In the world of outdoor machinery, comprehending the intricate details of your device is essential for optimal performance and longevity. This section delves into the essential elements that make up your snow-clearing machine, offering insights into its functionality and maintenance.

Each component plays a vital role in ensuring that the equipment operates smoothly and efficiently. By familiarizing yourself with these elements, you empower yourself to troubleshoot issues, conduct repairs, and perform routine upkeep with confidence.

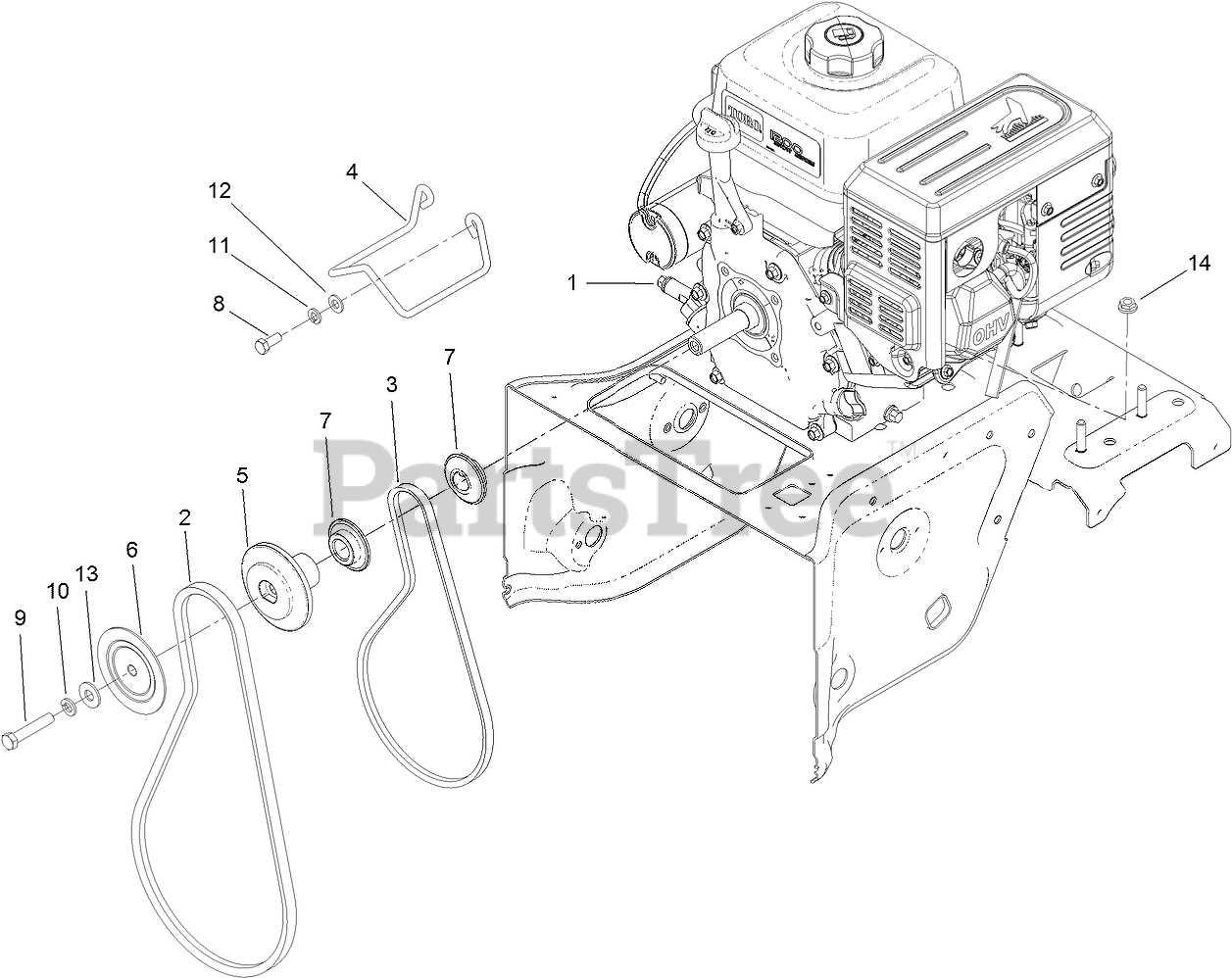

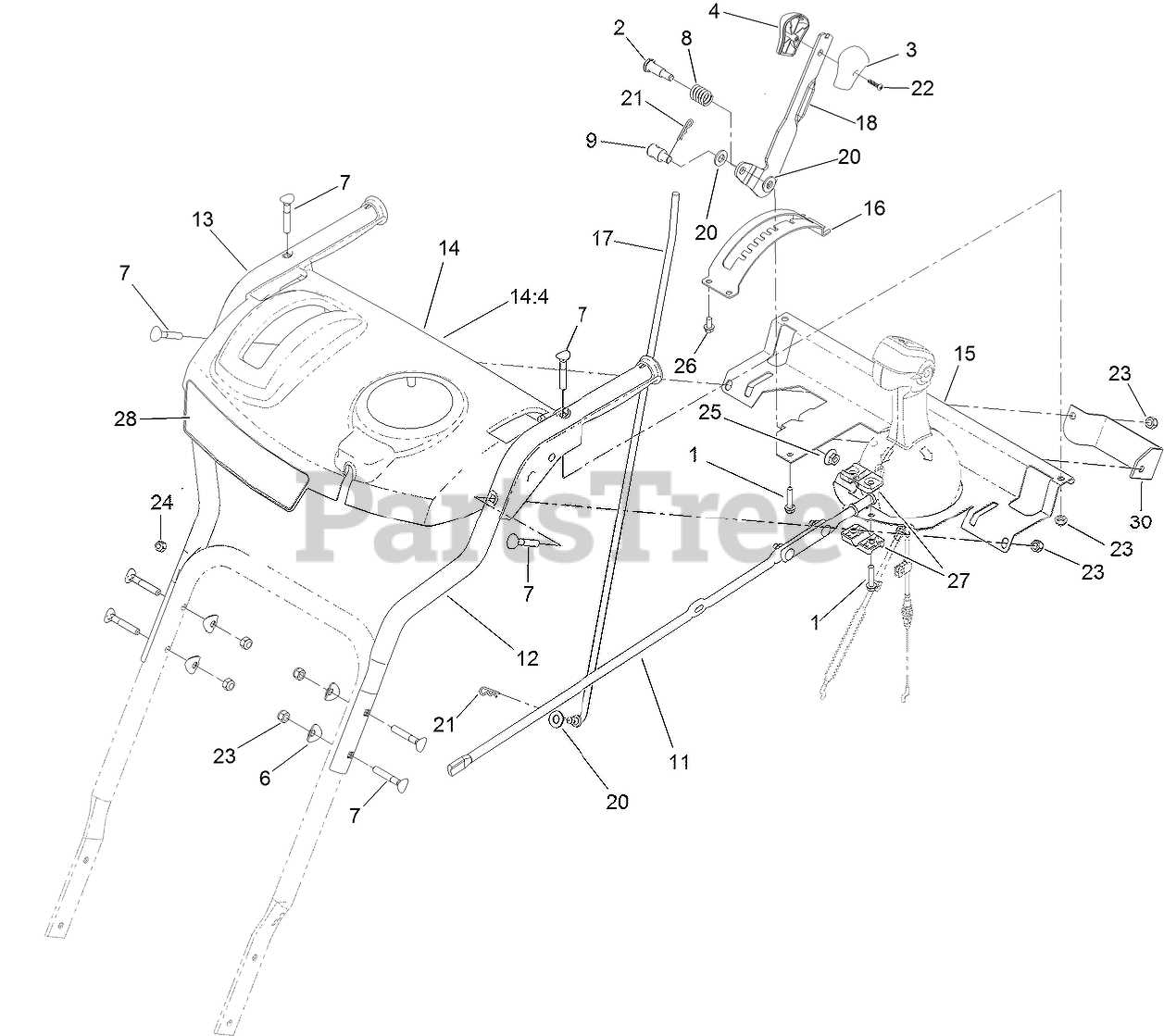

Visual representations of these components can greatly enhance your understanding. Detailed illustrations can serve as a valuable resource, guiding you through the specific parts and their interactions. Whether you are a seasoned operator or a newcomer, gaining knowledge of these crucial elements will ultimately lead to more effective use of your machinery.

Toro Power Max 824 OE Overview

This section provides a comprehensive look at a highly efficient snow clearing machine designed for optimal performance in winter conditions. Engineered to tackle challenging snowfall, it combines innovative technology with user-friendly features, ensuring effective operation and ease of maintenance. Whether you are dealing with light flurries or heavy drifts, this equipment offers reliability and power.

Key Features

Equipped with advanced functionalities, this machine includes a robust engine for enhanced durability and efficiency. Its specially designed auger system effectively breaks up snow and ice, while the self-propelled drive mechanism allows for effortless navigation across various terrains. Ergonomic controls enhance user comfort, making it suitable for both residential and commercial applications.

Maintenance and Support

Understanding Snow Blower Components

Snow clearing machines consist of various elements that work in unison to effectively tackle winter’s challenges. Grasping these components is crucial for proper maintenance and optimal performance during harsh weather conditions.

Main Parts Overview

- Engine: Powers the entire unit and determines its efficiency.

- Auger: Collects and moves snow towards the chute.

- Chute: Directs the expelled snow away from the path.

- Skids: Adjusts the height and stability while operating.

Importance of Each Component

- The engine’s strength directly impacts the machine’s capability.

- Augers must be well-maintained to prevent clogging.

- Chute positioning ensures effective snow removal.

- Skids affect maneuverability and ground clearance.

Importance of Parts Diagrams

Understanding the assembly and components of machinery is crucial for effective maintenance and repair. Visual representations of individual elements not only enhance comprehension but also facilitate efficient troubleshooting. This clarity is essential for both professionals and DIY enthusiasts, ensuring that every part functions optimally within the whole system.

Enhanced Clarity

Visual aids simplify complex assemblies by breaking them down into recognizable segments. This organized representation allows users to easily identify components, their relationships, and their specific roles. With a clear visual guide, even intricate machinery becomes manageable, reducing the likelihood of errors during repairs.

Streamlined Maintenance

Access to these visual guides can significantly improve the maintenance process. Technicians can quickly locate and replace worn-out or malfunctioning elements, thereby minimizing downtime. Furthermore, understanding the layout can help in planning preventative measures, ensuring the longevity and reliability of the equipment.

In summary, visual representations are invaluable tools that empower users with the knowledge needed for effective operation and maintenance. Embracing these resources not only enhances efficiency but also fosters a deeper understanding of how different components interact within the machinery.

Identifying Key Assembly Areas

Understanding the fundamental components of machinery is essential for effective maintenance and repair. This section focuses on recognizing critical sections of assembly that contribute to the overall functionality and performance of the equipment. By familiarizing yourself with these areas, you can streamline troubleshooting and enhance your operational efficiency.

Main Components Overview

The following table outlines the primary areas of assembly, highlighting their functions and significance in the overall system:

| Assembly Area | Function |

|---|---|

| Engine | Powers the machine, converting fuel into mechanical energy. |

| Transmission | Transmits power from the engine to the wheels, enabling movement. |

| Chassis | Framework supporting various components and providing structural integrity. |

| Control System | Manages operational functions, allowing user interaction and machine responsiveness. |

Importance of Each Area

Each of these sections plays a vital role in the machine’s operation. Regular inspection and maintenance of these key areas can prevent malfunctions and extend the lifespan of the equipment. Understanding their interconnections helps in diagnosing issues more effectively, leading to quicker resolutions and minimized downtime.

Common Replacement Parts for Toro

Maintaining outdoor equipment often requires the replacement of specific components to ensure optimal performance and longevity. Various parts may wear out over time due to regular use, making it essential for users to familiarize themselves with common replacements. Understanding which elements typically need attention can help keep machinery running smoothly and efficiently.

Essential Components for Maintenance

Among the most frequently replaced elements are those that directly impact functionality. These include items such as belts, blades, and filters, which are crucial for performance. Ensuring these parts are in good condition can significantly enhance the overall operation of your equipment.

Key Parts to Consider

| Component | Description |

|---|---|

| Blades | Sharp edges that cut grass and maintain a clean lawn. |

| Belts | Transmits power from the engine to the cutting deck or wheels. |

| Air Filters | Prevents dirt and debris from entering the engine, ensuring proper airflow. |

| Oil Filters | Removes impurities from the oil, extending engine life. |

| Battery | Powers electric starters and accessories for reliable operation. |

Being aware of these common components and their roles can greatly assist in effective maintenance practices, ultimately leading to a longer lifespan for your outdoor machinery.

Maintenance Tips for Longevity

Ensuring the durability and efficient performance of your outdoor equipment requires regular attention and care. By following a few essential maintenance practices, you can significantly extend the lifespan of your machinery and improve its overall functionality. Adopting a proactive approach will not only save you money in the long run but also enhance your experience while using the equipment.

Regular Cleaning

Keeping your machinery clean is fundamental to its maintenance. After each use, remove debris, dirt, and grass clippings from the exterior and working parts. Pay special attention to air filters and engine components, as accumulated dirt can lead to overheating and mechanical failure. Regular cleaning not only prevents corrosion but also allows for better performance during operation.

Routine Inspections

Conducting periodic inspections is crucial for identifying potential issues before they escalate. Check the belts, blades, and other vital components for wear and tear. Tighten loose parts and replace any damaged items promptly. Maintaining proper fluid levels and ensuring that all connections are secure will contribute to the reliable functioning of your equipment.

Tools Needed for Repairs

Having the right equipment is crucial for effectively carrying out maintenance and fixing tasks. A well-stocked toolkit not only makes the process smoother but also ensures safety and precision during repairs.

Essential Hand Tools

Start with basic hand tools such as wrenches, screwdrivers, and pliers. These versatile instruments allow for a wide range of adjustments and disassemblies, making them indispensable for any repair job. Additionally, having a good quality set of sockets can significantly enhance your efficiency.

Power Equipment and Safety Gear

For more demanding tasks, consider incorporating power tools like drills and saws. These can save time and effort when working with tougher materials. Moreover, always prioritize safety by using gloves, goggles, and protective footwear to shield yourself from potential hazards.

Safety Precautions During Maintenance

Maintaining equipment is essential for optimal performance and longevity. However, it is crucial to prioritize safety throughout the process. Following specific guidelines helps prevent accidents and ensures that the maintenance tasks are performed efficiently. Awareness and preparation are key components of a safe working environment.

Essential Safety Measures

Before commencing any maintenance work, take the time to review the following safety measures:

| Safety Measure | Description |

|---|---|

| Personal Protective Equipment | Always wear appropriate gear, such as gloves, goggles, and hearing protection, to shield yourself from potential hazards. |

| Work Area Organization | Keep the workspace clean and free from clutter to reduce the risk of trips and falls. |

| Disconnect Power Sources | Ensure that all power supplies are disconnected before beginning any maintenance to prevent accidental activation. |

| Follow Manufacturer Guidelines | Refer to the manufacturer’s instructions for specific maintenance procedures and safety protocols. |

Emergency Preparedness

In case of an accident, having a plan in place is vital. Familiarize yourself with emergency procedures and keep a first aid kit readily available. Additionally, knowing the location of emergency exits and how to contact emergency services can make a significant difference in critical situations.

Where to Find Genuine Parts

When it comes to maintaining and repairing outdoor equipment, sourcing authentic components is crucial for optimal performance and longevity. Utilizing original pieces ensures compatibility and reliability, ultimately enhancing the overall efficiency of your machinery.

Here are several reliable avenues to explore for procuring genuine components:

- Authorized Dealers: Visit local retailers or distributors recognized by the manufacturer. They often have a selection of verified items.

- Official Website: Browse the manufacturer’s online store for a comprehensive inventory of genuine replacements.

- Online Marketplaces: Use reputable e-commerce platforms that offer verified sellers. Always check reviews and seller ratings.

- Service Centers: Consult local repair shops or service centers that specialize in your equipment brand. They can often order genuine replacements directly.

Before making a purchase, verify that the components are authentic to ensure the best results for your outdoor equipment.

Comparing OEM and Aftermarket Options

When it comes to selecting components for machinery, the choice between original equipment manufacturer (OEM) parts and aftermarket alternatives can significantly impact performance, longevity, and overall satisfaction. Each option has its unique advantages and drawbacks, making it essential to understand the distinctions to make an informed decision.

OEM parts are crafted specifically for a particular machine, ensuring compatibility and reliability. These components often come with warranties and support from the manufacturer, giving users peace of mind regarding their investment. However, they tend to be priced higher than their counterparts, which can be a deterrent for budget-conscious consumers.

On the other hand, aftermarket parts provide a more affordable solution, often designed to meet or exceed the specifications of original components. They offer a wider variety of choices, catering to different needs and preferences. However, quality can vary significantly among aftermarket suppliers, which necessitates thorough research and careful selection to avoid potential issues.

Ultimately, the decision between OEM and aftermarket options will depend on individual priorities, including cost, quality, and long-term maintenance considerations. Weighing the pros and cons of each can help ensure optimal performance and satisfaction with your machinery.

Common Issues with Toro Snow Blowers

Snow clearing machines are essential tools for many during winter months, but they can sometimes encounter problems that hinder their performance. Understanding these common issues can help users troubleshoot effectively and maintain optimal functionality.

- Starting Difficulties:

- Check the fuel level and quality.

- Inspect the spark plug for wear or damage.

- Ensure the battery is charged (if applicable).

- Clogging:

- Ensure that the chute is not blocked by ice or snow.

- Use the machine when snow is not overly wet or heavy.

- Uneven Snow Dispersal:

- Check the auger for damage or wear.

- Adjust the chute direction properly.

- Stalling:

- Inspect the fuel system for clogs or leaks.

- Check for overheating by allowing the machine to cool down.

- Vibrations:

- Look for loose bolts or parts that may need tightening.

- Examine the auger and impeller for damage.

By identifying these potential issues early, operators can ensure smoother operation and extend the life of their snow-clearing equipment.

DIY Repair Techniques Explained

Engaging in self-repair can be a fulfilling endeavor that empowers individuals to address mechanical issues without relying on external assistance. This section explores effective methods and strategies for tackling repairs, emphasizing practical approaches that anyone can implement with the right tools and a bit of patience.

Assessment of the Problem: The first step in any repair is to accurately diagnose the issue. Observing symptoms and conducting a thorough inspection can help identify the root cause of the malfunction. Taking notes during this process can be invaluable for tracking progress.

Gathering Tools and Materials: Once the problem is understood, compiling the necessary tools and components is crucial. A well-organized workspace with all required items at hand can streamline the repair process and reduce frustration.

Step-by-Step Disassembly: Carefully disassembling the equipment is often necessary. It’s advisable to document each step with photos or written notes, ensuring that reassembly is straightforward. Using labeled containers for screws and small parts can prevent misplacement.

Repair Techniques: Depending on the issue, various methods may be applied. Techniques such as soldering, replacing worn-out components, or cleaning crucial parts can often restore functionality. Understanding the specific repair method required is key to a successful outcome.

Reassembly and Testing: After repairs are made, the reassembly process should be approached methodically. Once everything is back in place, thorough testing is essential to confirm that the issue has been resolved and the equipment is functioning as intended.

Continuous Learning: Each repair offers a learning opportunity. Engaging with online communities or tutorials can expand knowledge and enhance future repair endeavors. Embracing the trial-and-error aspect of DIY repairs fosters both skill development and confidence.

Resources for Toro Owners

Maintaining your outdoor equipment can enhance performance and longevity. Accessing reliable materials is essential for troubleshooting and servicing your machinery effectively. This section aims to provide valuable tools and information for enthusiasts and everyday users alike.

Online Manuals: Digital guides offer detailed insights into operation and maintenance. Websites often provide downloadable manuals that can help you navigate through various models and their unique requirements.

Community Forums: Engaging with fellow users can be invaluable. Online communities allow owners to share experiences, tips, and solutions to common challenges, fostering a supportive environment.

Replacement Resources: Finding quality replacements is crucial. Numerous suppliers specialize in providing authentic components to ensure that your equipment continues to function optimally.

Video Tutorials: Visual aids can simplify complex procedures. Platforms like YouTube feature countless instructional videos that guide users through repairs and enhancements step by step.

Local Workshops: Connecting with nearby service centers can provide hands-on assistance. Many shops offer expertise in repairs and maintenance, ensuring that your machinery stays in peak condition.