Maintaining outdoor equipment is crucial for ensuring long-lasting performance and reliable functionality. Each component plays a vital role in keeping the machine operating at its best, whether you’re managing large grounds or smaller residential lawns. By regularly inspecting and replacing elements, you can extend the lifespan of the equipment and avoid unexpected breakdowns.

This guide will provide a detailed overview of the essential elements that make up professional-grade lawn care machines. By familiarizing yourself with their structure, you’ll be better equipped to handle repairs and routine maintenance, ensuring smooth and efficient operation throughout the season.

Understanding how each part functions will help you identify potential issues early on, minimizing downtime and maximizing productivity. Whether it’s drive mechanisms, cutting blades, or control systems, knowing how everything fits together is key to keeping your equipment in optimal condition.

Understanding the Toro 30 TurfMaster Mower

When dealing with a professional-grade mower designed for large-scale areas, it’s important to familiarize yourself with its key features and how it operates. This equipment is known for its efficiency and reliability, making it a popular choice for those maintaining expansive lawns. Understanding the primary components and how they work together will ensure optimal performance and longevity.

Key Features of the Mower

This robust machine is equipped with a wide cutting deck that allows you to cover more ground with fewer passes. It also has a powerful engine, designed to handle tough grass and varied terrain. Other important elements include the adjustable height settings, which provide flexibility depending on the grass length, and the ergonomic controls that help reduce operator fatigue during extended use.

Maintenance and Longevity

To keep the mower in excellent condition, regular maintenance is essential. Routine tasks like sharpening the blades, checking the oil levels, and cleaning the air filters will prolong the machine’s life and ensure it runs smoothly. Proper care helps prevent costly repairs and downtime, keeping your equipment ready for action whenever needed.

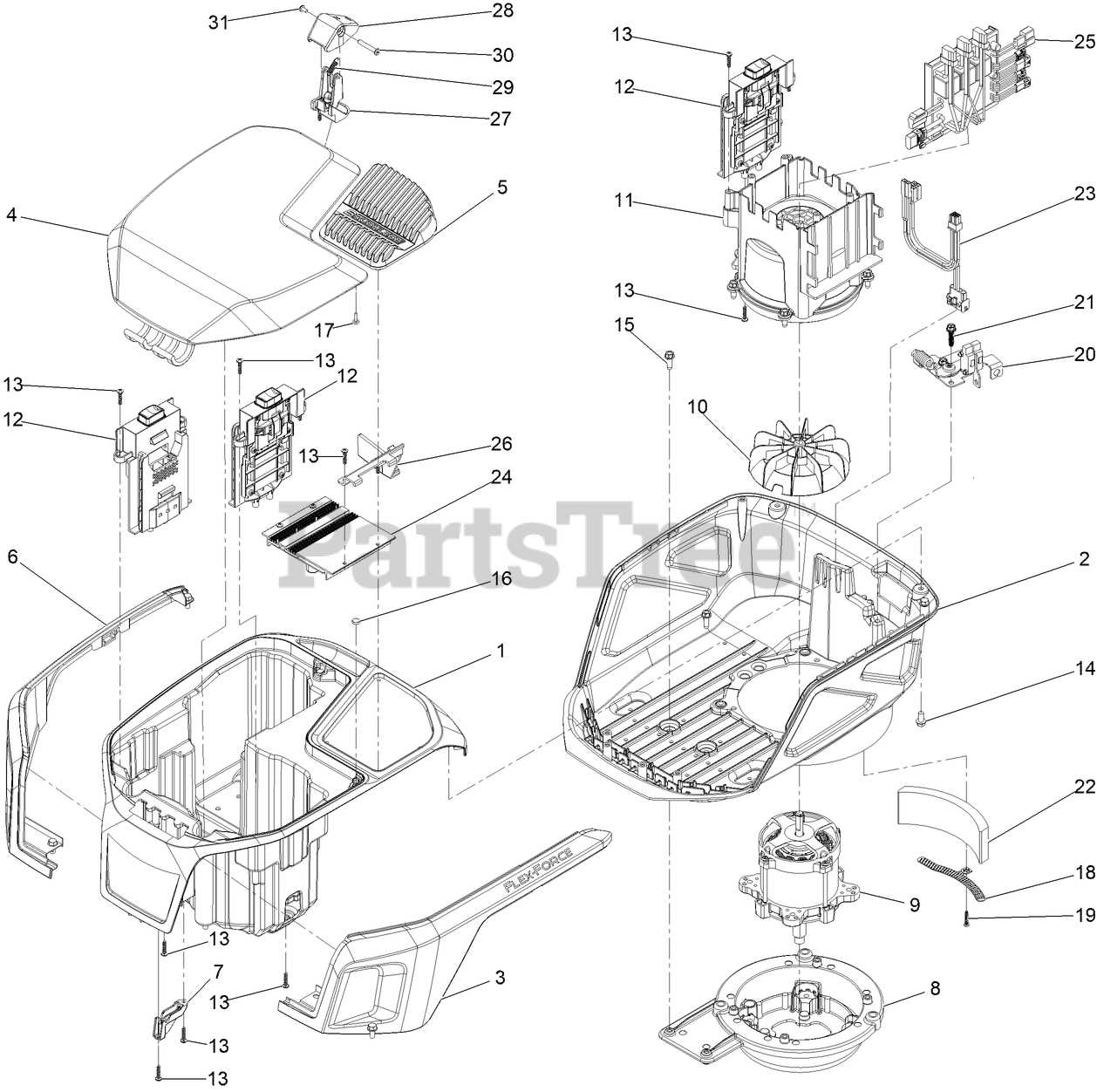

Essential Components of the TurfMaster

The machine in question relies on a series of key elements that ensure its performance and durability during extended use. Understanding these essential components helps to maintain functionality and enhance operational efficiency.

Engine and Drive System

The core of the machine’s operation lies in its engine, which powers both the cutting mechanism and the propulsion system. The drive system, consisting of belts and pulleys, transmits the engine’s power to the wheels, enabling movement and control.

Cutting Deck and Blades

The cutting deck houses a set of sharp blades responsible for trimming grass to the desired length. This component is designed for precision and efficiency, allowing for smooth and consistent cuts across large areas.

- Blades: These are the primary tools for cutting grass, designed for maximum sharpness and durability.

- Deck Wheels: Adjustable wheels on the cutting deck ensure consistent height and smooth operation on uneven surfaces.

- Discharge Chute: A chute directs clippings away from the deck, preventing clogging and ensuring clean operation.

- Control Panel: The control panel allows the operator to adjust settings and monitor machine status.

- Safety Features: Built-in safety mechanisms prevent accidental starts and ensure safe operation.

Blade Assembly and Replacement Guide

Proper maintenance of the cutting components is crucial for ensuring the efficiency and longevity of your equipment. This section provides a detailed overview of how to safely assemble and replace the cutting blades. Regular inspection and timely replacement of worn or damaged parts can prevent issues and improve overall performance.

Steps for Blade Removal

Before beginning the process, make sure the machine is turned off and disconnected from any power source. Secure the cutting mechanism to avoid accidental movement. Using the appropriate tools, loosen the fastening bolts and carefully remove the blade. Always handle the blade with caution as it may have sharp edges that can cause injury.

Installing the New Blade

When installing a new blade, ensure that it is aligned correctly with the mounting surface. Tighten the bolts securely, but avoid overtightening, which could damage the assembly. After installation, verify that the blade is properly seated and spins freely without obstruction. Periodic checks and maintenance are recommended to ensure ongoing operational efficiency.

How the Cutting Deck Operates

The cutting deck plays a crucial role in maintaining an even and clean cut across large areas. It consists of multiple components working in harmony to ensure the blades effectively slice through the grass, providing a smooth and consistent finish. Understanding the basic mechanics behind the operation of this system helps in maximizing its efficiency and extending the lifespan of the machine.

| Component | Function |

|---|---|

| Blades | Responsible for cutting grass at the desired height, rotating at high speed. |

| Spindle Assembly | Supports the blades and enables their rotation through mechanical force. |

| Deck Belt | Transfers power from the engine to the blades, driving their movement. |

| Height Adjustment Lever | Allows the user to control the cutting height for optimal performance on different terrains. |

| Discharge Chute | Directs the cut grass away from the deck, ensuring smooth operation. |

These elements function together to deliver precise cutting performance. Regular maintenance, including sharpening blades and checking belt tension, is key to maintaining smooth operation and preventing uneven cuts.

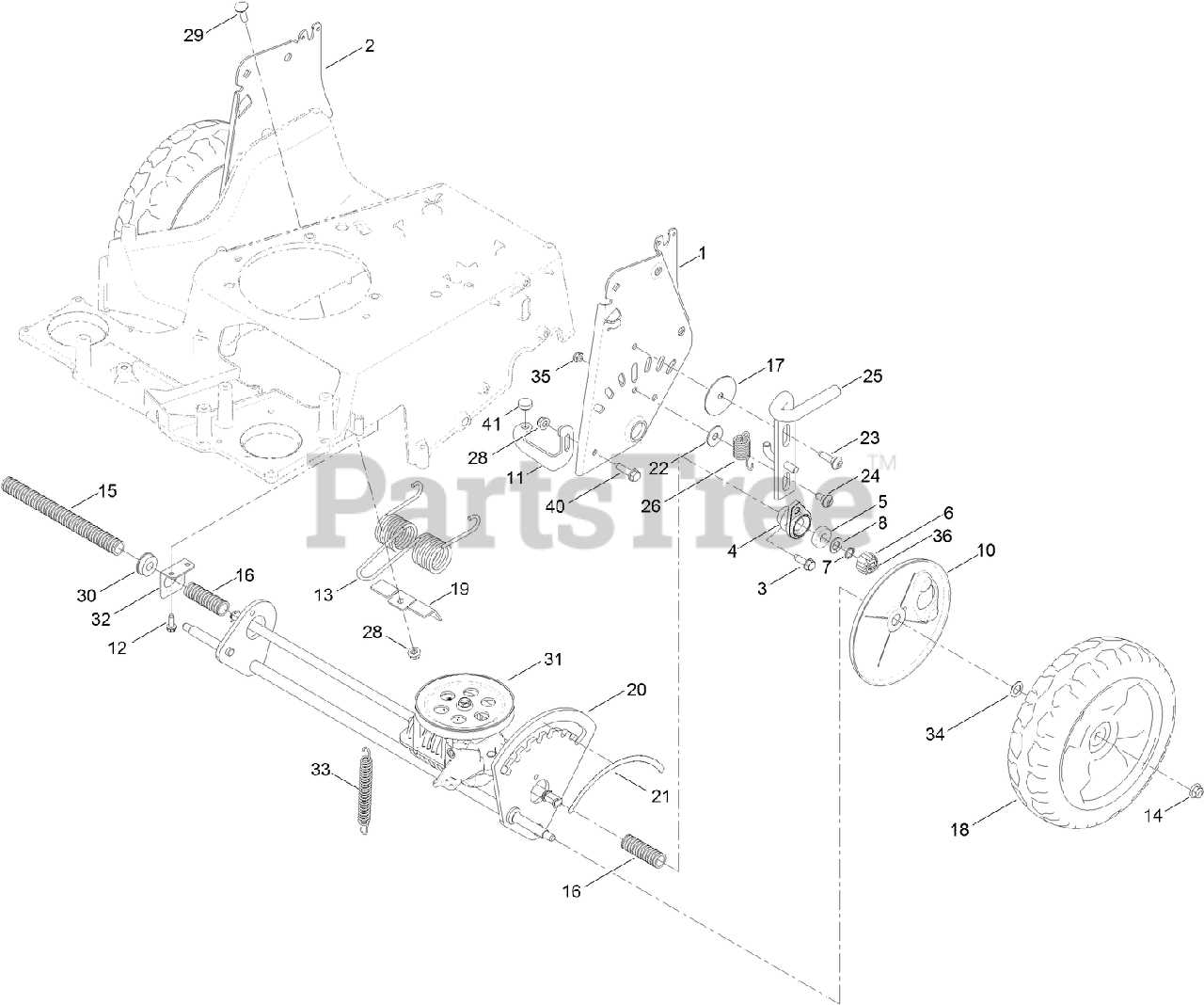

Drive System Overview for TurfMaster

The drive system of this commercial-grade mower is designed to provide reliable power transfer, ensuring smooth operation and high efficiency across various terrain types. This section will highlight the key components and their roles in maintaining optimal performance.

Key Components of the Drive System

- Transmission: Responsible for regulating the power sent to the wheels, allowing for controlled movement and speed adjustments.

- Drive Belt: Connects the engine to the transmission, ensuring a seamless transfer of power without slippage.

- Axle Assembly: Supports the wheels and ensures stable movement while handling uneven surfaces.

Maintenance Tips

- Regularly inspect the drive belt for wear and replace it if necessary to avoid power loss.

- Ensure the transmission is properly lubricated to prevent overheating and ensure smooth operation.

- Check the axle assembly for any signs of damage or looseness, which could affect the stability and maneuverability of the machine.

By keeping the drive system in optimal condition, you can maximize the machine’s efficiency and longevity, ensuring that it performs effectively even under challenging conditions.

Throttle and Control Mechanisms Explained

Understanding the operation of throttle and control systems is crucial for optimizing machinery performance. These components play a vital role in regulating engine speed and managing overall functionality, allowing users to maintain efficiency and precision during operation.

The throttle is a pivotal part of any engine system, responsible for controlling the flow of air and fuel mixture. By adjusting this flow, the throttle influences engine power output and responsiveness. When the throttle is engaged, it can either increase or decrease the speed, depending on the user’s requirements.

In addition to the throttle, control mechanisms are designed to enhance user experience and ensure safety. These include levers, switches, and electronic controls that allow for intuitive operation. A well-designed control interface provides the operator with the ability to make precise adjustments, ensuring optimal performance in various conditions.

Furthermore, maintaining these components is essential for long-term functionality. Regular inspections and adjustments can prevent wear and ensure that both the throttle and control systems operate smoothly, thus enhancing the lifespan of the equipment. Proper understanding and maintenance of these mechanisms can lead to more effective use of machinery and improved outcomes in various tasks.

Fuel System Parts and Maintenance

The fuel system is a crucial component that ensures optimal performance and efficiency of your equipment. Proper care and regular checks are essential to prevent issues related to fuel delivery, which can lead to decreased performance or even operational failure. Understanding the various elements involved in the fuel system can help in maintaining it effectively.

Key Components of the Fuel System

Several vital components work together to ensure a smooth fuel flow. The fuel tank stores the gasoline, while the fuel pump is responsible for transferring the fuel to the engine. Additionally, fuel filters are essential for removing contaminants from the fuel before it reaches the engine. Regular inspection of these elements is necessary to maintain functionality and prevent clogs or leaks.

Maintenance Tips

Routine maintenance is vital for keeping the fuel system in top condition. Regularly checking the fuel filter for signs of wear or blockage can prevent fuel flow issues. Additionally, it is advisable to inspect the fuel lines for any leaks or cracks, as this can lead to fuel loss and potential safety hazards. Keeping the fuel tank clean and ensuring it is filled with quality fuel will contribute to the overall longevity and performance of the system.

Air Filter and Engine Protection Components

The efficiency and longevity of any motorized equipment rely significantly on its filtration and protective mechanisms. These systems work harmoniously to ensure that the engine operates smoothly and remains shielded from harmful elements. Understanding these components is crucial for maintaining optimal performance and reliability.

Key Functions of the Air Filter

The air filter plays a vital role in sustaining engine health. Its primary functions include:

- Trapping dirt, dust, and debris to prevent them from entering the engine.

- Ensuring a steady supply of clean air for efficient combustion.

- Contributing to better fuel efficiency and power output.

Protection Mechanisms

In addition to the air filter, several other elements contribute to safeguarding the engine:

- Oil Filter: Keeps contaminants from the engine oil, ensuring smooth lubrication.

- Fuel Filter: Prevents impurities from reaching the combustion chamber, promoting efficient fuel delivery.

- Seals and Gaskets: Protect against leaks and maintain pressure within the engine system.

Regular inspection and replacement of these components are essential for prolonging the life of the engine and enhancing overall performance.

Wheels and Traction Parts Layout

This section provides an overview of the essential components that contribute to the mobility and grip of the equipment. Understanding the arrangement and functionality of these elements is crucial for maintaining optimal performance during operation.

Key Components

The configuration of wheels and traction elements significantly influences the handling and stability of the machine. Each component plays a vital role in ensuring smooth movement across various terrains. Key features include:

| Component | Description |

|---|---|

| Front Wheels | Designed for steering and maneuverability, providing agility in tight spaces. |

| Rear Wheels | Responsible for supporting the bulk of the weight and providing stability during operation. |

| Traction Treads | Specially designed patterns that enhance grip on various surfaces, improving control. |

| Wheel Hubs | Connect the wheels to the axle, facilitating rotation and load distribution. |

| Axles | Support the wheels and allow them to rotate, contributing to overall movement. |

Maintenance Considerations

Regular inspection and upkeep of these components are essential for ensuring durability and performance. Proper maintenance practices can prevent wear and enhance the longevity of the mobility system.

Common Issues with the Drive Belt

The drive belt is a crucial component in many machinery systems, providing the necessary power transfer for optimal performance. However, like any mechanical part, it can encounter various challenges that may affect functionality. Understanding these issues is essential for maintaining efficiency and ensuring the longevity of the equipment.

Wear and Tear

Over time, drive belts can experience significant wear due to constant friction and exposure to environmental factors. Signs of deterioration may include cracks, fraying, or a shiny appearance on the surface. Regular inspections are vital to identify these issues early, as neglect can lead to complete failure and costly repairs.

Misalignment

Improper alignment of the drive belt can result in uneven wear and increased strain on the machinery. This misalignment may stem from incorrect installation or wear of other components such as pulleys. Monitoring the alignment and adjusting it as necessary can help prevent premature damage and ensure smooth operation.

Handle and Operator Controls Diagram

This section provides an overview of the essential components that facilitate user interaction and machine operation. Understanding the layout and functionality of these elements is crucial for efficient use and maintenance of the equipment.

The operator controls are strategically positioned to enhance accessibility and usability. Below are the primary components typically found in such systems:

- Handle: The main grip area that allows for maneuvering the equipment effectively.

- Throttle Control: A lever or dial that adjusts the engine speed, enabling optimal performance based on the task.

- Height Adjustment Lever: This control allows the operator to set the cutting height according to the desired grass length.

- Power Switch: A simple toggle or button to start and stop the engine safely.

- Brake Control: Engages the braking system, ensuring the equipment stops safely when needed.

By familiarizing oneself with these controls, users can operate the machine confidently and efficiently. Proper understanding also aids in troubleshooting any operational issues that may arise.

Where to Find Genuine Toro Parts

When it comes to maintaining your lawn equipment, sourcing authentic components is crucial for optimal performance and longevity. Understanding where to obtain high-quality replacements can save time and ensure your machinery runs smoothly.

Authorized Dealers

One of the best ways to ensure you are getting original components is by visiting certified distributors. These retailers are trained to provide the right solutions for your machinery and typically stock a wide range of items. Additionally, they can offer expert advice and support for your specific needs.

Online Resources

The internet has made it easier to locate genuine components from reputable suppliers. Many websites specialize in providing authentic items, often with detailed descriptions and compatibility information. Always check reviews and ratings to confirm the reliability of the online store.

| Source Type | Description |

|---|---|

| Authorized Dealers | Official retailers with trained staff and a wide range of products. |

| Online Retailers | Websites specializing in original items, often with customer reviews. |

| Manufacturer’s Website | Direct access to authentic components and new releases. |