In the world of automotive maintenance, comprehending the intricate layouts of vehicle elements is essential for both enthusiasts and professionals alike. A thorough grasp of these schematics facilitates effective repairs and ensures optimal performance. Knowledge of how various components interact can save time and resources, leading to a more efficient workflow.

When delving into the specifics of a particular model, one encounters a wealth of information that reveals how each part functions in harmony with others. Such insights not only enhance troubleshooting skills but also empower individuals to undertake repairs with confidence. This guide aims to provide a detailed overview of a specific vehicle’s structural design, catering to those seeking clarity in their maintenance endeavors.

By examining the layout closely, one can appreciate the engineering that goes into each vehicle. Understanding these relationships between components is vital for anyone looking to delve deeper into automotive care or repair. This exploration invites readers to enhance their knowledge and approach vehicle maintenance with a more informed perspective.

Understanding the 2007 Toyota Sienna

This section aims to provide an insightful overview of a popular minivan model, highlighting its features, design, and functionality. Understanding the mechanics and components of this vehicle is essential for both enthusiasts and everyday users, ensuring optimal performance and maintenance.

Key Features

This model is known for its spacious interior, advanced safety features, and reliable performance. The layout is designed to accommodate families, offering ample seating and storage solutions. Additionally, various technological advancements enhance the driving experience.

Maintenance Essentials

Regular upkeep is crucial for longevity. Familiarizing oneself with the main components can aid in identifying potential issues early. Below is a table summarizing some critical elements that require attention:

| Component | Function | Maintenance Tips |

|---|---|---|

| Engine | Power generation | Regular oil changes, check filters |

| Transmission | Power distribution | Monitor fluid levels, regular inspections |

| Brakes | Safety and control | Inspect pads and rotors, replace as needed |

| Suspension | Ride comfort | Check for wear, ensure alignment |

Overview of Key Components

This section explores the essential elements of a vehicle’s structure, focusing on their roles and interactions. Understanding these components is crucial for maintenance and performance enhancement, ensuring optimal functionality and safety.

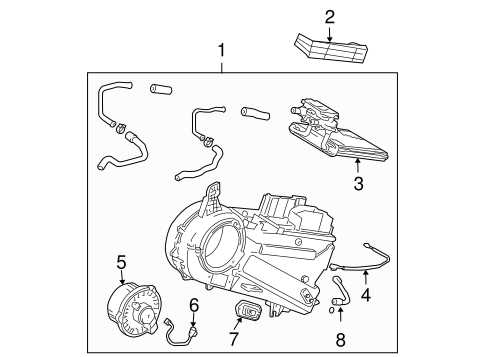

Powertrain Assembly

The powertrain is the heart of any automobile, encompassing the engine, transmission, and related systems. This assembly is responsible for generating power and transferring it to the wheels, making it vital for overall efficiency and driving experience.

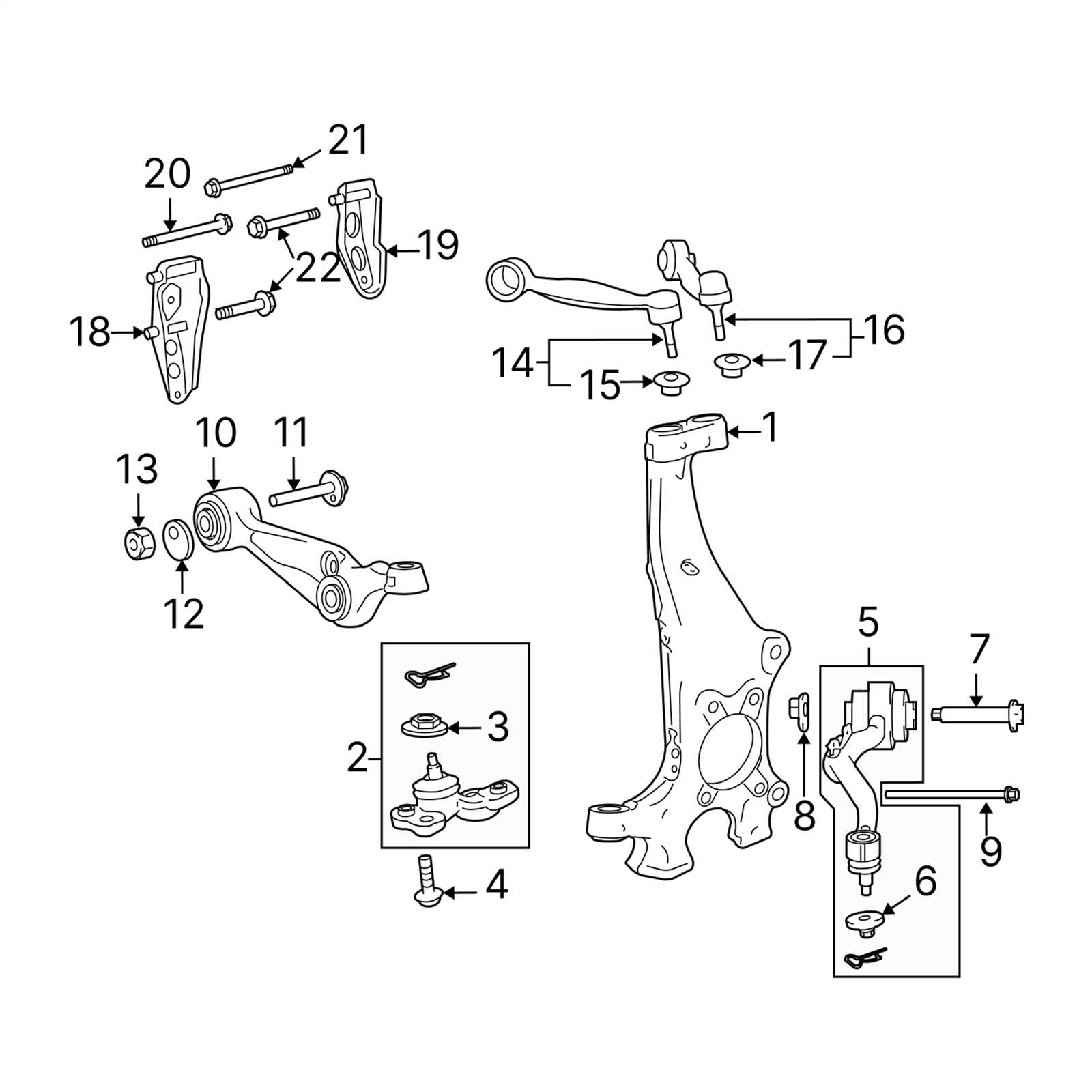

Suspension System

The suspension system plays a pivotal role in ensuring ride comfort and stability. It includes components like springs, shock absorbers, and control arms, which work together to absorb shocks and maintain tire contact with the road.

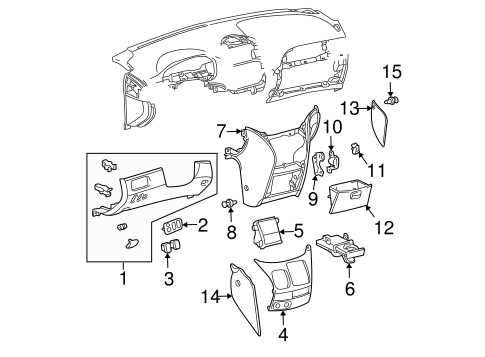

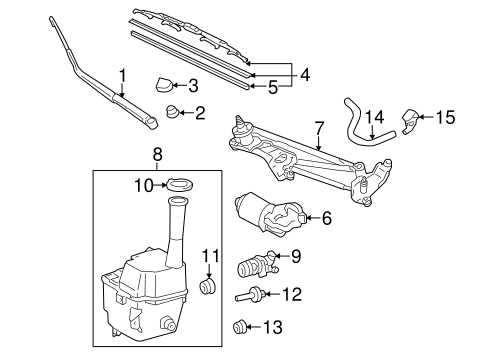

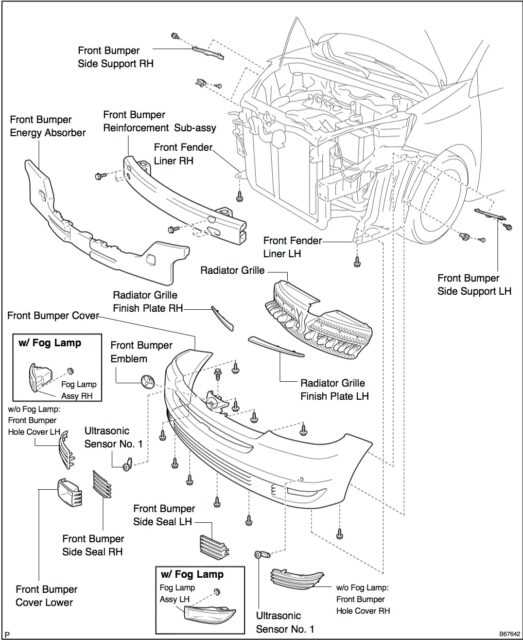

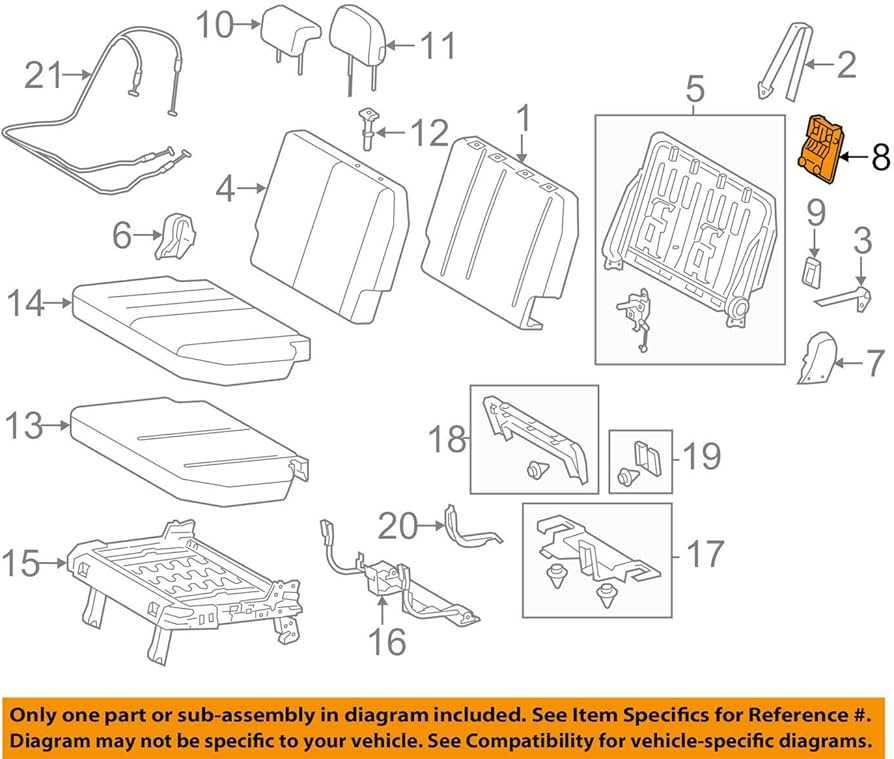

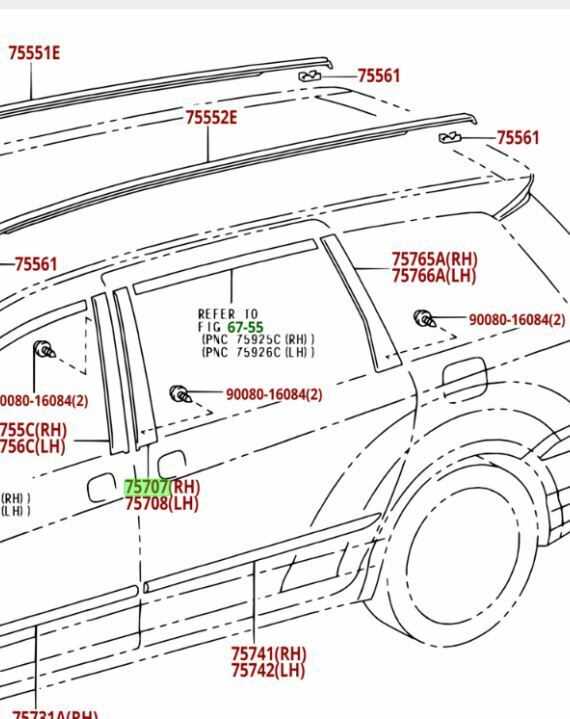

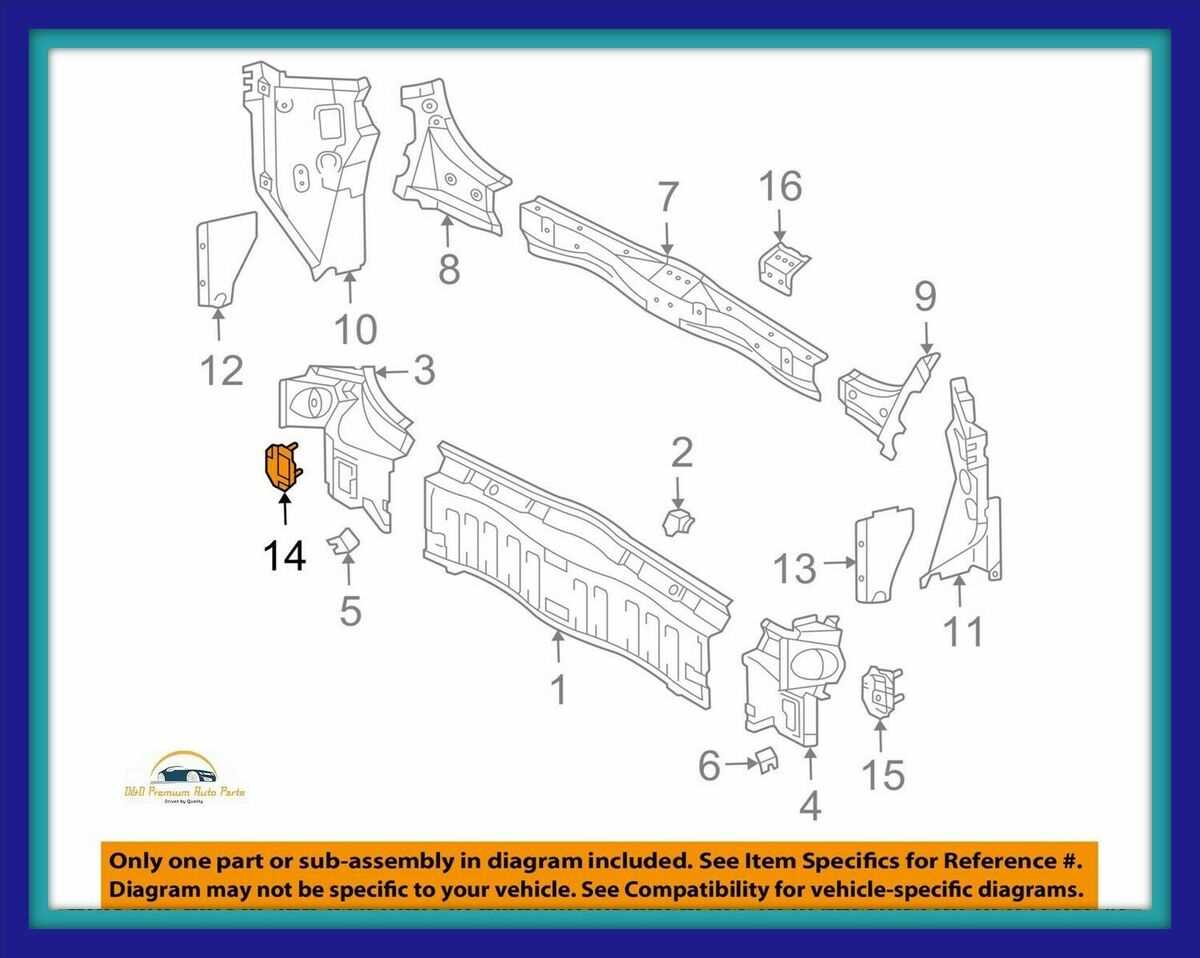

Importance of Parts Diagrams

Visual representations of vehicle components serve as essential tools for maintenance and repair. They provide a clear understanding of how each element fits together, facilitating efficient service and enhancing the overall repair experience.

Benefits of Visual Guides

- Improved Clarity: Illustrations help technicians grasp complex assemblies quickly.

- Time Efficiency: Access to clear visuals reduces the time spent on troubleshooting.

- Reduced Errors: Accurate depictions minimize the risk of misassembly.

Enhancing Knowledge and Skills

- Training Aid: Visual aids are invaluable in educating new mechanics.

- Reference Tool: They act as handy references for experienced professionals.

- Understanding Functionality: Diagrams clarify the role of each component in the overall system.

Incorporating these visual resources into repair processes ultimately leads to higher quality work and greater customer satisfaction.

Common Issues with the Sienna

Many vehicle owners encounter a range of typical problems that can affect performance and reliability over time. Understanding these common concerns can aid in early detection and maintenance, ensuring a smoother driving experience.

| Issue | Description |

|---|---|

| Transmission Problems | Shifting delays and slipping may arise, impacting acceleration and overall drivability. |

| Suspension Wear | Worn components can lead to decreased ride quality and increased noise while driving. |

| Electrical Failures | Issues with lights, sensors, or battery can cause functionality disruptions and safety hazards. |

| Engine Performance | Rough idling, stalling, or decreased power may indicate underlying engine problems. |

Where to Find Parts Diagrams

Finding accurate illustrations of vehicle components can greatly assist in maintenance and repair tasks. Whether you’re a professional mechanic or a DIY enthusiast, having access to detailed schematics is essential for identifying the necessary elements for your project. This section will explore various resources to help you locate these valuable visual guides.

Online Resources

The internet is a treasure trove of information. Numerous websites specialize in automotive resources, offering free or subscription-based access to extensive collections of component visuals. These platforms often include search features that allow you to quickly locate the specific illustrations you need.

Manuals and Repair Guides

Physical manuals, such as those published by manufacturers, are also reliable sources. Many repair guides include comprehensive drawings that are invaluable during repairs. These documents can be purchased or sometimes found at libraries, ensuring you have detailed references at your fingertips.

Local Dealerships can provide additional support, often having access to manufacturer-specific schematics. They may be able to assist you directly or direct you to online platforms that house these resources.

Utilizing these various avenues will ensure you have the necessary visuals to make informed decisions during your repair or maintenance projects.

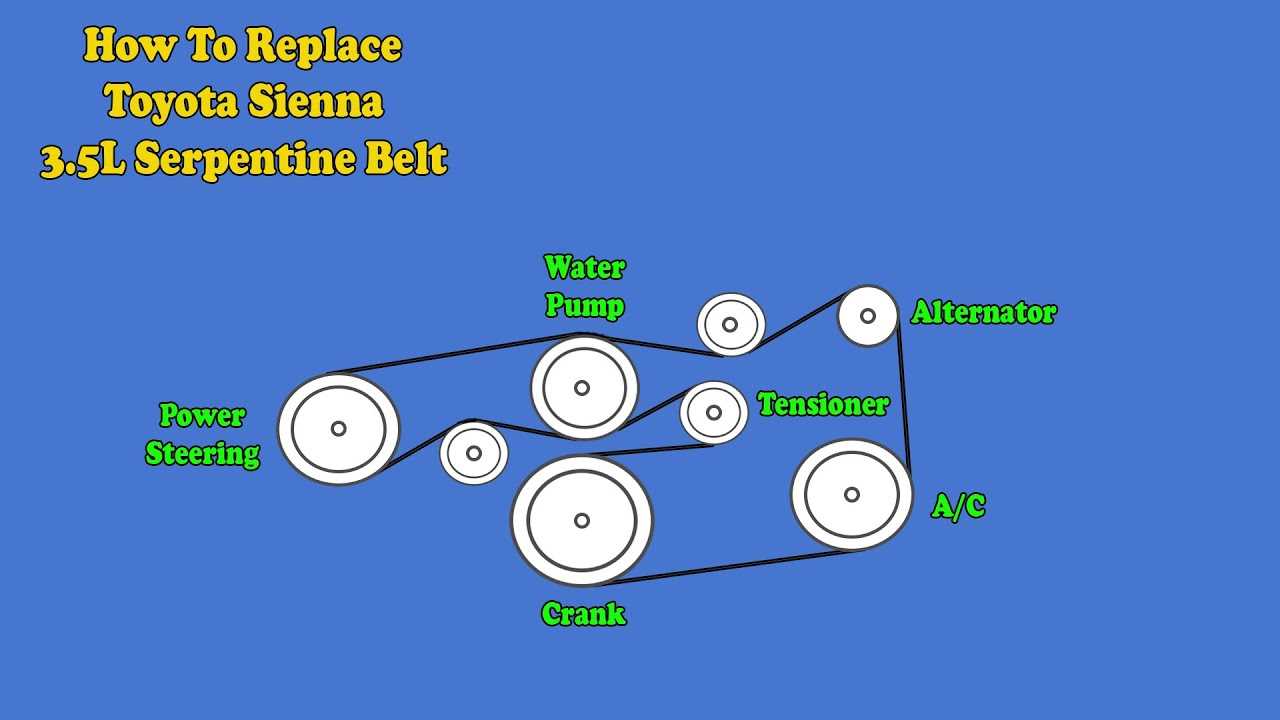

Interpreting the Diagrams Effectively

Understanding visual representations of vehicle components is crucial for efficient maintenance and repair. These illustrations serve as a roadmap, guiding users through the intricate layout of a vehicle’s system.

- Familiarize Yourself with Symbols: Each representation employs unique symbols. Knowing these will enhance comprehension.

- Identify Key Sections: Focus on major components, such as the engine, transmission, and electrical systems.

- Follow the Flow: Pay attention to the connections and pathways. This will help in troubleshooting issues effectively.

By mastering these techniques, individuals can better navigate complex visual aids, leading to more successful repairs and maintenance outcomes.

Essential Tools for Repairs

When undertaking any maintenance or restoration work, having the right equipment is crucial for achieving successful results. A well-equipped workspace not only enhances efficiency but also ensures safety and precision in every task. Below are key tools that should be part of every repair kit.

Basic Hand Tools

- Wrenches: A set of both metric and standard wrenches is vital for loosening and tightening various fasteners.

- Screwdrivers: Both flathead and Phillips screwdrivers in various sizes are essential for a multitude of tasks.

- Pliers: These are useful for gripping, twisting, and cutting wire or small components.

- Socket Set: A comprehensive socket set allows for easier access to bolts in tight spaces.

Power Tools

- Drill: A reliable drill is indispensable for making holes or driving screws quickly.

- Impact Wrench: This tool provides extra torque for loosening stubborn bolts.

- Saw: An electric or cordless saw is handy for cutting through various materials with precision.

- Multimeter: Essential for diagnosing electrical issues, it helps measure voltage, current, and resistance.

Equipping yourself with these fundamental tools can significantly streamline the repair process, ensuring you are prepared for any task that arises.

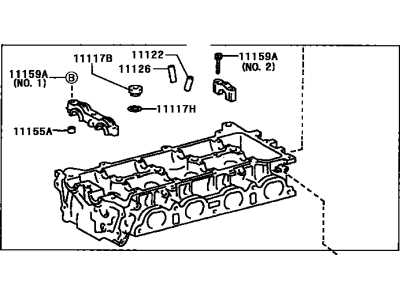

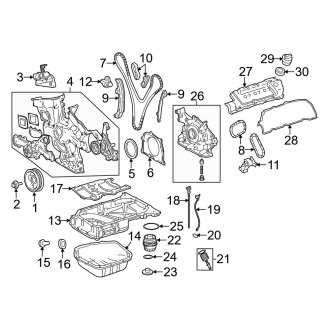

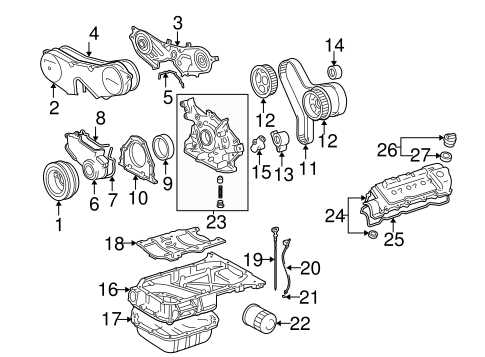

Engine Parts and Functions

The internal combustion mechanism consists of various components that work in harmony to convert fuel into motion. Each element plays a critical role in ensuring efficient operation and performance of the overall system. Understanding these elements enhances comprehension of how vehicles function and can aid in maintenance and troubleshooting.

Core Components

The heart of the system includes elements like the cylinder block, pistons, and crankshaft. The cylinder block houses the cylinders where combustion occurs, while pistons move up and down to convert pressure into mechanical energy. The crankshaft then transforms this linear motion into rotational force, powering the vehicle.

Supporting Systems

Additional systems, such as the intake and exhaust manifolds, facilitate airflow necessary for combustion. The intake manifold distributes air to the cylinders, whereas the exhaust manifold expels gases post-combustion. Together, these components ensure optimal air-fuel mixtures and efficient exhaust flow, crucial for peak engine performance.

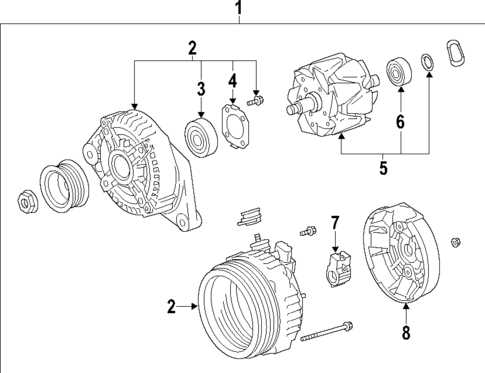

Electrical System Components Explained

The electrical system in a vehicle plays a crucial role in ensuring functionality and safety. Understanding its components helps in maintaining and troubleshooting various electrical issues. Each part serves a specific purpose, contributing to the overall operation of the automotive electrical network.

Key Components

Several vital elements make up the electrical system, each interacting with others to create a seamless experience for the driver. The most significant components include the battery, alternator, and wiring harness, among others.

| Component | Function |

|---|---|

| Battery | Stores electrical energy for starting the engine and powering electrical devices. |

| Alternator | Generates electricity while the engine runs, recharging the battery and powering systems. |

| Wiring Harness | Connects various electrical components, allowing for efficient communication and power distribution. |

Troubleshooting Tips

To ensure optimal performance, regular checks of these components are essential. Look for signs of wear or damage, such as frayed wires or corrosion, to prevent potential failures.

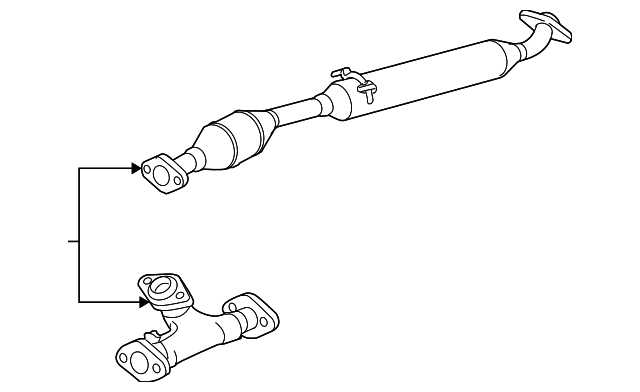

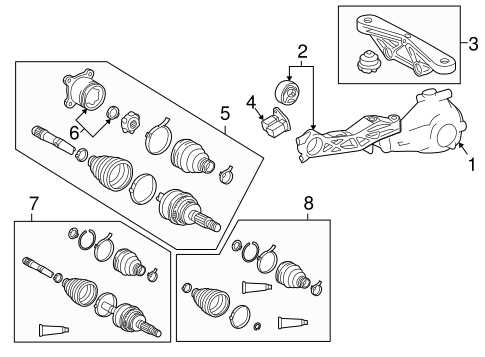

Transmission and Drivetrain Overview

This section provides an insight into the components responsible for transferring power from the engine to the wheels, ensuring smooth and efficient vehicle operation. Understanding the intricacies of this system is vital for maintenance and repair, as it plays a crucial role in overall performance.

Key Components

The primary elements include the transmission, which manages gear shifts and torque conversion, and the driveshaft, which transmits power to the wheels. Additionally, differential gears allow for varied wheel speeds, especially during turns, enhancing maneuverability.

Maintenance Considerations

Brake System Breakdown

The braking mechanism is a crucial component in any vehicle, ensuring safety and control during operation. Understanding its various elements is essential for effective maintenance and troubleshooting.

This section delves into the primary components of the braking system, highlighting their functions and significance:

- Brake Pedal: The initial interface for the driver, this component initiates the braking process when pressed.

- Master Cylinder: Responsible for converting the force from the brake pedal into hydraulic pressure.

- Brake Lines: These convey the hydraulic fluid from the master cylinder to the braking units at each wheel.

- Brake Calipers: Located at each wheel, these components clamp down on the brake pads to create friction against the rotors.

- Brake Pads: The friction material that presses against the rotors, slowing down the vehicle.

- Brake Rotors: Discs that the brake pads press against, facilitating the vehicle’s deceleration.

- Brake Fluid: A hydraulic fluid that transmits force within the braking system.

Understanding each of these elements allows for better diagnosis of braking issues, ensuring safe driving experiences. Regular inspections and timely replacements are vital for optimal performance.

Suspension and Steering Parts

This section explores the essential components that contribute to a vehicle’s handling and ride quality. Understanding these elements is crucial for maintaining performance and safety on the road.

- Shock Absorbers: Vital for dampening road vibrations and providing a smooth ride.

- Struts: Integrate the functions of a shock absorber and a supporting structural component.

- Sway Bars: Help reduce body roll during cornering, enhancing stability.

- Control Arms: Connect the wheel hub to the vehicle’s frame, allowing for controlled movement.

- Ball Joints: Provide a flexible connection between suspension components and the wheels.

In addition to these, steering mechanisms are equally important for maneuverability:

- Steering Rack: Converts the rotational movement of the steering wheel into lateral motion.

- Tie Rods: Connect the steering rack to the wheels, ensuring precise steering response.

- Power Steering Pump: Assists in steering effort, making it easier to navigate.

Maintenance Tips for Longevity

To ensure your vehicle remains reliable and efficient for years to come, regular upkeep is essential. By implementing a few key strategies, you can enhance performance, prevent costly repairs, and extend the overall lifespan of your automobile.

Regular Inspections

Fluid Changes

Consistently replacing engine oil, transmission fluid, and coolant is crucial for maintaining optimal performance. Adhering to the manufacturer’s recommendations for intervals can significantly impact longevity.