When delving into the intricate world of automotive structures, one quickly discovers the significance of various elements that contribute to both functionality and aesthetics. Each component plays a crucial role in the overall performance and durability of the vehicle. This discussion aims to illuminate the assembly and arrangement of specific elements found in a popular model.

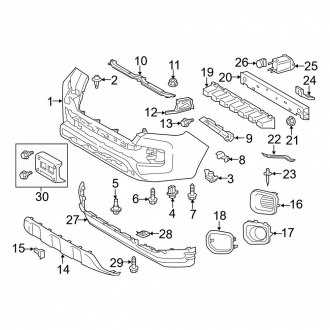

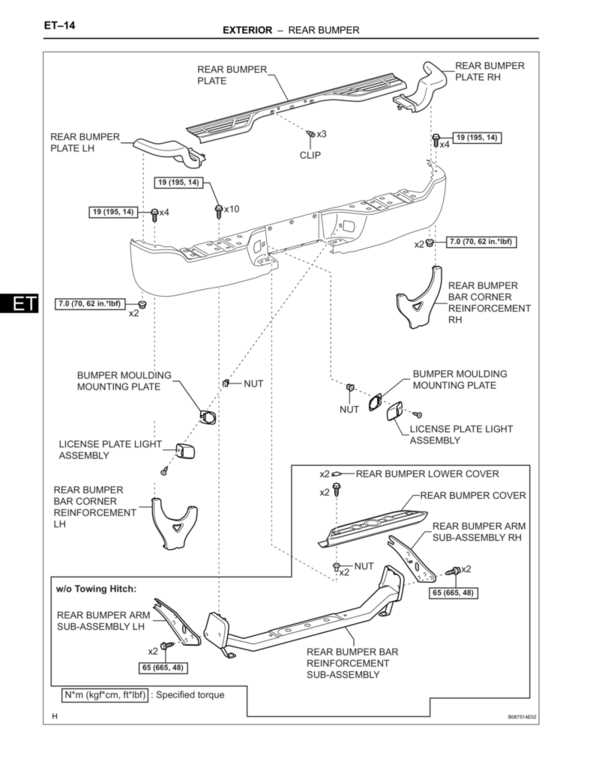

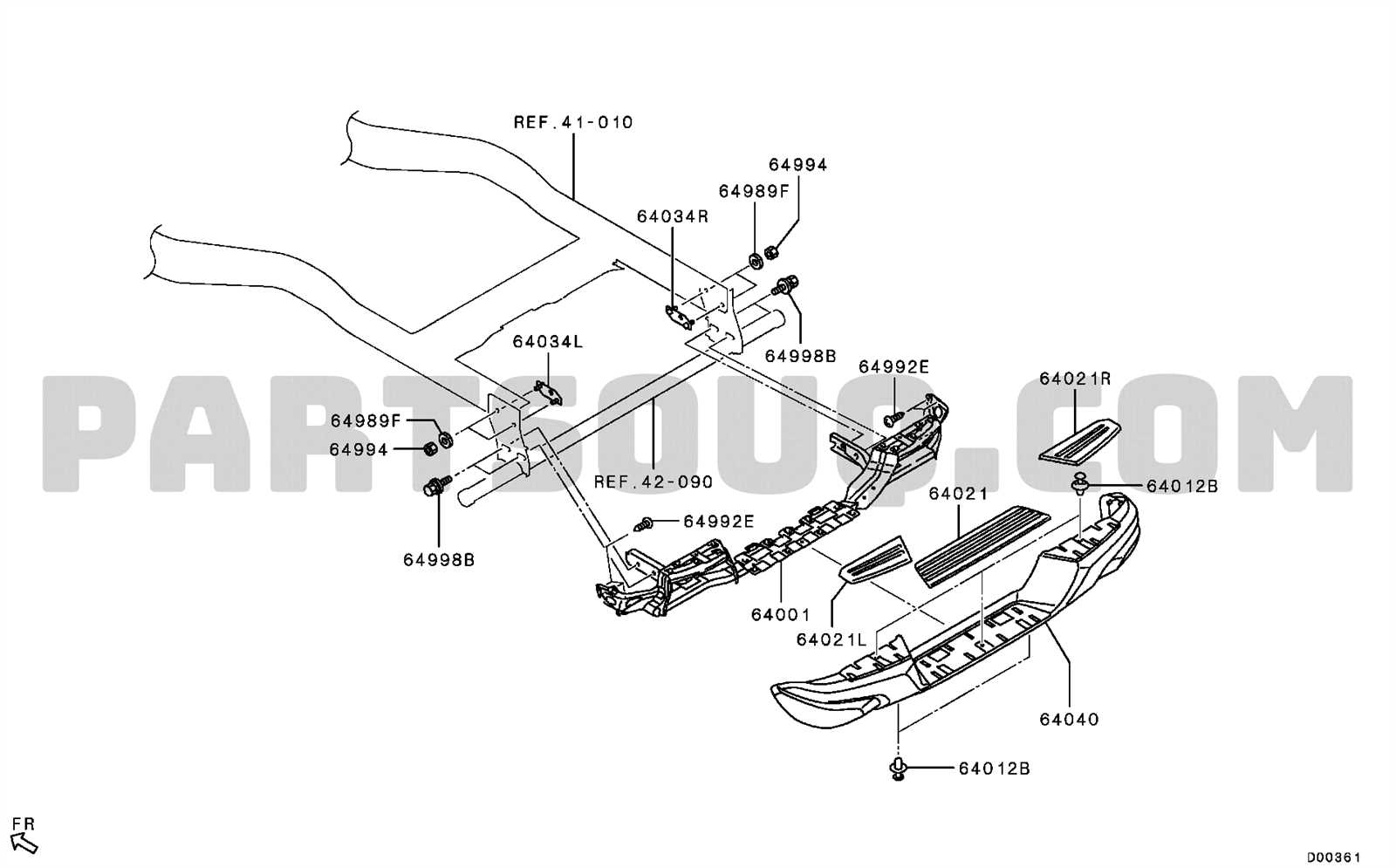

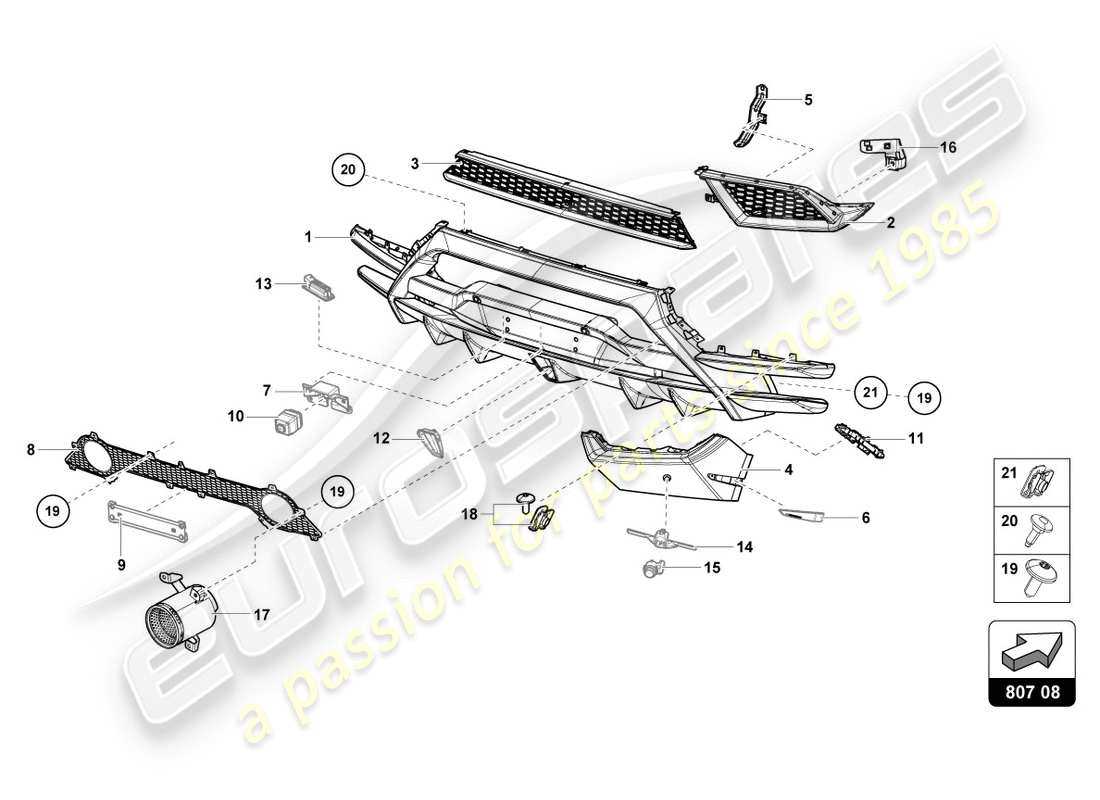

For enthusiasts and mechanics alike, having a clear visual representation of the components is essential. It not only aids in identifying each section but also assists in understanding how they interact within the larger framework. This knowledge is invaluable for repairs, upgrades, or simply enhancing one’s appreciation for engineering craftsmanship.

Furthermore, recognizing the differences in designs and functionalities can lead to better decision-making when it comes to maintenance and customization. Whether you are seeking to replace a damaged element or looking to enhance your vehicle’s capabilities, familiarity with these components is the first step towards achieving your goals.

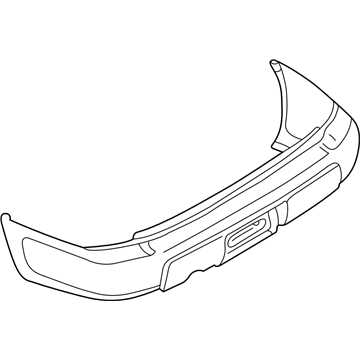

Overview of 2017 Toyota Tacoma Bumper

The rear protective component of a vehicle plays a crucial role in both safety and aesthetics. It not only safeguards the structure but also contributes to the overall design language of the model. Understanding its features and functionalities is essential for maintenance and potential upgrades.

Key Features

This specific protective element is designed to withstand impacts while enhancing the vehicle’s visual appeal. It often includes various attachments and modifications, which allow for customization and improved functionality. Additionally, the material used typically combines durability with lightweight properties, ensuring optimal performance without compromising on efficiency.

Maintenance and Upgrades

Regular inspection of this essential component is necessary to identify wear and tear. Upgrading to aftermarket options can also provide enhanced features, such as improved protection or a more aggressive look. Knowledge of the various available accessories will enable owners to make informed decisions regarding both repairs and enhancements.

Importance of Rear Bumper Components

The significance of various components at the back end of a vehicle cannot be understated. These elements not only contribute to the aesthetics but also play crucial roles in safety and functionality. Understanding their purpose is essential for any vehicle owner seeking to maintain performance and enhance protection.

Key Functions

Each element serves multiple purposes, from safeguarding against impacts to supporting towing capabilities. Moreover, these components can influence the overall handling and stability of the vehicle, ensuring a safer driving experience.

Maintenance and Replacement

Regular inspection and timely replacement of these parts are vital. Neglecting any damage can lead to more significant issues, compromising the vehicle’s integrity and safety. Proper care extends the lifespan of these components and ensures optimal performance.

| Component | Function | Common Issues |

|---|---|---|

| Impact Absorber | Reduces collision forces | Cracks or deformation |

| Reinforcement Bar | Enhances structural integrity | Rust or bending |

| Mounting Brackets | Secures components in place | Corrosion or loosening |

| Cover Panel | Improves appearance | Scratches or fading |

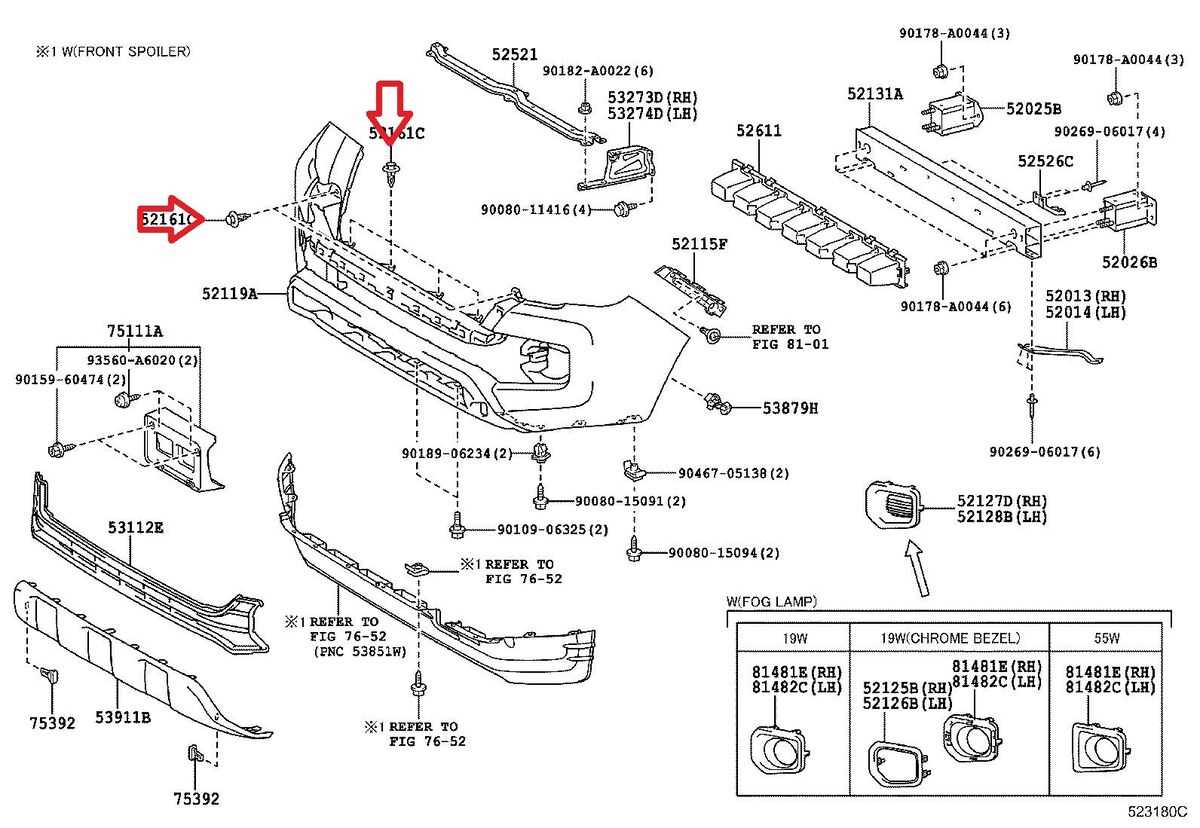

Understanding Bumper Diagram Symbols

Comprehending the visual representations used in automotive schematics is essential for effective repairs and modifications. These illustrations often utilize various symbols to denote components, connections, and specifications, allowing technicians to identify and work with each element efficiently.

Common Symbols and Their Meanings

| Symbol | Description |

|---|---|

| ➤ | Indicates a connection point. |

| ⚙️ | Represents a mechanical component. |

| Denotes a fastening element. | |

| Indicates a tool required for assembly. |

Importance of Accurate Interpretation

Understanding these symbols enhances the ability to execute repairs accurately. Misinterpretation can lead to improper installations or safety hazards, making it vital to delve into each symbol’s significance to ensure the ultimate effectiveness of maintenance efforts.

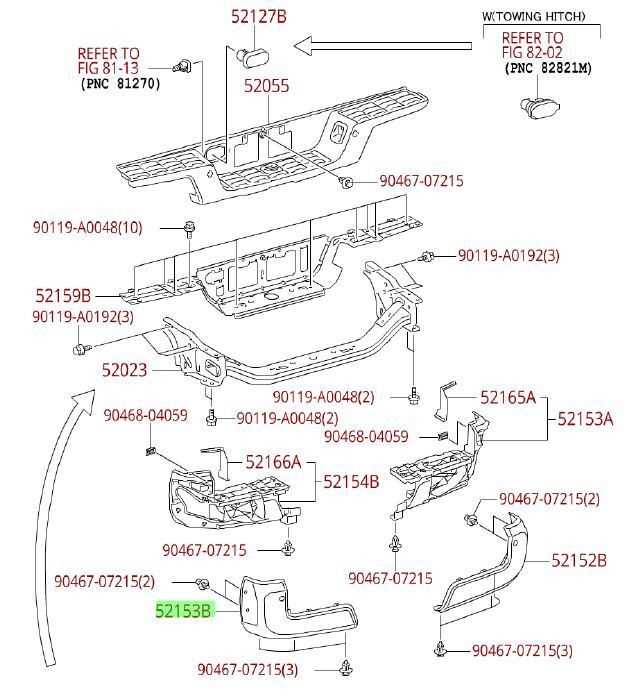

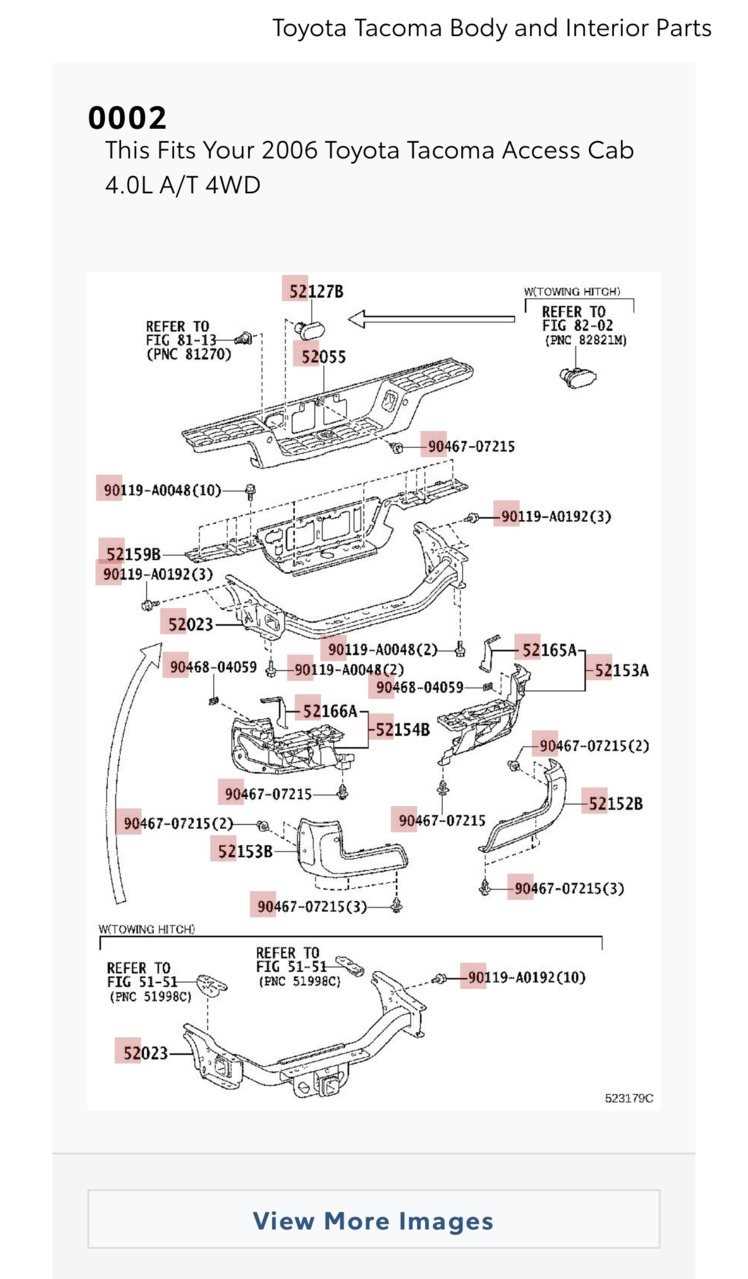

Key Parts of Rear Bumper Assembly

The assembly at the back of a vehicle serves crucial functions, providing both protection and aesthetic appeal. Understanding the components that make up this structure can help in maintenance and repair, ensuring longevity and functionality.

Main Components

The primary elements include the outer shell, which offers a sleek appearance and shields internal mechanisms. Additionally, reinforcement bars enhance durability, absorbing impact during collisions. Mounting brackets are essential for securing the assembly to the vehicle frame, while impact sensors may be integrated to improve safety features.

Some assemblies also include tail lights and other electrical components, which are crucial for signaling and visibility. Trim pieces add to the overall design, allowing for customization and improved aesthetics. Each component plays a vital role in the overall functionality of the assembly, contributing to the vehicle’s performance and safety on the road.

Materials Used in Bumper Construction

When it comes to the construction of protective vehicle components, a variety of materials are employed to ensure durability, functionality, and aesthetic appeal. Each material offers unique properties that cater to specific requirements, contributing to the overall performance and resilience of the assembly.

Common Materials

Typical choices include steel and aluminum, which provide strength and impact resistance. Plastic materials, such as polypropylene, are also widely used due to their lightweight nature and resistance to corrosion. Additionally, composite materials combine different substances to enhance strength while reducing weight.

Future Trends

Innovative developments are paving the way for the use of advanced materials, such as carbon fiber, which offers exceptional strength-to-weight ratios. As technology evolves, manufacturers aim to improve sustainability and impact performance through these cutting-edge materials.

Replacement Options for Tacoma Bumpers

When it comes to upgrading or replacing vehicle protective components, there are several alternatives available to ensure both functionality and aesthetics. Exploring various choices can enhance the overall look while providing the necessary durability for off-road adventures and daily driving.

| Option | Description | Advantages |

|---|---|---|

| OEM Parts | Original equipment manufacturer components designed specifically for the vehicle model. | Perfect fit, reliable quality, warranty support. |

| Aftermarket Alternatives | Third-party options that may offer unique designs or added features. | Variety of styles, often more affordable, customizable options. |

| Custom Builds | Tailored components made to specific requirements or preferences. | Unique design, personalized features, exact specifications. |

| Reinforced Versions | Upgraded components designed for enhanced protection and durability. | Increased strength, ideal for heavy-duty use, better resistance to damage. |

Choosing the right alternative depends on individual needs, driving habits, and personal style. Each option provides a unique set of benefits that cater to various preferences and requirements.

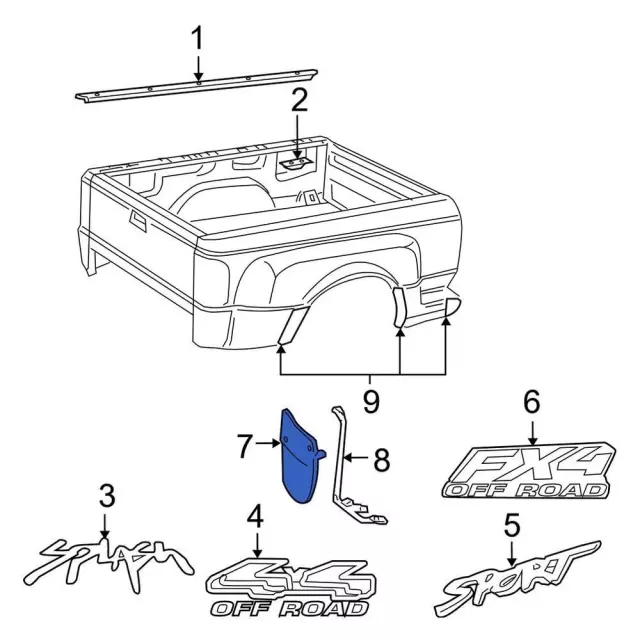

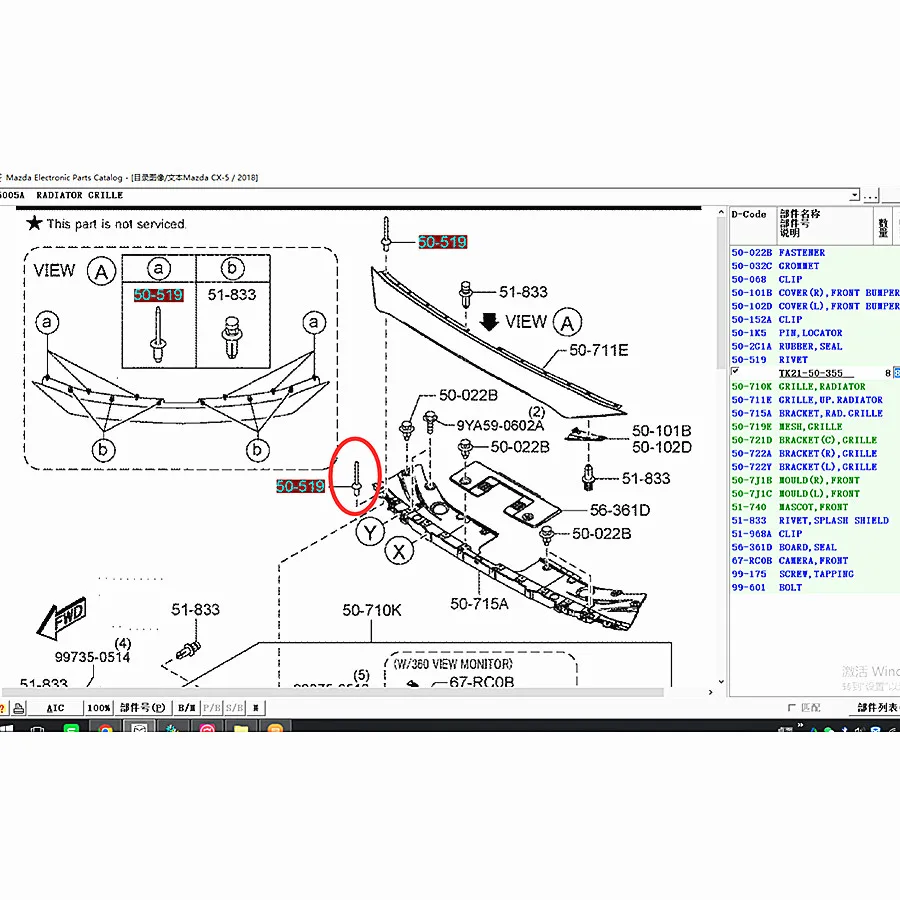

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective repairs and maintenance. This guide will help you interpret these illustrations, ensuring you can identify each element and its function within the assembly.

Start by familiarizing yourself with the overall layout, noting the arrangement of various elements. Each item is typically labeled with a unique identifier, making it easier to reference when ordering or discussing components.

Pay attention to the accompanying legend, which explains symbols and abbreviations used throughout the illustration. This can provide critical information about the specifics of each piece, such as size, orientation, and connection points.

Look for any additional notes or specifications that may clarify installation methods or special requirements. Understanding these nuances can enhance your knowledge and improve the accuracy of your repairs.

Finally, practice by comparing different visual guides for various assemblies. This will deepen your understanding and allow you to navigate similar illustrations with confidence in the future.

Installation Steps for New Bumper Parts

Replacing the protective rear component on your vehicle can enhance both its appearance and functionality. This guide provides a clear overview of the essential steps to ensure a successful installation.

-

Gather Necessary Tools:

- Socket wrench set

- Screwdrivers (flathead and Phillips)

- Torque wrench

- Pliers

- Safety goggles

- Gloves

-

Prepare the Vehicle:

- Park on a flat surface.

- Engage the parking brake.

- Disconnect the battery to avoid electrical issues.

-

Remove the Old Component:

- Locate and unscrew the bolts securing the existing unit.

- Carefully detach any wiring connected to it.

- Remove the old assembly and set it aside.

-

Install the New Assembly:

- Align the new piece with the mounting points.

- Reconnect any electrical connections, if applicable.

- Screw in the bolts and tighten them securely.

-

Final Checks:

- Ensure all bolts are tightened to the manufacturer’s specifications.

- Reconnect the battery.

- Inspect the installation for any loose components.

Following these steps will help ensure a proper and secure installation, contributing to the overall integrity and safety of your vehicle.

Common Issues with Tacoma Rear Bumpers

Many vehicle owners encounter specific challenges related to their vehicle’s protective components at the back. These issues can stem from various factors, including design flaws, environmental wear, and accidental damage. Understanding these common problems can help drivers maintain their vehicles effectively and avoid costly repairs.

Wear and Tear

Over time, components can suffer from deterioration due to exposure to the elements. Factors such as moisture, UV rays, and road debris can lead to rust, fading, or cracking. Regular inspections and timely maintenance can significantly extend the lifespan of these parts.

Improper Installation

Another frequent issue arises from incorrect installation. If the protective component is not aligned or secured properly, it can lead to misalignment with the vehicle’s structure. This may cause rattling noises or even detachment in severe cases, necessitating immediate attention to ensure safety on the road.

Aftermarket vs. OEM Parts Explained

When it comes to vehicle maintenance and repairs, the choice between factory-manufactured components and those produced by third-party companies can significantly impact performance, longevity, and cost. Understanding the differences between these options is essential for making informed decisions that align with your vehicle’s needs and your budget.

Quality and Performance

Factory components are designed to meet specific standards set by the manufacturer, ensuring a perfect fit and reliable performance. In contrast, aftermarket alternatives can vary widely in quality. Some may offer enhancements or superior durability, while others might compromise on performance. It’s crucial to research and choose wisely based on reviews and specifications.

Cost Considerations

Pricing is often a deciding factor in this debate. Factory parts generally come with a higher price tag due to their guaranteed quality and brand reputation. Aftermarket options, however, can be more affordable, providing a budget-friendly solution for many car owners. Balancing cost with the need for quality is vital to achieving long-term satisfaction with your vehicle.

Maintenance Tips for Bumper Longevity

Ensuring the durability of your vehicle’s protective components requires a combination of regular care and mindful usage. By adopting a few simple practices, you can significantly extend the life of these essential features while maintaining their appearance and functionality.

Regular inspections are crucial. Check for signs of wear, cracks, or scratches that could worsen over time. Addressing minor issues promptly can prevent more significant damage later. Additionally, cleaning the surface regularly helps remove dirt, salt, and debris that can cause corrosion or deterioration.

Avoiding unnecessary impacts is essential. When parking or maneuvering, take extra care to avoid obstacles that could lead to scratches or dents. Using protective films can also provide an extra layer of defense against minor abrasions and environmental factors.

Applying appropriate wax or sealant periodically will create a barrier against moisture and UV rays. This not only enhances the appearance but also adds to the overall lifespan by preventing fading and cracking.

Lastly, consider professional evaluations. If you frequently drive in harsh conditions, having an expert assess the condition can help identify potential issues before they become major problems. Following these simple strategies can keep your vehicle’s protective components in optimal condition for years to come.

Cost Factors for Bumper Replacement

Replacing a protective structure at the rear of a vehicle can involve various financial considerations that influence the overall expense. Understanding these elements can help vehicle owners make informed decisions and prepare for potential costs associated with the process.

Material Quality

The type of materials used significantly impacts the price of a replacement structure. High-quality components made from durable substances may cost more initially but can offer enhanced longevity and protection. Conversely, opting for lower-quality alternatives may save money upfront but could lead to more frequent replacements.

Labor and Installation

Another crucial aspect to consider is the labor involved in the installation process. Professional services may charge varying rates based on their expertise and the complexity of the task. DIY installations can save on labor costs, but they require a certain level of skill and the right tools to ensure a proper fit and function.

Additionally, unforeseen damages during the removal of the old structure may arise, potentially increasing labor costs further. Overall, weighing these factors can provide clarity on the financial commitment required for a successful replacement.

Resources for Parts and Diagrams

Finding accurate resources for automotive components is essential for both enthusiasts and professionals. Access to reliable illustrations and descriptions enhances understanding of assembly and repair processes.

Online Platforms: Numerous websites offer extensive catalogs featuring detailed visuals and specifications for various vehicles. These platforms are invaluable for identifying specific elements needed for maintenance or upgrades.

Service Manuals: Comprehensive manuals often contain in-depth breakdowns of vehicle systems, complete with labeled schematics. Utilizing these documents can significantly aid in troubleshooting and replacement tasks.

Forums and Communities: Engaging with online forums allows users to share insights and experiences related to automotive repairs. These communities often provide links to resources or offer advice on sourcing rare components.

Local Dealerships: Authorized dealers maintain up-to-date information on parts availability. They can provide accurate diagrams and assist with locating OEM components essential for ensuring optimal vehicle performance.