When it comes to maintaining efficient machinery designed for snow management, a thorough comprehension of its components is essential. This knowledge not only aids in effective operation but also ensures longevity and reliability in performance during the harshest winter conditions.

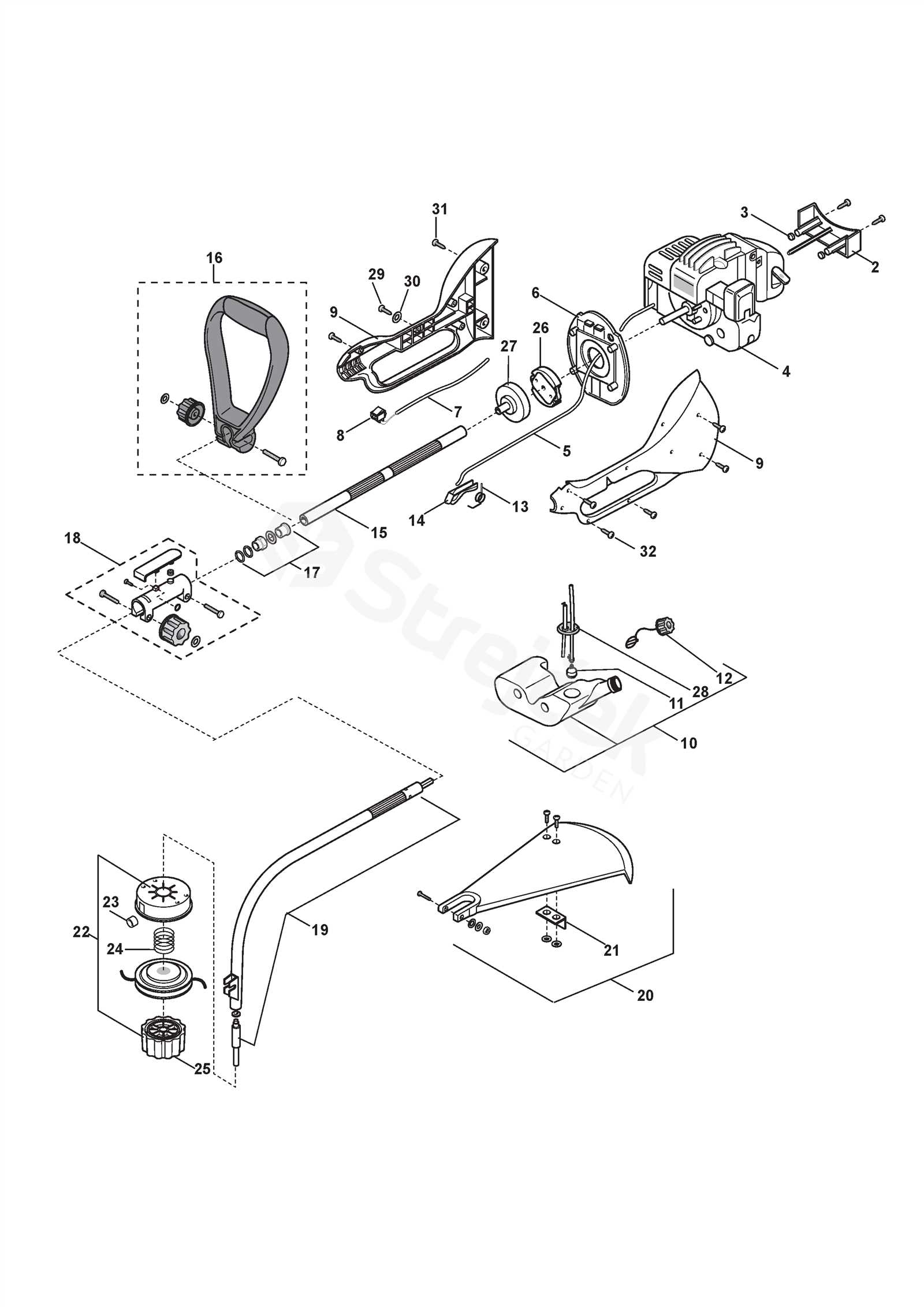

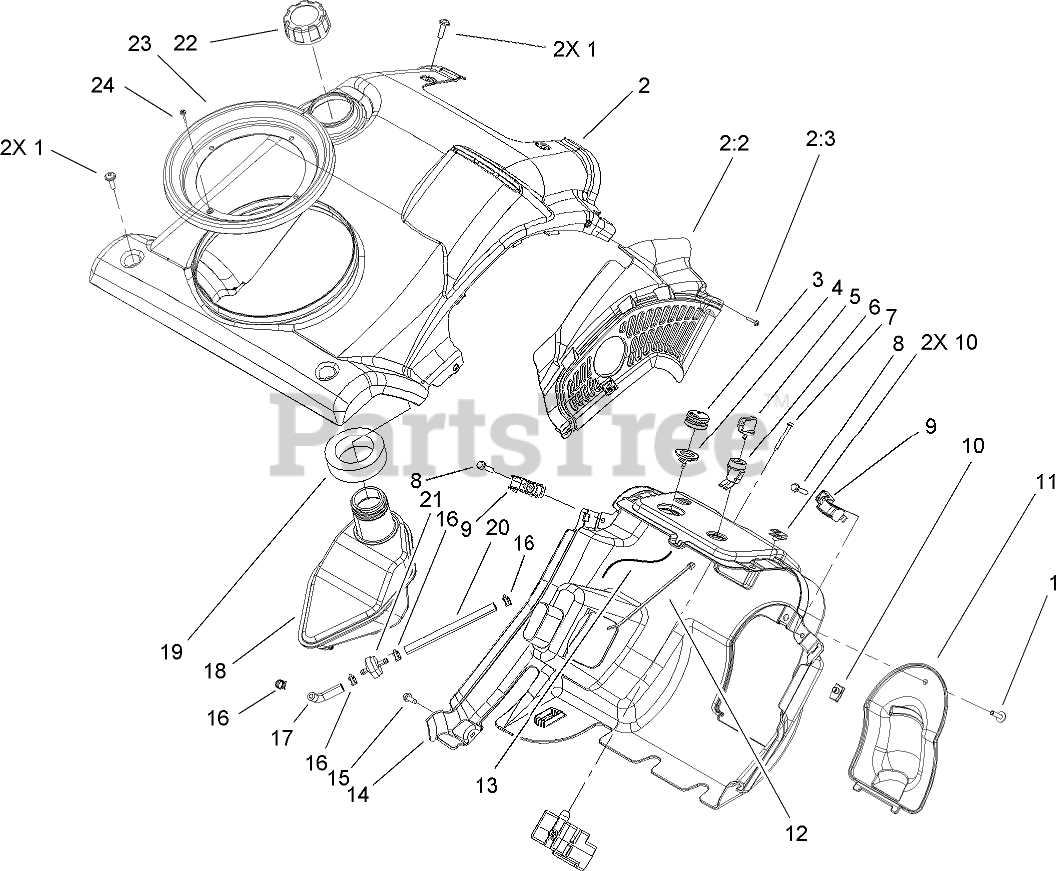

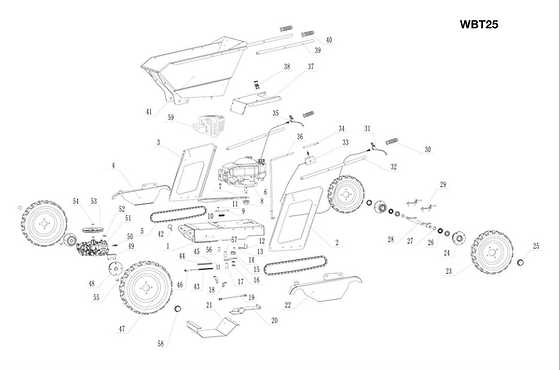

Visual representations of the essential elements within these machines serve as a valuable tool for users. They simplify the process of identifying specific parts, making troubleshooting and repairs much more accessible for both novices and seasoned operators alike.

By exploring these detailed illustrations, one can gain insights into the ultimate assembly and functionality of the equipment. This exploration ultimately empowers users to make informed decisions, leading to enhanced performance and satisfaction.

Toro Power Clear Parts Overview

This section provides a comprehensive look at the essential components that make up the equipment, offering insights into their functions and importance. Understanding these elements can enhance your ability to maintain and troubleshoot effectively, ensuring optimal performance throughout the seasons.

Key Components

The main elements include the engine, auger, and housing, each playing a critical role in operation. The engine serves as the powerhouse, generating the necessary energy, while the auger facilitates the movement of snow. The housing protects internal mechanisms from external elements, contributing to durability.

Maintenance and Care

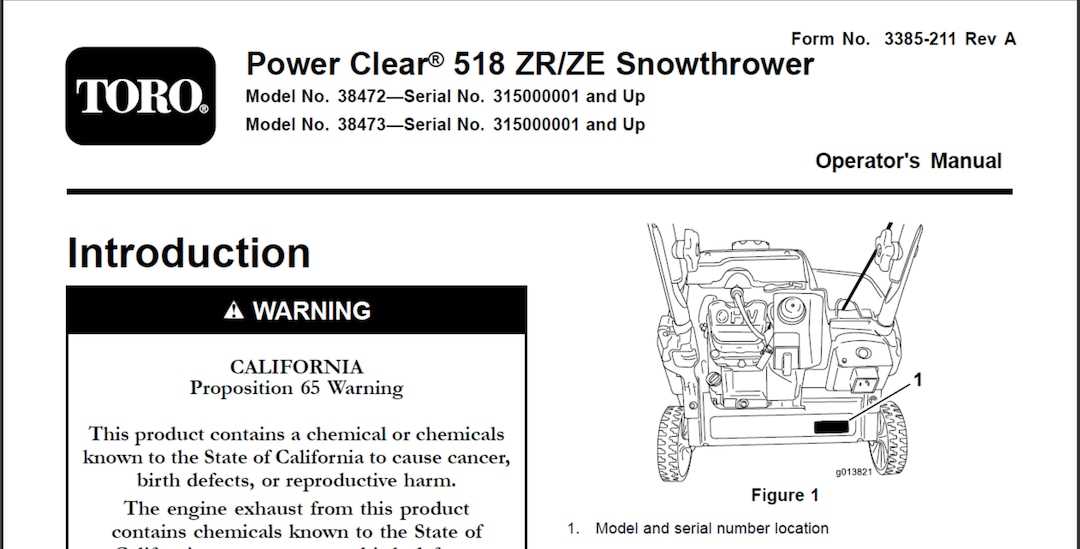

Understanding Toro Power Clear Models

When exploring various models of snow removal equipment, it’s essential to grasp their design and functionality. Each model boasts unique features tailored to different user needs and conditions. By examining these machines closely, one can determine the best fit for effective snow management.

Key elements to consider include engine performance, clearing width, and user-friendly controls. Understanding these attributes will help users make informed choices that enhance their efficiency during winter tasks. Moreover, maintenance and compatibility with accessories also play crucial roles in the longevity and effectiveness of the equipment.

Key Components of Snow Blowers

Understanding the essential elements of snow removal machines is crucial for optimal performance and maintenance. Each component plays a vital role in ensuring efficient operation during winter months.

- Auger: The mechanism responsible for gathering snow and pushing it towards the impeller.

- Impeller: This part throws the collected snow out of the chute, determining the distance it can be ejected.

- Chassis: The framework that supports all components and provides stability during use.

- Engine: Powers the entire system, influencing speed and efficiency.

- Controls: The interface for the operator to manage speed, direction, and chute positioning.

These critical components work together to ensure snow blowers perform effectively, allowing for smooth and swift snow clearance.

Identifying Replacement Parts

Understanding how to recognize and source components is crucial for maintaining the functionality and efficiency of your equipment. Whether you’re dealing with wear and tear or unexpected breakdowns, knowing what to look for can save time and ensure that your machine runs smoothly. This section provides a structured approach to identifying the necessary items needed for repairs or upgrades.

When you need to find the right components, start by assessing the condition and functionality of the unit. Look for any signs of damage, wear, or missing elements. Creating a checklist of these observations can streamline the process of sourcing replacements.

| Observation | Action |

|---|---|

| Visible Damage | Inspect and list damaged areas. |

| Unusual Noises | Identify potential faulty components. |

| Decreased Performance | Check for clogged or worn items. |

| Missing Elements | Make a note of parts that need replacement. |

After gathering observations, consult the manual or an online resource specific to your equipment for a detailed list of components. This will help ensure you obtain the correct replacements. Additionally, consider reaching out to local suppliers or online retailers who specialize in these items for further assistance.

Importance of Using Genuine Parts

Using authentic components in machinery ensures optimal performance and longevity. These original items are specifically designed to fit and function seamlessly within your equipment, maintaining efficiency and reliability.

Quality Assurance: Genuine components undergo rigorous testing, guaranteeing they meet high standards. This minimizes the risk of malfunctions and enhances safety during operation.

Cost-Effectiveness: While aftermarket alternatives may seem cheaper, they often lead to more frequent repairs and replacements, ultimately increasing long-term expenses. Authentic parts provide a durable solution that can save you money over time.

Warranty Protection: Utilizing original components often keeps your warranty intact, safeguarding your investment and providing peace of mind in case of unexpected issues.

In summary, choosing genuine components is essential for achieving the ultimate functionality and reliability of your machinery, ensuring it operates at its best for years to come.

Common Issues and Solutions

When dealing with outdoor machinery, users often encounter various challenges that can impede performance. Understanding these common problems and their resolutions can enhance the user experience and prolong the lifespan of the equipment. Below are frequent issues along with practical solutions to address them effectively.

Performance Problems

One of the most prevalent concerns is inadequate performance during operation. This may manifest as reduced efficiency or inability to operate altogether. Potential causes include clogged components, insufficient maintenance, or improper settings. To resolve these issues, ensure regular cleaning of all relevant parts, check fluid levels, and verify that all settings are correctly adjusted according to the manufacturer’s guidelines.

Starting Difficulties

Another frequent challenge is trouble starting the machine. This can often be traced back to battery issues, faulty ignition components, or fuel supply problems. To troubleshoot, inspect the battery for proper charge, examine the ignition system for any damage, and ensure that fuel lines are clear and filled with high-quality fuel. Implementing these steps can significantly improve starting reliability.

Maintaining Your Toro Equipment

Proper upkeep of your machinery is essential for optimal performance and longevity. Regular maintenance not only enhances efficiency but also helps to prevent unexpected breakdowns. By following a structured approach, you can ensure your equipment remains in peak condition throughout its lifespan.

| Task | Frequency | Description |

|---|---|---|

| Inspect | Weekly | Check for any signs of wear and tear or damage. |

| Clean | After Each Use | Remove debris and dirt to maintain efficiency. |

| Lubricate | Monthly | Apply lubricant to moving parts to reduce friction. |

| Replace Filters | Every Season | Ensure air and fuel filters are fresh for optimal performance. |

| Check Fluids | Monthly | Inspect and top off oil, coolant, and fuel levels as needed. |

How to Read Parts Diagrams

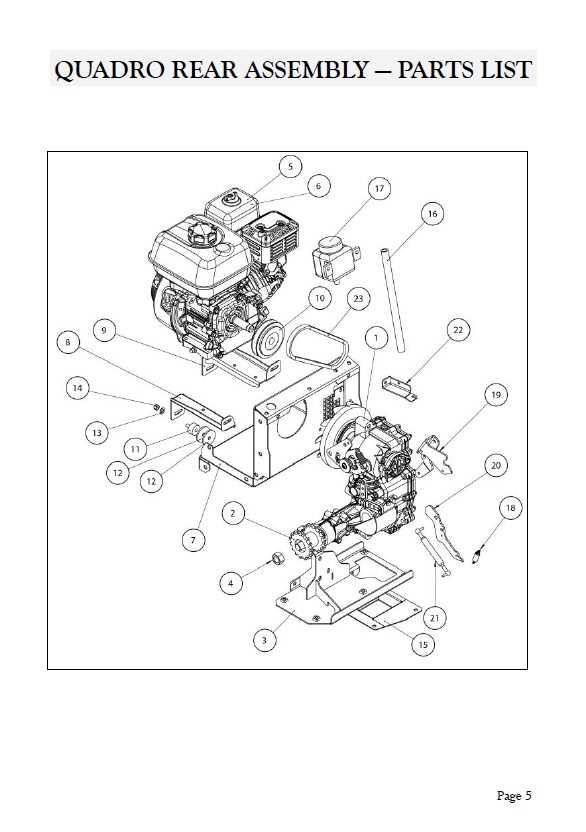

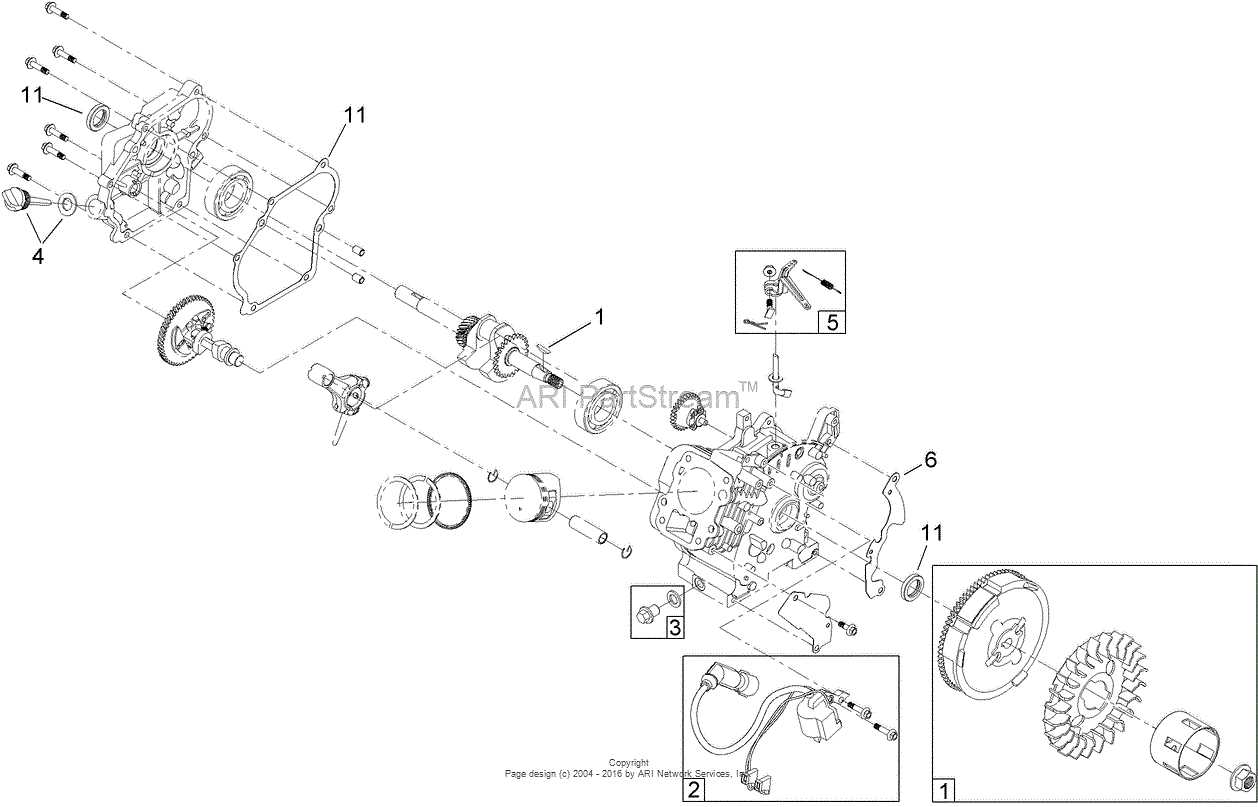

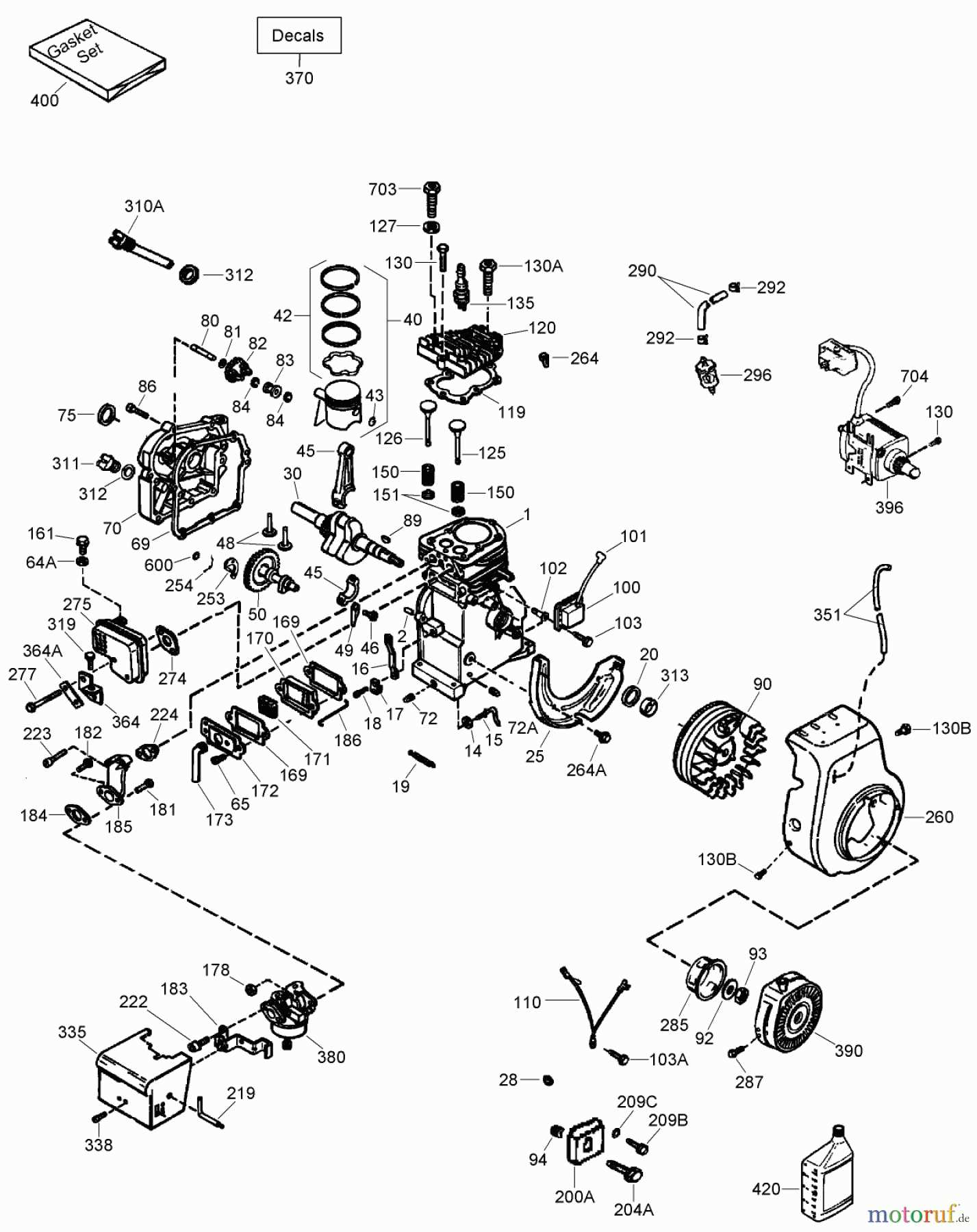

Understanding technical illustrations can greatly enhance your ability to maintain and repair equipment. These visual guides provide a clear representation of components, making it easier to identify each element and its function within the whole assembly. By familiarizing yourself with the layout and symbols used, you can streamline your repair process and ensure you have the right pieces for the job.

Begin by examining the overall structure. Most illustrations will present a complete view of the assembly, often including a reference number for each component. This numbering system allows for quick identification when cross-referencing with parts lists or catalogs.

Next, pay attention to the symbols and color codes used. Different shapes or colors can signify various functions or materials, providing essential insights into the assembly process. Be sure to consult the accompanying legend or key that typically accompanies these illustrations for accurate interpretation.

Lastly, look for exploded views. These renderings show the arrangement of components separated from each other, offering a comprehensive perspective on how each piece fits together. This can be particularly useful for visualizing assembly or disassembly during maintenance tasks.

Parts Diagram for Easy Reference

This section aims to provide a visual guide for quick identification of components, enhancing maintenance and repair tasks. Having a clear illustration at hand allows users to efficiently locate and understand each element’s role within the overall system.

Key advantages of using a visual guide include:

- Streamlined troubleshooting

- Reduced downtime during repairs

- Increased familiarity with machinery

To make the most of this reference, consider the following steps:

- Identify the specific part needed for your task.

- Cross-reference it with the labeled illustration.

- Follow the provided guidelines for installation or replacement.

This approach ultimately ensures a smoother experience when working with your equipment, minimizing errors and enhancing efficiency.

Ordering Parts from Authorized Dealers

Acquiring components from certified vendors ensures quality and compatibility with your equipment. Authorized dealers provide genuine items that enhance performance and reliability, safeguarding your investment.

Benefits of Authorized Purchases

Choosing licensed suppliers comes with numerous advantages, including access to expert advice, warranty support, and the assurance of authenticity. This approach minimizes risks associated with counterfeit or inferior products.

How to Order

Follow these steps to successfully order components:

| Step | Description |

|---|---|

| 1 | Identify the specific component needed. |

| 2 | Contact your nearest authorized dealer. |

| 3 | Provide necessary details such as model and serial number. |

| 4 | Place your order and confirm delivery options. |

DIY Repairs: Tips and Tricks

When it comes to maintaining and fixing equipment, knowing a few essential techniques can make all the difference. Whether you’re tackling a minor issue or a more complex challenge, having the right approach can save time and money. This section provides useful insights to empower you in your repair endeavors.

Before diving into any repairs, always ensure you have the necessary tools at hand. Familiarize yourself with common issues related to your equipment, and don’t hesitate to consult manuals or online resources for guidance. Proper preparation can significantly enhance the repair process.

| Tip | Description |

|---|---|

| Stay Organized | Keep your workspace tidy and categorize tools and components to avoid confusion. |

| Document Your Steps | Take notes or photos while disassembling parts, which can help during reassembly. |

| Use Quality Parts | Invest in reliable components to ensure durability and optimal performance of the repaired unit. |

| Test After Repair | Always run a thorough test after completing repairs to ensure everything functions correctly. |

By following these suggestions, you’ll be better equipped to handle repairs effectively and confidently, ensuring your equipment operates smoothly for years to come.

Seasonal Maintenance Checklist

Regular upkeep of your outdoor equipment is essential to ensure optimal performance throughout the year. A well-structured seasonal maintenance checklist can help you identify necessary tasks and prepare your machinery for varying weather conditions. By following these guidelines, you can prolong the lifespan of your tools and enhance their efficiency.

1. Inspect and Clean Components: Begin by thoroughly examining all parts for wear or damage. Remove any debris, dirt, or rust that may have accumulated, as this can affect functionality. Pay special attention to filters and air intakes.

2. Check Fluids: Ensure that all necessary fluids are at appropriate levels. This includes oil, fuel, and coolant. Replace or top off as needed to maintain smooth operation.

3. Sharpen Cutting Edges: For equipment with cutting mechanisms, ensure that blades or edges are sharp. Dull blades can lead to inefficient performance and increased wear.

4. Inspect Belts and Cables: Examine belts for signs of wear, cracking, or fraying. Ensure cables are intact and properly connected. Replace any damaged components to prevent breakdowns.

5. Test Safety Features: Check that all safety mechanisms are functioning correctly. This includes switches, guards, and emergency stops. Proper safety checks can prevent accidents and injuries.

6. Store Properly: When the season ends, clean your equipment and store it in a dry, sheltered location. Covering machinery can protect it from dust and moisture, ensuring it remains in good condition for the next season.

By adhering to this checklist, you can help maintain your outdoor equipment’s reliability and readiness for action, no matter the time of year.

Frequently Asked Questions on Toro Parts

This section aims to address common inquiries related to components and their functionalities, providing clarity for users looking to maintain or repair their equipment effectively.

What should I do if a component is damaged?

It’s essential to assess the damage thoroughly. If it’s minor, a simple repair may suffice, but for significant issues, replacement is often the best route.

How can I find the right component for my model?

Always refer to the model number of your equipment. This ensures you acquire the correct replacement, as different models may require specific components.

Are aftermarket options reliable?

While aftermarket components can be cost-effective, their quality varies. It’s advisable to research and read reviews to ensure reliability.

How do I maintain my equipment for longevity?

Regular maintenance, including cleaning and checking for wear and tear, is crucial. Following the manufacturer’s guidelines will help prolong the lifespan of your equipment.

Where can I find diagrams for assembly?

Most manufacturers provide online resources or manuals that include detailed assembly visuals. These can be invaluable for proper reassembly and troubleshooting.