In the realm of outdoor machinery, the efficiency and performance of your device largely depend on the intricate relationships between its various elements. A comprehensive understanding of how these components interact can significantly enhance maintenance efforts and operational effectiveness. With an array of features designed to support a multitude of tasks, familiarity with the assembly of your equipment is essential for any operator.

Recognizing the individual roles of each section can aid in troubleshooting and repairs. This knowledge not only empowers users to identify potential issues before they escalate but also facilitates informed decisions regarding upgrades and replacements. Each part serves a unique function, contributing to the overall reliability and durability of the machine.

Whether you are a seasoned professional or a novice, accessing a detailed overview of your equipment’s structure will equip you with the tools needed for optimal care. By exploring the layout of components, users can gain insights into the design and operation of their machinery, ensuring that it remains in peak condition for years to come.

Toro Z Master Parts Overview

This section provides a comprehensive look at the various components essential for the optimal functioning of a specific line of outdoor machinery. Understanding the arrangement and roles of these elements can enhance maintenance and performance, ensuring longevity and efficiency. Each piece plays a critical role in the overall operation, contributing to the seamless experience users expect from high-quality equipment.

Familiarity with these components allows for informed decisions regarding repairs and upgrades, facilitating a deeper appreciation of the engineering behind the machinery. Users can delve into the specific functions and relationships between different elements, which ultimately aids in troubleshooting and enhancing performance. Knowledge of these crucial pieces empowers operators to maintain their equipment effectively.

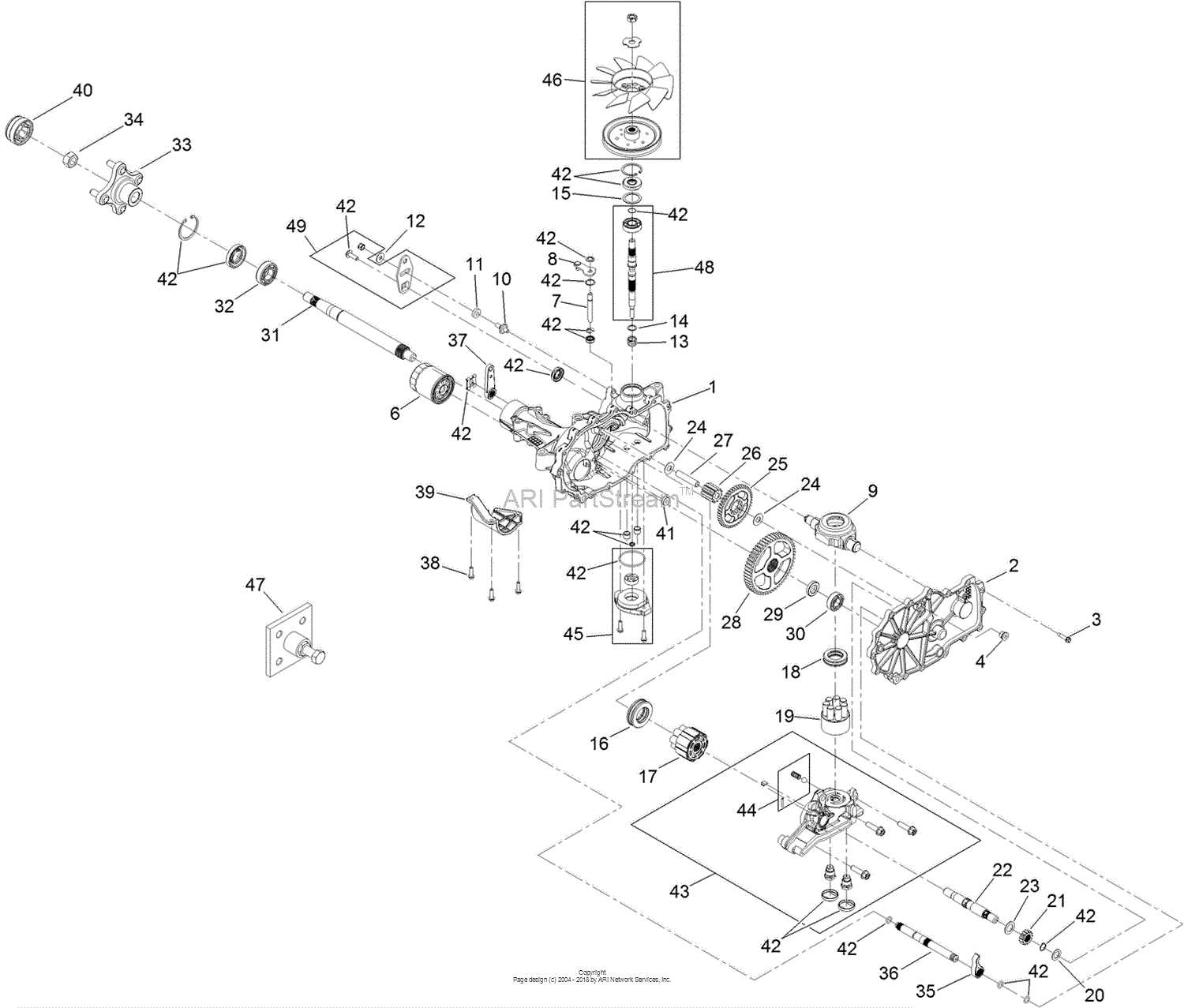

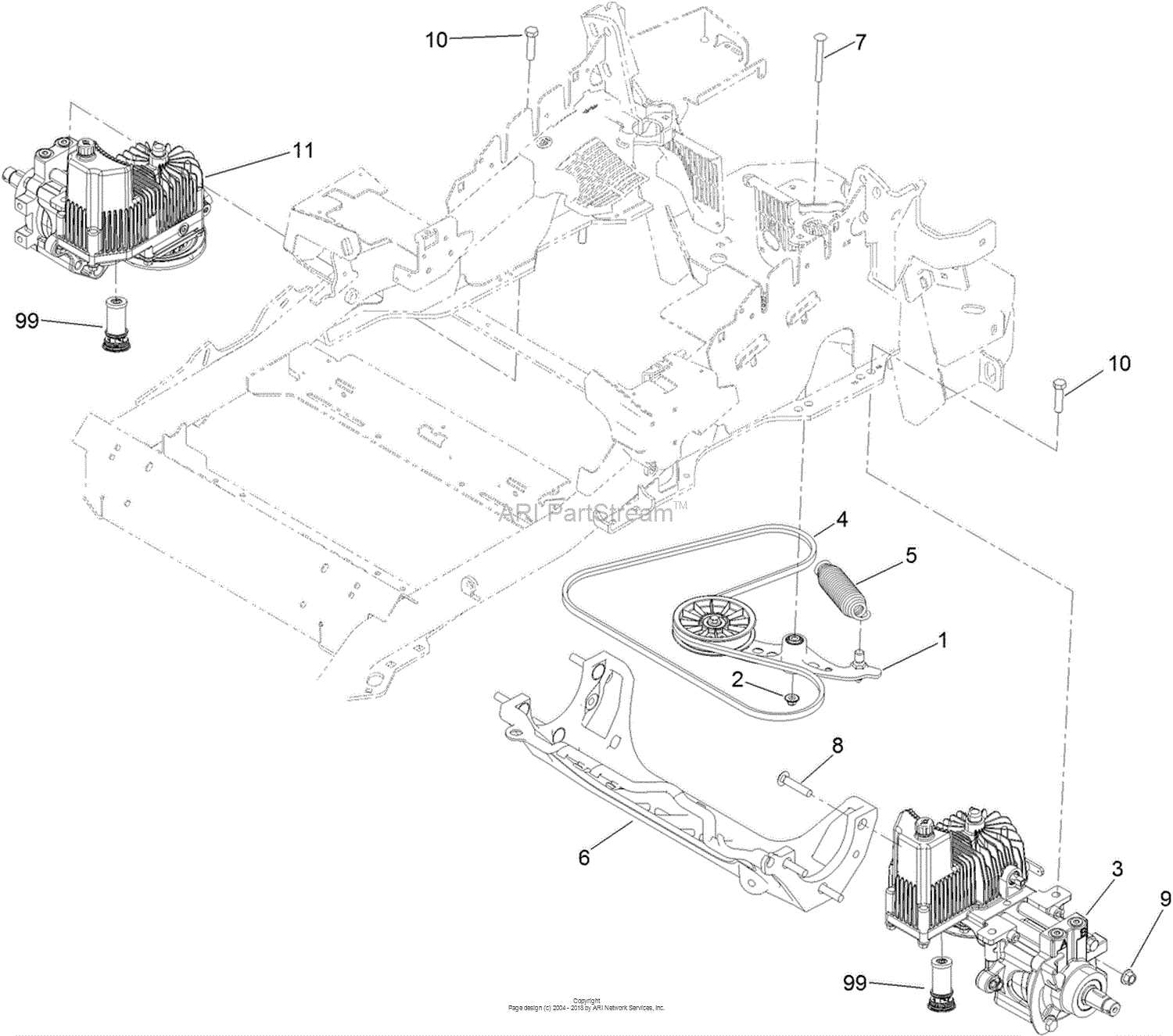

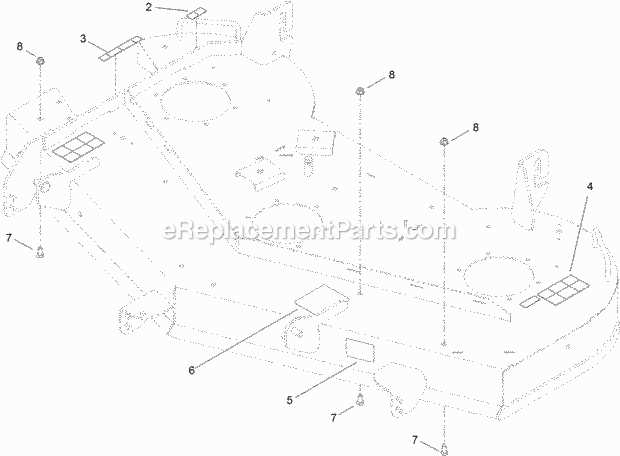

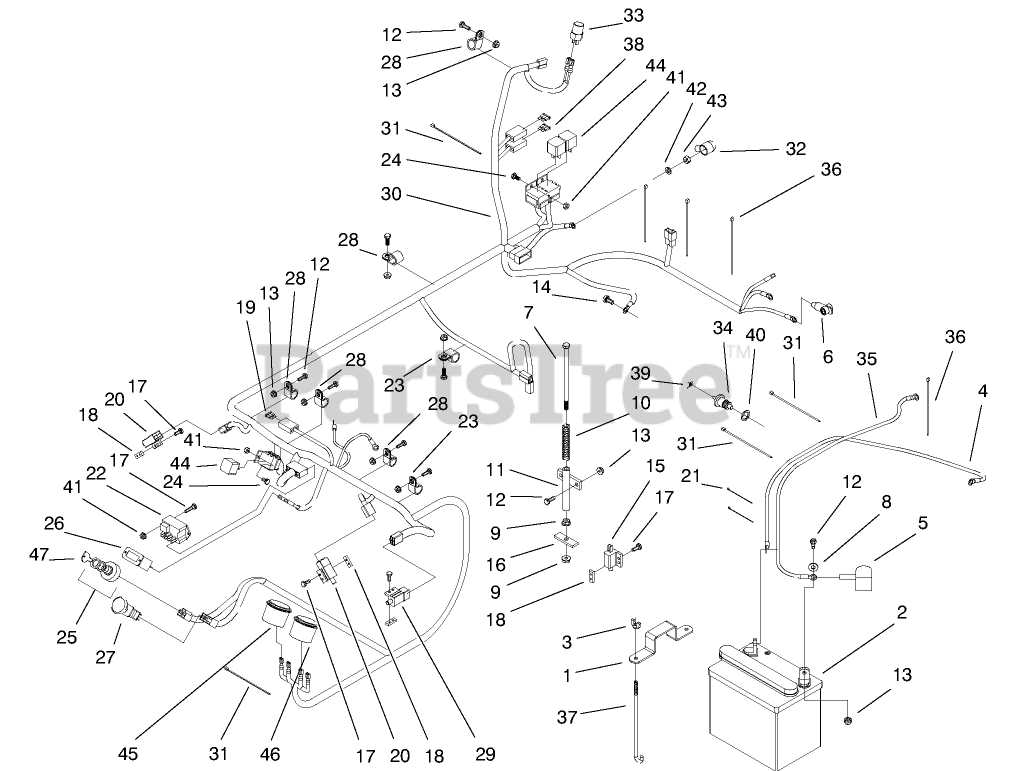

Importance of Parts Diagrams

Understanding the intricacies of machinery is essential for maintenance and repair. Visual representations of components serve as invaluable tools, allowing users to identify and locate essential elements within a system.

Enhancing Communication

Illustrations facilitate clearer communication among technicians and engineers. They provide a common reference point, reducing misunderstandings and improving collaboration.

- Standardizes terminology

- Clarifies complex structures

- Streamlines problem-solving

Facilitating Maintenance

Access to visual guides significantly aids in maintenance tasks. Users can quickly reference the location and function of various components, enhancing efficiency and accuracy.

- Improves diagnostic procedures

- Speeds up repairs

- Reduces errors

Understanding the Toro Z Master

The advanced mowing equipment is designed to enhance efficiency and precision in lawn care. By examining its components and functionality, users can gain insights into optimizing their performance and maintenance practices. This knowledge is essential for anyone looking to achieve exceptional results in landscape management.

At the core of this machine is its robust engine, which provides the necessary power for various tasks. Coupled with a sophisticated transmission system, it ensures smooth operation across different terrains. Users will appreciate the agility and maneuverability offered, making it suitable for both residential and commercial applications.

Maintenance is crucial for longevity and reliability. Regular inspections and understanding of key elements can prevent common issues and extend the lifespan of the equipment. Familiarity with essential components allows operators to identify when service is required, ensuring optimal performance throughout its use.

Moreover, operators should be aware of the innovative features that enhance usability, such as adjustable cutting heights and user-friendly controls. These enhancements contribute to a more comfortable and efficient mowing experience, catering to a variety of landscaping needs.

In summary, comprehending the intricacies of this high-performance lawn care tool empowers users to maximize their investment. By focusing on both operational efficiency and proactive maintenance, one can ensure a beautifully maintained outdoor space year-round.

Key Components of the Mower

Understanding the essential elements of a lawn cutting machine is crucial for effective maintenance and operation. Each component plays a significant role in ensuring optimal performance and longevity.

- Engine: The powerhouse that drives the entire mechanism, providing the necessary energy for cutting.

- Deck: The housing that contains the blades and supports the structure, affecting both durability and cutting efficiency.

- Blades: The sharp instruments responsible for cutting grass, available in various shapes and sizes for different mowing styles.

- Wheels: Essential for mobility, they determine the mower’s maneuverability and ease of use on varied terrain.

- Handle: Provides control and stability, allowing the user to steer and guide the mower effectively.

By delving into these vital components, operators can enhance their understanding and improve their mowing experience.

Common Issues and Solutions

When working with outdoor power equipment, users often encounter various challenges that can hinder performance and efficiency. Understanding these common problems and their solutions can help maintain optimal functionality and extend the lifespan of the machinery. Here, we will explore frequent issues and practical remedies to address them effectively.

Frequent Problems

One of the most prevalent issues involves difficulty starting the equipment. This can stem from a range of factors, including fuel quality, battery condition, or ignition system malfunctions. Additionally, users may experience uneven cutting or reduced power output, often due to dull blades or clogged filters. Regular maintenance is crucial in preventing these complications.

Practical Solutions

To resolve starting difficulties, ensure that the fuel is fresh and the battery is fully charged. Checking the spark plug for wear can also prove beneficial. For issues related to cutting performance, regularly sharpening blades and cleaning air filters will help maintain efficiency. Implementing a routine maintenance schedule can significantly reduce the occurrence of these common issues, ensuring the equipment remains in peak condition.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers numerous advantages that enhance the overall performance and longevity of machinery. These products are designed specifically for the equipment in question, ensuring compatibility and optimal functionality.

One significant benefit is the assurance of quality. OEM components undergo rigorous testing and adhere to strict manufacturing standards, which leads to increased reliability compared to generic alternatives. This reliability translates into reduced maintenance costs and fewer unexpected breakdowns.

Additionally, employing these specialized parts can enhance the efficiency of the equipment. When each component is engineered to work harmoniously within the system, the overall performance improves, resulting in better fuel economy and productivity.

Another important aspect is warranty protection. Many manufacturers provide extended warranties for equipment that utilizes original components, giving users peace of mind and safeguarding their investment against future issues.

Lastly, choosing OEM options often supports the resale value of the equipment. Prospective buyers are more likely to prefer machines that have been maintained with genuine components, knowing they are less likely to encounter problems in the future.

How to Read Parts Diagrams

Understanding visual schematics can greatly enhance your ability to identify and assemble components effectively. These illustrations serve as a roadmap, allowing you to navigate through various elements and their relationships. Familiarizing yourself with the layout and symbols used will empower you to tackle repairs or modifications with confidence.

Identifying Key Components

Begin by focusing on the labeled sections, which typically highlight significant items. Look for unique identifiers or codes that correspond to specific elements, making it easier to locate and reference them in your maintenance or replacement tasks.

Understanding Relationships

Pay attention to the connections and orientations shown in the visuals. Arrows or lines often indicate how different pieces interact with one another, providing insight into assembly and disassembly processes. This knowledge is crucial for achieving the ultimate effectiveness in your projects.

Maintenance Tips for Longevity

To ensure the prolonged functionality of your equipment, it is essential to adopt a consistent care routine. Regular attention not only enhances performance but also reduces the likelihood of unexpected breakdowns. By implementing a few simple practices, you can extend the lifespan and efficiency of your machinery.

Regular Inspections

Frequent checks for wear and tear can prevent major issues down the line. Look for signs of damage, corrosion, or loose components. Addressing these concerns promptly can save time and resources.

Proper Cleaning

Keeping your equipment clean is crucial. Debris and dirt can cause malfunctions and inefficiencies. Regularly clean surfaces, filters, and moving parts to maintain optimal performance and prevent deterioration.

Where to Find Replacement Parts

Finding the right components for your equipment can enhance its longevity and performance. Knowing where to look can save time and ensure you get the best quality for your needs.

Online Resources

- Manufacturer’s Website: Check the official site for authorized sellers.

- Retail Websites: Large online retailers often carry a wide range of options.

- Specialized Forums: Communities can provide recommendations and reviews.

Local Options

- Authorized Dealers: Visit or call local distributors for authentic components.

- Hardware Stores: Some may carry common replacement items.

- Repair Shops: Professionals often have access to various parts or can assist in sourcing them.

Comparing Different Toro Models

When evaluating various outdoor equipment options, it’s essential to understand the unique features and specifications of each variant. This analysis will help consumers make informed decisions based on their specific needs and preferences.

Key Features to Consider

- Engine Performance

- Cutting Width

- Durability and Build Quality

- Fuel Efficiency

- Ease of Use

- Maintenance Requirements

Popular Variants Overview

-

Model A

- Ideal for residential lawns

- Features a compact design

- Offers efficient fuel consumption

-

Model B

- Designed for larger properties

- Equipped with advanced cutting technology

- Higher horsepower for enhanced performance

-

Model C

- Versatile for various terrains

- Features adjustable cutting heights

- Renowned for reliability and ease of maintenance

By analyzing these distinct models, users can identify which machine aligns best with their requirements, ensuring optimal performance and satisfaction.

Customer Reviews and Feedback

This section highlights the valuable insights and experiences shared by users regarding their recent purchases. Customer opinions not only inform potential buyers but also provide essential feedback for manufacturers to improve their offerings.

Many users have expressed their satisfaction with the quality and functionality of the products. Here are some common themes observed in reviews:

- Durability: Customers appreciate the robust construction, noting its ability to withstand various conditions.

- Performance: Many reviews highlight efficient operation, enhancing user experience during tasks.

- Support: Positive feedback regarding customer service, with prompt responses to inquiries and concerns.

- Ease of Use: Users often mention straightforward assembly and user-friendly features.

While the majority of feedback is positive, some constructive criticism has emerged:

- Pricing: A few customers feel that the cost could be more competitive compared to alternatives.

- Availability: Some users expressed concerns about stock shortages, making it difficult to purchase.

Overall, customer reviews serve as a critical resource for prospective buyers, guiding them in making informed decisions while helping manufacturers refine their products for ultimate satisfaction.

DIY Repair vs. Professional Service

When it comes to fixing equipment or machinery, individuals often face the choice between tackling the repair themselves or hiring an expert. Each option carries its own advantages and disadvantages, impacting both time and cost. Understanding these aspects can help one make an informed decision based on specific needs and circumstances.

Taking the DIY Approach can be rewarding for those who enjoy hands-on tasks and possess the necessary skills. Engaging in self-repair often leads to significant savings on labor costs, and it can provide a sense of accomplishment. Additionally, working on repairs personally allows for a deeper understanding of the equipment, fostering better maintenance practices in the future. However, this route also comes with risks; a lack of experience may result in further damage or safety hazards, potentially increasing costs in the long run.

Opting for Professional Assistance ensures that repairs are handled by skilled technicians with expertise in the field. This can significantly reduce the likelihood of errors and guarantee a higher quality of work. Furthermore, professionals often offer warranties on their services, providing peace of mind. On the downside, relying on experts typically involves higher expenses and may result in longer wait times, especially if parts need to be ordered or if the technician’s schedule is full.

Ultimately, the decision between self-repair and professional service depends on individual capability, the complexity of the issue, and the value placed on time versus money. Weighing these factors carefully will lead to a more satisfactory outcome, whether it involves rolling up your sleeves or reaching out for help.