In the world of lawn care equipment, having a comprehensive grasp of the internal structure and components is crucial for optimal performance. This section delves into the intricate details of a specific model, highlighting its essential features and how they interconnect. By exploring the various elements involved, users can gain valuable insights into maintenance and troubleshooting.

When tackling any mechanical device, knowledge of its individual parts not only aids in repairs but also enhances overall efficiency. A well-organized breakdown of the elements allows for easier identification of issues and streamlines the repair process. This understanding is particularly beneficial for both seasoned professionals and enthusiastic DIYers.

Furthermore, familiarizing oneself with the assembly of components fosters a greater appreciation for the engineering that goes into creating reliable machinery. This exploration serves as a guide for anyone looking to enhance their skills in equipment management and upkeep, ensuring longevity and peak performance of their tools.

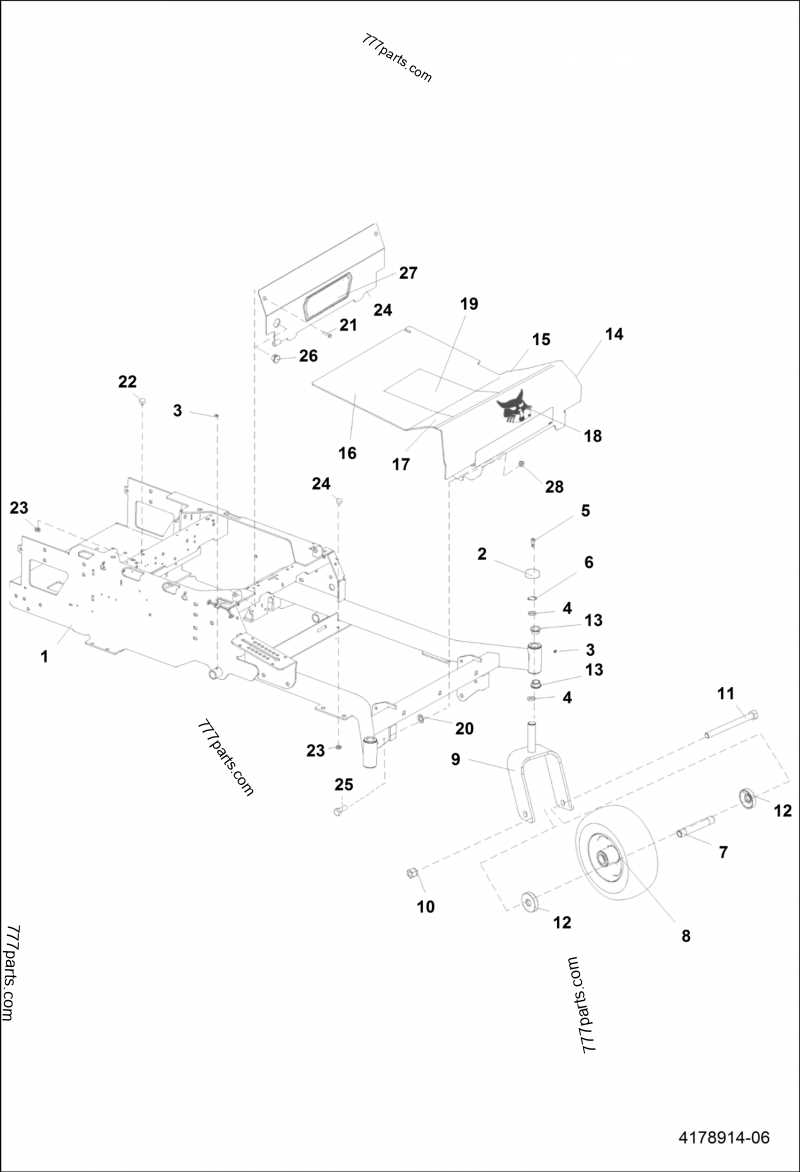

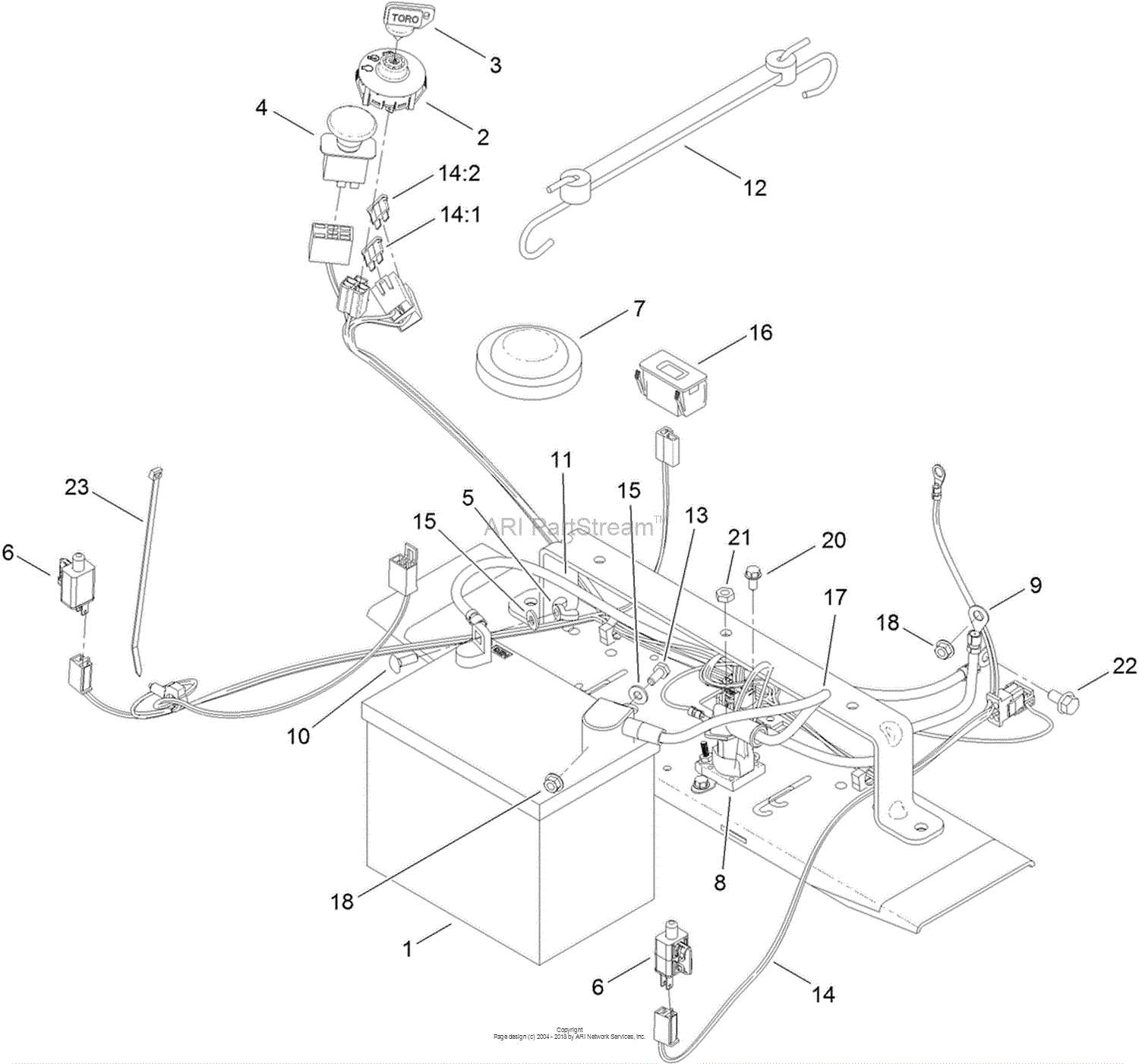

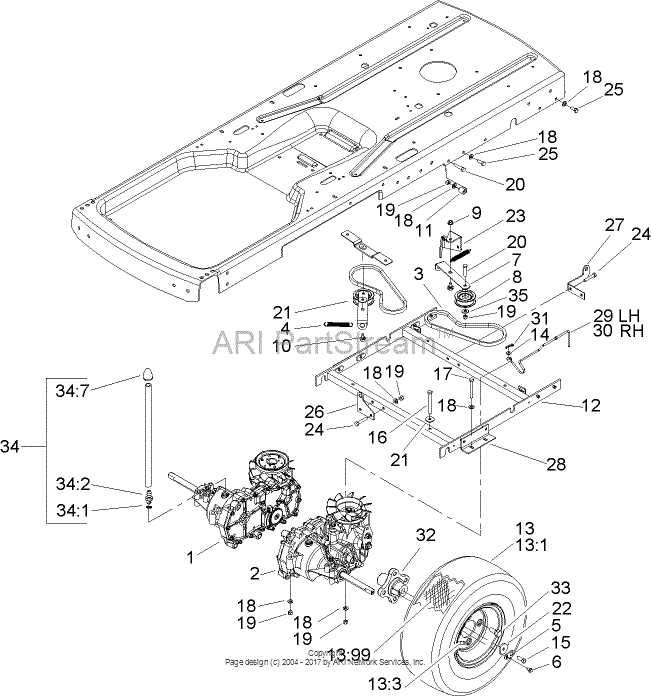

Understanding Toro 75750 Parts Diagram

Grasping the layout of components for a specific model is essential for effective maintenance and repairs. A clear illustration of various elements aids in identifying the necessary items for servicing and replacement, ensuring the longevity and optimal performance of your equipment. Familiarity with these visuals empowers users to address issues efficiently and with confidence.

Importance of Component Identification

Recognizing individual components and their functions allows for a streamlined approach to troubleshooting. By understanding how each piece interacts within the assembly, operators can pinpoint potential failures more rapidly. This knowledge not only reduces downtime but also minimizes the risk of overlooking critical aspects during servicing.

Utilizing Visual Guides for Repairs

Visual aids serve as a valuable resource during maintenance tasks. They provide a reference point that simplifies the reassembly process, ensuring that all necessary items are correctly positioned. Moreover, these guides can highlight specific details that may be overlooked in written instructions, enhancing the overall repair experience. Investing time in studying these visuals can ultimately lead to greater efficiency and effectiveness in upkeep.

Overview of Toro 75750 Model

This model stands out in the realm of outdoor equipment, offering a blend of durability and performance. Designed for efficiency, it caters to the needs of both residential and commercial users, ensuring reliable operation in various conditions.

Key features include advanced technology and user-friendly controls, which enhance the overall experience. Its robust construction is built to withstand the rigors of regular use, making it a trusted choice for many.

Maintenance and support are also prioritized, with readily available resources to help users keep the equipment in top condition. Overall, this model embodies the ultimate in functionality and reliability for outdoor tasks.

Importance of Accurate Parts Identification

Identifying components with precision is crucial for maintaining functionality and efficiency in machinery. Misidentification can lead to improper replacements, resulting in potential malfunctions and increased repair costs.

Benefits of Accurate Identification

- Enhanced Performance: Ensures optimal operation of equipment.

- Cost Efficiency: Reduces unnecessary expenditures on incorrect replacements.

- Extended Lifespan: Promotes longevity of machinery through appropriate upkeep.

Consequences of Misidentification

- Increased Downtime: Equipment failure can lead to significant delays.

- Safety Hazards: Incorrect components can create dangerous situations.

- Wasted Resources: Time and money spent on unsuitable items can add up.

Common Issues with Toro 75750

When it comes to outdoor maintenance equipment, certain challenges often arise that can hinder performance and efficiency. Understanding these frequent problems can help users troubleshoot effectively and maintain their machinery in optimal condition.

Frequent Problems

- Difficulty in starting the engine

- Inconsistent power delivery

- Clogged air filters

- Fuel system blockages

- Worn-out blades

Preventive Measures

- Regular maintenance checks

- Cleaning or replacing air filters

- Inspecting fuel lines for clogs

- Sharpening or replacing blades as needed

- Ensuring proper storage and winterization

Addressing these common issues with preventive care can greatly enhance the longevity and functionality of your equipment, ensuring it performs at its best season after season.

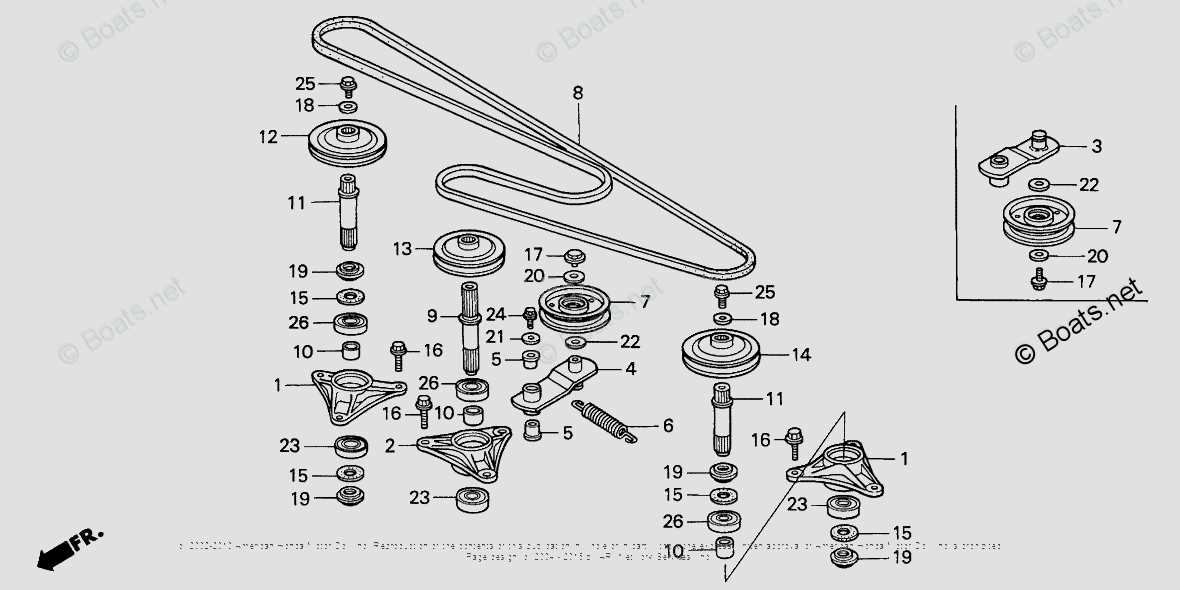

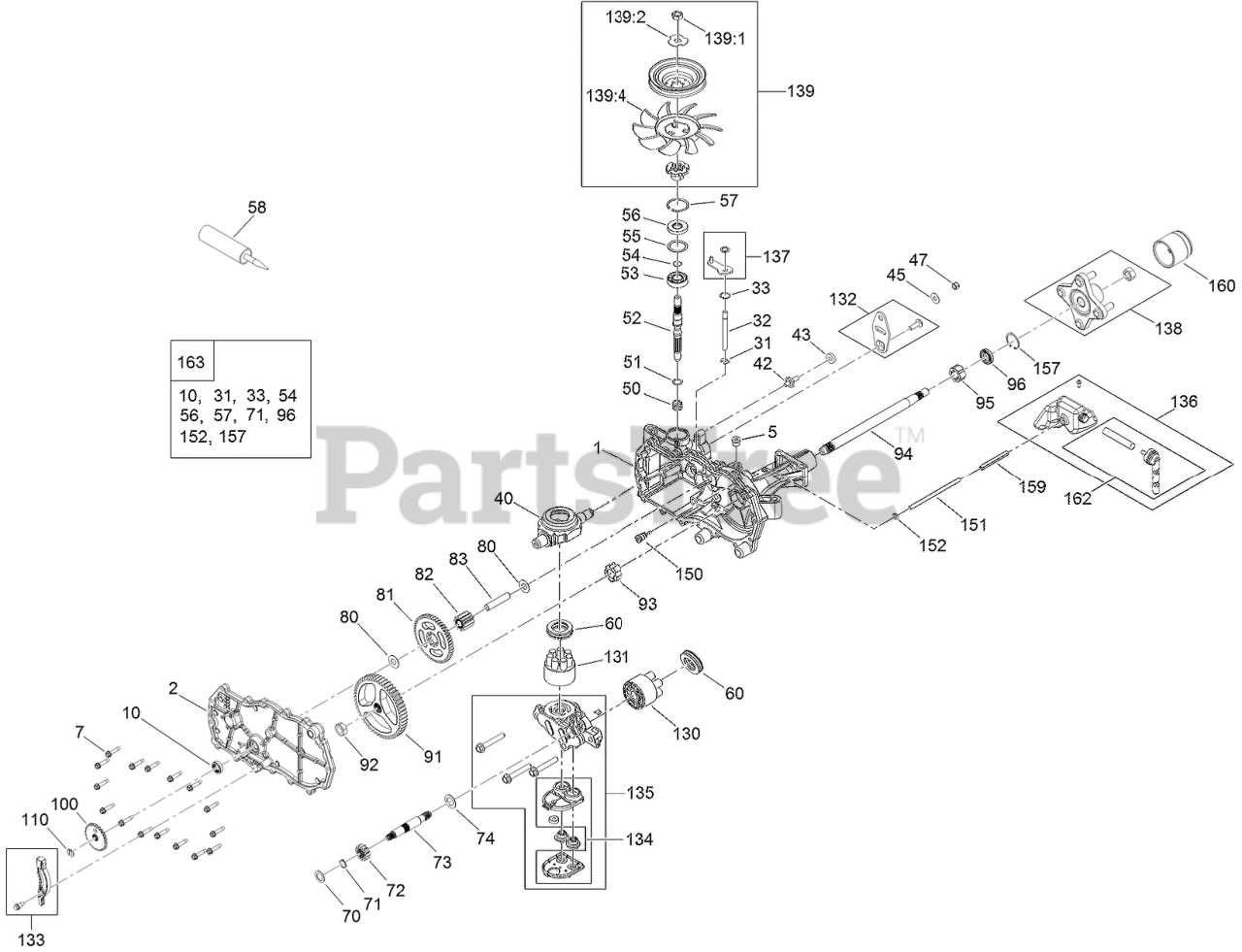

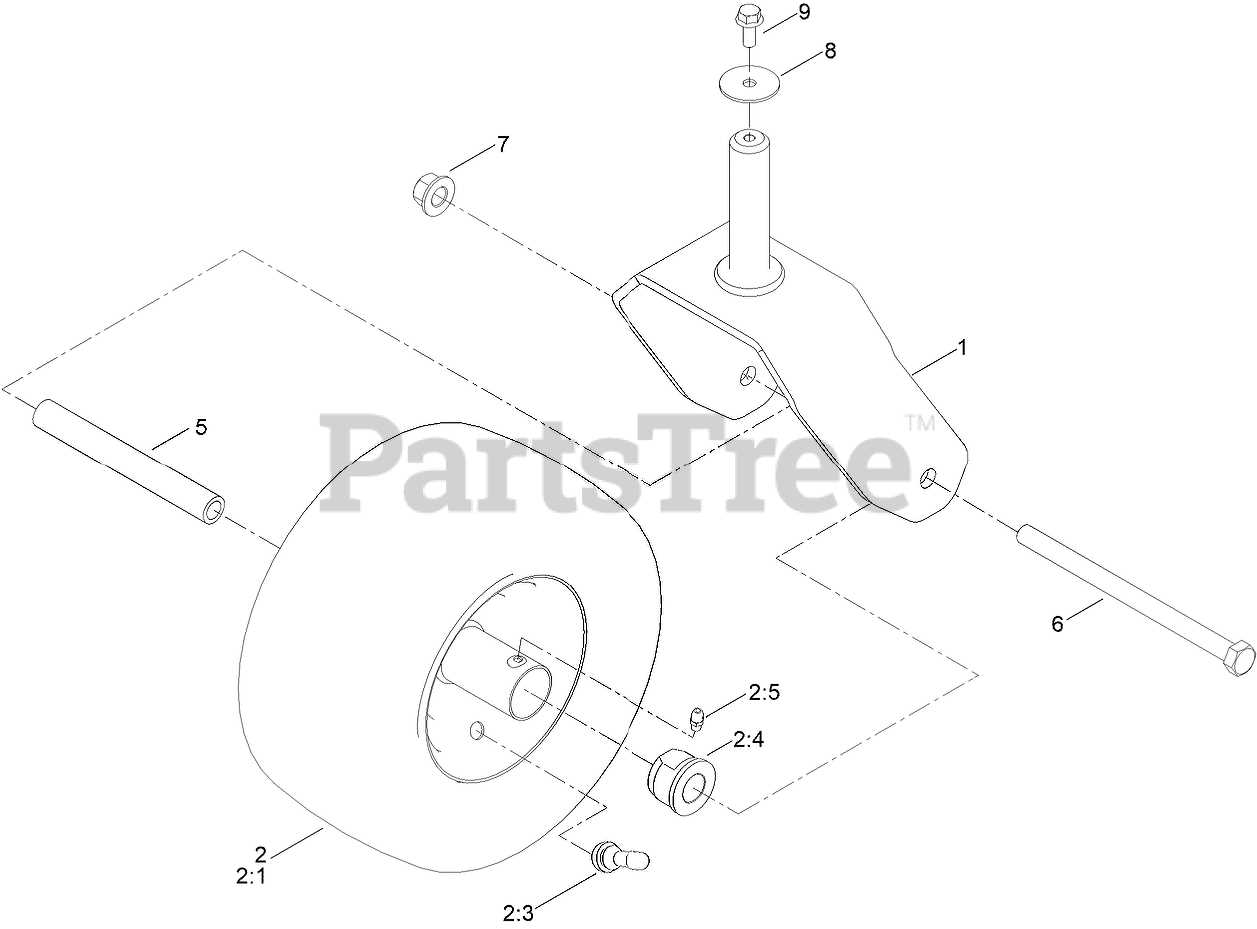

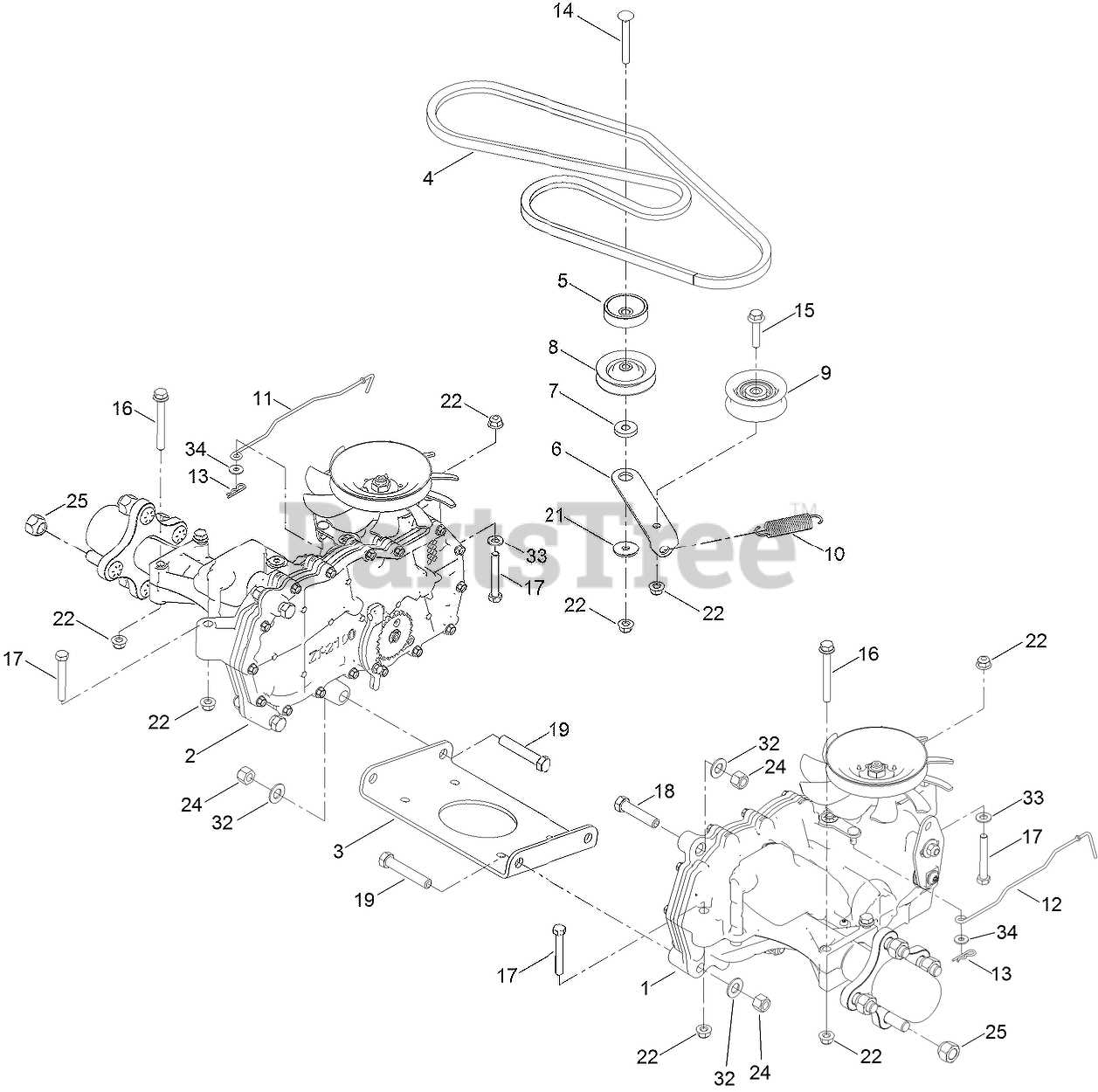

How to Read the Parts Diagram

Understanding a schematic representation of components can greatly enhance your ability to maintain and repair machinery. Familiarity with the visual layout, symbols, and codes used can save time and reduce frustration during the assembly or disassembly process.

Interpreting the Layout

Each section typically corresponds to a specific area of the equipment, allowing you to easily locate various items. Pay attention to the numbering system, which often indicates the order of assembly or the relationship between different elements.

Common Symbols and Notations

Familiarize yourself with the common icons and abbreviations used in these illustrations. Understanding these symbols can simplify your search for particular components and help in identifying compatible parts.

| Symbol | Description |

|---|---|

| Fastener | |

| ⚙️ | Gear |

| Tool Required |

Where to Find Replacement Parts

Locating suitable components for your equipment can be a straightforward process if you know where to look. A variety of resources are available to help you source high-quality replacements, ensuring that your machine operates efficiently and reliably.

One of the most reliable options is to check with authorized dealers who specialize in your specific model. These retailers often have a comprehensive inventory and can provide expert advice on compatibility and installation. Additionally, manufacturer websites usually feature an online shop or a list of recommended vendors, making it easy to find exactly what you need.

Another valuable resource is online marketplaces where users can buy and sell components. These platforms often include both new and gently used items, providing cost-effective options. However, it’s important to verify the seller’s reputation to ensure that you’re receiving authentic products.

| Resource Type | Description |

|---|---|

| Authorized Dealers | Specialized retailers with direct access to the manufacturer’s inventory. |

| Manufacturer Websites | Official online shops or lists of trusted vendors for easy sourcing. |

| Online Marketplaces | Platforms for buying and selling new and used components from various sellers. |

By exploring these options, you can ensure that your equipment remains in top condition with the right replacements. Always prioritize quality and compatibility to maintain optimal performance.

Tips for DIY Repairs

Engaging in do-it-yourself maintenance can be rewarding and cost-effective. Whether you’re addressing minor issues or undertaking more significant fixes, a methodical approach is essential. Understanding the components involved and having the right tools at your disposal can make a substantial difference in the outcome of your project.

Start by gathering all necessary tools and materials before beginning any repair. Having everything on hand will help you avoid interruptions and maintain focus. Familiarize yourself with the device’s structure, as this knowledge will guide you through the disassembly and reassembly processes.

Document the steps you take, especially when removing parts. Taking photographs or making notes can serve as a valuable reference, ensuring that you can easily put everything back together. Additionally, consider organizing screws and small components in separate containers to prevent loss and confusion.

Don’t hesitate to consult online resources or community forums for advice and troubleshooting tips. Many experienced enthusiasts share their insights, which can provide useful guidance and innovative solutions. Lastly, always prioritize safety by wearing protective gear and ensuring your workspace is tidy and well-lit.

Essential Tools for Maintenance

Effective upkeep of machinery and equipment requires a well-rounded selection of tools. Having the right implements at hand not only streamlines the maintenance process but also ensures optimal performance and longevity of your devices. Understanding the key instruments needed for regular servicing can help prevent costly repairs and improve overall efficiency.

Wrenches are fundamental for tightening and loosening various components. A set of adjustable wrenches can accommodate different sizes, making them versatile for various tasks. Screwdrivers also play a crucial role, with both flat-head and Phillips types necessary for accessing screws in tight spaces.

In addition to these basics, pliers can be indispensable for gripping and manipulating parts that are otherwise difficult to handle. Multi-tools combine several functions into one compact design, providing convenience and efficiency during maintenance work.

Another essential is a socket set, which allows for the easy removal and installation of bolts and nuts, particularly in hard-to-reach areas. For those working with electronics, a digital multimeter is vital for diagnosing electrical issues accurately.

Finally, keeping a toolbox organized ensures that all necessary implements are readily accessible, saving time and reducing frustration during maintenance tasks. By investing in these essential tools, you can ensure that your equipment remains in peak condition for years to come.

Safety Precautions When Repairing

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. Adhering to proper guidelines and employing effective strategies can significantly mitigate risks while working on machinery.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Disconnect the power source before beginning any repair to avoid electrical hazards.

- Work in a well-ventilated area to reduce exposure to harmful fumes or gases.

- Keep your workspace organized and free from clutter to prevent trips and falls.

- Use the correct tools for each task to minimize the risk of injury.

By following these precautions, you can create a safer environment and focus on effectively completing your maintenance projects.

Customer Reviews and Experiences

This section aims to gather insights from users regarding their encounters with the equipment in question. Sharing feedback and personal stories can greatly assist potential buyers in making informed decisions, providing a glimpse into the real-world performance and reliability of the machinery.

Positive Feedback

Many users have expressed satisfaction with the functionality and efficiency of their machines. They often highlight how well the devices perform under various conditions, ensuring that tasks are completed effectively. The ease of use and user-friendly design have also received commendations, making it accessible for both beginners and seasoned operators.

Common Concerns

While numerous reviews are favorable, some users have pointed out issues that could be addressed. Common concerns include the availability of replacements and the need for clearer maintenance guidelines. These insights are crucial for manufacturers to enhance their offerings and ensure a better experience for all users.

| Aspect | Positive Reviews | Negative Feedback |

|---|---|---|

| Performance | Highly efficient and reliable | Occasional performance inconsistencies |

| User-Friendliness | Intuitive design, easy to operate | Initial learning curve for new users |

| Maintenance | Generally easy to maintain | Limited availability of replacement parts |

Frequently Asked Questions About Parts

This section aims to address common inquiries related to components used in various machinery. Understanding these elements can enhance your experience and ensure optimal performance.

What should I consider when replacing components?

When substituting items, it’s crucial to ensure compatibility with your equipment’s specifications, including size, material, and functionality.

How can I identify a malfunctioning part?

Signs of wear, unusual noises, or performance issues are indicators that a component may need attention or replacement.

Where can I find reliable replacement options?

Reputable suppliers and authorized dealers often provide high-quality alternatives. Researching reviews can also guide you toward trustworthy sources.

How do I maintain my equipment to prolong its lifespan?

Regular maintenance, including cleaning and timely replacements, is essential. Follow the manufacturer’s recommendations for best results.

What is the ultimate way to ensure proper installation?

Refer to the user manual or seek professional assistance to guarantee that new components are installed correctly for safe operation.