Understanding the intricate layouts of automotive elements is crucial for any enthusiast or owner. A clear representation of various components not only aids in maintenance but also enhances the overall knowledge about the vehicle’s functionality. Whether you’re troubleshooting an issue or planning upgrades, having access to detailed visual guides can be immensely beneficial.

Comprehensive schematics offer insights into how different systems interact, providing a roadmap for repairs and modifications. Familiarity with these layouts enables individuals to tackle challenges confidently and efficiently. Furthermore, recognizing each element’s position and relationship to others can streamline the repair process.

With the right visual aids, navigating the complexities of modern vehicles becomes a more manageable task. This exploration of component arrangements serves as a valuable resource for anyone looking to deepen their understanding of their machinery and improve their hands-on skills.

Understanding the 2012 Toyota Tundra

This section delves into the characteristics and features of a robust pickup designed for versatility and durability. The model stands out for its impressive performance, ample cargo capacity, and a range of options catering to various needs. Its design elements and engineering contribute to a driving experience that balances strength with comfort.

Key Features

- Powerful engine choices providing optimal performance.

- Spacious cabin accommodating passengers and cargo alike.

- Advanced safety features ensuring peace of mind on the road.

- Multiple trim levels allowing customization based on preferences.

Performance and Handling

The vehicle boasts a solid frame that enhances stability and control. With a variety of powertrains available, drivers can select an option that suits their towing and hauling requirements. The handling is designed to navigate both urban environments and rugged terrains effectively.

- Strong towing capacity for trailers and heavy loads.

- Responsive steering system improving maneuverability.

- Suspension designed for comfort during long drives.

In summary, this model offers a blend of power, space, and safety features, making it a suitable choice for both everyday use and adventurous pursuits.

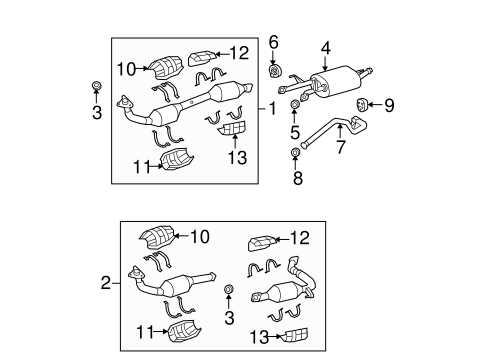

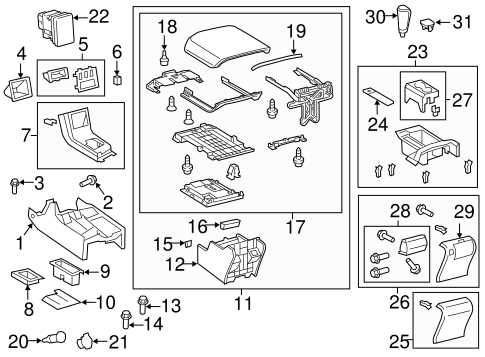

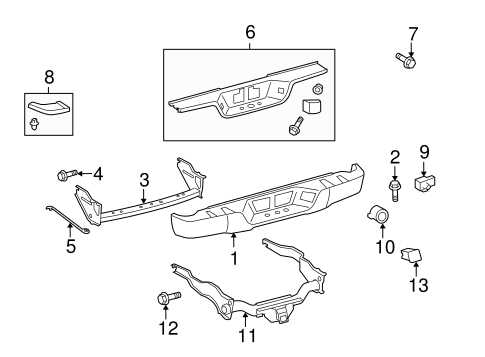

Importance of Parts Diagrams

Understanding the layout and relationship of components in a vehicle is essential for effective maintenance and repair. Visual representations serve as crucial tools that simplify the process, ensuring that both professionals and enthusiasts can identify and work on individual elements efficiently.

Enhanced Clarity

Visual aids provide clarity by illustrating how various components interact within the overall system. This helps technicians diagnose issues more effectively and reduces the chances of errors during repairs.

Facilitating Repairs

Having a detailed visual reference streamlines the repair process, allowing for quicker identification of parts that need replacement or adjustment. This ultimately leads to improved performance and longevity of the vehicle.

Common Issues with Tundra Parts

Many vehicle owners encounter challenges with specific components over time. Understanding these common problems can aid in better maintenance and informed decisions when it comes to repairs. This section highlights frequent concerns associated with various elements of a popular model.

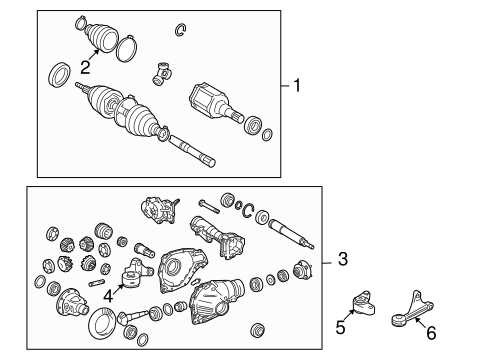

Wear and Tear on Suspension Components

One of the prevalent issues involves the suspension system. Over time, elements such as shocks and struts may deteriorate, leading to decreased ride quality and handling. Regular inspection and timely replacement can enhance overall performance and safety.

Electrical System Malfunctions

Another area that often presents difficulties is the electrical system. Owners may experience issues such as flickering lights or malfunctioning sensors. These problems can stem from faulty wiring or aged connectors. It’s advisable to address these symptoms promptly to avoid more significant complications.

In summary, being aware of these common problems can significantly aid in maintaining your vehicle’s reliability and performance. Regular checks and timely interventions can prolong the life of essential components.

Locating Genuine Replacement Parts

Finding authentic components for your vehicle can significantly enhance its performance and longevity. Utilizing high-quality replacements ensures optimal functionality and reliability, providing peace of mind for any owner.

Benefits of Genuine Components

- Enhanced durability

- Perfect fit and compatibility

- Improved safety standards

- Warranty coverage

Where to Search

- Authorized dealerships

- Reputable online retailers

- Certified automotive shops

- Manufacturer websites

Maintenance Tips for Longevity

Ensuring the durability and reliability of your vehicle requires regular attention and care. By adhering to a structured maintenance routine, you can enhance performance and extend its lifespan significantly. Simple practices can prevent costly repairs and keep your vehicle running smoothly over the years.

Regular Inspections

Conducting frequent checks on critical components is essential. Focus on the engine, brakes, and suspension systems. Visual inspections can help identify wear and tear before it escalates into serious issues. Pay attention to fluid levels, tire pressure, and the condition of belts and hoses.

Fluid Maintenance

Keeping fluids at optimal levels is crucial for a well-functioning machine. This includes not just oil, but also coolant, brake fluid, and transmission fluid. Regularly changing these fluids as per the manufacturer’s recommendations ensures that the engine and other systems operate efficiently, reducing the risk of breakdowns.

Exploring Aftermarket Options

When it comes to enhancing vehicle performance and aesthetics, exploring alternative components can be a rewarding venture. Aftermarket solutions offer a wide range of enhancements that cater to various needs, whether for improved efficiency, increased durability, or a personalized look.

Here are some benefits of considering aftermarket alternatives:

- Customization: Tailor your vehicle’s appearance and performance to match your unique style and requirements.

- Performance Upgrades: Many aftermarket options are designed to enhance power output and handling capabilities.

- Cost-Effectiveness: Often, these alternatives provide better value compared to original equipment options, without compromising quality.

- Variety: A vast selection allows for specific choices in materials, designs, and functions that may not be available through standard channels.

However, it’s essential to consider several factors when choosing these alternatives:

- Compatibility: Ensure the selected components are compatible with your specific make and model.

- Quality: Research brands and read reviews to identify reliable manufacturers.

- Warranty: Check if the aftermarket parts come with a warranty to protect your investment.

- Installation: Determine whether you will install the components yourself or require professional assistance.

By carefully assessing these options, you can enhance your vehicle’s performance and aesthetics while enjoying the benefits of customized solutions that aftermarket alternatives provide.

Identifying OEM vs. Aftermarket Parts

Understanding the distinction between original equipment and alternative components is essential for ensuring quality and compatibility in vehicle maintenance. Original equipment manufacturers provide parts that meet the exact specifications of the vehicle, while alternative suppliers may offer similar items at a potentially lower cost.

OEM components are designed specifically for the make and model, often guaranteeing a perfect fit and performance. These items typically come with a manufacturer’s warranty, providing peace of mind for consumers.

On the other hand, aftermarket options can vary widely in quality. Some may meet or exceed original standards, while others might not provide the same level of durability. It’s crucial to evaluate the reputation of the supplier and the materials used in these alternatives.

To make an informed choice, researching reviews and understanding the potential risks and benefits associated with each type can greatly enhance your purchasing decisions.

Tools Needed for Tundra Repairs

Proper maintenance and repairs of your vehicle require a selection of essential instruments. Having the right tools on hand not only simplifies the process but also ensures that tasks are completed efficiently and effectively. Below is a list of must-have equipment for anyone looking to perform repairs on their truck.

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening bolts and nuts |

| Wrench Set | To access hard-to-reach fasteners |

| Jack and Jack Stands | For lifting the vehicle safely during repairs |

| Torque Wrench | To apply the correct torque to fasteners |

| Screwdriver Set | For various screw types and sizes |

| Pliers | For gripping and manipulating small parts |

| Oil Filter Wrench | To easily remove the oil filter |

| Diagnostic Scanner | For reading error codes and troubleshooting issues |

Equipping yourself with these tools will significantly enhance your repair capabilities, allowing you to handle most maintenance tasks with confidence.

Step-by-Step Repair Process

This section outlines a systematic approach to conducting repairs on your vehicle. By following a structured method, you can ensure that each phase is executed efficiently and effectively, minimizing the risk of oversight. Understanding the components involved and their functions is essential for a successful outcome.

Start by gathering all necessary tools and materials. This preparation step is crucial, as it saves time and allows you to focus on the task at hand. Next, ensure that you have a clean workspace to facilitate organization and prevent any misplaced items.

Once your area is ready, assess the situation thoroughly. Identify the issues that need addressing, taking note of any symptoms or malfunctions. Documenting these observations can be helpful for reference during the repair process.

Proceed by disassembling the relevant components in a careful manner. Keep track of all fasteners and parts, as reassembly will require them to be organized. Utilize labeled containers to separate different items, ensuring you can easily find them later.

After disassembly, inspect the individual parts for wear and damage. Replace any components that show signs of deterioration. If repairs are necessary, follow the manufacturer’s specifications and guidelines to ensure proper handling and installation.

Once all repairs or replacements are completed, reassemble the vehicle methodically. Refer back to your notes and organization system to ensure everything is placed back correctly. Tighten all fasteners to the recommended torque specifications.

Finally, conduct a thorough testing phase to confirm that all systems function as intended. Address any remaining issues before completing the process. This meticulous approach not only enhances the longevity of your vehicle but also ensures a safe driving experience.

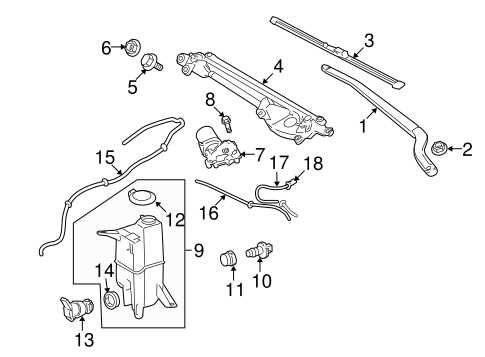

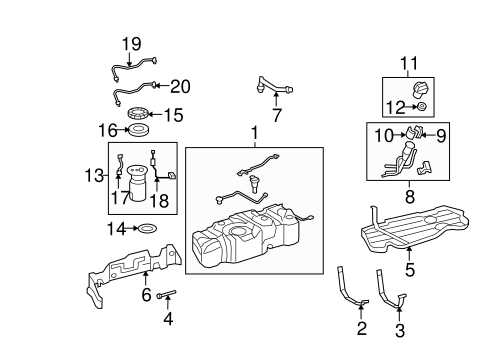

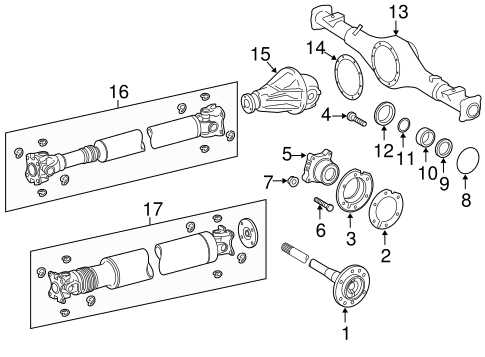

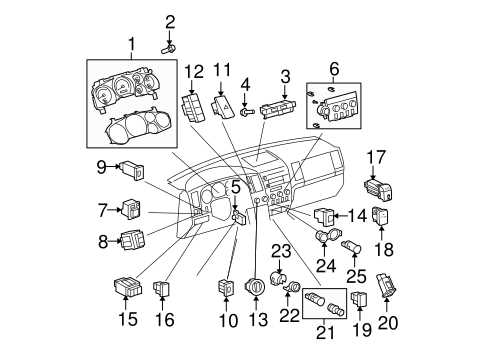

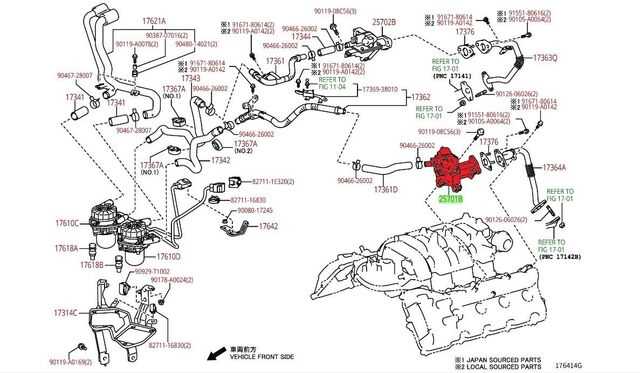

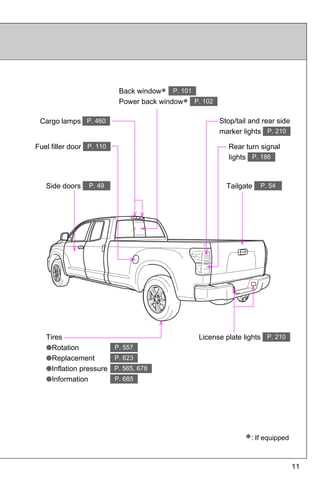

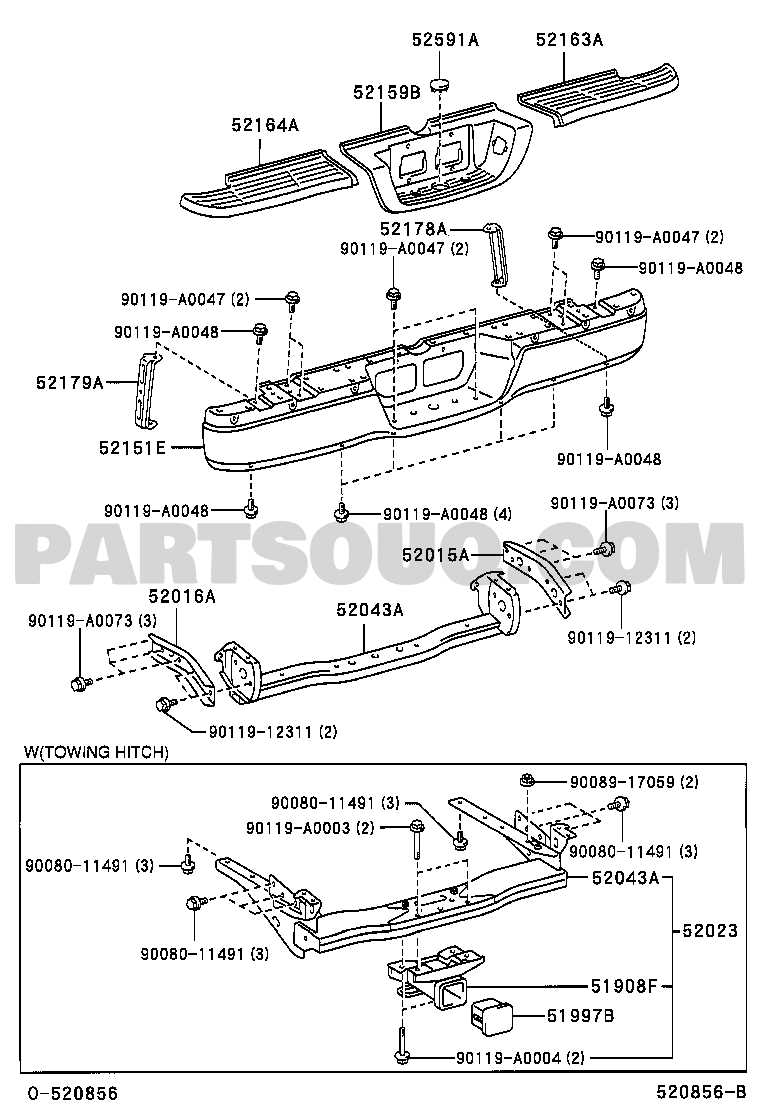

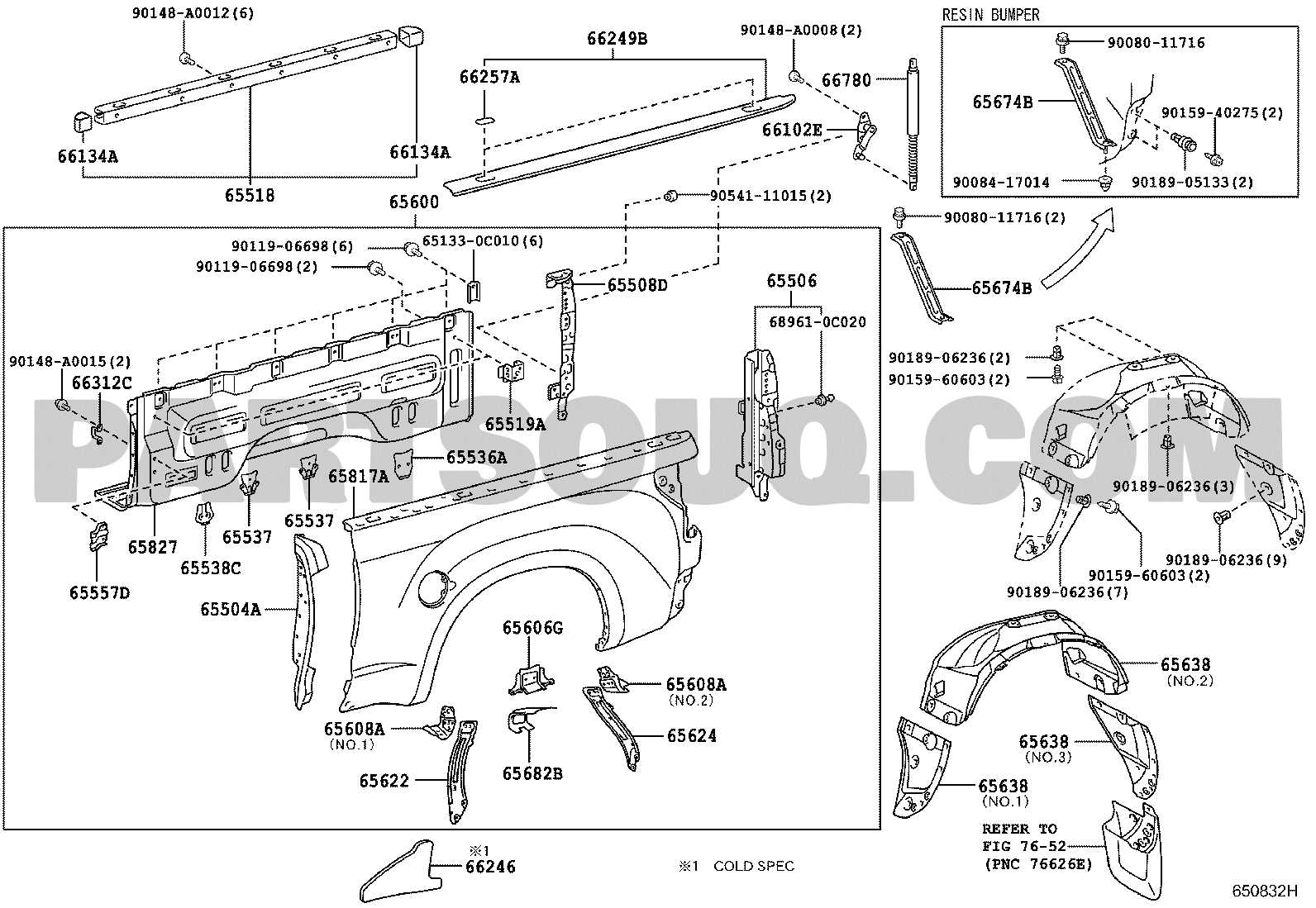

How to Read a Parts Diagram

Understanding a schematic representation of vehicle components is essential for effective maintenance and repair. These visual guides help users identify various elements and their relationships within a mechanical system, enabling efficient troubleshooting and part replacement.

Start by Familiarizing Yourself with the Layout: Most illustrations follow a standard format, showcasing individual components along with their corresponding labels. Familiarizing yourself with the layout allows for quicker navigation through the visual material.

Identify Key Components: Look for major sections and crucial parts that are highlighted. Each element typically has a reference number that corresponds to a list or legend, providing further details on specifications and compatibility.

Pay Attention to Connections: Arrows and lines often indicate how various elements are connected. Understanding these connections is vital for ensuring that replacements fit properly and function as intended.

Utilize the Legend: Many schematics include a legend or key that explains symbols and color codes used throughout the illustration. Referencing this section can clarify any ambiguities you might encounter.

Cross-Reference with Documentation: Once you’ve identified the necessary components, cross-check them with your repair manuals or service documents. This step ensures that you have the most accurate information before proceeding with any repairs or orders.

Resources for Tundra Owners

For those who own this robust pickup, having access to reliable information and tools is essential for maintenance and upgrades. A variety of resources can help ensure your vehicle remains in optimal condition, providing support for both DIY enthusiasts and those seeking professional assistance.

Online forums and communities offer invaluable insights, allowing owners to share experiences and solutions. Websites dedicated to automotive repair provide comprehensive guides, while parts retailers often include helpful diagrams and specifications. Additionally, manufacturer manuals serve as a crucial reference for detailed maintenance protocols.

For visual learners, video tutorials on platforms like YouTube can be particularly beneficial, showcasing step-by-step repairs and modifications. Engaging with local clubs or groups can also foster a sense of community, enabling knowledge exchange and camaraderie among fellow owners.

Community Support and Forums

Engaging with fellow enthusiasts can provide invaluable insights and assistance when navigating the complexities of vehicle maintenance and upgrades. Online communities and discussion boards serve as platforms where individuals share knowledge, experiences, and resources related to automotive needs.

Benefits of Joining Forums

Participating in these communities allows users to delve into various topics, from troubleshooting common issues to discovering the ultimate aftermarket modifications. Members often post detailed guides, answer questions, and provide support, creating a collaborative environment that fosters learning.

Finding the Right Community

When searching for the best forum, look for active discussions and knowledgeable participants. Many platforms also host sections for local meetups and events, enhancing the connection among members. Engaging in these groups can significantly improve your understanding and enjoyment of your vehicle.