When it comes to maintaining your outdoor machinery, knowing the structure of its key elements can greatly simplify any repair or maintenance process. Understanding the inner workings of your tool not only ensures smooth functionality but also extends its life span. By having a clear visual representation of its configuration, you can easily identify which components may need attention.

In this guide, we will explore the detailed layout of your equipment’s various mechanisms. Whether you’re handling a routine check-up or diagnosing an issue, this breakdown will provide clarity on how different segments are interconnected. With a clear overview, you’ll have the confidence to approach any task with ease.

Toro 22 Inch Recycler Mower Overview

This machine represents a balance between efficiency and user-friendly design, making it ideal for maintaining outdoor spaces. It incorporates a system that repurposes natural elements to create a healthier environment for your yard, while providing a smooth experience for users. The device is engineered to offer reliability and convenience, ensuring consistent performance during use.

Key Features

The equipment is designed with several standout features. One of the highlights is its ability to process material effectively, allowing it to be reused in a way that benefits the area you’re maintaining. Additionally, the unit’s compact frame makes it easy to handle, providing smooth navigation and control even in tight spaces.

Performance and Durability

Built with high-quality materials, the device is designed to withstand regular use. Its system promotes longevity while maintaining peak efficiency, ensuring you can rely on it season after season. The combination of its resilient components and smart design contributes to a powerful yet sustainable solution for yard upkeep.

Main Components of the Toro 22 Recycler

This equipment consists of several essential elements, each designed to work together efficiently. By understanding the key structures, one can gain a better grasp of how the entire system functions. Let’s break down the most significant components that ensure optimal performance.

Engine System

The engine serves as the core of the machinery, providing the power needed for operation. Its performance dictates the efficiency and smoothness of use. Modern designs often incorporate features that enhance fuel efficiency and reduce emissions, ensuring long-lasting performance with minimal environmental impact.

- Fuel tank – stores the energy source needed for the machine to run.

- Air filter – protects the engine by filtering out dust and debris.

- Exhaust – releases gases produced during combustion.

Cutting and Collection System

The cutting system is the part responsible for trimming vegetation, while the collection mechanism ensures neat disposal of the clippings. A sharp, durable blade ensures clean cuts, contributing to the overall look of the maintained area.

- Blade – sharp, rotating piece that slices through grass efficiently.

- Deck – houses the blade and ensures proper airflow for optimal cutting.

- Bagging unit – collects the trimmed material for easy disposal.

Blade Design and Maintenance Tips

Efficient cutting is directly influenced by the design and upkeep of the cutting edge. Maintaining the sharpness and balance of this crucial component is key to ensuring consistent performance and longevity.

- Shape and Balance: The overall form of the cutting edge determines its ability to slice through various materials smoothly. It’s important to keep the edges well-balanced to avoid unnecessary strain on the machine.

- Regular Sharpening: Dull edges reduce cutting efficiency, requiring more effort and potentially damaging the surface. Sharpening should be done periodically, using appropriate tools for precision.

- Cleaning: Debris and dirt accumulate over time, affecting performance. Cleaning after use prevents buildup and rust, ensuring smoother operation.

- Inspection for Damage: Regularly check for nicks, bends, or other deformations. Damaged edges can cause uneven cuts or even break during operation, posing safety risks.

By focusing on these essential maintenance practices, you can ensure a smooth and efficient cutting experience, prolonging the life of your equipment while enhancing overall performance.

Deck Assembly and Structure Breakdown

The structure of the deck plays a critical role in ensuring the optimal performance of any cutting equipment. By understanding the arrangement of its components, you can appreciate how each part works together to provide efficient cutting and support. This breakdown explores the framework, showcasing the way various elements are connected to maintain stability and improve cutting effectiveness.

The deck is designed with a balance of support and precision. It includes a strong base that holds the blades securely, allowing for smooth movement and consistent performance. Additionally, strategic mounting points ensure that all elements align properly, reducing the likelihood of wear or damage during use.

Each part of the deck structure is interconnected, creating a system that enhances durability and functionality. The outer shell not only protects internal components but also contributes to the airflow needed for proper cutting action. This combination of elements is essential for achieving reliable results, even under challenging conditions.

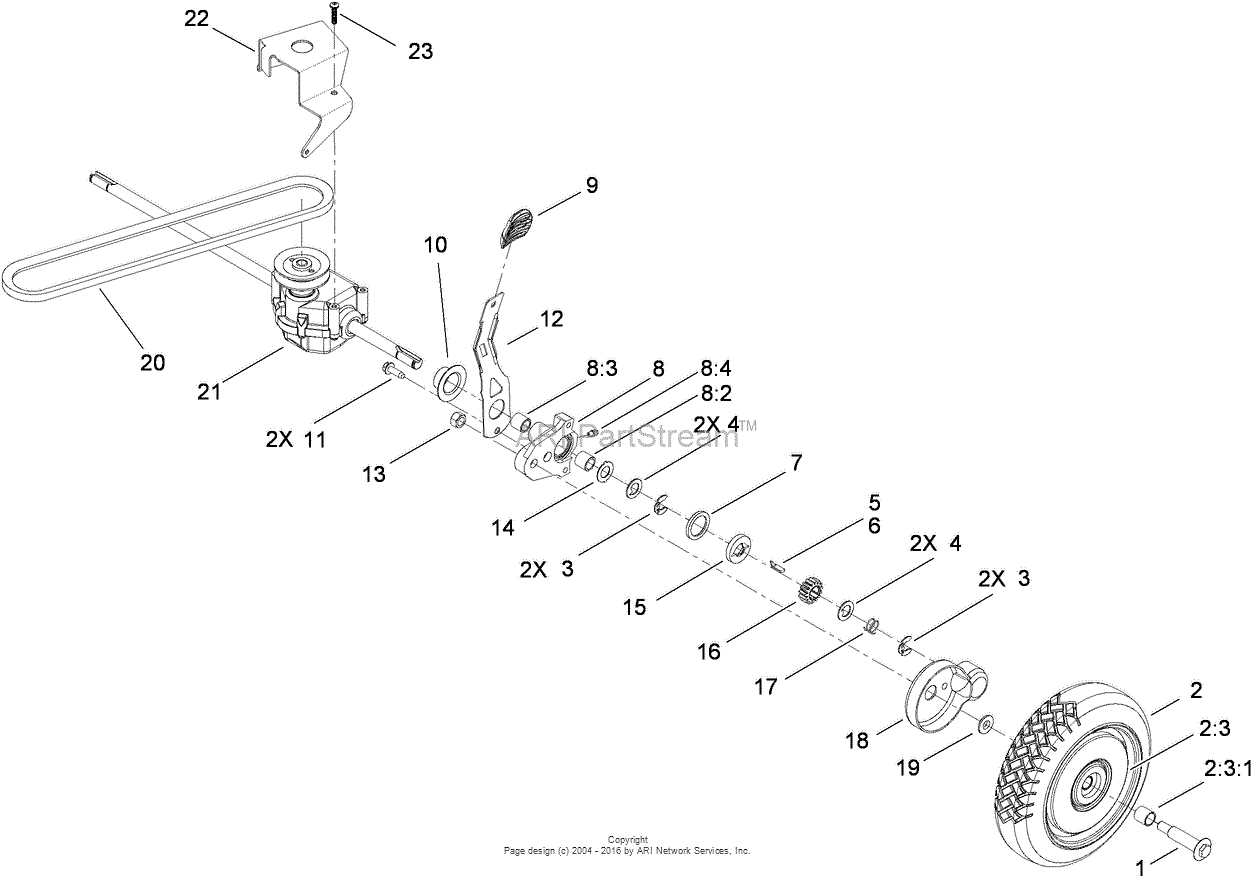

Understanding the Drive System Mechanism

The propulsion system in any outdoor cutting tool relies on a series of interconnected components that work together to ensure smooth motion. This mechanism is designed to transfer power efficiently, allowing the operator to move the equipment without excessive effort. By exploring the details of how this system functions, one can better grasp its significance in overall performance and maintenance.

Below are the key elements involved in the propulsion setup:

- Drive Belt: This component transmits force from the engine to the wheels, enabling forward movement. Over time, wear and tear may reduce its effectiveness, requiring periodic replacement.

- Transmission: The transmission adjusts speed and torque, ensuring that the machine moves at a controlled pace, regardless of terrain or user input.

- Axle and Wheels: The axle distributes power to the wheels, which provide traction and support. The choice of wheel type can impact how well the equipment handles different surfaces.

- Engagement Lever: The lever allows the user to activate or deactivate the propulsion system, giving greater control over movement during operation.

Maintaining these components is essential for keeping the tool running efficiently. Regular inspection and adjustment can prevent common issues, such as loss of power or uneven movement.

Engine Parts and Functionality Guide

The engine is the driving force that powers the entire machine. Understanding its key components and how they interact is essential for maintaining peak performance. By knowing the core elements, you can better diagnose issues and ensure smooth operation.

- Cylinder: The core where fuel combustion occurs, generating the energy needed to power the device.

- Crankshaft: Transforms the energy from combustion into rotary motion, propelling other mechanical systems.

- Carburetor: Mixes fuel and air in the right proportions for efficient combustion.

- Flywheel: Stores rotational energy and helps maintain a consistent engine speed.

- Valves: Regulate the flow of air and fuel into the combustion chamber and control the exhaust gases.

- Spark Plug: Ignites the fuel-air mixture to initiate combustion within the cylinder.

Each element plays a critical role, working together to convert energy into motion. Proper care and understanding of these components ensure reliable and effective performance.

Wheel Configuration and Adjustment Guide

Understanding how to configure and adjust the wheels is essential for maintaining optimal performance of your equipment. A properly aligned wheel system ensures smoother operation and better control. This section will guide you through the steps needed to fine-tune the wheel settings, allowing for efficient movement and enhanced stability on various surfaces.

- Ensure that the wheels are securely attached to the frame before any adjustments.

- Check for even height on all sides to prevent tilting or uneven cutting.

- Each wheel can typically be adjusted by using height levers or a similar mechanism. Locate these controls near the wheelbase and select the desired setting.

- If your equipment operates on uneven terrain, adjusting the wheels to different heights can improve balance and maneuverability.

- Position the equipment on a flat surface for the most accurate adjustment.

- Identify the adjustment controls for each wheel. Typically, these are found near the wheel hub.

- Adjust each wheel individually, ensuring that the height matches your preferred level.

- Test the equipment to ensure smooth movement and make further adjustments if necessary.

Maintaining proper wheel alignment will result in consistent performance, providing a smooth and stable user experience. Regularly checking the wheel settings can help prolong the lifespan of your equipment.

Handlebar Setup for Comfortable Use

Setting up the handlebar properly is crucial for ensuring long-term comfort and ease of use. By adjusting the positioning and grip, you can minimize strain on your wrists and shoulders, making outdoor tasks less tiring and more efficient. The right configuration allows for a more relaxed posture and better control over your equipment.

Adjusting the Height

The height of the handlebar plays a significant role in creating an ergonomic experience. Make sure to adjust it according to your height so that your hands rest naturally without requiring you to hunch over or overextend your arms. This simple step can prevent fatigue and improve your overall comfort while working.

Grip Considerations

Comfortable grips are essential to reduce hand strain during prolonged use. Choose handles with soft, cushioned surfaces that allow for a firm yet gentle hold. Additionally, you may want to ensure that the grip design minimizes slippage, which is especially helpful when operating the equipment in varying conditions.

Fuel Tank and Fuel Line Layout

The fuel system ensures the smooth delivery of gasoline to the engine, allowing it to operate efficiently. The arrangement of the components within the system plays a key role in maintaining reliable performance and preventing disruptions during operation. Understanding the configuration of these elements can help you identify potential issues and perform necessary maintenance to keep everything running smoothly.

Fuel Tank Structure

The fuel container is designed to securely store gasoline while minimizing leakage and evaporation. It is built with durable materials to withstand wear and tear over time. The tank connects to the engine through a secure line that delivers fuel as needed, ensuring a steady flow without interruptions.

Fuel Line Configuration

The fuel line connects the tank to the engine, providing a seamless route for gasoline to travel. This line must be kept free from blockages and damage to prevent any operational problems. Regular checks of the hose and its connections are essential for maintaining an uninterrupted fuel supply.

Grass Bagging System: How It Works

The collection system is designed to efficiently gather cut vegetation, keeping the area clean and enhancing the overall performance. Understanding the process behind this system helps in maximizing its effectiveness and prolonging its lifespan.

Here’s a breakdown of how the collection mechanism functions:

- The blades finely chop the grass, creating small clippings that are easy to collect.

- A strong airflow directs the cut pieces into the attached bag, ensuring minimal scattering.

- The collection container is designed to hold a large volume, reducing the need for frequent emptying.

- Proper sealing and airflow management prevent debris from escaping during operation.

By regularly maintaining the bagging system, users can ensure smooth operation and optimal collection results every time.

Control Panel and Lever Functions Explained

The control area and levers provide the user with full command over the machine’s operation. Understanding how these elements work together allows for better efficiency and smoother functionality. Each lever and button serves a specific role, ensuring easy navigation and adjustments during use.

Below is a breakdown of the primary control mechanisms and their respective functions:

| Component | Function |

|---|---|

| Engine Start Lever | Engages the mechanism to power up the engine for operation. |

| Throttle Control | Regulates the engine’s speed, allowing for adjustments based on conditions. |

| Drive Lever | Activates forward movement, helping to guide the device with ease. |

| Height Adjustment Lever | Enables the user to modify the height, adjusting to preferred settings. |

| Stop Control | Shuts off the engine or halts movement when necessary. |

Maintaining the Mulching Feature Efficiently

The ability to finely process grass clippings and distribute them evenly back onto the ground is a highly efficient way to nourish the soil while keeping your yard neat. However, ensuring this feature continues to work at its best requires consistent care and attention to specific components that help break down and spread organic material. By regularly checking these elements, you can extend the overall efficiency of the mulching system.

Cleaning the Cutting Blades

Sharp, well-maintained blades are key to achieving optimal performance. Dull edges can hinder the proper cutting process, leading to larger clumps of debris. Cleaning the blades after each session and sharpening them periodically will ensure they maintain their efficiency, contributing to a finer, more even distribution of the clippings.

Ensuring Proper Airflow

A key aspect of efficient grass processing is sufficient airflow through the cutting deck. If airflow is restricted, the mulched material may not be properly distributed. Cleaning any debris buildup and inspecting the vents for blockages is essential to keep air circulation uninterrupted. This not only enhances performance but also prevents potential mechanical issues.

Troubleshooting Common Issues with the Toro 22

Addressing frequent problems can enhance the performance and longevity of your outdoor equipment. Understanding potential malfunctions is essential for maintaining optimal functionality. This section will explore typical challenges users may encounter and provide effective solutions to ensure your machine operates smoothly.

Engine Not Starting

If your equipment fails to start, it could be due to several factors. Checking the fuel level, battery charge, and ignition system can help identify the issue. Below is a troubleshooting table for a quick reference.

| Potential Cause | Solution |

|---|---|

| Empty fuel tank | Refill with fresh gasoline |

| Dead battery | Charge or replace the battery |

| Clogged air filter | Clean or replace the air filter |

| Faulty spark plug | Inspect and replace if necessary |

Poor Cutting Performance

Inadequate cutting may result from dull blades or improper height settings. Regular maintenance ensures that your blades remain sharp and the equipment is correctly adjusted for the desired grass length. Here’s a quick reference to assist you.

| Issue | Recommended Action |

|---|---|

| Dull blades | Sharpen or replace the blades |

| Incorrect cutting height | Adjust the cutting height settings |

| Grass buildup under deck | Clean the underside of the deck regularly |

| Uneven terrain | Level the area before operation |