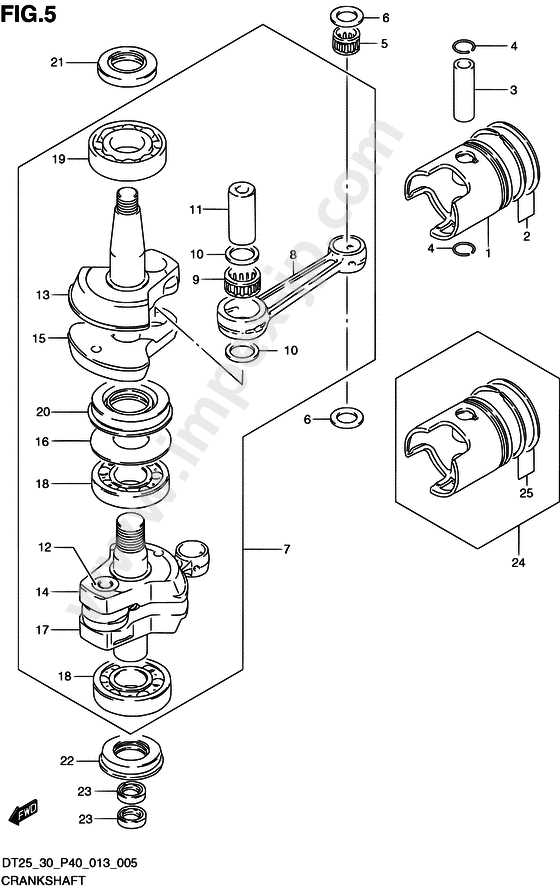

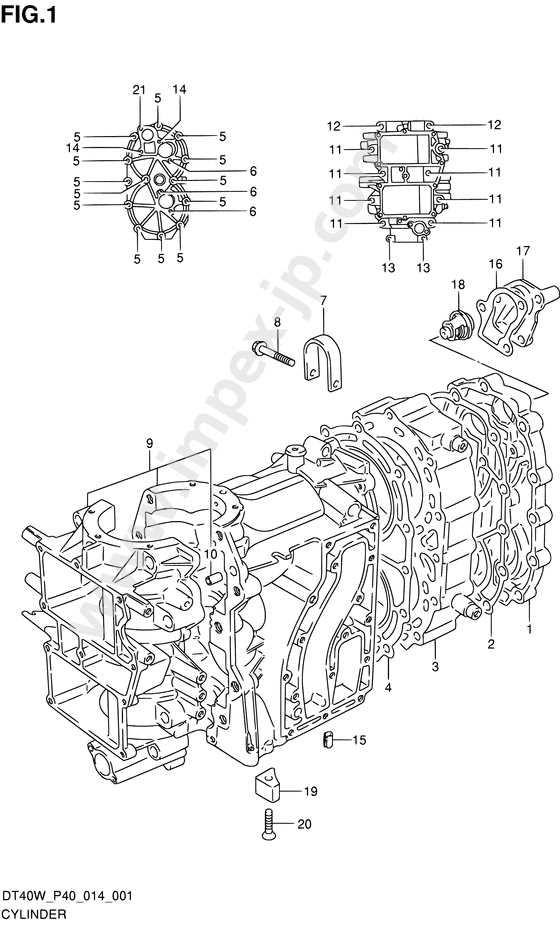

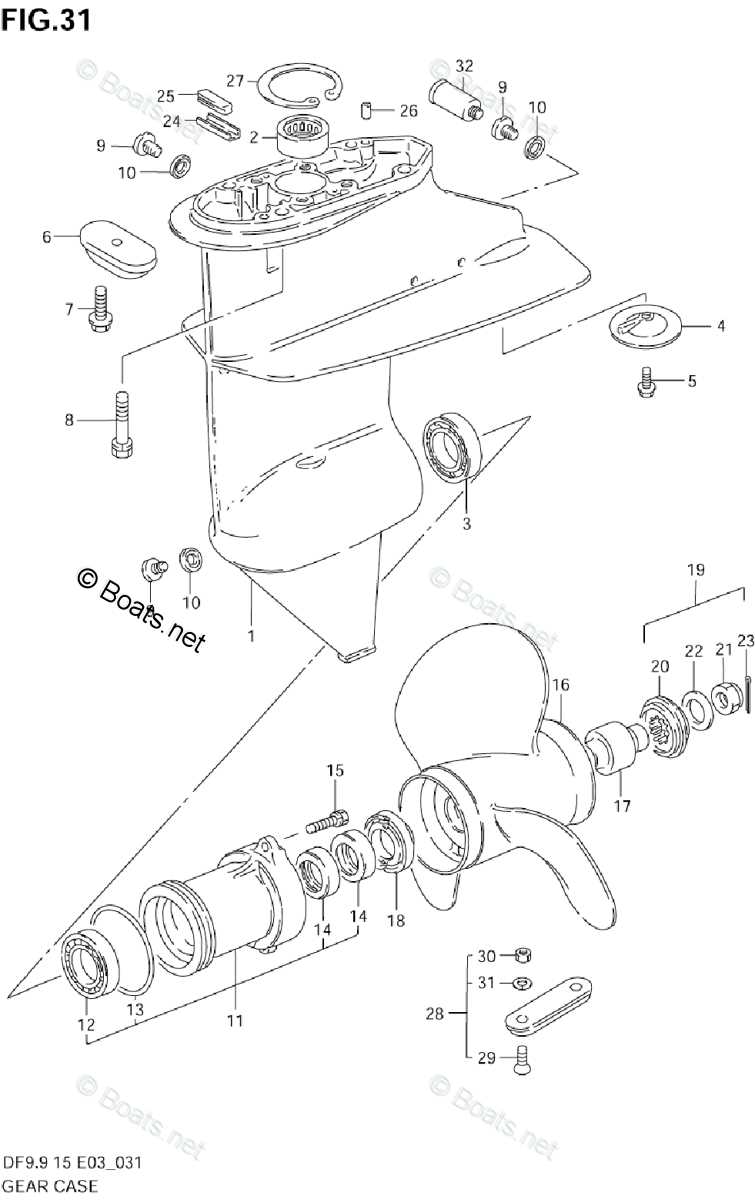

Visual aids play a pivotal role in simplifying this complex information. They provide a structured representation of the various segments, making it easier to identify and locate specific items. By dissecting these visuals, one can gain a deeper understanding of how each element contributes to the overall functionality of the engine.

Ultimately, this exploration not only enhances maintenance skills but also fosters a greater appreciation for the technology that drives marine adventures. Delving into these representations opens up a world of knowledge that can significantly impact both repair and enhancement efforts.

Suzuki Outboard Parts Overview

This section provides an in-depth examination of the components essential for marine propulsion systems. Understanding these elements is crucial for maintenance, repair, and overall performance enhancement. The intricate design of these mechanisms ensures reliability and efficiency, catering to various boating needs.

Key Components

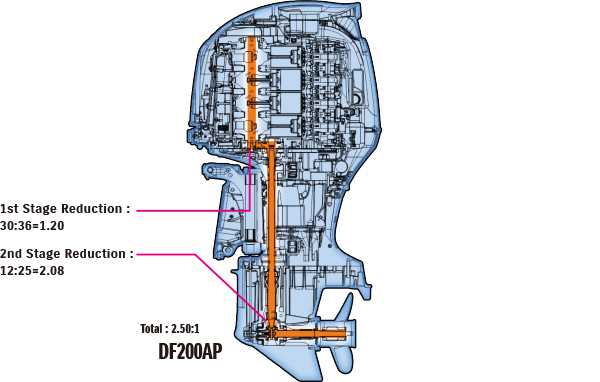

Essential elements include the engine, fuel system, cooling system, and transmission components. Each part plays a significant role in the overall functionality, and familiarity with their operation can greatly benefit users. Here’s a brief look at some of the fundamental elements:

| Component | Description |

|---|---|

| Engine | The heart of the system, responsible for converting fuel into mechanical energy. |

| Fuel System | Handles the storage, delivery, and management of fuel for optimal performance. |

| Cooling System | Ensures the engine operates within safe temperature limits to prevent overheating. |

| Transmission | Facilitates power transfer from the engine to the propulsion mechanism. |

Maintenance Importance

Regular upkeep of these components is vital for longevity and reliability. Proper knowledge of each element allows for timely interventions, reducing the risk of failure during operation. By prioritizing maintenance, users can enhance performance and ensure safe travels on the water.

Understanding Diagrams for Maintenance

Effective upkeep of marine engines hinges on the ability to interpret technical illustrations that detail their components. These visuals serve as invaluable guides, offering clarity on the assembly and functionality of various elements within the machinery. Familiarizing oneself with these representations can significantly enhance troubleshooting and repair processes.

Importance of Visual Aids

Visual aids streamline the identification of parts, helping technicians locate issues swiftly. By providing a clear depiction of how components fit together, these aids facilitate a deeper understanding of the engine’s inner workings.

Tips for Utilizing Technical Illustrations

When examining these visuals, focus on labeling and color coding to easily differentiate between elements. Take time to delve into each section, as this thorough approach ensures a comprehensive grasp of maintenance needs, ultimately leading to more efficient repairs.

Common Components in Outboard Motors

Understanding the fundamental elements of marine propulsion systems is essential for maintenance and performance optimization. Each component plays a vital role in ensuring efficiency and reliability on the water.

Key Elements

Several critical components work together to facilitate smooth operation. These include the power unit, transmission, and cooling systems, each contributing to the overall functionality of the vessel.

Component Overview

| Component | Function |

|---|---|

| Engine | Provides propulsion through combustion. |

| Gearcase | Transfers power from the engine to the propeller. |

| Propeller | Propels the vessel forward by converting rotational energy. |

| Cooling System | Prevents overheating by regulating engine temperature. |

Benefits of Using Original Parts

Utilizing authentic components ensures optimal performance and longevity of your marine equipment. These specially designed pieces are crafted to meet exact specifications, enhancing reliability and reducing the risk of failure. Investing in genuine items not only maintains the integrity of your vessel but also promotes safety on the water.

Another significant advantage lies in the warranty coverage associated with original items. Manufacturers typically provide robust guarantees, offering peace of mind and financial protection. Additionally, using these components can enhance resale value, as potential buyers often seek assurance of quality and proper maintenance.

Finally, authentic parts contribute to seamless compatibility with existing systems, minimizing the need for modifications. This precision engineering fosters efficient operation and reduces the likelihood of costly repairs, ultimately ensuring a superior experience on the water.

How to Read Parts Diagrams

Understanding visual representations of components is essential for efficient maintenance and repairs. These illustrations serve as a roadmap, guiding users through various elements, their relationships, and assembly instructions. Grasping how to interpret these visuals can significantly enhance the repair process.

To begin, familiarize yourself with the overall layout. Each section is typically organized to reflect the physical arrangement of the components. Key identifiers, such as numbers or letters, are often used to correspond with a detailed list, providing clarity on each item’s function and specifications.

Next, pay attention to color coding and symbols, which can indicate different materials or specific features. Recognizing these visual cues is crucial for selecting the correct components for repairs or replacements. Additionally, understanding the orientation of the parts can prevent errors during reassembly.

Finally, practice makes perfect. Regularly consulting these visual aids will improve your proficiency in reading and interpreting them, ultimately leading to more successful maintenance endeavors.

Identifying Parts by Model Number

Understanding the specific components of your marine engine can significantly enhance maintenance and repair efforts. Each model features a unique identification number, allowing users to accurately locate the necessary elements for service or replacement. This systematic approach not only simplifies the process but also ensures compatibility and optimal performance.

Why Model Numbers Matter

Model numbers serve as a critical reference point. They encapsulate essential information about the engine’s specifications, design, and compatibility with various components. By using the model number, individuals can access precise information, reducing the chances of errors and improving the efficiency of repairs.

How to Use Model Numbers Effectively

To effectively utilize model numbers, locate the identification label on the engine, which typically contains the relevant information. Once obtained, this number can be cross-referenced with manufacturer resources or online databases. This step ensures that you acquire the correct components, streamlining the maintenance process and prolonging the life of your marine engine.

Replacement Parts for Popular Models

Maintaining the performance of your marine engine often requires sourcing specific components tailored to various models. Understanding the essential elements needed for repairs can enhance longevity and reliability on the water.

Key Components

Familiarity with the most sought-after elements is crucial. Here are some critical items commonly needed for popular models:

| Component | Description | Model Compatibility |

|---|---|---|

| Fuel Pump | Ensures proper fuel delivery. | Model A, Model B |

| Propeller | Enhances thrust efficiency. | Model C, Model D |

| Starter Motor | Crucial for engine ignition. | Model E, Model F |

Finding Quality Replacements

When searching for these components, consider authorized retailers and reputable suppliers to ensure you receive high-quality alternatives that meet the required standards.

Tools Needed for Installation

When embarking on a maintenance or upgrade project, having the right instruments is crucial for a successful outcome. The following list outlines essential tools that will facilitate a smooth installation process, ensuring efficiency and precision.

- Wrenches: Adjustable and socket wrenches for loosening and tightening fasteners.

- Screwdrivers: A variety of Phillips and flathead screwdrivers to accommodate different screws.

- Pliers: Needle-nose and slip-joint pliers for gripping and manipulating components.

- Torque Wrench: To ensure bolts are tightened to the manufacturer’s specifications.

- Cutting Tools: Utility knife or wire cutters for trimming and shaping materials as needed.

In addition to these basic tools, consider the following specialized equipment:

- Drill: For creating holes or securing items with screws.

- Multimeter: To check electrical connections and ensure everything is functioning properly.

- Safety Gear: Goggles and gloves to protect against debris and sharp edges during installation.

Having these tools on hand will not only streamline the installation process but also enhance safety and effectiveness in your project.

Common Issues and Solutions

In the world of marine engines, various challenges can arise, impacting performance and reliability. Identifying these common problems is essential for effective troubleshooting and ensuring smooth operation. Below are some frequently encountered issues and their respective solutions.

Engine Won’t Start

One of the most frustrating situations is when the engine fails to ignite. This can be caused by a faulty battery, poor fuel quality, or issues with the ignition system. Solution: Check the battery charge, ensure fuel is fresh and clean, and inspect the ignition components for damage.

Overheating

Overheating is a critical concern that can lead to severe engine damage. It often results from inadequate cooling, blocked water intake, or malfunctioning thermostats. Solution: Regularly clean the cooling system, ensure water intake is clear, and test the thermostat to maintain optimal temperatures.

Where to Find Genuine Parts

Ensuring the longevity and performance of your marine equipment requires sourcing authentic components. Genuine items not only enhance efficiency but also maintain safety standards. Here are the best avenues to explore for acquiring these crucial elements.

Authorized Dealers

Visiting authorized retailers guarantees access to high-quality offerings. These establishments are often backed by official brands, ensuring that you receive reliable components that fit your needs.

Online Marketplaces

Numerous online platforms specialize in marine supplies. When browsing these sites, always look for verified sellers and read customer reviews to confirm the authenticity of the products. Prioritizing reputable sources will lead you to the ultimate choices for your equipment.

Importance of Regular Inspections

Routine examinations play a crucial role in ensuring the longevity and efficiency of marine machinery. Regular checks help identify potential issues before they escalate, thereby maintaining optimal performance and safety on the water. By prioritizing these assessments, owners can avoid costly repairs and enhance the overall reliability of their equipment.

Early Detection of Problems

Frequent evaluations enable the early identification of wear and tear or malfunctioning components. This proactive approach allows for timely interventions, reducing the risk of breakdowns during critical moments. Addressing minor concerns swiftly can prevent them from developing into more significant, more expensive issues.

Enhanced Safety and Performance

Ensuring that equipment is in top condition directly impacts safety and operational efficiency. Regular inspections help maintain the integrity of essential systems, promoting smoother navigation and reducing the likelihood of accidents. A well-maintained vessel provides peace of mind for operators and passengers alike.

Upgrades and Performance Enhancements

Enhancing the efficiency and capability of marine engines can significantly improve your experience on the water. By focusing on various modifications and accessories, you can achieve better performance, fuel efficiency, and overall reliability. Understanding the available options allows you to tailor your vessel to meet specific needs and preferences.

Popular Upgrades

Some of the most sought-after enhancements include high-performance propellers, advanced fuel systems, and optimized exhaust systems. These components can collectively contribute to smoother handling and increased power output.

Table of Key Enhancements

| Upgrade Type | Benefit |

|---|---|

| High-Performance Propellers | Improved speed and acceleration |

| Fuel System Modifications | Enhanced fuel efficiency and throttle response |

| Exhaust Upgrades | Better engine cooling and reduced noise |

Customer Support and Resources

In any field, reliable assistance and access to resources are crucial for ensuring optimal performance and longevity of equipment. This section highlights available support options and valuable materials for users, empowering them to address issues efficiently.

- Technical Support: Reach out to experienced professionals who can offer guidance and troubleshooting advice tailored to specific needs.

- Online Resources: Utilize websites featuring a wealth of information, including FAQs, instructional videos, and community forums for shared experiences.

- Manuals and Guides: Access comprehensive documentation that outlines essential procedures and maintenance tips, ensuring users have the ultimate reference at hand.

Engaging with these resources can significantly enhance understanding and facilitate a smoother experience, whether for routine checks or complex repairs.