Understanding the configuration of essential components in lawn maintenance machinery is crucial for effective upkeep and repair. A clear representation of these elements allows users to quickly identify parts and their respective functions. This knowledge not only enhances the performance of the equipment but also extends its lifespan through regular maintenance.

In this section, we will delve into the various segments and components found in a specific model of outdoor machinery. By examining the layout, users can gain insights into the assembly and arrangement of each piece, facilitating easier repairs and replacements when necessary. This approach empowers users to take charge of their equipment, ensuring optimal functionality.

The exploration of these layouts provides a valuable resource for both novice users and experienced technicians. Whether you are troubleshooting an issue or simply aiming to familiarize yourself with the structure of the machinery, having a comprehensive view of the components will significantly enhance your understanding and capability to manage the equipment effectively.

This section aims to provide a comprehensive overview of a specific model of equipment, highlighting its essential features and components. Understanding the structure and functioning of these elements is crucial for efficient operation and maintenance.

Key Features

- Robust design for enhanced durability

- Efficient performance metrics for optimal operation

- User-friendly interface for ease of use

- Compatibility with various attachments and accessories

Maintenance Tips

- Regularly check and clean the major components to ensure longevity.

- Follow the manufacturer’s guidelines for servicing and repairs.

- Utilize quality replacement items to maintain performance.

- Keep an inventory of essential spare elements for quick access.

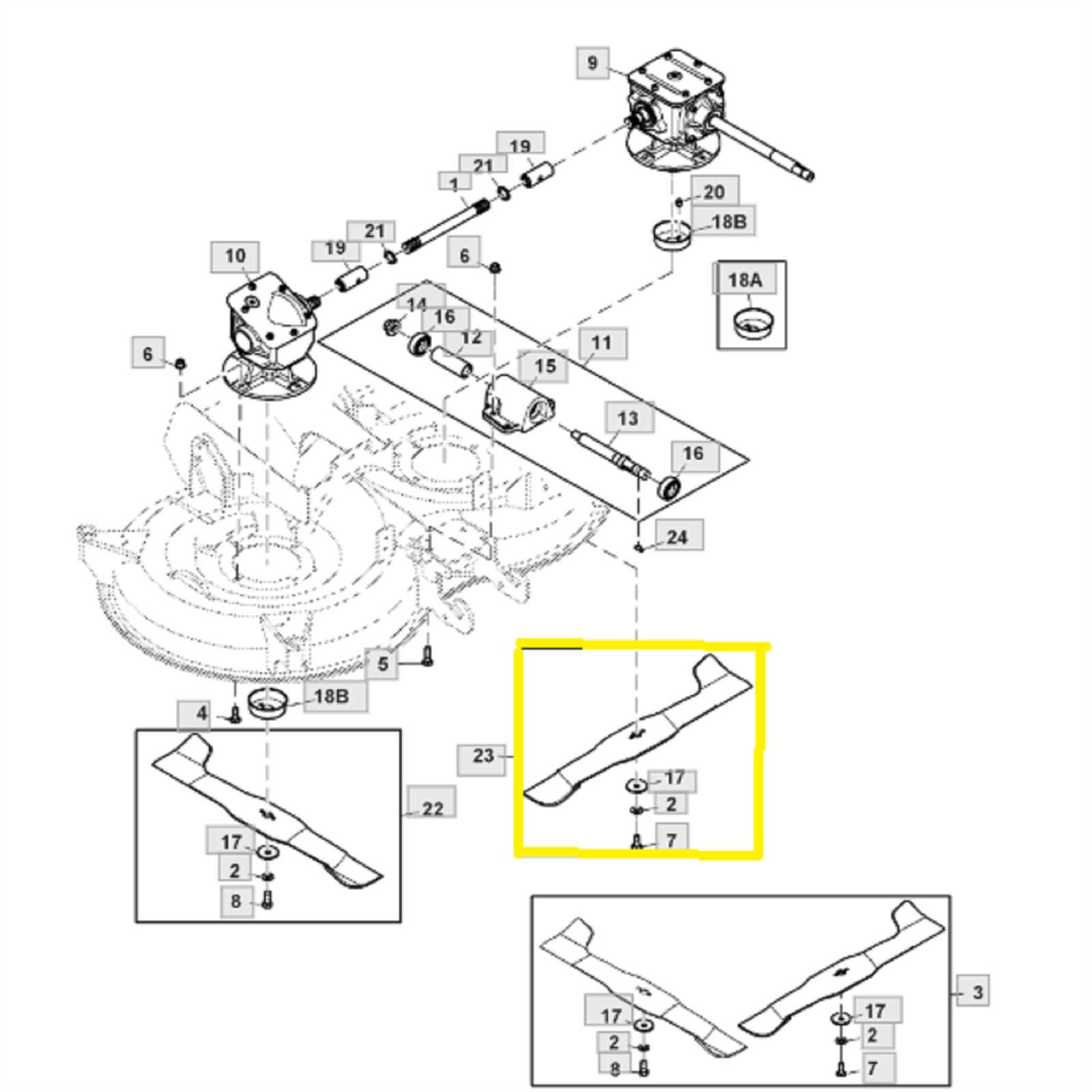

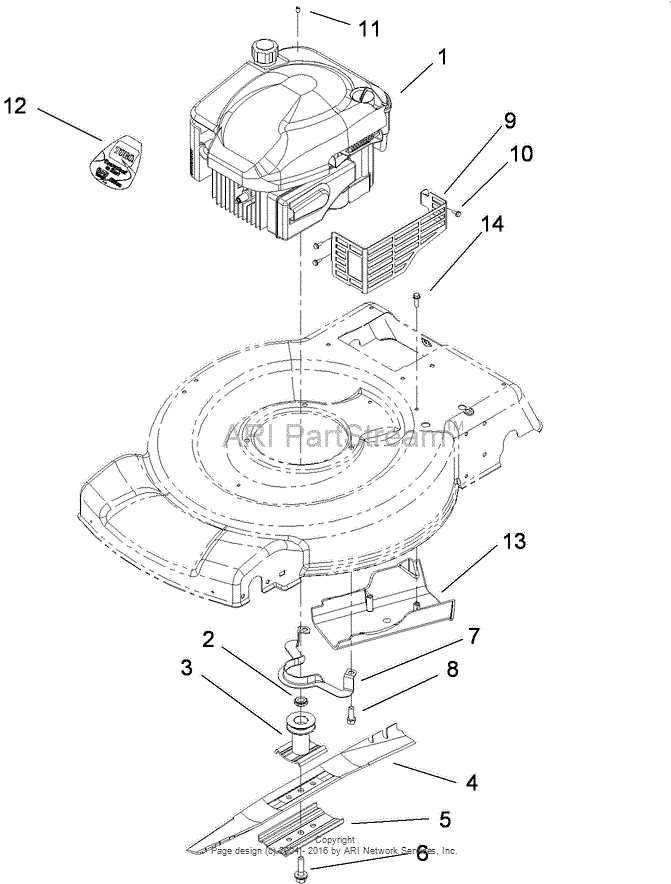

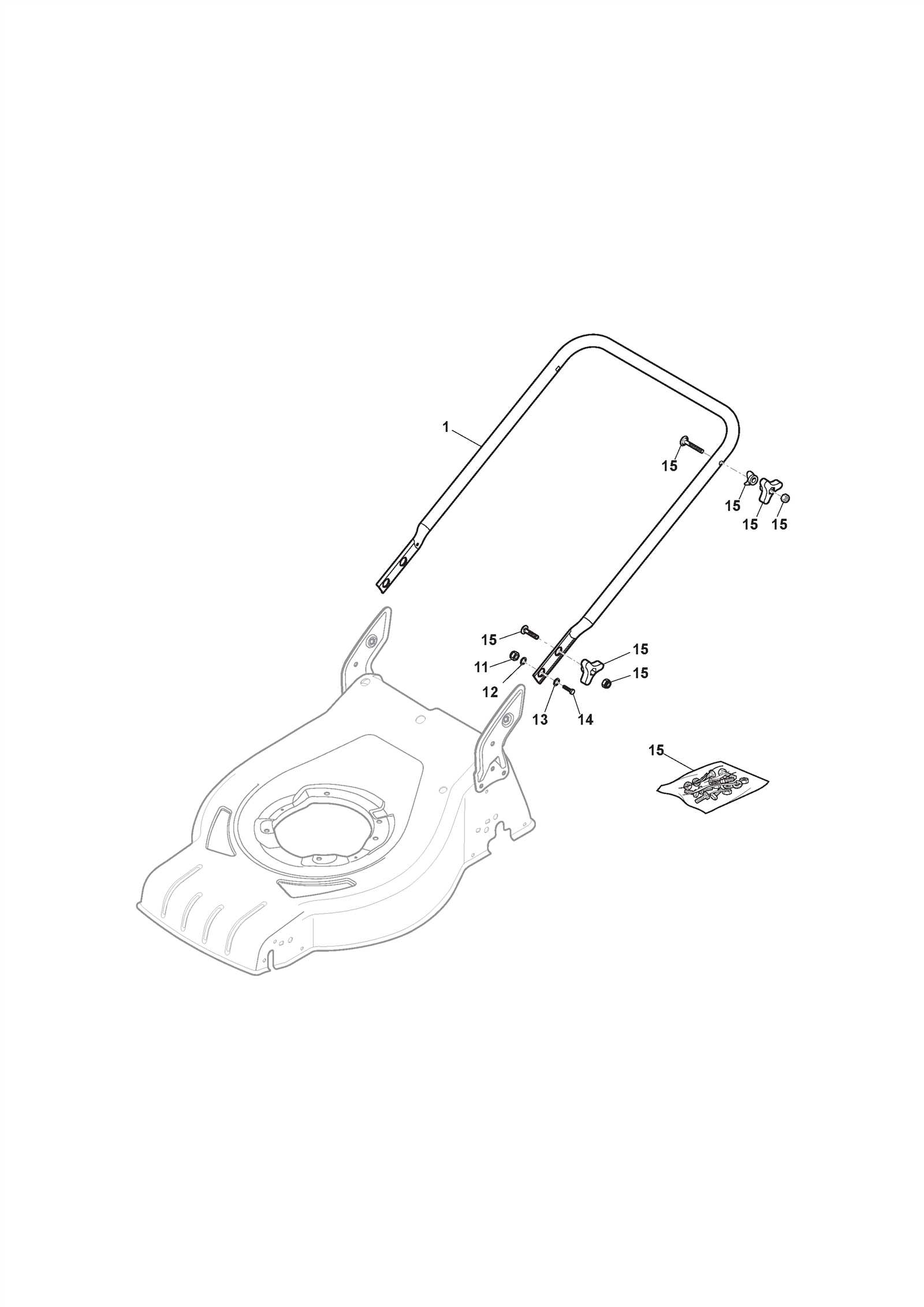

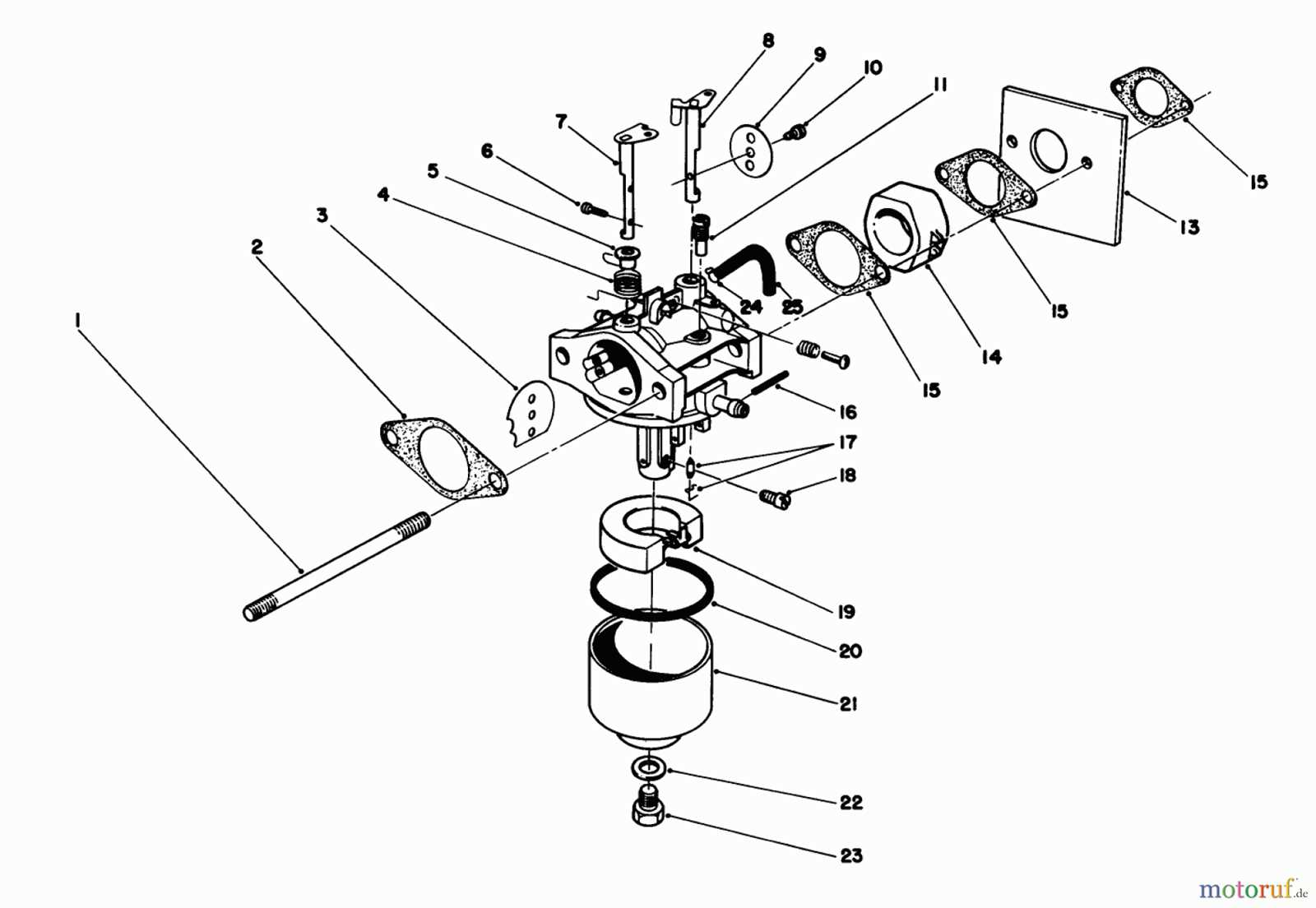

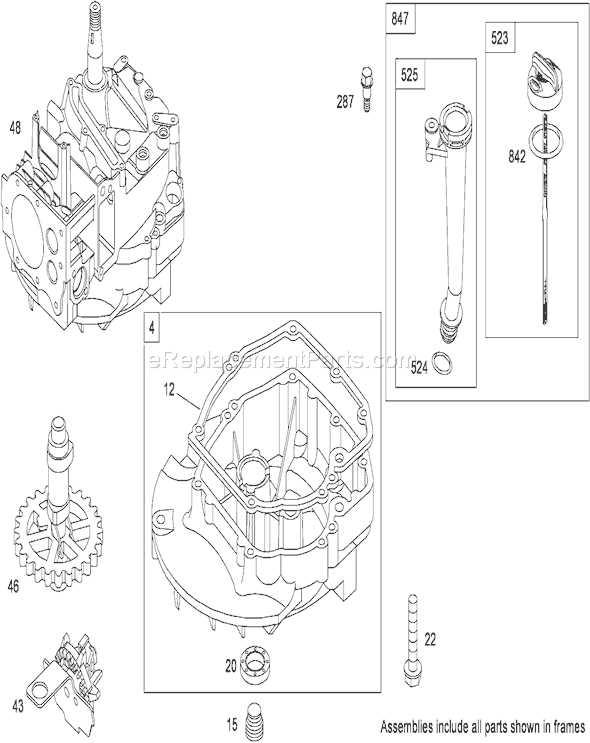

Understanding the Parts Diagram

Grasping the layout of components is essential for effective maintenance and repair of equipment. A well-structured visual representation can significantly enhance comprehension, enabling users to identify each section and its function seamlessly. This understanding aids in diagnosing issues, ensuring that users can perform tasks with confidence and precision.

Components Overview

The visual representation typically showcases various elements, each labeled for clarity. This labeling allows users to correlate the visual information with their physical counterparts, making it easier to locate specific items. Recognizing the different sections of the equipment can streamline the maintenance process, preventing unnecessary confusion.

Importance of Familiarization

Becoming familiar with the layout is crucial for troubleshooting and repairs. Users who understand the configuration of each segment can approach problems methodically. Furthermore, this knowledge supports efficient ordering of replacements, as users can identify exactly what is needed without guesswork.

Key Components of Toro 20334

This section explores the essential elements that contribute to the functionality and efficiency of the equipment. Understanding these components is crucial for effective maintenance and optimal performance. Each part plays a significant role in ensuring the overall system operates smoothly.

Core Elements

- Engine: Provides the necessary power to operate the machinery.

- Blades: Essential for achieving a clean cut, these components require regular inspection and sharpening.

- Wheels: Facilitate mobility and maneuverability, allowing the user to navigate various terrains.

- Fuel System: Supplies energy to the engine, necessitating periodic checks for leaks or blockages.

Additional Features

- Handle: Designed for comfort and control during operation.

- Deck: Protects the inner components while also housing the cutting elements.

- Control Panel: Offers user interface for adjusting settings and monitoring performance.

- Safety Mechanisms: Include features that prevent accidental starts and ensure user safety.

Common Issues and Solutions

When dealing with outdoor power equipment, various challenges may arise that can affect performance and reliability. Understanding these common problems and their solutions can help users maintain their machinery efficiently and effectively. By addressing these issues promptly, users can extend the lifespan of their equipment and ensure optimal functionality.

Below are some frequent issues encountered with similar devices, along with potential remedies:

| Issue | Possible Solutions |

|---|---|

| Engine Won’t Start |

|

| Uneven Cutting |

|

| Excessive Vibration |

|

| Overheating |

|

Maintenance Tips for Longevity

Regular upkeep is essential for extending the life of your equipment. Implementing simple practices can ensure optimal performance and reliability over time. This section highlights key maintenance strategies that can significantly enhance durability and functionality.

Routine Inspections

Conducting frequent inspections allows you to identify wear and tear before it escalates into more significant issues. Check components for signs of damage, rust, or loosening. Addressing minor problems promptly can prevent costly repairs and prolong the lifespan of your machinery.

Proper Cleaning

Maintaining cleanliness is vital for efficient operation. Remove debris and buildup after each use to prevent blockages and overheating. Use appropriate cleaning agents and tools to avoid damaging sensitive parts. A clean machine runs more smoothly and efficiently, reducing the likelihood of breakdowns.

How to Replace Parts Effectively

Replacing components in machinery requires a systematic approach to ensure optimal functionality and longevity. Proper planning and execution can prevent common mistakes and enhance the performance of your equipment. This section outlines the steps necessary for a successful replacement process.

Preparation Steps

- Identify the specific component that needs to be changed.

- Gather all necessary tools and replacement items beforehand.

- Consult the manufacturer’s guidelines for detailed instructions.

Replacement Procedure

- Ensure the machine is powered off and unplugged for safety.

- Carefully remove the faulty component, taking note of how it is installed.

- Install the new part, ensuring it fits securely and aligns properly.

- Test the equipment to confirm the new component functions as intended.

Following these guidelines will help maintain your equipment’s performance and reduce the risk of future issues. Regular maintenance and timely replacements are key to keeping machinery in optimal condition.

Safety Precautions While Repairing

When undertaking any maintenance or repair tasks, ensuring personal safety is paramount. It is essential to follow specific guidelines to prevent accidents and injuries during the process. By adhering to safety measures, you can create a secure environment that allows for effective and efficient repairs.

Always wear appropriate personal protective equipment (PPE), such as gloves, safety goggles, and sturdy footwear. This equipment protects against potential hazards like sharp edges, heavy components, and harmful substances. Furthermore, ensure your workspace is well-lit and organized to minimize the risk of slips and trips.

Before starting any work, disconnect power sources and follow proper procedures to avoid electrical shocks. Carefully read manuals and instructions associated with the equipment to familiarize yourself with its components and functions. Additionally, keep children and pets away from the work area to avoid distractions and accidents.

Maintain a clean workspace by regularly clearing away tools and debris. This practice not only enhances safety but also improves efficiency. Finally, if you are unsure about any repair process, seek assistance from a professional or experienced individual to avoid unnecessary risks.

Frequently Asked Questions

This section addresses common inquiries regarding maintenance and components related to outdoor equipment. Here, we provide clear answers to help users understand their tools better and enhance their operational efficiency.

- What should I do if a part is not functioning properly?

If a component fails to operate as expected, check for any visible damage or wear. Refer to the manual for troubleshooting steps specific to your model.

- How can I order replacement components?

You can obtain replacements through authorized dealers or online retailers specializing in garden machinery. Ensure to have the model number ready for accurate ordering.

- Are there any maintenance tips to prolong the lifespan of my equipment?

Regular maintenance is key. Clean the unit after use, check for loose screws, and ensure that all moving parts are lubricated as recommended in the user guide.

- What warranty options are available for my machinery?

Warranties can vary by model and retailer. Typically, they cover defects in materials and workmanship. Review your purchase details for specific warranty information.

- Can I perform repairs on my own?

Many users can complete basic repairs with the right tools and guidance. However, for complex issues, consulting a professional is advisable to avoid further damage.

Where to Find Genuine Parts

Finding authentic components for your equipment is crucial for ensuring optimal performance and longevity. Quality replacements not only guarantee proper functionality but also help maintain the integrity of your machinery. Therefore, sourcing genuine items should be a priority for any owner.

One of the most reliable options is to visit authorized dealers or distributors. These vendors typically have a direct connection to manufacturers, ensuring that the items they offer are legitimate and meet specific standards. Additionally, many manufacturers have official websites that provide lists of certified retailers.

Another excellent avenue is online marketplaces specializing in outdoor equipment and machinery. Look for platforms that emphasize authenticity and offer buyer protection policies. It’s also wise to read customer reviews to gauge the reliability of the seller.

Lastly, consider reaching out to local repair shops or service centers. Often, these establishments have access to original equipment and can provide insights on where to obtain the correct components. Their expertise can save you time and ensure you acquire what you need without hassle.

Benefits of Using OEM Parts

When it comes to maintaining and repairing machinery, opting for original equipment manufacturer (OEM) components offers numerous advantages. These authentic replacements are designed specifically for the equipment, ensuring a perfect fit and optimal performance.

Quality Assurance: OEM components are manufactured to the same high standards as the original units, providing reliability and durability. By choosing these genuine parts, users can rest assured that they are investing in quality that will last.

Enhanced Performance: Utilizing OEM components helps to maintain the intended functionality of the equipment. These parts work seamlessly with the existing systems, contributing to better overall performance and efficiency.

Warranty Protection: Many manufacturers offer warranties on their OEM parts, which can provide peace of mind for users. In the event of any issues, these warranties often cover repairs or replacements, protecting the investment.

Long-Term Cost Savings: While OEM components may come with a higher upfront cost compared to aftermarket alternatives, their longevity and reliability can lead to significant savings over time. Users can avoid frequent repairs and replacements, ultimately reducing overall maintenance expenses.

Resale Value: Keeping equipment in top condition with OEM components can enhance its resale value. Potential buyers often prefer machinery that has been maintained with genuine parts, as it indicates better care and longevity.

DIY Repairs vs. Professional Service

When it comes to fixing equipment, individuals often face the choice between tackling repairs themselves or seeking the help of a trained expert. Each approach has its own advantages and disadvantages, and understanding these can aid in making an informed decision.

DIY repairs can be an appealing option for those who enjoy hands-on work and wish to save money. This method allows for flexibility in timing and the satisfaction of completing a task independently. Additionally, many online resources are available, providing guidance and tips for various repair projects. However, this route can also present challenges, such as the potential for mistakes that may lead to further damage.

On the other hand, professional services offer expertise and efficiency. Experts have the knowledge and tools necessary to diagnose issues accurately and perform repairs correctly. This can save time and reduce the risk of complications. However, hiring a professional usually involves a higher cost and may require waiting for an appointment.

Ultimately, the choice between handling repairs personally or hiring an expert depends on individual skills, the complexity of the issue, and personal preferences. Each option has its merits, and weighing them can help determine the best course of action.

Customer Reviews and Experiences

This section aims to provide insights into user feedback and experiences regarding the product. By sharing their thoughts, customers can highlight the advantages and disadvantages they encountered, helping potential buyers make informed decisions.

Positive Feedback

Many users appreciate the reliability and performance of their equipment. The ease of operation is frequently mentioned, with several customers noting how intuitive the controls are. One customer stated that the machine exceeded their expectations, particularly in handling challenging tasks with efficiency.

Areas for Improvement

While there is a lot of positive feedback, some users have expressed concerns regarding specific features. A few customers reported issues with certain components, suggesting that improvements could enhance overall satisfaction. Overall, the insights from users serve as a valuable resource for anyone considering this equipment, as they reflect real-world experiences and practical usage.

Comparing Toro Models

When evaluating different models from the same manufacturer, it’s essential to understand the unique features and specifications that set each one apart. This comparison helps potential users make informed decisions based on their specific needs and preferences.

Here are some key factors to consider when comparing models:

- Performance: Assess the power and efficiency of each model, as these can significantly affect functionality.

- Durability: Examine the materials used in construction, which can influence longevity and maintenance requirements.

- Usability: Consider ease of operation, including controls, weight, and maneuverability.

- Features: Identify any unique features that enhance user experience, such as adjustable settings or additional attachments.

- Price: Compare costs to ensure you are getting the best value for the features offered.

Ultimately, a thorough comparison allows buyers to choose the model that aligns with their operational needs, ensuring optimal performance and satisfaction.