In the realm of winter maintenance, knowledge of the various elements that comprise a snow clearing device is essential for efficient operation and repair. Grasping the intricate relationships among these components can enhance performance and longevity, ensuring a smoother experience during the cold months.

Identifying each segment of this essential machinery not only aids in troubleshooting but also empowers users to make informed decisions regarding replacements and upgrades. Whether you are a seasoned technician or a casual user, familiarity with these components will ultimately contribute to better care and effective usage.

By delving into the structure and function of these vital pieces, one can appreciate their roles in delivering optimal results. A thorough understanding serves as the foundation for maintaining functionality and maximizing efficiency, thereby enhancing the overall user experience.

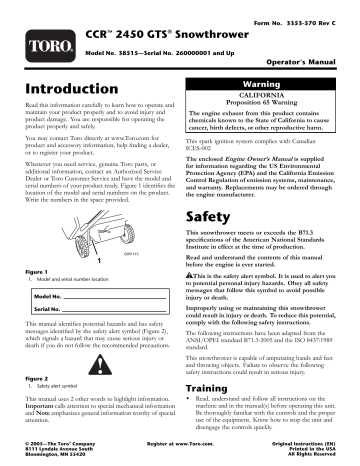

Toro CCR 2450 Overview

This section provides a comprehensive look at a powerful snow-clearing machine designed for efficient performance during winter conditions. It combines advanced technology with user-friendly features, ensuring optimal functionality and reliability.

Key Features

Equipped with a robust engine, this model excels in removing snow quickly and effectively. Its lightweight design and ergonomic handle facilitate ease of use, allowing operators to navigate through challenging environments effortlessly.

Performance and Efficiency

With a high-capacity discharge chute, it efficiently directs snow away from pathways, minimizing the need for manual labor. The adjustable settings enable users to tackle various snow depths, providing ultimate versatility for all winter weather conditions.

Understanding Toro CCR 2450 Features

When it comes to snow clearing machines, understanding their essential characteristics can significantly enhance user experience and operational efficiency. These machines are designed to tackle various winter challenges, offering a range of features tailored to different environments and user needs.

Key Characteristics

- Powerful Engine: The machine is equipped with a robust engine, providing the necessary strength to clear heavy snowfall.

- Adequate Clearing Width: An optimal clearing width ensures that snow removal is both efficient and swift.

- Adjustable Chute: Users can direct the snow where needed, making it easier to manage accumulation.

- Lightweight Design: The overall weight facilitates maneuverability, especially in tight spaces.

- User-Friendly Controls: Intuitive controls make operation straightforward, even for novice users.

Enhanced Features for Efficiency

- Anti-Clogging Technology: This feature minimizes the risk of blockages, ensuring smooth operation during heavy use.

- Ergonomic Handle: Designed for comfort, reducing fatigue during extended periods of operation.

- Easy Maintenance: Simple access to vital components helps keep the machine in optimal condition.

By familiarizing oneself with these features, users can better appreciate the capabilities of their snow clearing equipment and make informed decisions regarding maintenance and usage.

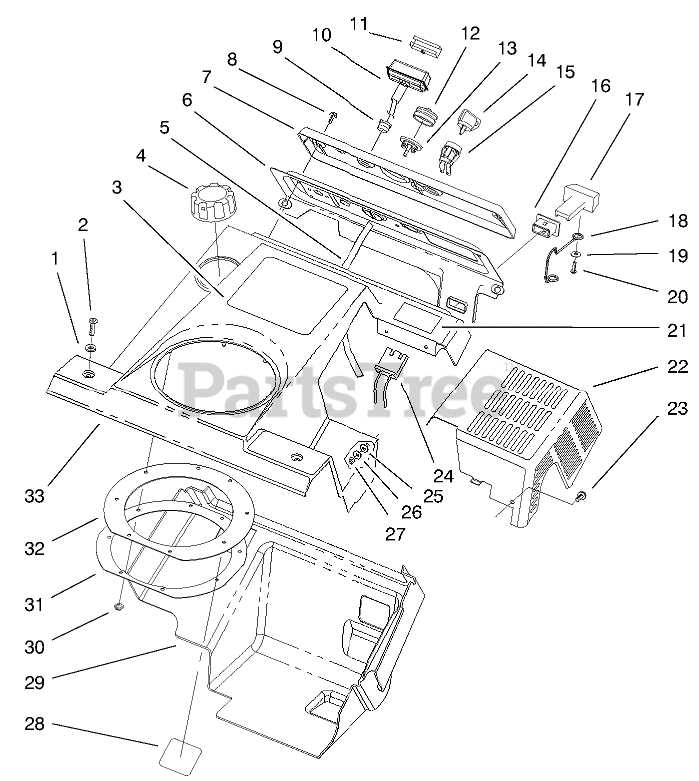

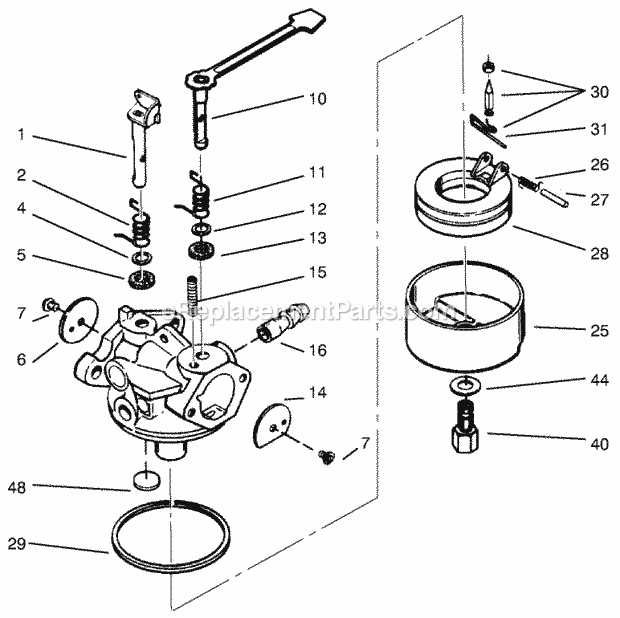

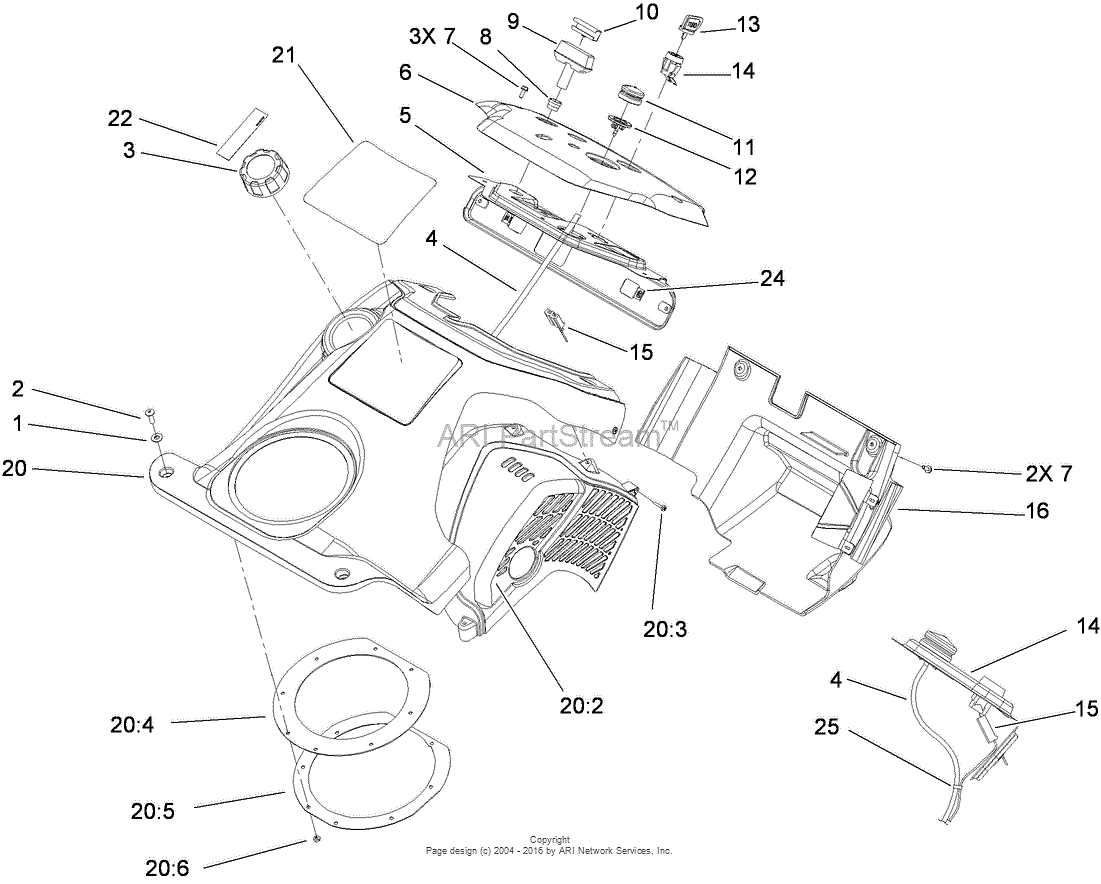

Importance of Parts Diagrams

Understanding the layout and components of machinery is essential for effective maintenance and repair. Visual representations of these elements serve as crucial tools, enabling users to identify and access individual components easily. This clarity can significantly streamline troubleshooting processes and enhance overall efficiency.

Visual Guides: Diagrams provide a clear visual reference, making it easier to grasp complex structures. They help technicians locate parts quickly, reducing the time spent searching and increasing productivity.

Enhanced Communication: These illustrations facilitate better communication between users and service providers. When discussing repairs or replacements, referring to a visual aid can minimize misunderstandings, ensuring that everyone is on the same page.

Improved Maintenance: Regular upkeep is vital for the longevity of equipment. By utilizing visual aids, operators can better understand which components require attention, thus preventing potential issues before they escalate.

Learning Tool: For those new to the equipment, visual representations serve as effective educational resources. They can enhance comprehension of how different parts work together, fostering a deeper understanding of the machinery as a whole.

In summary, visual schematics are invaluable assets that contribute to improved maintenance practices, effective communication, and a greater understanding of machinery, ultimately leading to better performance and reliability.

Key Components of Toro Snowblowers

Understanding the essential elements of snow removal machines enhances their effectiveness and longevity. These machines incorporate various parts that work together to ensure optimal performance during winter conditions.

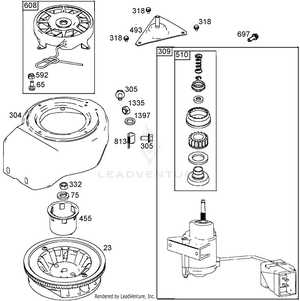

Engine: The power source drives all functions, providing the necessary force to clear snow efficiently.

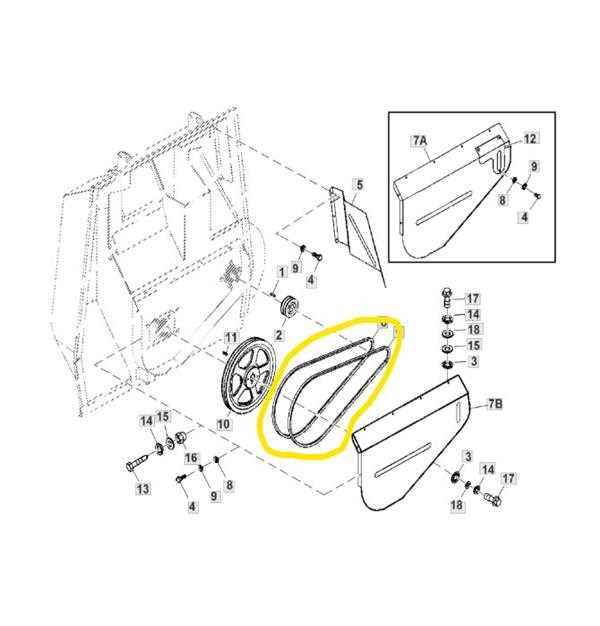

Auger: This component is responsible for gathering and breaking up snow, preparing it for discharge.

Impeller: Working in tandem with the auger, the impeller propels the snow out of the chute, ensuring effective snow removal.

Chassis: The frame supports all components, contributing to the overall durability and stability of the machine.

Controls: User-friendly controls allow operators to adjust settings, enhancing maneuverability and efficiency in varying conditions.

By examining these fundamental parts, users can make informed decisions about maintenance and upgrades, ultimately improving performance.

How to Read Parts Diagrams

Understanding assembly illustrations is crucial for effective maintenance and repair. These visuals provide a detailed view of components, showcasing how they interact within the overall mechanism. Familiarizing yourself with these representations can simplify the process of identifying, ordering, and replacing elements.

Begin by examining the legend, which typically explains symbols and codes used in the illustration. This key can guide you in interpreting various parts accurately. Next, focus on the layout, noting how each section is organized and where specific components are located.

As you analyze the image, pay attention to connections and attachments, as these details reveal how items fit together. It’s also beneficial to cross-reference with a list of parts to ensure you grasp the function and placement of each piece. With practice, interpreting these illustrations will become a straightforward task, enhancing your repair skills significantly.

Common Issues with Toro CCR 2450

When dealing with snow removal equipment, users may encounter several recurring challenges that can hinder performance. Understanding these common problems can facilitate prompt resolutions and enhance efficiency during operation.

Frequent Problems

- Difficulty starting the engine

- Ineffective snow throwing

- Unusual vibrations during operation

- Clogs in the chute

Troubleshooting Tips

- Check the fuel level and quality.

- Inspect the spark plug for wear.

- Ensure the auger and impeller are clear of debris.

- Regularly maintain and lubricate moving parts.

Finding Replacement Parts Online

Locating suitable components for outdoor equipment can be a straightforward task when you know where to look. The internet provides a vast array of resources that cater to various needs, ensuring you can keep your machinery running smoothly. Understanding how to navigate these options effectively is key to a successful search.

Where to Search

- Manufacturer Websites

- Authorized Dealers

- Online Marketplaces

- Specialty Retailers

Tips for a Successful Search

- Know your model number.

- Use specific keywords related to your equipment.

- Check for reviews and ratings of sellers.

- Compare prices across different platforms.

Maintenance Tips for Snowblowers

Proper upkeep of your snow-clearing equipment is essential to ensure its efficiency and longevity. Regular maintenance not only enhances performance but also prevents unexpected breakdowns during critical times. By following a few simple guidelines, you can keep your machine running smoothly and tackle winter conditions with confidence.

Routine Maintenance Checks

Establishing a regular maintenance schedule is key. Here are some fundamental tasks to include:

| Task | Frequency |

|---|---|

| Inspect and clean the spark plug | Every season |

| Change the oil | Every 25 hours of use |

| Check the fuel system for leaks | Before each use |

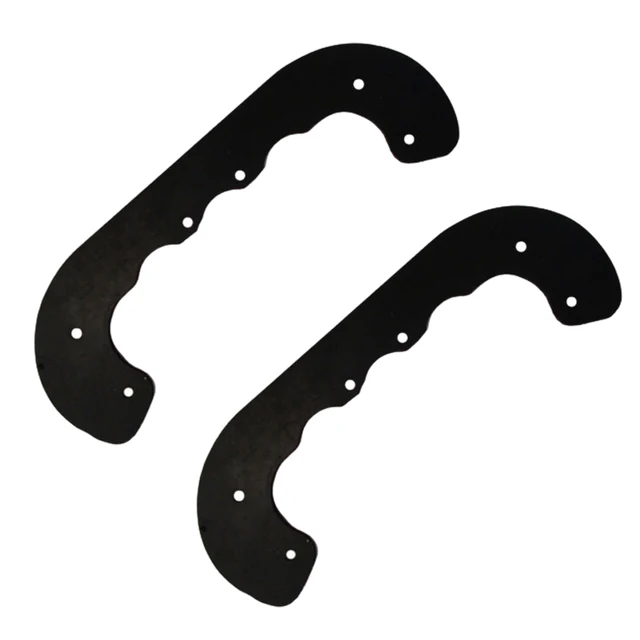

| Examine the blades for wear and tear | Every season |

| Inspect belts and cables | Every season |

Winter Preparation Tips

Before the winter season begins, ensure your equipment is ready for action. Here are additional recommendations:

- Store the machine in a dry place to avoid rust and corrosion.

- Fill the fuel tank before storage to prevent moisture buildup.

- Use a fuel stabilizer to maintain fuel quality.

DIY Repairs for Toro CCR 2450

Undertaking repairs on your snow-clearing equipment can be a rewarding experience, allowing you to save money while gaining valuable skills. This guide focuses on common issues that can arise with your machine and provides straightforward solutions that you can perform at home. With a little patience and the right tools, you can keep your equipment in top shape.

Common Issues and Solutions

When dealing with your snowblower, it’s essential to know the frequent problems and how to address them effectively. Here’s a list of common issues along with their potential solutions:

| Issue | Possible Solution |

|---|---|

| Engine won’t start | Check the fuel level and replace the spark plug if necessary. |

| Uneven snow throwing | Inspect the impeller for blockages and clear any debris. |

| Excessive vibrations | Tighten loose screws and check for bent components. |

| Stalling during operation | Ensure the air filter is clean and replace if it’s clogged. |

Preventive Maintenance Tips

To avoid future issues, regular maintenance is crucial. Here are some tips to keep your snow-clearing machine running smoothly:

- Store the equipment in a dry place to prevent rust.

- Change the oil regularly to ensure optimal performance.

- Sharpen the blades before the snow season for effective operation.

- Inspect cables and belts for wear and replace as needed.

Where to Buy Genuine Parts

Finding authentic components for your equipment is crucial for maintaining its performance and longevity. Using genuine items ensures compatibility and reliability, providing peace of mind during operation. Here are some reliable sources where you can purchase these essential components:

- Authorized Dealers: Visiting a certified distributor guarantees that you receive original items tailored for your model.

- Manufacturer’s Website: The official site often provides a comprehensive catalog of available components, along with easy ordering options.

- Specialized Retailers: Many stores focus on specific brands and models, offering a selection of verified products.

- Online Marketplaces: Reputable e-commerce platforms can be great for sourcing genuine items, but ensure the seller has positive reviews and ratings.

- Local Repair Shops: These businesses may have access to original components and can assist with installation if needed.

By choosing one of these sources, you can ensure that your equipment runs smoothly and efficiently for years to come.