Exploring the intricate arrangements of various automotive elements can significantly enhance your knowledge of vehicle functionality. By delving into these configurations, enthusiasts and professionals alike can gain valuable insights into maintenance and repair processes.

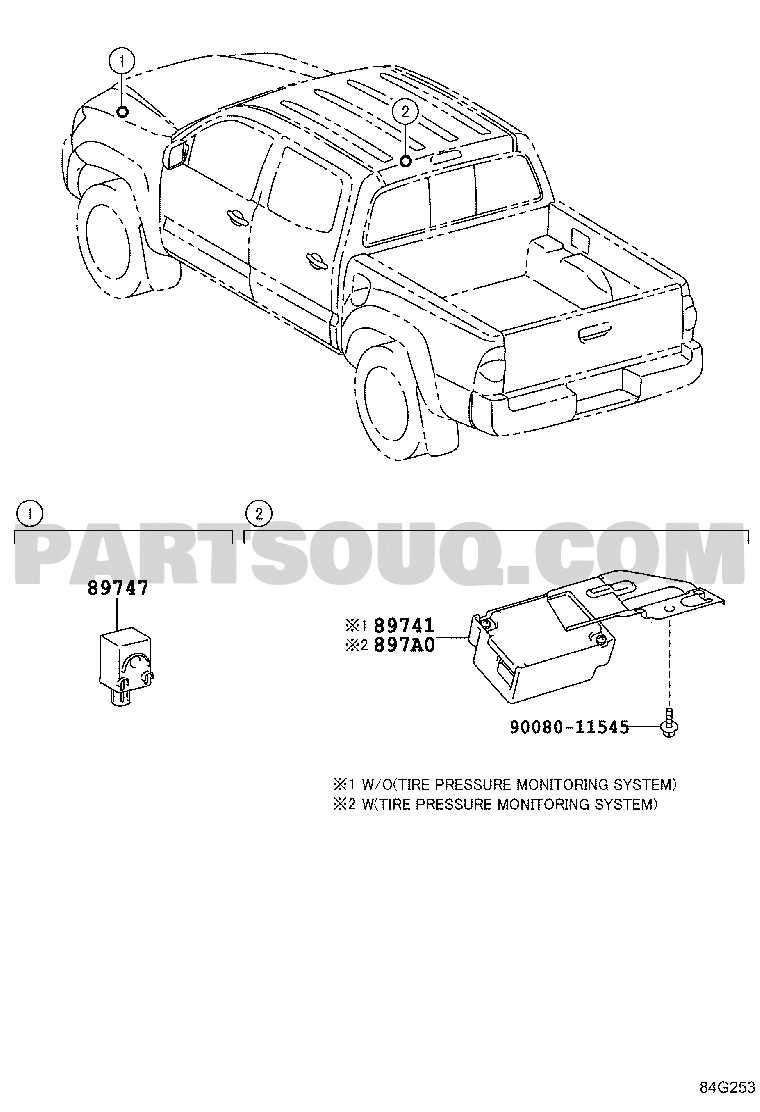

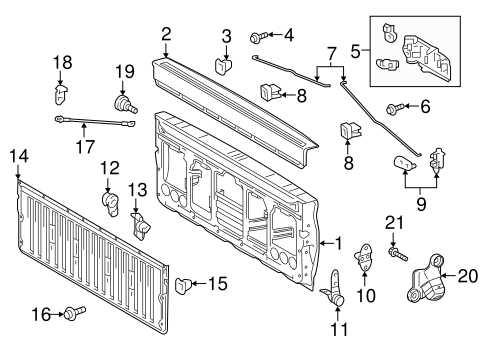

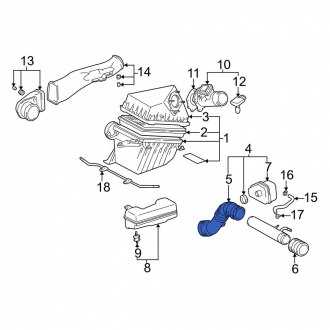

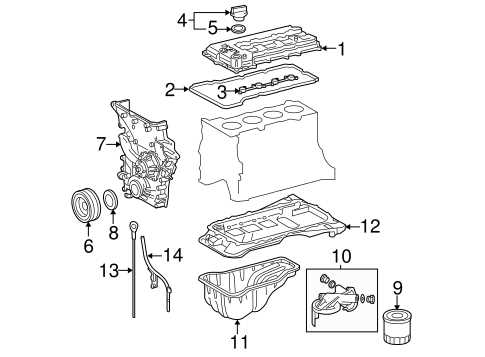

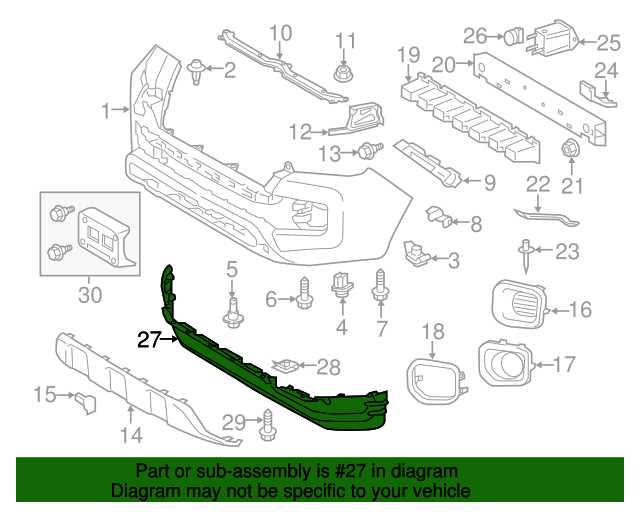

Visual representations of these structures provide a comprehensive overview of how individual units interact within the broader assembly. This understanding is crucial for effective troubleshooting and optimizing performance. With detailed illustrations, one can easily identify essential components and their respective placements.

Moreover, having access to these visual guides allows users to efficiently navigate through complex systems. Whether you’re an experienced technician or a dedicated hobbyist, familiarizing yourself with these layouts will undoubtedly streamline your hands-on experiences.

Understanding the Parts Layout

Grasping the arrangement of components is essential for effective maintenance and repair. A clear visualization of how various elements fit together enhances comprehension and aids in identifying issues. By breaking down the assembly into manageable sections, one can navigate the complexity with greater ease.

Each segment plays a crucial role in the overall functionality, and recognizing their placement can lead to more efficient troubleshooting. Understanding how different components interact allows for a more streamlined approach to diagnostics.

Moreover, a well-structured overview not only simplifies repairs but also empowers individuals to take proactive measures in upkeep. Familiarity with the layout fosters confidence in addressing potential challenges that may arise during use.

Key Assembly Sections Explained

This section provides an overview of essential components found in vehicle assembly. Understanding these sections is crucial for both maintenance and repair, as they play a vital role in the overall functionality of the vehicle.

One of the primary elements involves the structural framework, which serves as the backbone, supporting various systems and components. This assembly is designed to withstand significant stress while providing stability and safety.

Additionally, the drivetrain assembly is essential for transferring power from the engine to the wheels. It encompasses various mechanisms that ensure smooth operation and efficient performance. Proper maintenance of this section is vital for optimal driving experience.

The electrical assembly, consisting of wiring and connectors, facilitates communication between different systems. A well-functioning electrical network is crucial for the operation of critical features, including lighting and instrumentation.

Lastly, the suspension assembly plays a significant role in ride comfort and handling. It consists of various components that absorb shocks and maintain contact with the road, enhancing stability and control. Regular inspections and maintenance of this section contribute to overall safety and performance.

Essential Tools for Maintenance

Proper upkeep of any vehicle requires a variety of tools to ensure that all components function optimally. These instruments not only enhance efficiency but also promote safety during repairs and adjustments. Having the right equipment on hand can make a significant difference in maintaining the overall performance of the vehicle.

Basic Hand Tools

Basic hand tools are essential for everyday maintenance tasks. They allow for easy access to hard-to-reach areas and enable quick fixes. Below is a table listing some of the fundamental hand tools every vehicle owner should consider.

| Tool | Purpose |

|---|---|

| Wrench Set | Tightening and loosening bolts |

| Screwdriver Set | Fastening screws of various sizes |

| Pliers | Gripping and manipulating wires |

| Socket Set | Applying torque to fasteners |

Power Tools and Equipment

In addition to hand tools, power tools can greatly assist in maintenance tasks that require more force or precision. These tools often save time and effort, making them invaluable for both novice and experienced users.

| Tool | Purpose |

|---|---|

| Electric Drill | Drilling holes and driving screws |

| Impact Wrench | Loosening stubborn bolts |

| Angle Grinder | Cuts, grinds, and polishes metal |

| Floor Jack | Lifting the vehicle for access |

Identifying Electrical System Parts

Understanding the components of an electrical system is essential for effective troubleshooting and maintenance. This section aims to provide a clear overview of the various elements that make up the electrical framework, enabling users to recognize and assess each part’s functionality.

Key Components

- Batteries: Store electrical energy and supply power to the system.

- Wiring Harness: A collection of wires and connectors that facilitate electrical flow.

- Fuses: Safety devices that protect the system from overloads.

- Relays: Electrically operated switches that control power to various components.

Diagnostic Tools

Utilizing appropriate diagnostic tools can enhance the identification process:

- Multimeter: Measures voltage, current, and resistance.

- Test Light: A simple tool to check for voltage presence.

- Scan Tool: Interfaces with the system to retrieve error codes.

Chassis and Suspension Insights

The framework and support systems of a vehicle play a crucial role in its performance and stability. Understanding these components is essential for maintaining optimal driving dynamics and ensuring longevity.

Robust construction is vital for handling various terrains and loads. The structural integrity of the base contributes to a smoother ride and enhances the vehicle’s overall responsiveness. Key elements, such as shock absorbers and springs, work together to mitigate bumps and vibrations, providing a comfortable experience for passengers.

Additionally, the alignment and tuning of these systems significantly impact handling and steering precision. Regular inspections and adjustments can prevent wear and tear, ensuring that the vehicle operates efficiently under different conditions.

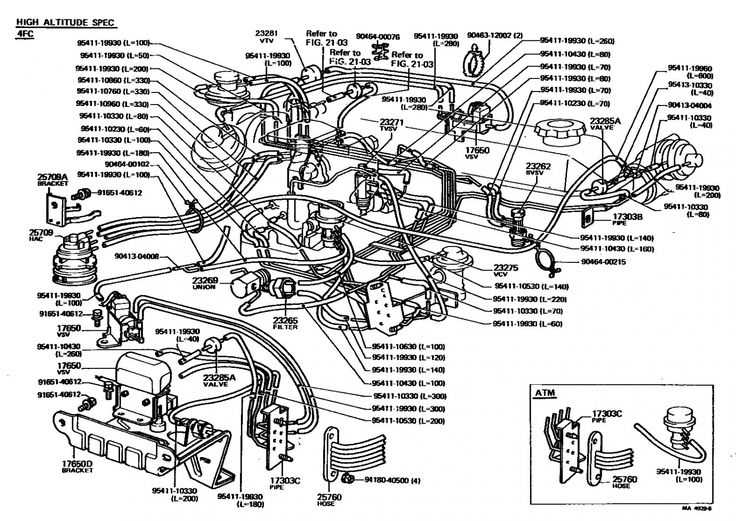

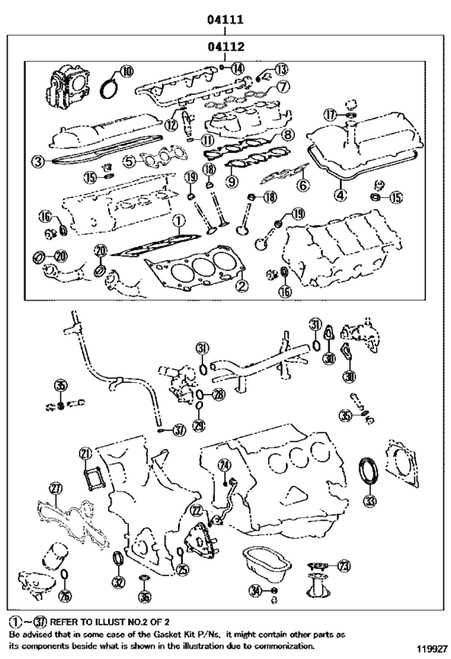

Engine and Transmission Overview

This section provides a comprehensive look at the core components that drive performance in modern vehicles. The engine and transmission work in tandem to deliver power, efficiency, and reliability, playing a crucial role in the overall driving experience.

| Component | Description |

|---|---|

| Engine | The powerhouse that converts fuel into mechanical energy, featuring various technologies to enhance performance and fuel economy. |

| Transmission | The system responsible for transferring power from the engine to the wheels, available in different types such as manual and automatic. |

| Cooling System | Maintains optimal operating temperatures for the engine, preventing overheating and ensuring efficient performance. |

| Lubrication System | Reduces friction between moving parts, enhancing longevity and efficiency by ensuring smooth operation. |

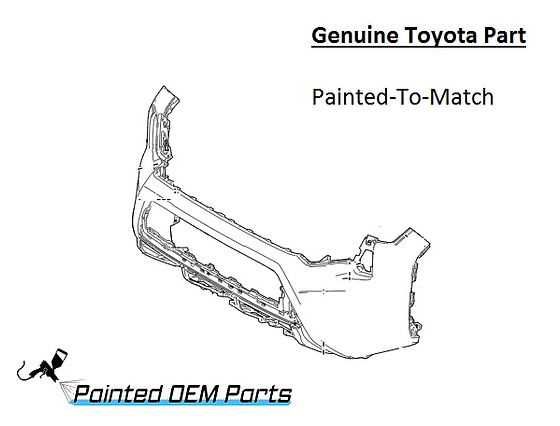

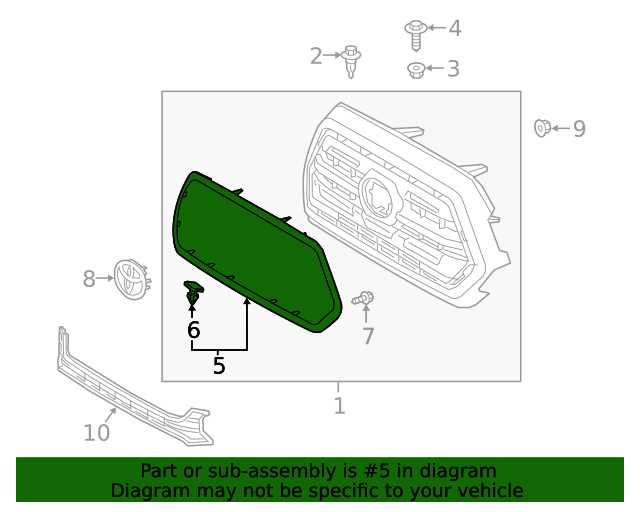

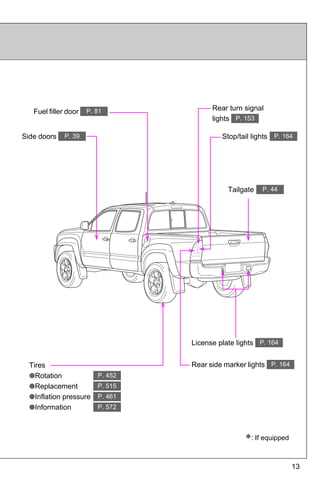

Body Parts and Accessories Guide

This section offers a comprehensive overview of exterior components and enhancements for vehicles, focusing on various elements that contribute to both aesthetics and functionality. Understanding these features is essential for anyone looking to personalize their ride or ensure optimal performance.

Exterior Components

Vehicle exteriors include crucial elements such as bumpers, hoods, and fenders, each playing a vital role in protection and style. Proper maintenance and selection of these components can enhance durability and visual appeal.

Custom Accessories

Custom accessories range from decorative trims to practical additions like roof racks and towing equipment. These enhancements not only improve usability but also allow owners to express their individuality, making the vehicle uniquely theirs.

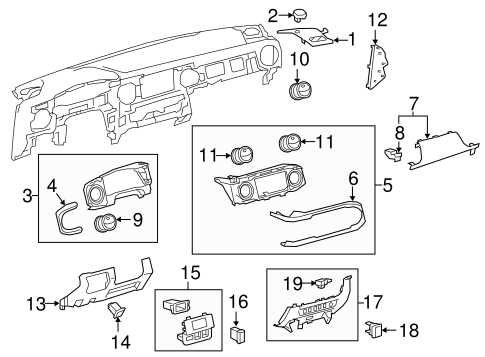

Interior Components Breakdown

Understanding the various elements within the cabin of a vehicle is crucial for both maintenance and enhancement. Each component plays a vital role in providing comfort, functionality, and aesthetic appeal.

- Dashboard: Houses essential instruments and controls, providing the driver with crucial information at a glance.

- Seating: Designed for comfort and support, the seats may come in various materials and styles, impacting the overall driving experience.

- Trim and Panels: Decorative and functional, these elements contribute to the vehicle’s style and can affect acoustics within the cabin.

- Infotainment System: Centralized hub for entertainment and navigation, integrating various technologies for convenience.

- Storage Compartments: Strategically placed throughout the interior to maximize space and organization for personal items.

- Climate Control: Essential for maintaining comfort, allowing occupants to adjust temperature and airflow.

Each of these components works together to create a cohesive and enjoyable environment for both the driver and passengers, highlighting the importance of regular checks and upgrades as needed.

Common Replacement Parts Needed

In the realm of vehicle maintenance, understanding the essential components that often require substitution can significantly enhance the longevity and performance of your automobile. These elements, which wear down over time due to regular use and environmental factors, are crucial for ensuring your vehicle operates smoothly and efficiently.

Engine Components

Among the most frequently replaced items are those related to the engine. This includes filters, belts, and gaskets. Regular checks and timely replacements of these components can prevent more severe issues and maintain optimal engine function.

Suspension and Braking Systems

The suspension and braking systems also necessitate routine attention. Key items like shock absorbers and brake pads are vital for safety and comfort. Ensuring these components are in good condition is essential for a smooth driving experience and effective stopping power.

Understanding OEM vs Aftermarket Parts

When it comes to vehicle maintenance and repairs, choosing the right components can significantly impact performance and longevity. There are two primary categories of components available in the market: original equipment manufacturer (OEM) and aftermarket options. Each has its own advantages and disadvantages, making it essential for vehicle owners to understand their differences.

OEM components are produced by the vehicle manufacturer and are designed to meet specific standards set by them. On the other hand, aftermarket components are produced by third-party companies and may vary in quality and compatibility. The choice between these options often comes down to budget, availability, and individual preferences.

| Feature | OEM Components | Aftermarket Components |

|---|---|---|

| Quality | Manufactured to strict specifications | Varies by manufacturer |

| Warranty | Typically comes with a warranty | Warranty depends on the supplier |

| Price | Generally higher cost | Often more affordable |

| Compatibility | Guaranteed fit and performance | May require research for proper fit |

Ultimately, the decision between OEM and aftermarket components should be made based on thorough research and consideration of the specific needs of the vehicle. Understanding these differences can help ensure optimal performance and reliability in the long run.

Importance of Accurate Diagrams

Precise visual representations are essential in various fields, facilitating a clear understanding of components and their relationships. They serve as vital tools for technicians and enthusiasts alike, enabling effective troubleshooting and maintenance. An accurate portrayal of elements not only enhances efficiency but also minimizes errors during assembly or repairs.

Enhanced Clarity

Clear illustrations provide a straightforward way to comprehend complex systems. By presenting information visually, users can quickly identify each element’s role and position, reducing the likelihood of mistakes during the repair process.

Time Efficiency

Using well-constructed visuals can significantly save time in both learning and practical application. Technicians can quickly reference diagrams to find solutions, leading to faster diagnosis and resolution of issues.

| Benefit | Description |

|---|---|

| Accuracy | Minimizes misinterpretation of components and procedures. |

| Accessibility | Makes information available to individuals with varying levels of expertise. |

| Efficiency | Streamlines the repair and maintenance process. |