When it comes to maintaining outdoor machinery, having a clear understanding of its structure and individual elements is essential for effective repair and maintenance. A well-organized overview of these components not only simplifies the process of identifying parts but also enhances the overall efficiency of servicing tasks. Whether you are a seasoned technician or a novice user, visual references can significantly aid in grasping how various pieces fit together.

In this section, we will explore the intricate arrangement of different sections of your equipment. By breaking down the assembly into easily identifiable components, you can streamline your maintenance routine. Each element plays a crucial role in the machine’s functionality, and being familiar with them empowers you to make informed decisions during repairs or replacements.

Additionally, understanding the layout can assist in troubleshooting issues that may arise during operation. Recognizing how each component interacts with others not only aids in pinpointing problems but also fosters a deeper appreciation for the design and engineering behind your machinery. Armed with this knowledge, you will be better equipped to ensure the longevity and performance of your outdoor equipment.

Toro MX 5060 Overview

The machine in focus is a versatile piece of equipment designed for a range of outdoor tasks. It excels in enhancing productivity and efficiency, making it a valuable asset for both residential and commercial use. With its robust build and innovative features, this model caters to the needs of various users, from hobbyists to professional landscapers.

Engineered for performance, this unit offers exceptional maneuverability and ease of operation. The thoughtful design incorporates user-friendly controls, allowing for seamless adjustments and operation. Its capacity to handle diverse terrains ensures that it can tackle different landscaping challenges with ease.

Moreover, the construction emphasizes durability, ensuring longevity even under demanding conditions. Maintenance is simplified, with easy access to key components, which aids in prolonging the lifespan of the machine. This blend of reliability and practicality makes it a favored choice in the market.

In summary, this equipment stands out due to its blend of power, efficiency, and user-centric design. Whether for routine maintenance or extensive landscaping projects, it provides the tools necessary to achieve outstanding results.

Importance of Parts Diagrams

Visual representations of component arrangements play a crucial role in the maintenance and repair of machinery. They provide a clear overview of the different elements involved, facilitating easier identification and understanding of each component’s function.

Utilizing these illustrations can lead to various benefits:

- Enhanced Understanding: Users can quickly grasp how components interact within the system.

- Efficient Repairs: Identifying specific elements reduces downtime during maintenance.

- Streamlined Ordering: Clear visuals help in accurately requesting replacements or accessories.

- Improved Safety: Understanding the layout minimizes risks associated with incorrect assembly.

Incorporating these visual guides into the repair process not only promotes efficiency but also fosters a deeper comprehension of the machinery’s overall structure and functionality.

Common Components of Toro MX 5060

This section delves into the essential elements that contribute to the functionality and efficiency of the machine. Each component plays a vital role in ensuring optimal performance, durability, and ease of maintenance. Understanding these key parts can enhance the user experience and prolong the lifespan of the equipment.

Main Features

The machine is equipped with various critical features that support its operational capabilities. These include the power system, transmission components, and control mechanisms, all designed to work seamlessly together.

Key Elements Overview

| Component | Description |

|---|---|

| Engine | Drives the machine, providing the necessary power for operation. |

| Transmission | Facilitates smooth movement and controls speed adjustments. |

| Chassis | The framework that supports all components and ensures structural integrity. |

| Hydraulic System | Enables efficient movement and operation of attachments and implements. |

| Control Panel | Interface for the operator to manage settings and monitor performance. |

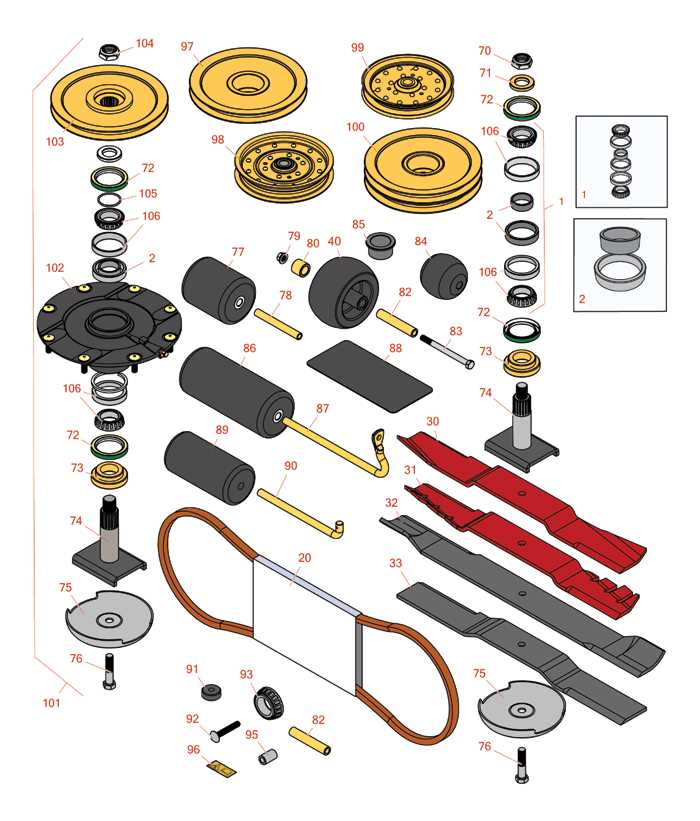

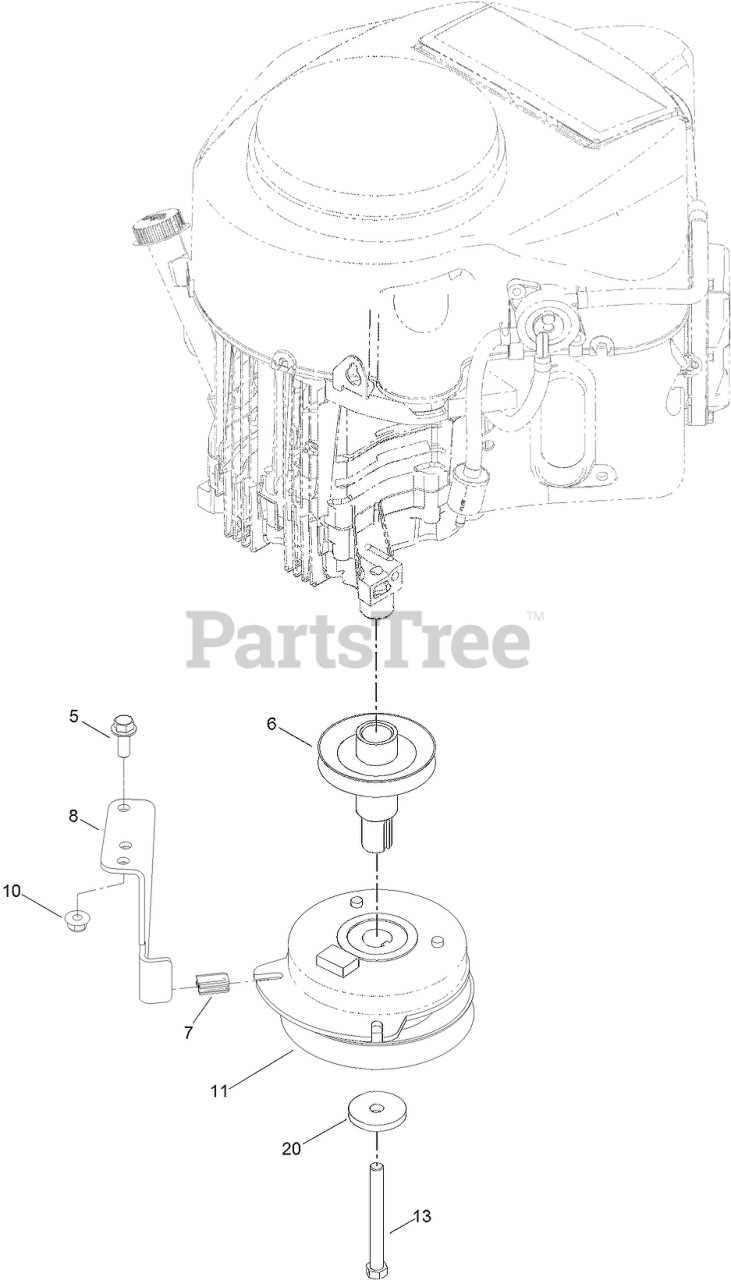

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair tasks. These illustrations provide crucial information about the various elements of a machine, allowing users to identify and locate specific items efficiently. By mastering the art of interpreting these visuals, one can ensure proper assembly, disassembly, and replacement of components, leading to enhanced performance and longevity of equipment.

Identifying Symbols and Labels

Each representation typically includes various symbols and annotations that indicate specific functions or types of components. Familiarize yourself with common icons, as they can significantly aid in understanding what each part does. Labels may also provide additional context, such as part numbers or specifications, which are vital for sourcing replacements.

Understanding Layout and Orientation

The arrangement of components within the illustration often reflects their physical layout within the machine. Pay attention to the orientation, as it can help visualize how parts fit together. By analyzing the spatial relationships and connections, you can gain insights into assembly order and troubleshooting procedures.

Identifying Replacement Parts

Understanding how to locate and recognize components for machinery is crucial for maintaining optimal performance and ensuring longevity. A thorough grasp of each element’s function and compatibility can significantly ease the process of replacement, minimizing downtime and enhancing efficiency. This section focuses on methods to accurately identify the necessary components when repairs or upgrades are needed.

Utilizing Manuals and Schematics

One effective approach is to consult the user manual or schematics related to your equipment. These resources typically provide detailed illustrations and descriptions of each component, allowing you to cross-reference the necessary items. Pay close attention to model specifications and part numbers, as this information is essential for securing the correct replacements.

Online Resources and Communities

The internet offers a wealth of information for identifying necessary components. Numerous websites and forums are dedicated to equipment maintenance and can provide valuable insights from other users’ experiences. Engaging with online communities can also lead to recommendations for reputable suppliers, further simplifying the search for the right items.

Maintenance Tips for Toro MX 5060

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Following a consistent maintenance routine helps to identify potential issues before they escalate, allowing for smooth operation and reduced downtime.

Routine Maintenance Procedures

- Check Fluid Levels: Regularly inspect and top off engine oil, coolant, and hydraulic fluids to keep the system functioning efficiently.

- Inspect Air Filters: Clean or replace air filters to ensure proper airflow and prevent debris from entering the engine.

- Sharpen Blades: Keep cutting blades sharp to enhance cutting efficiency and reduce strain on the engine.

- Clean the Chassis: Remove dirt and debris from the chassis to prevent rust and corrosion, ensuring a longer lifespan.

Seasonal Checks

- Before the mowing season, perform a thorough inspection of belts and cables for wear and tear.

- At the end of the season, store the equipment in a dry, sheltered location and consider adding fuel stabilizer to the tank.

- In colder months, consider changing the oil to a winter-grade product to ensure smooth starts.

By implementing these practices, you can maintain the efficiency and reliability of your equipment, ensuring it serves you well for years to come.

Where to Find Parts Diagrams

Locating technical illustrations for machinery components can significantly enhance your maintenance and repair efforts. These visual resources are essential for understanding how each element fits together, ensuring efficient operation and troubleshooting. Here are some reliable sources to consider when searching for these valuable references.

- Manufacturer’s Website: The official site often provides a wealth of resources, including detailed illustrations for various models. Look for a dedicated section for service or support.

- Online Retailers: Websites specializing in equipment sales frequently have links to relevant visual aids to assist customers in selecting the correct components.

- User Forums and Communities: Engaging with online groups dedicated to machinery enthusiasts can yield shared resources, including helpful illustrations contributed by other users.

- Service Manuals: Obtaining a copy of the service manual can be beneficial, as these documents typically include detailed visual references along with maintenance guidelines.

- Local Dealers: Authorized distributors often possess physical copies of technical illustrations and can provide assistance with specific inquiries related to your machinery.

By exploring these options, you can effectively find the necessary visual references to aid in the upkeep of your equipment.

Comparison with Other Toro Models

This section explores the similarities and differences between various models from the same manufacturer, highlighting their unique features and functionalities. By examining different designs, users can better understand how these machines cater to specific needs and preferences in landscaping and gardening tasks.

Design Variations: Each model showcases distinct architectural elements, with some prioritizing compactness for maneuverability in tight spaces, while others emphasize durability for larger, more demanding applications. This diversity allows consumers to select an option that best aligns with their operational requirements.

Performance Metrics: When evaluating efficiency, several models exhibit different power outputs and cutting capabilities. Some units are engineered for extensive use, boasting enhanced fuel efficiency and cutting precision, while others might focus on user-friendly features, making them suitable for novice operators.

Attachment Compatibility: The range of available accessories varies across models. While certain machines support an extensive lineup of attachments, enhancing versatility for various tasks, others may have a more limited selection, focusing on specific applications to streamline operations.

Price Points: Budget considerations also play a crucial role in the decision-making process. Different models cater to a wide spectrum of financial plans, ensuring that consumers can find an option that provides optimal value without compromising on essential features.

Understanding these aspects can significantly aid users in making informed choices, ensuring they select a machine that not only meets their immediate requirements but also aligns with their long-term landscaping goals.

Understanding Assembly and Disassembly

This section explores the fundamental concepts of putting together and taking apart mechanical systems. Grasping these principles is essential for effective maintenance and repair, ensuring that machinery functions optimally and remains in good condition. Whether you’re an experienced technician or a novice, knowing the assembly process aids in recognizing how components interconnect.

Key Considerations

- Preparation: Before starting, gather all necessary tools and ensure you have a clean workspace.

- Documentation: Keep reference materials handy, such as manuals or schematics, to guide you through the steps.

- Safety: Always prioritize safety by using protective gear and adhering to standard operating procedures.

Steps for Assembly

- Begin with a thorough inspection of all components to ensure they are in proper condition.

- Organize parts by type and function to streamline the assembly process.

- Follow the outlined steps carefully, securing each piece in place as you progress.

- Test functionality at various stages to identify any issues early on.

Understanding the disassembly process is equally crucial. It allows for effective troubleshooting and replacement of worn-out or defective components.

Disassembly Tips

- Document each step with notes or photographs to facilitate reassembly.

- Use appropriate tools to avoid damaging parts during removal.

- Handle components with care, especially fragile or sensitive items.

Frequently Asked Questions

This section aims to address common inquiries related to maintenance, functionality, and components of various outdoor equipment models. Here, we provide concise answers to frequently posed questions to assist users in understanding their machinery better.

General Inquiries

- What should I consider when purchasing replacement components?

- Compatibility with your specific model.

- Quality and durability of the items.

- Availability of warranty or guarantees.

- How can I ensure proper maintenance of my equipment?

- Regularly check fluid levels and filters.

- Follow the manufacturer’s guidelines for upkeep.

- Inspect for wear and tear on all operational parts.

Technical Assistance

- What should I do if I encounter operational issues?

- Refer to the user manual for troubleshooting steps.

- Contact customer service for specialized assistance.

- Consider consulting a certified technician if problems persist.

- Where can I find a list of compatible accessories?

- Check the manufacturer’s website for detailed compatibility charts.

- Consult authorized retailers for recommendations.

- Look for online forums where users share experiences and advice.

Cost Considerations for Replacement Parts

When maintaining machinery, understanding the financial implications of component replacement is crucial. Several factors can influence the overall expenses involved in acquiring new elements, impacting both short-term budgets and long-term ownership costs.

- Quality vs. Price: Opting for high-quality components often comes with a higher initial investment but can lead to greater durability and reduced frequency of replacements.

- Brand Reliability: Established manufacturers may charge more due to their reputation for reliability, which can result in savings over time through lower maintenance needs.

- Aftermarket Options: Exploring aftermarket alternatives can provide cost-effective solutions, but it is essential to assess their compatibility and reliability.

- Warranty Considerations: Components that include warranties can mitigate risk by offering free replacements or repairs for defects, thus reducing long-term costs.

Understanding these factors can help in making informed decisions regarding replacements, ensuring optimal performance without overspending.

Supplier Options for Toro Parts

When it comes to maintaining and repairing your machinery, sourcing high-quality components is crucial. Various providers offer an extensive range of items to ensure optimal performance and longevity of your equipment. Exploring different avenues for procurement can help you find the best options to suit your specific needs.

Authorized Dealers

Authorized dealers are a reliable source for acquiring original components. These suppliers often carry a comprehensive inventory, ensuring that you receive genuine products designed specifically for your equipment. Additionally, they may provide expert advice and support, helping you to choose the right items for your repair or maintenance projects.

Online Retailers

In today’s digital age, numerous online platforms facilitate easy access to a wide variety of components. These retailers often offer competitive pricing and convenient shipping options. However, it is essential to verify the credibility of the seller and ensure that the products meet the necessary quality standards before making a purchase.

Benefits of Using Genuine Parts

Opting for authentic components when maintaining machinery provides numerous advantages that significantly enhance performance and longevity. These original items are specifically designed and tested to meet stringent quality standards, ensuring they fit seamlessly into your equipment.

One of the primary benefits of using original components is their reliability. Authentic items are manufactured using high-quality materials that contribute to superior durability and effectiveness. This reduces the likelihood of malfunctions, saving you time and money on repairs.

Another critical aspect is the assurance of compatibility. Genuine components are engineered to work harmoniously with your equipment, minimizing the risk of improper fit or performance issues. This compatibility translates into smoother operation and greater efficiency in your tasks.

Furthermore, investing in authentic items often enhances the resale value of your machinery. Prospective buyers are more likely to invest in equipment that has been maintained with original components, as it indicates a commitment to quality and care.

Lastly, using genuine components supports the manufacturer’s warranty, providing peace of mind that you are protected against defects and other potential issues. This protection is crucial for long-term investments, ensuring you receive the full benefits of your machinery.