Every riding mower is a complex machine made up of numerous interconnected elements that ensure smooth operation and durability. The key to maintaining and repairing this equipment lies in understanding how these various mechanisms work together and how they are arranged. This knowledge helps users identify issues early and keep the machine in optimal condition for extended use.

For those who perform regular maintenance, it’s essential to have a clear visual reference to see where each component fits within the overall system. By studying the layout, users can easily locate specific elements, ensuring repairs and replacements are done accurately and efficiently. Proper care of these mechanisms not only enhances performance but also extends the lifespan of the equipment.

In this guide, we will explore the critical aspects of such machines, breaking down their structure and highlighting the most important sections. With a detailed approach, you’ll gain a comprehensive understanding that will assist you in handling any technical issues or upgrades with ease.

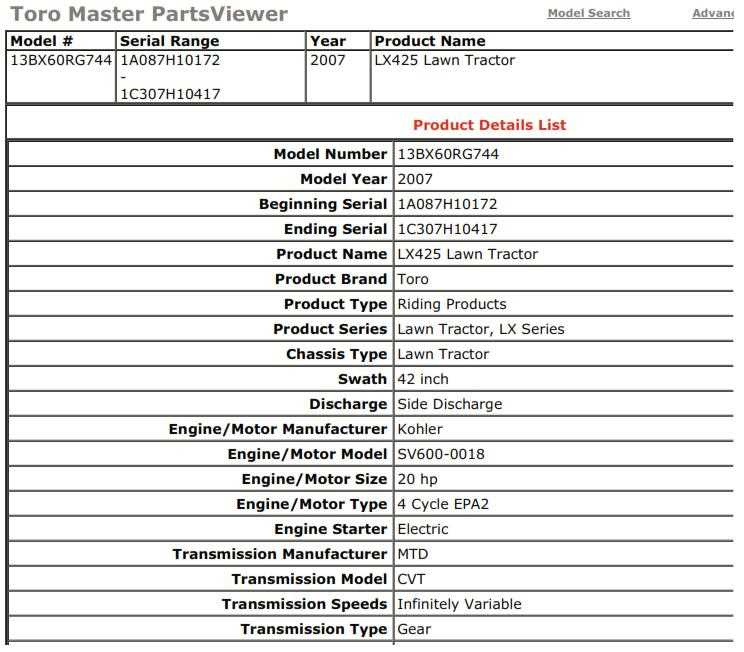

Toro LX425 Components Breakdown

This section provides an in-depth overview of the key mechanical and functional elements that ensure smooth operation and performance. Each element plays a crucial role in maintaining the system’s reliability and efficiency, making it important to understand how these components interact within the whole structure.

Engine System

The power unit is the heart of the machine, responsible for driving various operational mechanisms. It consists of multiple interconnected elements designed for optimal power delivery, fuel efficiency, and reduced emissions.

- Air intake system

- Fuel delivery components

- Cooling mechanism

Transmission and Drive Mechanism

The drive system ensures controlled movement and allows the machine to operate smoothly across different terrains. The transmission, combined with various moving parts, creates seamless transitions between speeds and directions.

- Hydraulic pump

- Axles and shafts

- Control levers

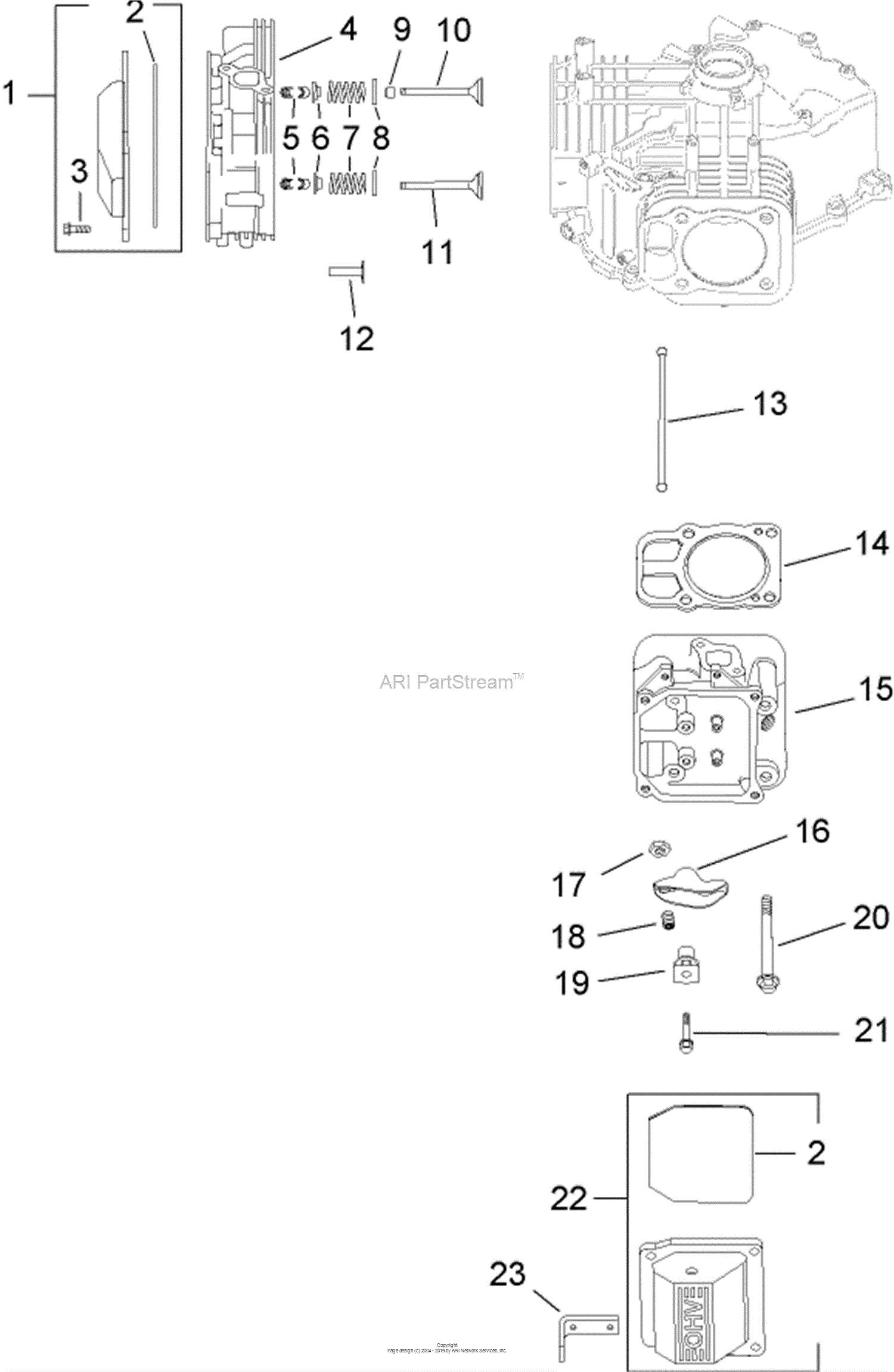

Engine Parts and Their Functions

The internal structure of a lawn tractor’s motor consists of multiple interconnected components, each contributing to the overall performance. Understanding the role of these elements helps in maintaining and troubleshooting the machine effectively. Below is an overview of key sections within the engine and their respective functions.

| Component | Function | |||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cylinder Block | Houses the combustion chambers where fuel is ignited to generate power. | |||||||||||||||||||||||||||||||||||||||||||||||||||

| Piston | Moves up and down within the cylinder, converting fuel energy into mechanical motion. | |||||||||||||||||||||||||||||||||||||||||||||||||||

| Crankshaft | Transforms the piston’s vertical movement into rotational force, driving the wheels

Understanding the Electrical System Layout

The electrical system within a machinery unit is crucial for its overall functionality. It orchestrates the operation of various components, ensuring that power is efficiently distributed to essential systems. A well-structured layout not only enhances performance but also simplifies maintenance and troubleshooting tasks. Key Components of the Electrical System

Layout ConsiderationsWhen examining the electrical architecture, several factors should be considered:

Key Features of the Cutting Deck Assembly

The cutting deck assembly is a crucial component in lawn care machinery, designed to enhance efficiency and effectiveness during operation. This system is engineered to deliver precise cutting performance while ensuring durability and ease of maintenance. Understanding its essential characteristics can significantly improve the user experience and extend the lifespan of the equipment. Robust Construction: One of the standout features of the cutting deck assembly is its sturdy build. Typically made from high-quality materials, it is designed to withstand the rigors of frequent use and adverse weather conditions, ensuring long-term reliability. Adjustable Cutting Height: This feature allows users to customize the height of the grass cut, catering to different lawn types and personal preferences. Such versatility enables optimal performance across varying terrains and grass species. Efficient Grass Discharge: The design of the cutting deck facilitates effective grass discharge, whether through side discharge, mulching, or bagging. This capability not only ensures a cleaner cut but also promotes healthier lawn growth by returning nutrients to the soil. Easy Maintenance: User-friendly access points and simple design make the cutting deck assembly easy to maintain. Regular upkeep is vital for optimal performance, and features that simplify this process can save time and effort for the operator. Compatibility with Attachments: Many cutting deck assemblies are designed to be compatible with various attachments, enhancing functionality and allowing for additional tasks such as aeration or dethatching. This flexibility adds value to the machinery, making it a multi-functional tool in lawn care. Maintenance Tips for Steering Mechanism

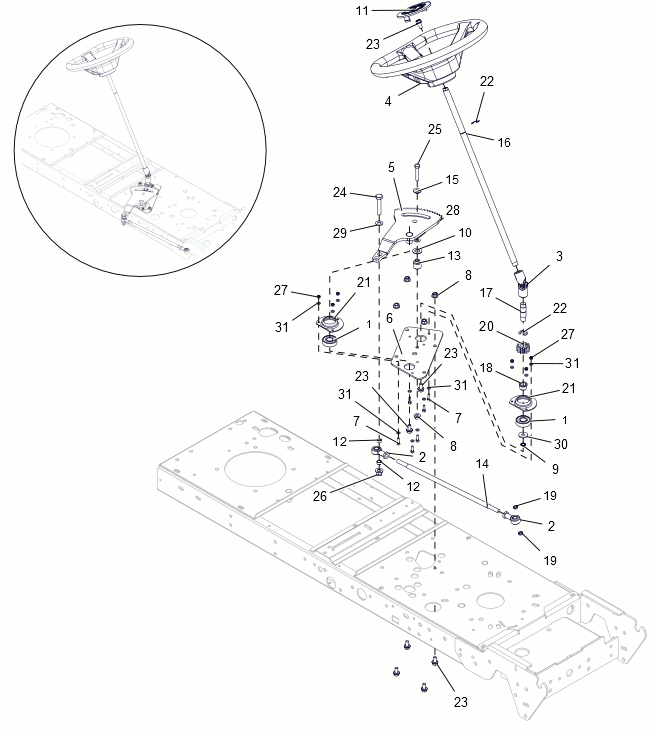

Proper upkeep of the steering system is crucial for ensuring optimal performance and safety during operation. Regular maintenance not only prolongs the lifespan of the components but also enhances the overall driving experience. Following a few essential practices can help in keeping the steering mechanism in excellent condition. Regular InspectionFrequent checks of the steering components are vital. Look for any signs of wear, damage, or looseness in the joints and linkages. Pay special attention to the bushings and bearings, as these parts are often prone to deterioration over time. Early detection of issues can prevent more significant problems down the line. Lubrication and Cleaning

Keeping the steering mechanism clean and well-lubricated is essential for smooth operation. Use appropriate lubricants on moving parts to reduce friction and wear. Additionally, remove any dirt, debris, or corrosion that may accumulate in the system, as these can impede functionality and lead to premature failure of components. How to Identify Drive System Parts

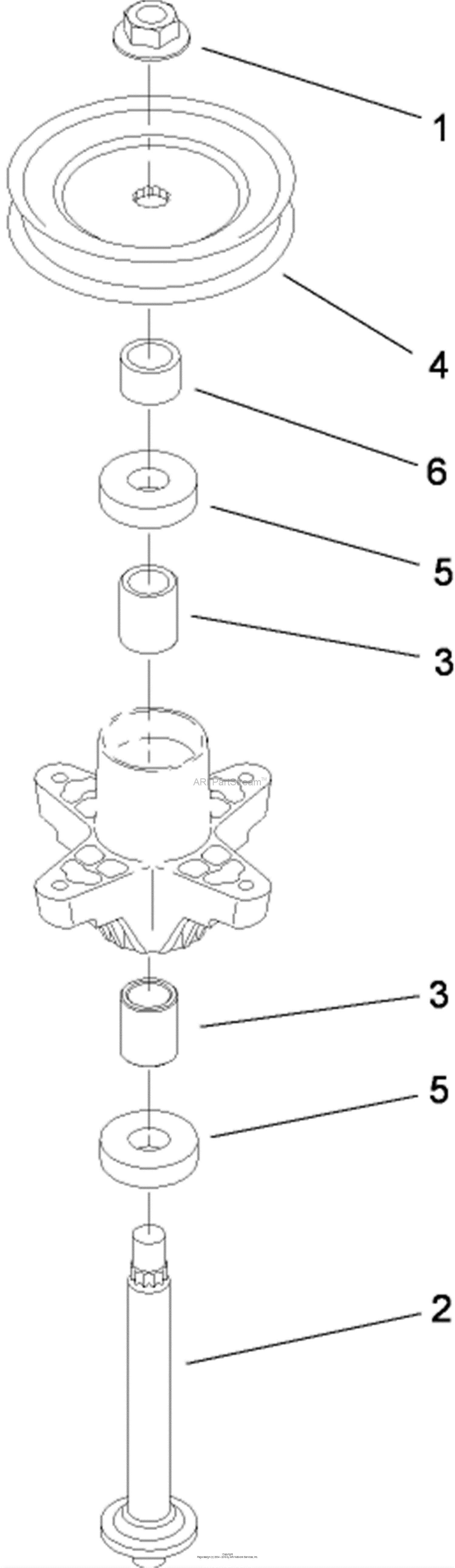

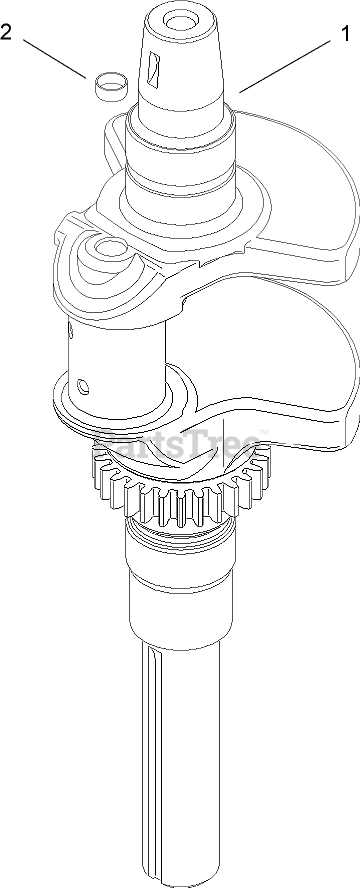

Understanding the components of a drive mechanism is essential for maintenance and repairs. By familiarizing yourself with the key elements, you can ensure optimal performance and longevity of your equipment. This section will guide you through the identification process of these critical components. Start by examining the drive assembly, which typically consists of several interconnected elements. Pay attention to the shapes and functions of each part, as this will help you differentiate between similar-looking components.

By recognizing these elements, you can effectively troubleshoot issues and perform necessary replacements or adjustments. Always consult the equipment manual for specific identification and maintenance guidelines. Replacement Procedures for Blade Assembly

Proper maintenance of the cutting mechanism is essential for optimal performance and safety. This section outlines the steps required to efficiently replace the blade assembly, ensuring the equipment operates effectively. Preparation: Before starting, ensure that you have the necessary tools and a suitable replacement blade on hand. It is crucial to disconnect the power source to prevent accidental activation during the process. Removing the Old Blade: Begin by carefully lifting the cutting deck. Locate the fastening mechanisms securing the blade assembly. Use the appropriate tools to loosen and remove these fasteners. Gently detach the old blade from its mounting, taking care to avoid any sharp edges. Installing the New Blade: Position the new blade onto the mounting bracket. Ensure it is aligned correctly, following the manufacturer’s guidelines. Secure the blade in place by tightening the fasteners firmly, but avoid over-tightening, which may cause damage. Final Checks: Once the new blade is installed, lower the cutting deck and reconnect the power source. Perform a thorough inspection to ensure everything is properly assembled and secure. It is advisable to run the equipment briefly to confirm that the blade operates smoothly. Common Issues with the LX425 TransmissionThe transmission system is crucial for the smooth operation of any outdoor equipment. Understanding the frequent problems that may arise can help in timely maintenance and repairs, ensuring longevity and efficiency. Below are some of the common complications users might encounter. 1. Fluid Leaks

One of the most prevalent issues is the occurrence of fluid leaks. This can lead to insufficient lubrication and cause significant damage to the transmission components. Key indicators of leaks include:

2. Slipping Gears

Another common complication is slipping gears, which can hinder performance and responsiveness. This issue can manifest in various ways:

Regular inspections and prompt attention to these issues can help maintain optimal performance and extend the life of the transmission system. Fuel System Diagram and ComponentsThe fuel system is a crucial part of any machinery, ensuring the proper delivery of fuel for optimal performance. It consists of various elements that work together to store, filter, and supply fuel to the engine. Understanding these components is essential for maintenance and troubleshooting purposes. Key elements of this system typically include the fuel tank, which stores the fuel; the fuel pump, responsible for transporting the fuel to the engine; and the fuel filter, which removes impurities before the fuel reaches the combustion chamber. Additionally, fuel lines connect these components, facilitating a seamless flow of fuel throughout the system. Each part plays a significant role in maintaining efficiency and reliability, highlighting the importance of regular checks and maintenance for the overall health of the machinery. Wheels and Tire Parts Overview

This section provides a comprehensive examination of the components related to the rolling mechanisms of garden equipment. Understanding these elements is crucial for maintenance and ensuring optimal performance during operation. Key ComponentsThe primary elements that contribute to the functionality of the rolling system include the wheels, tires, hubs, and related fittings. Each part plays a significant role in providing stability, traction, and ease of movement across various terrains. Specifications and Features

When selecting components for replacement or upgrades, it is important to consider various specifications such as size, material, and tread design. These factors influence the performance and durability of the equipment. Below is a summary of typical specifications:

Hydraulic System Key ElementsThe hydraulic system plays a vital role in the operation of various machinery, utilizing fluid power to facilitate movement and control. Understanding its critical components is essential for effective maintenance and troubleshooting. Each element contributes to the overall functionality and efficiency, ensuring optimal performance during operation.

Safety Features and Their ComponentsEnsuring a secure operational environment is paramount in any machinery. Various elements contribute to the overall safety of equipment, allowing users to operate confidently while minimizing risks. Understanding these features and their specific components is essential for effective maintenance and safe usage.

Understanding these safety features and their individual components can greatly enhance the reliability and security of equipment operation. Regular checks and maintenance of these elements are vital for preserving their effectiveness and ensuring user safety. Upgrading and Replacing Control Panel PartsEnhancing and substituting components within the control interface can significantly improve functionality and user experience. Whether you aim to modernize features or replace malfunctioning elements, a thorough understanding of available options and their compatibility is essential. Before embarking on this process, it is crucial to assess the current condition of the existing components. Identifying worn-out or outdated elements will help you determine what needs to be upgraded or replaced. Keep in mind that selecting high-quality replacements can lead to improved performance and longevity.

When replacing any component, ensure that you follow manufacturer guidelines for installation. Proper fitting and calibration are vital to maintaining optimal performance. Additionally, consulting with professionals or referring to reliable resources can provide valuable insights during this enhancement process. |