Maintaining the exterior of a vehicle requires a clear understanding of how various elements are assembled and function together. This section will provide a comprehensive look at the outer framework and its essential components, focusing on their role in ensuring the vehicle’s overall performance and safety.

The smooth operation and durability of a vehicle depend heavily on the condition of its external mechanisms. By learning about the individual elements and how they fit together, it becomes easier to handle repairs or replacements when necessary.

In the following section, we will explore a detailed breakdown of the essential components that contribute to the functionality and structure of this important area of the car. This will help you make informed decisions about upkeep and modifications.

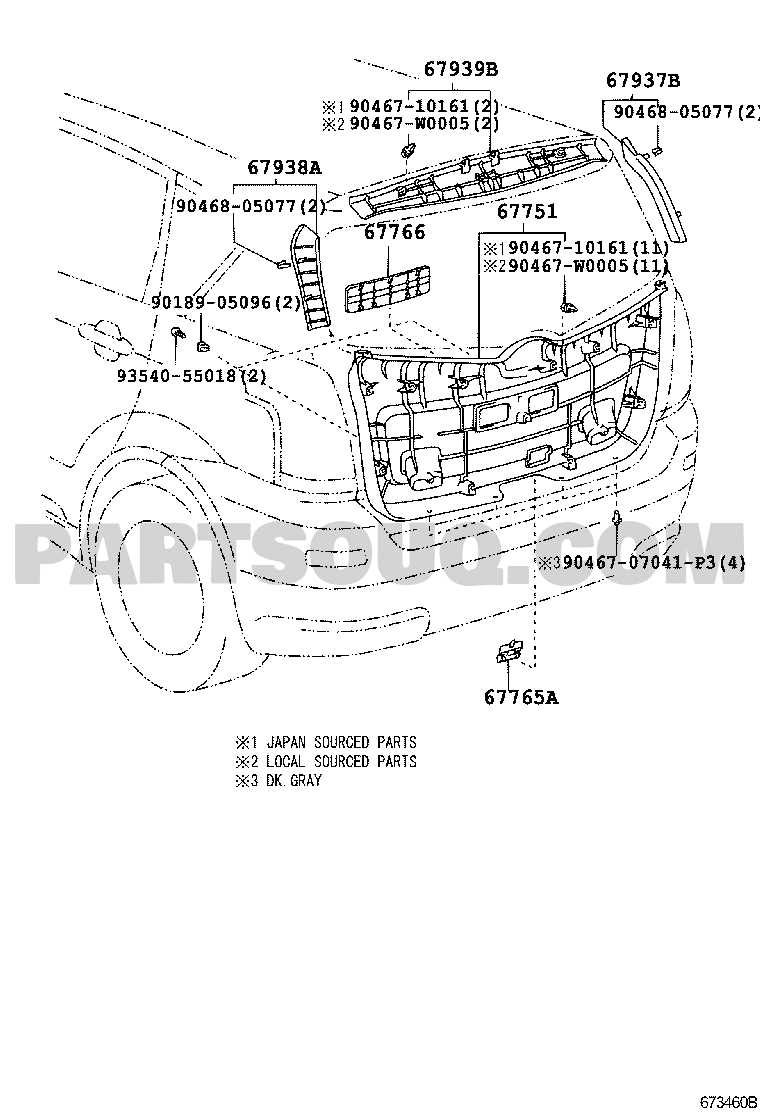

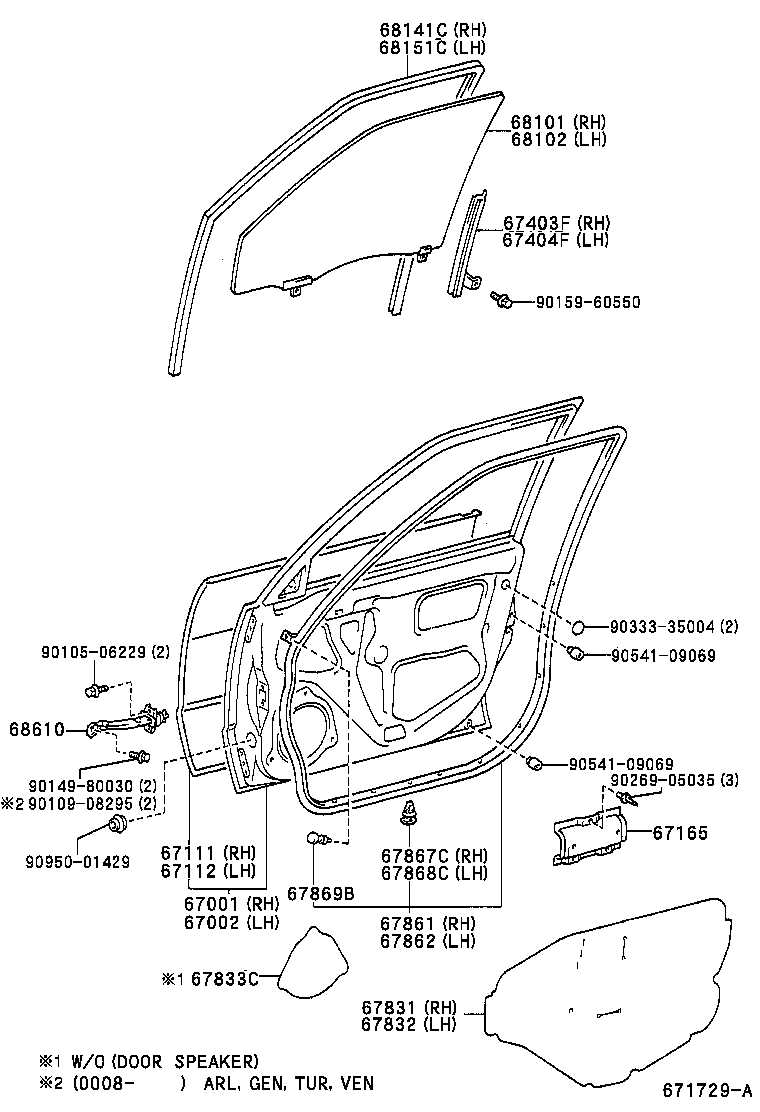

Vehicle Entryway Components Overview

The structure of a car’s entry system involves multiple interconnected elements designed to ensure functionality, security, and user comfort. Each section works in tandem to provide not only accessibility but also protection from external elements. The internal mechanisms and exterior materials are carefully engineered for durability and ease of use.

Key Structural Elements

The primary framework of the entry system includes an outer panel, internal reinforcements, and an assembly of hinges that support the overall structure. These components are essential for both the strength and longevity of the system, ensuring it operates smoothly over time.

Control and Safety Features

Within the entry mechanism, there are various systems responsible for locking, unlocking, and window control. These parts are crucial for maintaining the security of the vehicle and providing passengers with convenient control options, whether mechanical or electronically powered.

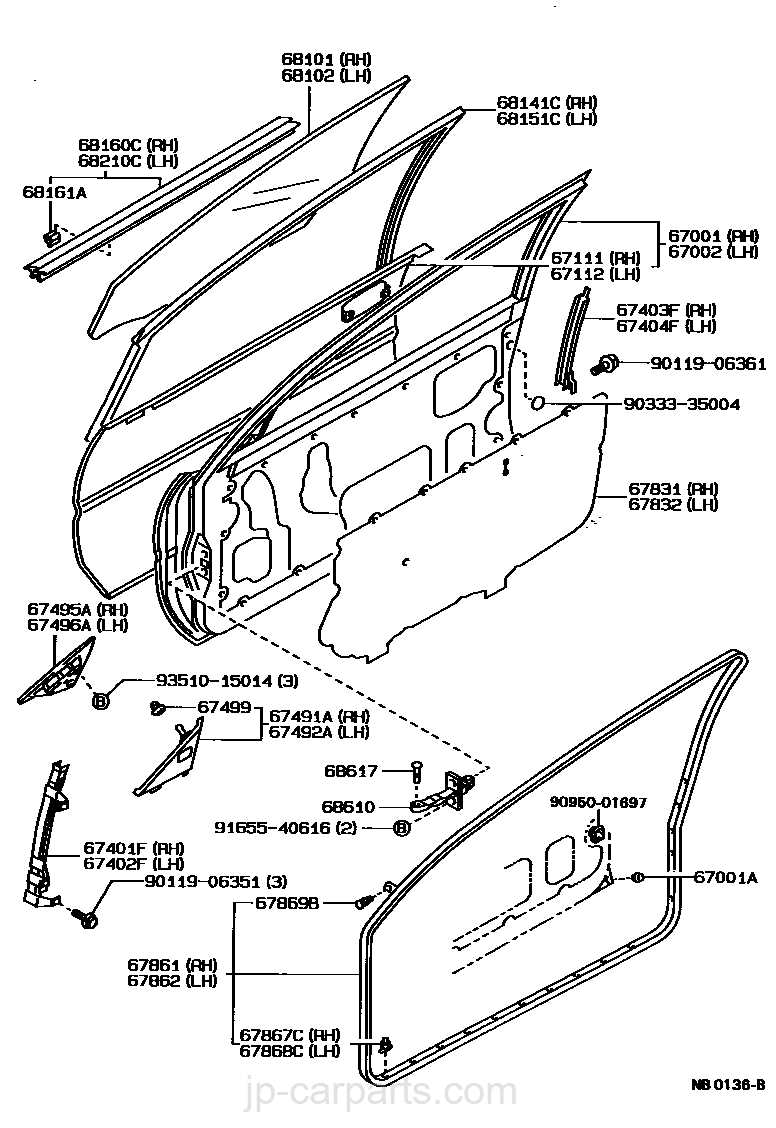

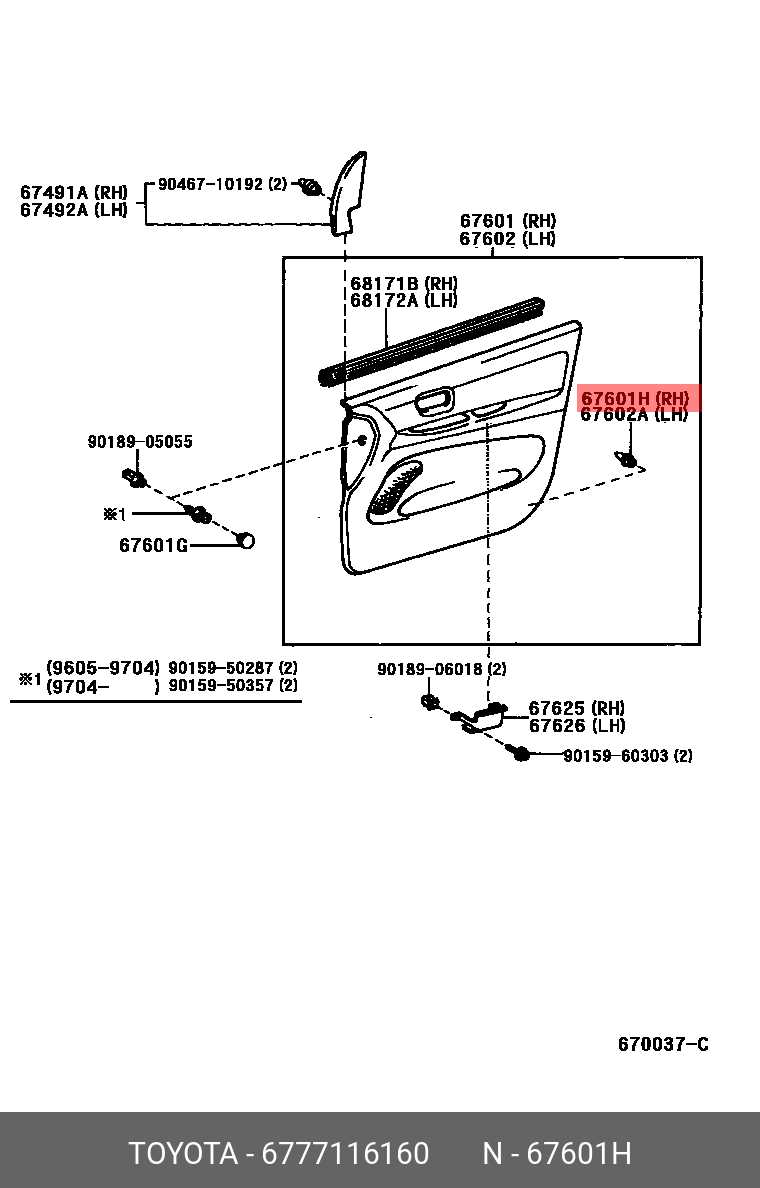

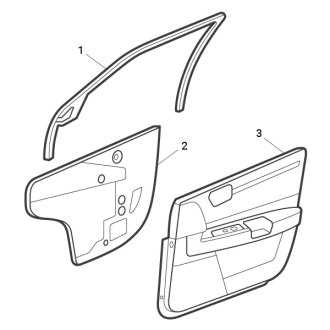

Exterior Door Panel Structure Explained

The outer shell of a vehicle is designed with multiple layers, each serving a crucial function for both aesthetics and safety. Understanding the composition of this exterior paneling is essential for grasping how it contributes to the overall durability and appearance of the vehicle.

First Layer: The outermost section is typically made from lightweight, durable materials such as metal or composite, providing the initial protective barrier against environmental factors like weather and debris.

Second Layer: Beneath the surface, a reinforcement structure is added to ensure that the frame can absorb and distribute impact forces effectively, enhancing both protection and rigidity.

Inner Support: Inside, insulating components help reduce noise while also serving to seal the frame from air or water infiltration. These layers contribute not only to comfort but also to the overall longevity of the panel.

Every element of the panel structure works together to create a balance between style, functionality, and safety. The combination of outer and inner materials ensures that the vehicle remains visually appealing while providing essential protection and support.

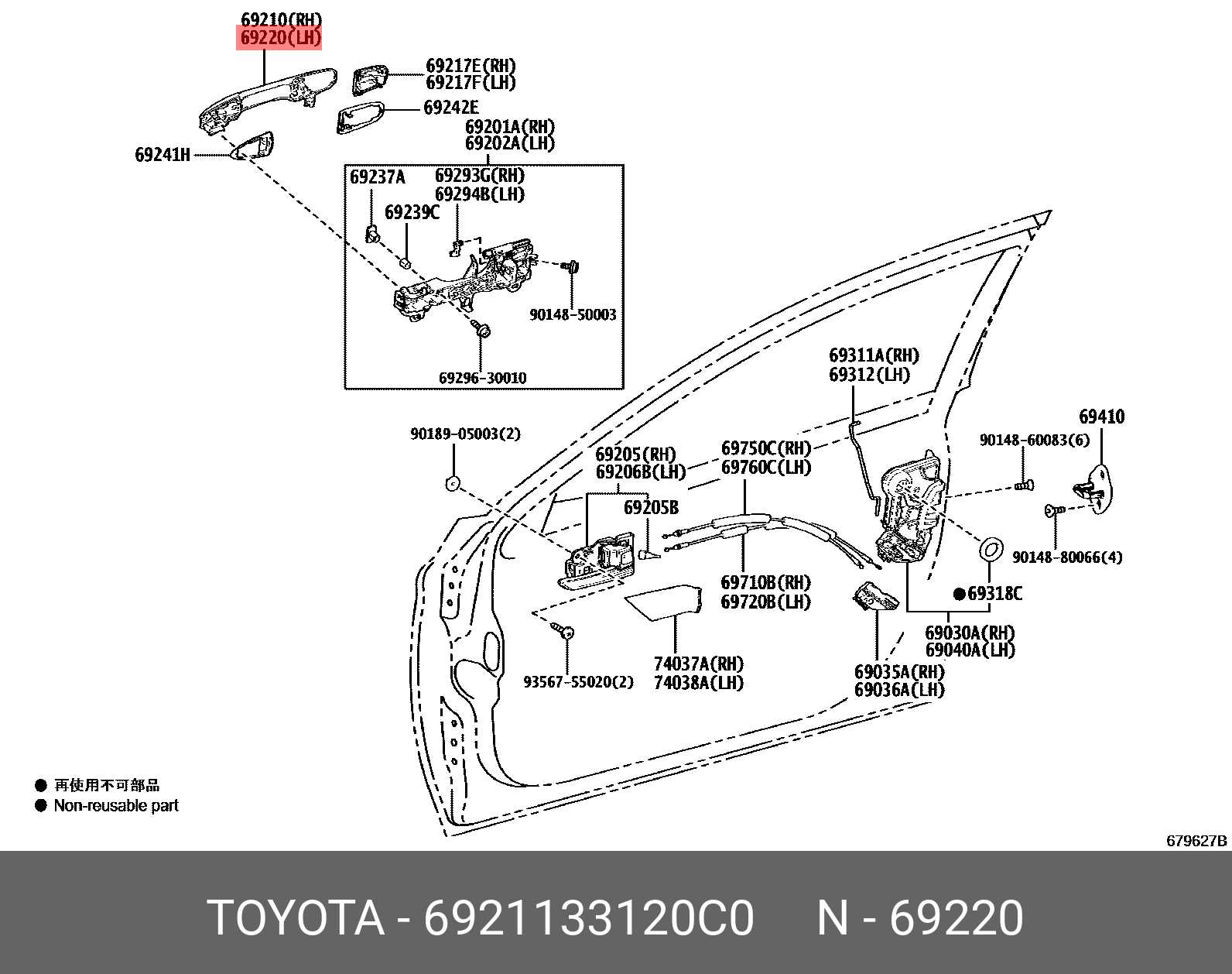

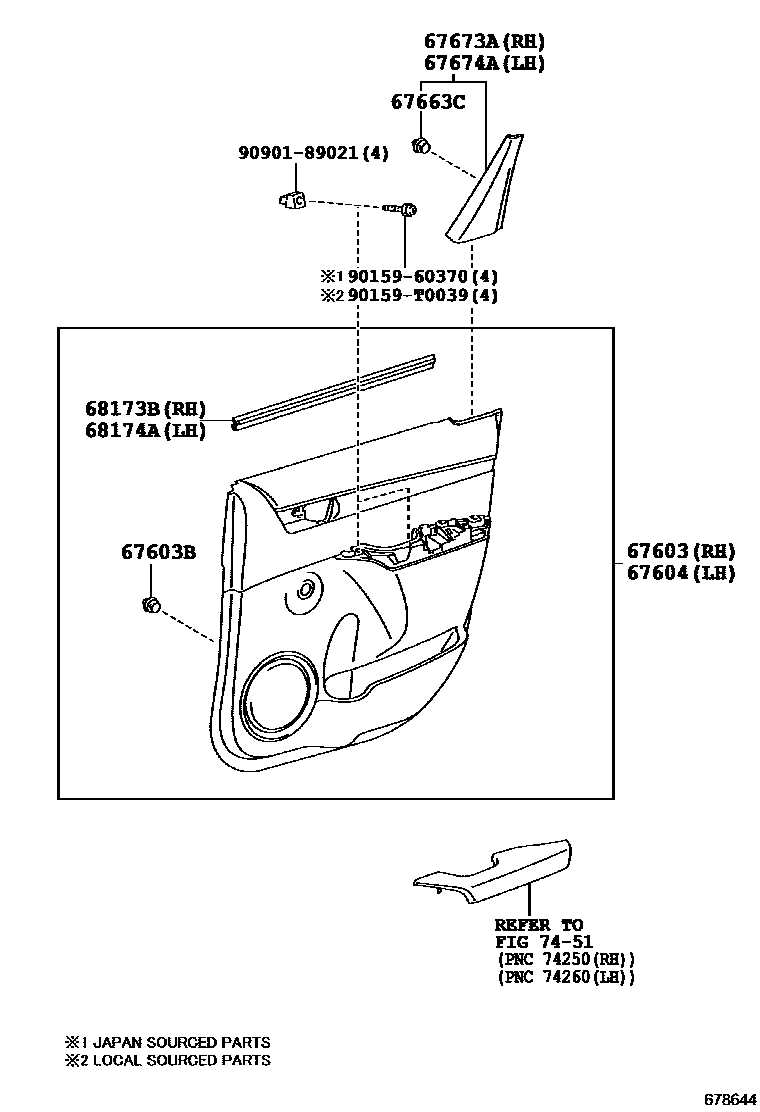

Interior Door Handle and Mechanism Layout

The internal mechanism of the vehicle’s entry handle is a crucial component for both functionality and safety. It ensures smooth operation when accessing the cabin from the inside, integrating multiple elements designed to provide a seamless user experience. The configuration involves several interconnected parts that work together to allow easy opening and closing, while also contributing to overall vehicle security.

The handle assembly includes levers, linkages, and locking systems, all precisely engineered to interact without friction or unnecessary resistance. These components are typically hidden behind the panel, yet their importance is evident in everyday use. Each part is carefully aligned to ensure that pressure applied to the handle efficiently translates into movement of the mechanism, activating the latch or lock in a coordinated manner.

Additionally, the internal structure is designed to withstand frequent use and protect against wear and tear. The materials used, such as metals and durable plastics, are selected to provide long-lasting reliability. Proper alignment and maintenance of these elements are key to ensuring continued smooth operation over time, preventing issues like sticking or jamming during use.

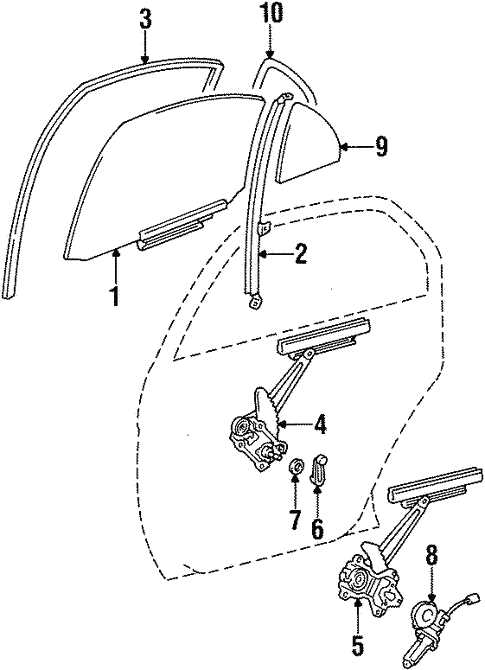

Window Regulator and Motor Assembly Guide

A functional window mechanism is essential for smooth operation and user convenience in any vehicle. In this section, we will walk through the key components involved in the regulation and movement of the side glass, as well as how the motor assembly works in conjunction to ensure efficient operation.

To begin with, the system responsible for raising and lowering the glass relies on a combination of mechanical and electrical elements. The core of this mechanism is a regulator that directs the movement, assisted by a motor to provide the necessary force. These components work in harmony to allow for manual or powered window adjustments.

Main Components of the System

- Regulator: This mechanical framework manages the up-and-down motion of the window. It is usually connected to a series of cables or gear-based structures that ensure smooth transitions.

- Motor: The motor powers the regulator in an automatic window system. When activated, it delivers the required torque to move the window effortlessly.

- Switch: The control unit that triggers the motor. The switch can be located on the vehicle’s control panel, allowing easy access for the user.

Step-by-Step

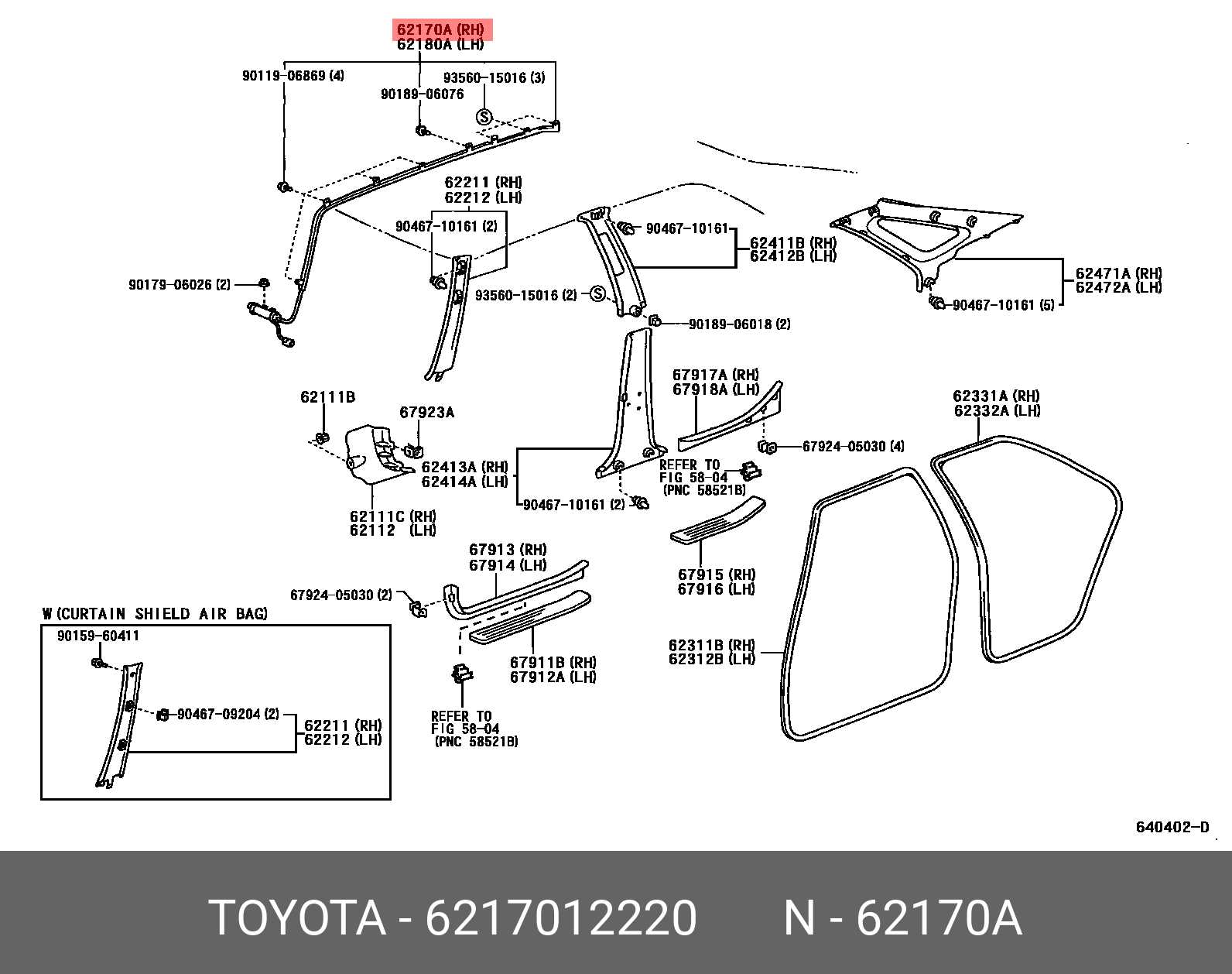

Side Mirror Attachment Points and Design

The mounting structure of the side mirror plays a crucial role in both functionality and aerodynamics. Properly designed attachment mechanisms ensure that the mirror remains stable even at high speeds while minimizing wind resistance. These components are essential for maintaining visibility and driver safety.

Primary Connection Points

- Base mount: Secures the mirror housing to the frame, providing a sturdy foundation.

- Pivot joints: Allow for adjustable movement, enabling users to reposition the mirror as needed.

- Fastening bolts: Ensure that the assembly remains securely in place, reducing vibrations.

Design Considerations

The design of side mirrors must balance aesthetics and practicality. Aerodynamic shapes help reduce drag, while durable materials protect against external elements. Modern versions often incorporate features such as heating elements or integrated signal lights for enhanced safety.

Door Lock Cylinder Placement and Function

The lock cylinder is a critical component responsible for securing the entry point of a vehicle. It enables the user to engage or disengage the locking mechanism using a key. This device ensures that the vehicle can be locked and unlocked securely, preventing unauthorized access.

Typically located within the exterior panel near the handle, the cylinder interacts with internal components that manage the locking and unlocking process. It is connected to a set of gears and pins that engage when the key is turned, allowing for smooth operation. The exact positioning of the cylinder ensures both accessibility and protection from external elements, like weather or tampering.

The functionality of the lock cylinder relies on a combination of mechanical design and precision engineering. When the proper key is inserted and rotated, it moves the internal pins in such a way that the locking mechanism releases or engages. This process is essential for the safety and integrity of the vehicle’s access system.

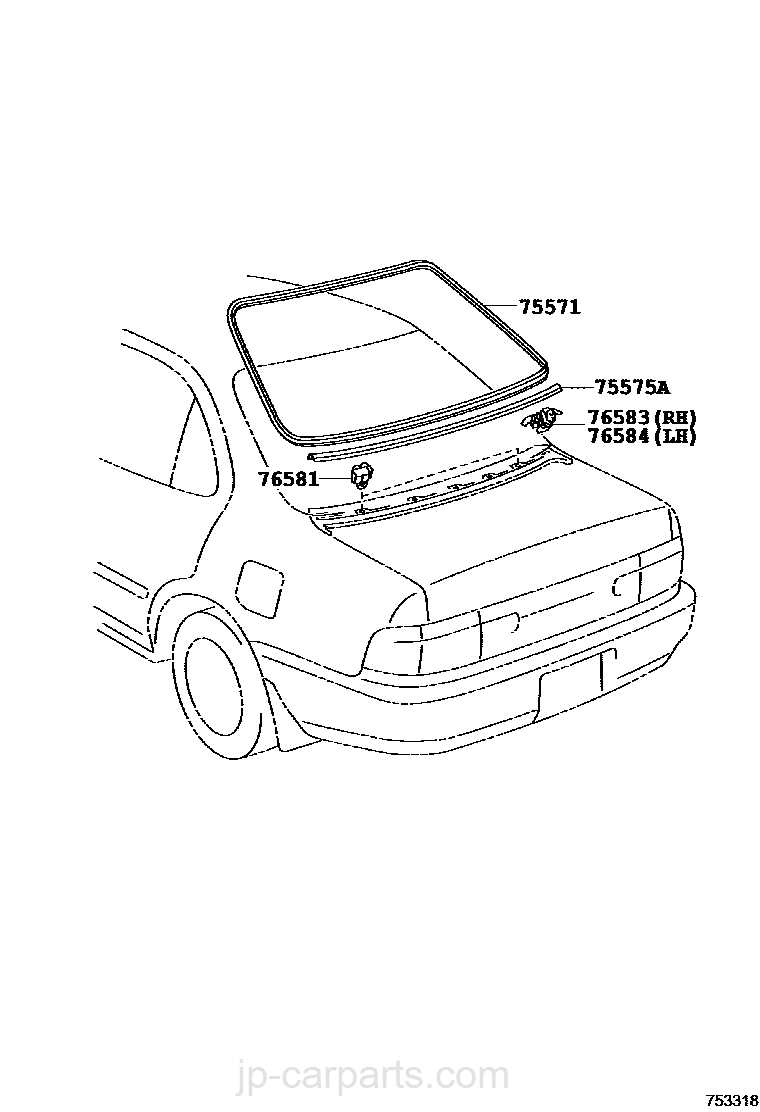

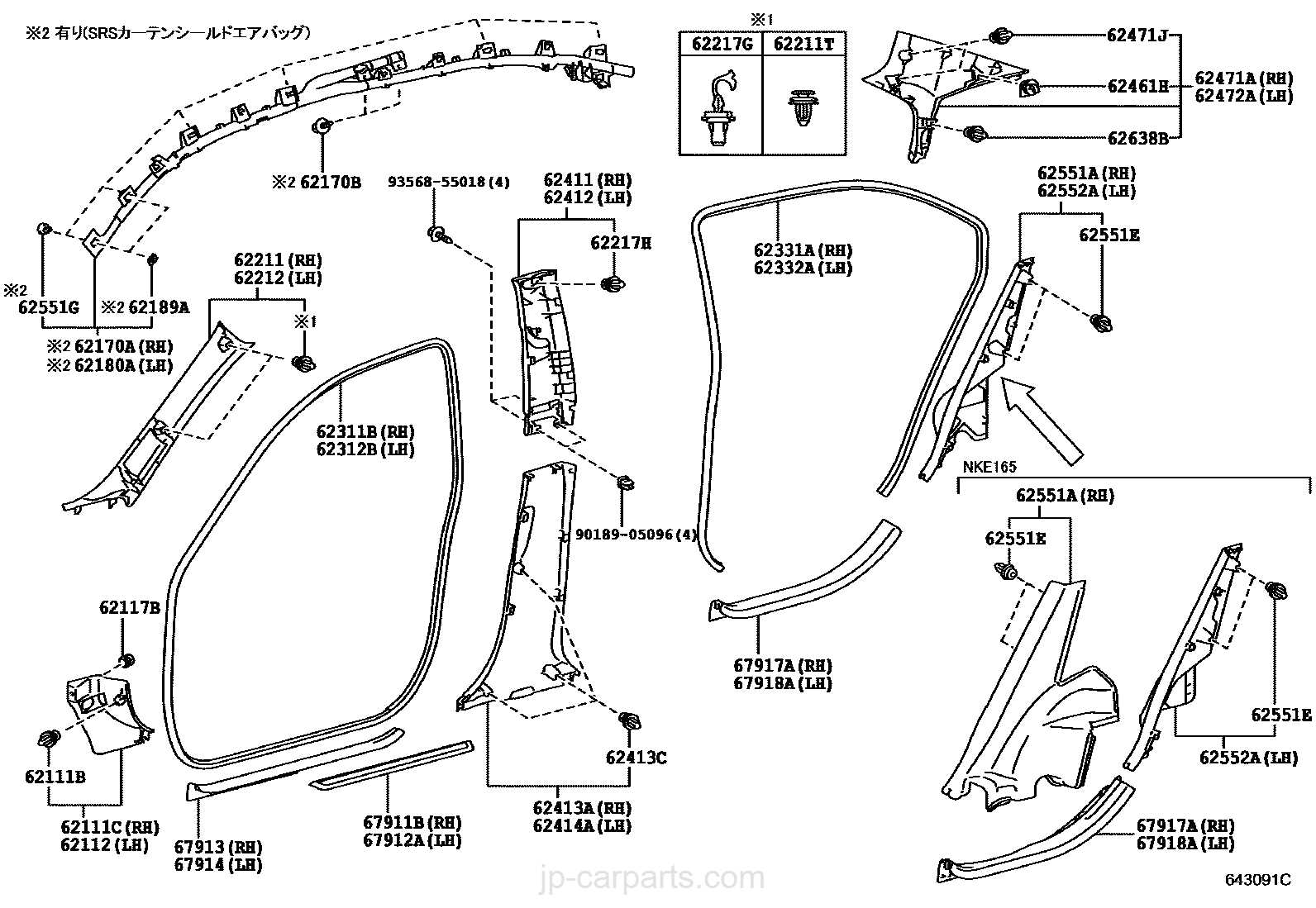

Weatherstripping and Seal Design on Doors

Effective weatherproofing and sealing are crucial components for ensuring a smooth and quiet driving experience. These elements not only enhance the aesthetic appearance of the vehicle but also serve functional purposes by keeping out environmental elements such as water, dust, and noise. Properly designed sealing systems are essential for maintaining comfort and performance under various weather conditions.

The weatherstripping and seals are designed to form a tight barrier between the exterior and interior of the vehicle. This prevents unwanted infiltration and protects sensitive components from exposure to the elements. The key features of these sealing systems include:

- Durability: The materials used must withstand prolonged exposure to varying temperatures, sunlight, and moisture.

- Flexibility: Seals need to remain pliable to accommodate door movement without losing effectiveness.

- Noise reduction: A well-designed sealing system helps minimize road noise and vibrations, improving overall cabin comfort.

- Water resistance: The system must prevent water from seeping into the cabin, even during heavy rainfall or while driving through puddles.

Advanced designs often include multiple layers of sealing material, ensuring that the vehicle remains protected in even the harshest weather. The selection of high-quality materials is essential for creating an efficient and long-lasting barrier. Overall, effective weatherstripping and seal design significantly contribute to the vehicle’s ability to offer a quiet, comfortable, and secure driving experience in all conditions.

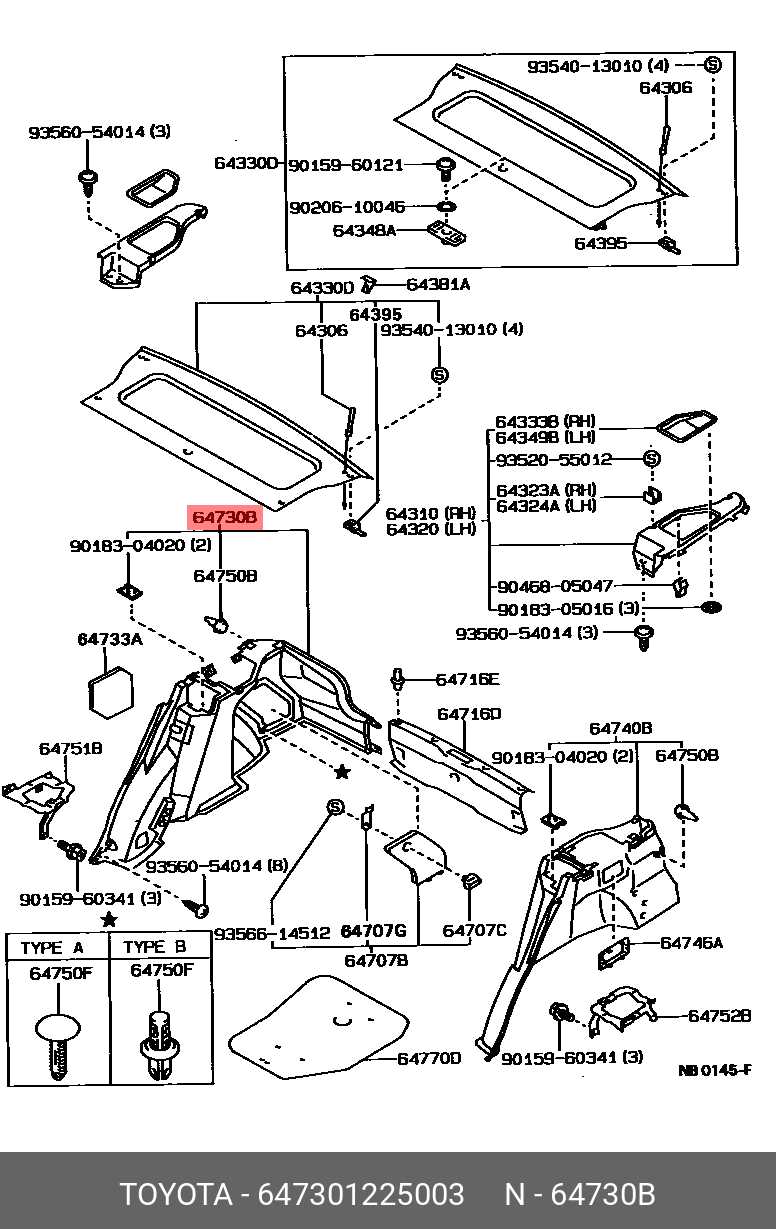

Door Hinge and Alignment Adjustment Process

Ensuring proper alignment of the exterior panels is essential for smooth operation and durability. Adjusting the hinge mechanisms can improve the fit and alignment, which may be necessary due to wear, damage, or misalignment during assembly. This section outlines the steps involved in adjusting the hinge system and ensuring proper alignment for optimal functionality.

Hinge Adjustment Overview

To begin the adjustment process, the first step is to inspect the hinge system for any visible damage or wear. Misalignment can result from a loose or damaged hinge, which can cause difficulty in securing the panel correctly. Ensuring the hinge is functioning properly is crucial before making any further adjustments.

Steps for Alignment Modification

Follow these steps to adjust the hinge and achieve the correct alignment:

| Step | Description |

|---|---|

| Step 1 | Check the condition of the hinge system for any signs of wear, bending, or damage that may affect the alignment. |

| Step 2 | Loosen the hinge bolts slightly to allow for movement but ensure they are not completely detached. |

| Step 3 | Carefully align the panel by adjusting the hinge position to achieve the desired fit. Use a level or measuring tool to ensure symmetry. |

| Step 4 | Tighten the bolts securely once the alignment is achieved, and recheck the fit to confirm there is no movement. |

| Step 5 | Perform a functional test by opening and closing the panel to ensure smooth operation without any resistance or rubbing. |

Proper adjustment of the hinge system is key to maintaining the functionality and appearance of the exterior components. Periodic inspection and realignment may be necessary to keep the system operating smoothly and prevent further issues down the road.

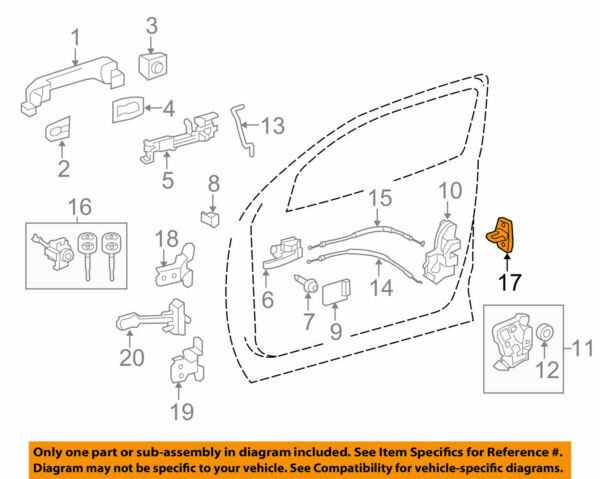

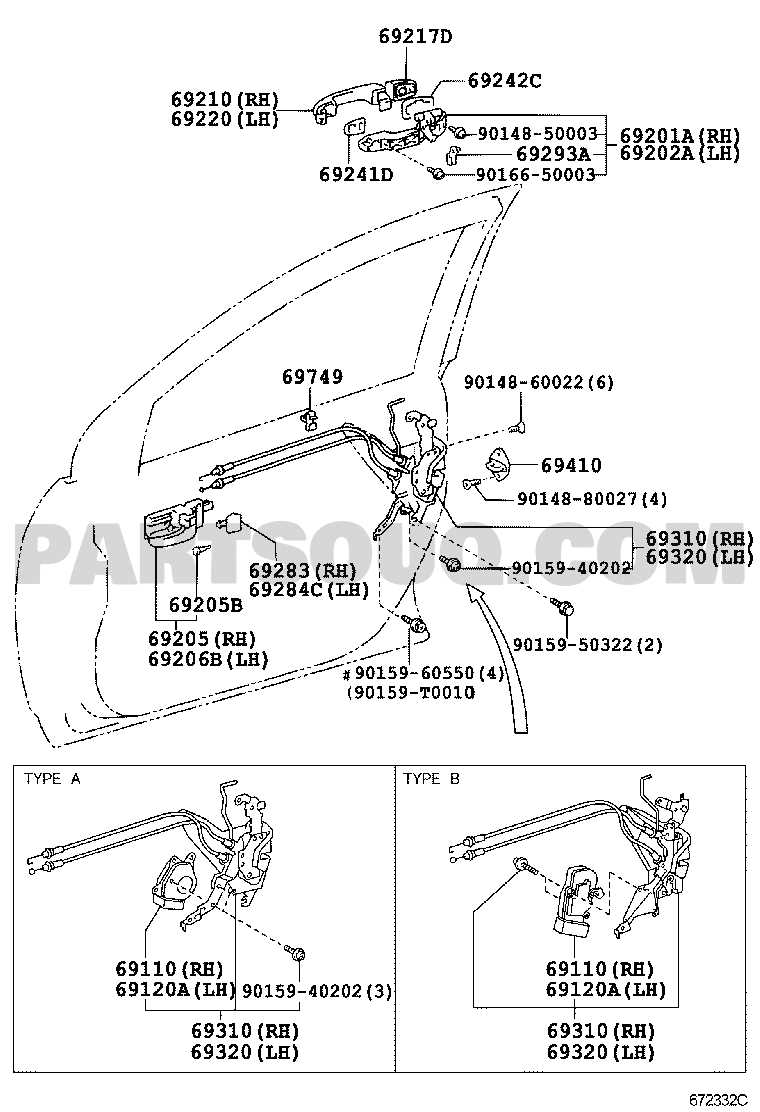

Exploring Door Latch Mechanism Components

The locking system of a vehicle’s entryway plays a critical role in ensuring security and proper functionality. Understanding the key components that make up this mechanism can shed light on how the mechanism works and what to check during maintenance. Each element is designed to work in unison to facilitate a smooth operation, providing safety and convenience for the user.

Latch Assembly

The latch assembly is the core of the locking system. It secures the access point when closed and unlocks when disengaged. The mechanism often includes a spring that holds the latch in place, ensuring the access point remains firmly closed until manually released. This component is essential for preventing unintended openings during transit.

Release Handle

The release handle allows for the disengagement of the locking mechanism. Once pulled, it activates a set of levers that disengage the latch, freeing the access point to be opened. The handle is connected to a cable or rod, which communicates the action to the locking system, allowing for effortless access when needed.

Additional elements such as the striker plate and actuator also play significant roles in the overall performance of this mechanism, ensuring proper alignment and functionality. Keeping these components in good condition is essential for ensuring the smooth operation and longevity of the vehicle’s locking system.

Wiring Connections in Door Electronics

In modern vehicles, the integration of electrical components within the entry structure is essential for various functions such as power windows, locks, and mirrors. These systems rely on a well-organized network of wiring to ensure smooth operation and communication between switches, motors, and control units. Understanding how these connections are made is crucial for diagnosing issues and performing repairs efficiently.

Wiring harnesses typically run through the structure, connecting different devices and sensors within the assembly. The complexity of these circuits requires precise planning to prevent short circuits or malfunctions. Common elements include connectors, relays, and fuse systems that protect the wiring and prevent damage to the electronics in case of a fault.

| Component | Function | Connection Type |

|---|---|---|

| Power Window Motor | Operates the movement of the window | Wired to switch and relay via a direct current circuit |

| Lock Mechanism | Controls the locking and unlocking of the vehicle | Connected to control module via multi-wire cable |

| Side Mirror Adjuster | Allows adjustment of the side mirror’s position | Linked through a two-wire system for precise adjustments |

| Speaker | Provides audio output for the sound system | Attached via a four-wire connection for power and signal transmission |

Door Speaker Placement and Audio System Parts

When setting up an in-vehicle audio experience, the positioning of sound components plays a crucial role in achieving optimal audio quality. Every element must be carefully integrated to ensure balanced acoustics throughout the cabin. A well-placed speaker system, along with supporting audio accessories, enhances sound clarity and creates an immersive environment for passengers.

Speaker Location and Its Impact

Positioning sound units is essential for delivering consistent and clear audio. Typically, these units are placed at strategic locations within the cabin, such as near the front panels and along the sides, to avoid sound distortion. The location affects both the bass and treble frequencies, ensuring that sound waves are properly dispersed across the interior space.

Supporting Components for Audio Systems

In addition to the primary audio devices, several auxiliary components are necessary for a complete system. These include amplifiers, wiring harnesses, and connectors that enhance signal quality and power delivery. Subwoofers may also be installed to boost low-end frequencies, providing depth to the audio experience. Each element works together seamlessly to ensure high performance and reliable sound reproduction.