When it comes to ensuring the smooth operation of heavy machinery, knowing how different mechanical and electrical elements are interconnected is essential. Each piece plays a crucial role in maintaining overall functionality, and recognizing these individual elements can help in both daily maintenance and troubleshooting. Identifying these links allows for a deeper understanding of the structure and how it supports efficient performance.

The ability to pinpoint various elements and their arrangement provides valuable insights into the system’s operation. By gaining a better grasp of these connections, you can effectively address any issues that arise, ensuring everything runs seamlessly. A clear understanding of how everything fits together is key to improving both reliability and long-term functionality.

With a well-organized overview of the essential components, it’s easier to plan regular checkups, replacements, and repairs. Knowing what to look for and how everything is interconnected contributes to a smoother workflow and minimizes downtime caused by unexpected malfunctions.

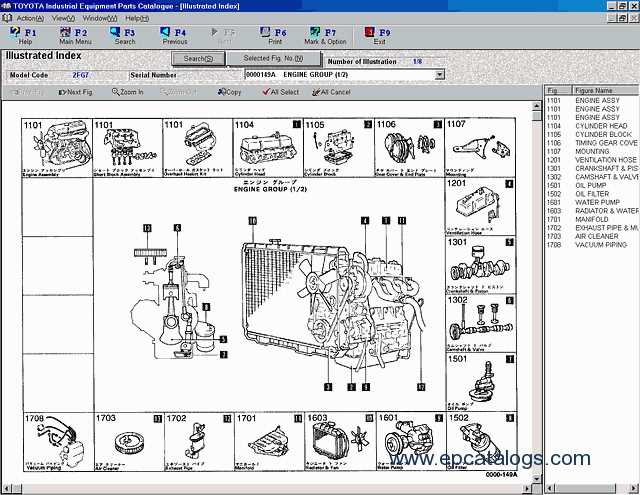

Component Overview for Industrial Equipment

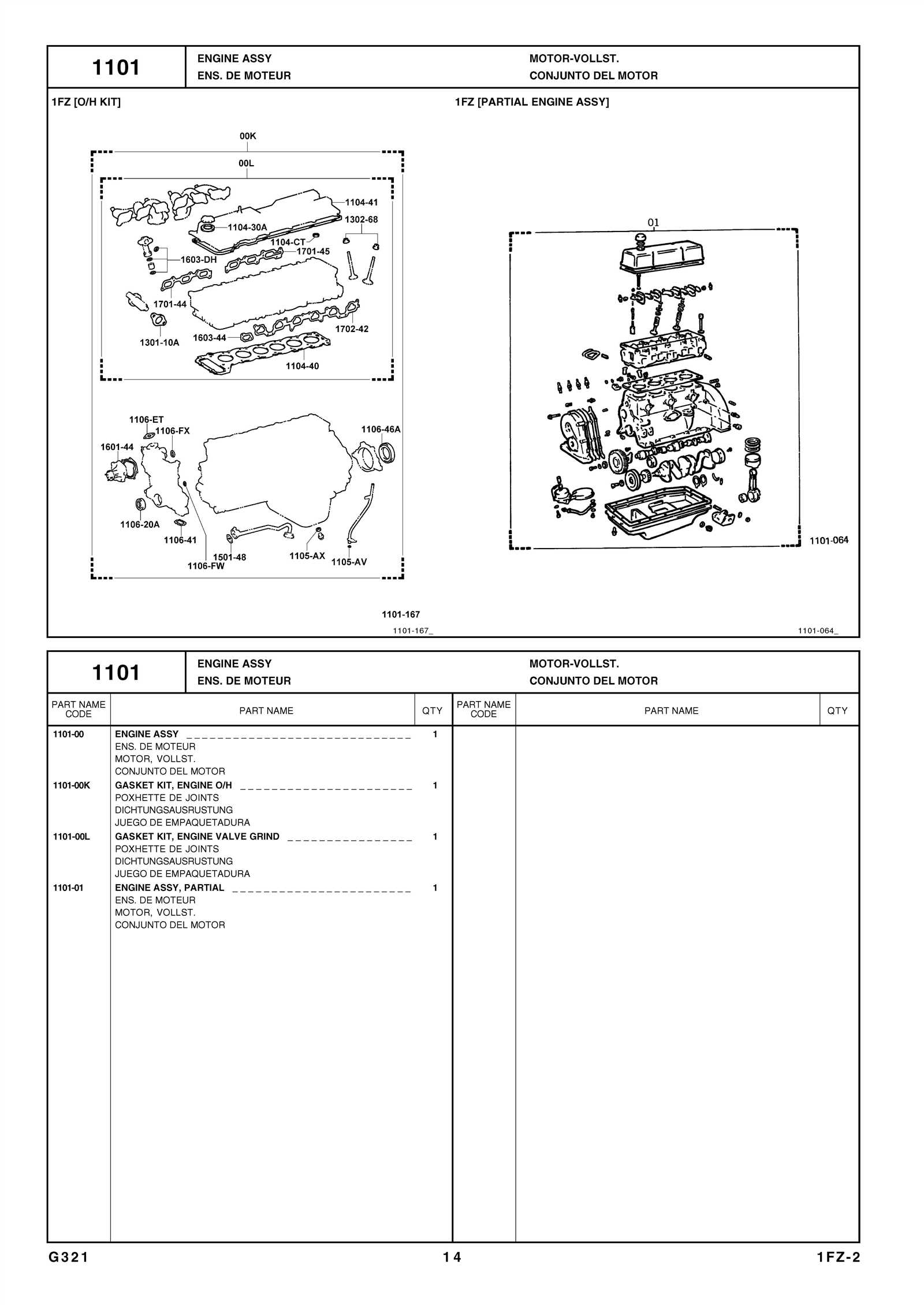

This section provides a detailed look at various elements that ensure the optimal functioning of heavy-duty machinery. Understanding the relationship between different components is crucial for maintaining operational efficiency and minimizing downtime.

Engine System: The heart of the machine, this section powers the entire unit. It is essential to keep it in good condition to ensure smooth and consistent performance.

Hydraulic Mechanism: Responsible for lifting and moving loads, this system plays a key role in handling operations. Proper maintenance helps in preventing leaks and ensuring safety during operation.

Steering and Control: This system allows precise maneuverability, enabling the operator to navigate tight spaces with ease. Regular checks are vital to avoid any unexpected malfunctions.

Load Handling Attachments: Various attachments enhance the versatility of the machinery, allowing it to perform multiple tasks. Selecting the right accessory ensures efficiency and safety.

Understanding Key Mechanical Systems

When it comes to maintaining and optimizing equipment, it’s crucial to understand how the various mechanical systems function together. These systems ensure smooth operation, efficiency, and durability in everyday tasks. By gaining insight into their roles, you can make informed decisions regarding upkeep and repairs.

- Power Transmission: This system is responsible for transferring energy from the engine to the wheels, allowing movement. It includes several components that must work in harmony to ensure proper force distribution.

- Hydraulic Operation: This system handles lifting and positioning by converting energy into controlled motion. Understanding the pressure dynamics and flow regulation is essential for maintaining precision.

- Steering Mechanism: Essential for maneuverability, this system controls the direction and responsiveness of the vehicle. Regular maintenance is key to ensuring accurate control during navigation.

- Brake System: Responsible for stopping and controlling speed, it consists of components that need to be regularly checked to ensure safety and performance.

Each of these systems plays a vital role in ensuring the equipment operates smoothly

Electrical System Parts and Functions

The electrical system plays a crucial role in ensuring the smooth operation of various components, allowing seamless communication between different circuits and ensuring optimal functionality. Understanding the key elements and their roles is essential for proper maintenance and troubleshooting.

Core Components

- Battery: Acts as the primary power source, supplying energy to start and run the entire system.

- Alternator: Recharges the battery while the engine is running, ensuring a consistent power flow.

- Fuses and Relays: Provide protection by preventing overloads and managing the distribution of current to different circuits.

Wiring and Connectivity

The wiring network ensures that electrical signals travel between different elements efficiently. Proper connections between cables and terminals guarantee the functionality of all integrated components.

- Signal wires carry low-voltage communication between controls and devices.

- Power

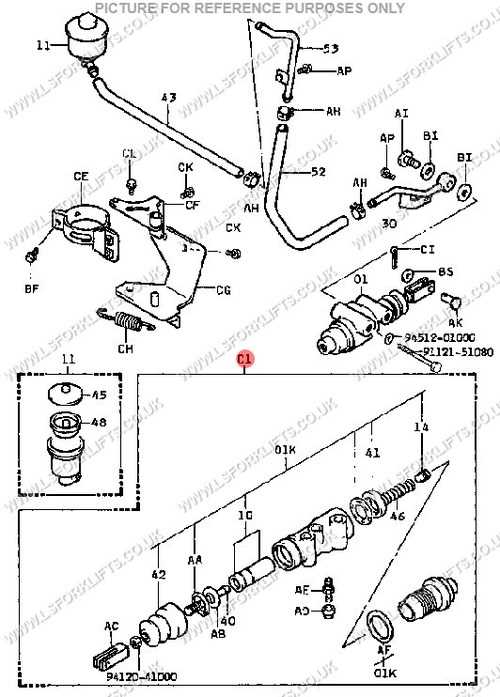

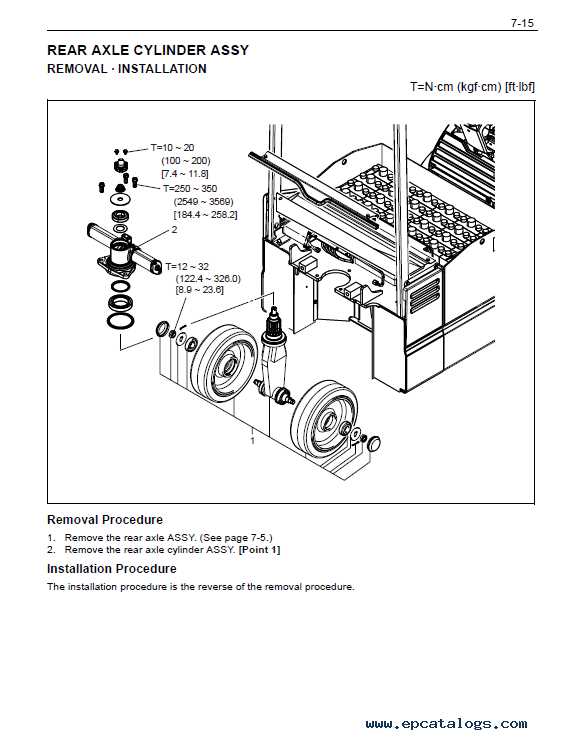

Hydraulic Components Breakdown

The hydraulic system is essential for ensuring smooth and efficient operation, driving the movement and control of various mechanical functions. Understanding the key elements of this system helps maintain proper functionality and enhances overall performance. By breaking down the individual components, one can get a clearer picture of how hydraulic mechanisms contribute to seamless operation.

Component Function Pump Generates the necessary pressure to drive the hydraulic fluid through the system. Cylinders Convert hydraulic pressure into mechanical force, allowing controlled movement. Valves Regulate fluid flow, ensuring accurate control of direction and pressure. Reservoir Stores hydraulic fluid, ensuring consistent supply for system operation. Hoses Transport hydraulic fluid between components, maintaining proper flow and pressure. Each of these elements

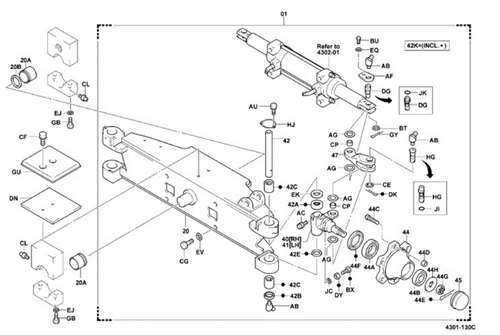

Exploring the Steering Mechanism

The steering system plays a crucial role in ensuring smooth and efficient control of the vehicle during operation. Understanding its components and how they work together allows for better handling and improved maneuverability, especially in tight spaces. A well-maintained system ensures precision and stability while driving, making navigation safer and easier.

Key elements involved in this system work in unison to translate the driver’s input into precise movement. Understanding the interaction between these components helps in recognizing potential issues early and ensuring long-term reliability. Regular inspection and adjustments can prevent wear and improve overall performance.

Brake System Parts and Their Role

The braking mechanism of industrial vehicles plays a crucial role in ensuring safety and control during operation. This section delves into the essential components involved in the braking system and their respective functions, highlighting how they contribute to effective stopping power and overall vehicle performance.

Key Components of the Braking Mechanism

At the heart of the braking mechanism are several vital elements that work in unison to facilitate reliable stopping. The brake pedal acts as the primary control, allowing the operator to initiate the braking process. When engaged, it activates the brake master cylinder, which generates hydraulic pressure to transfer force throughout the system. This hydraulic action is critical for the performance of the brake calipers, which then clamp down on the brake pads to create friction against the discs, ultimately slowing down or stopping the vehicle.

Importance of Maintenance

Regular inspection and maintenance of the braking components are vital to ensure optimal functionality. Over time, wear and tear can affect the efficiency of the brake pads and discs, leading to diminished stopping power. Timely replacements and adjustments not only enhance safety but also prolong the lifespan of the entire braking system, ensuring smooth operation during every task.

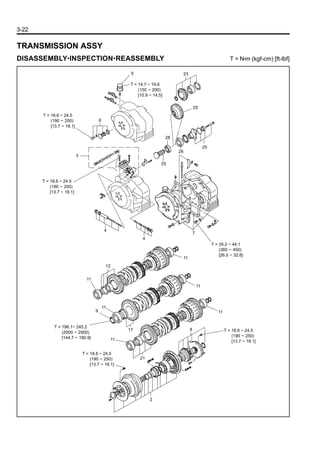

Transmission and Drivetrain Elements

The transmission and drivetrain components play a crucial role in the overall functionality and efficiency of industrial vehicles. These systems work in tandem to ensure that power generated by the engine is effectively transferred to the wheels, enabling smooth and reliable operation across various terrains.

Transmission systems are designed to manage gear ratios, allowing the vehicle to adapt to different speed and torque requirements. This adaptability is essential for maintaining optimal performance, especially when handling heavy loads. The components within the transmission, such as gears and clutches, work together to facilitate seamless gear shifts and enhance overall responsiveness.

In addition to the transmission, the drivetrain encompasses various elements, including driveshafts, differentials, and axles. Each of these components contributes to the vehicle’s ability to navigate challenging environments. For instance, the differential ensures that power is distributed evenly to the wheels, allowing for improved traction and stability when turning or driving on uneven surfaces.

Understanding the intricate relationship between these systems is essential for effective maintenance and troubleshooting. Regular inspections and servicing can prevent potential issues, ensuring that all elements function harmoniously to extend the lifespan of the vehicle and enhance its operational efficiency.

Fuel System Components Explained

The fuel system is a critical aspect of any machinery that relies on combustion for power. Understanding its components is essential for ensuring optimal performance and longevity. This section delves into the various elements that make up the fuel delivery system, highlighting their functions and interconnections.

At the heart of this system is the fuel tank, which stores the liquid energy source until it is needed. Fuel is drawn from the tank by a pump, which plays a vital role in maintaining the correct pressure for effective delivery. Once the fuel reaches the engine, it passes through a filter designed to remove impurities, ensuring that only clean fuel is utilized for combustion.

The fuel injector or carburetor is another key component, responsible for mixing the fuel with air in the correct proportions for efficient combustion. This mixture is then delivered to the combustion chamber, where it ignites to produce power. Additionally, various sensors monitor the system’s performance, providing feedback that helps optimize fuel delivery and overall efficiency.

Regular maintenance and inspection of these components are essential to prevent issues such as clogging or leaks, which can adversely affect performance. Understanding the role and function of each element within the fuel system can greatly enhance operational reliability and efficiency.

Cooling System Parts and Maintenance

The effective functioning of the cooling mechanism is vital for maintaining optimal performance and extending the lifespan of industrial equipment. This system plays a crucial role in regulating temperature and preventing overheating, which can lead to severe damage and costly repairs. Proper understanding and regular upkeep of its components ensure efficiency and reliability.

Key components of the cooling mechanism include radiators, water pumps, hoses, and thermostats. Each of these elements contributes to the overall effectiveness of the system. Regular checks and maintenance of these components can prevent malfunctions and improve the performance of the machinery.

Component Function Maintenance Tips Radiator Helps dissipate heat from the engine Clean regularly and check for leaks Water Pump Circulates coolant throughout the system Inspect for wear and replace if noisy Hoses Transport coolant to and from components Check for cracks and replace as needed Thermostat Regulates coolant flow based on temperature Test periodically and replace if faulty By adhering to a routine maintenance schedule and understanding the functions of each component, operators can ensure that the cooling system operates smoothly, thereby preventing overheating and promoting longevity of the machinery.

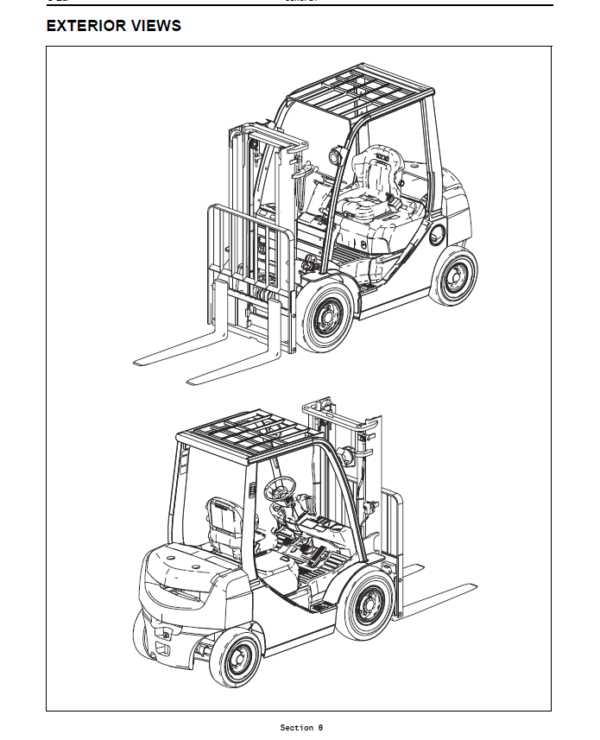

Analyzing Fork and Mast Assembly

The assembly comprising the lifting arms and vertical structure plays a crucial role in enhancing the functionality and efficiency of industrial equipment. Understanding the configuration and operation of these components is essential for optimal performance and maintenance. Proper integration ensures that the unit operates smoothly, allowing for effective load handling and stability during lifting operations.

The lifting arms are designed to support and carry the weight of the load, while their construction and materials are vital for durability and strength. Factors such as length and width influence the capacity and range of movement, allowing for various lifting tasks. Regular inspection of these components can prevent failures and ensure safety during operations.

The vertical structure, often referred to as the mast, provides stability and support to the entire assembly. It is essential to assess its integrity and functionality, as any compromise can lead to significant operational hazards. The mast’s design includes features that enable tilting and lifting, which enhance maneuverability in tight spaces. Maintenance of this structure is critical for preserving its alignment and ensuring effective load handling.

Control Panel and Instrumentation Details

The control interface and instrumentation system of industrial handling machinery play a crucial role in ensuring operational efficiency and safety. This section delves into the essential components that facilitate monitoring and control, providing operators with the necessary information for effective machine management.

Key Components

- Control Switches: These allow operators to manage various functions, including movement and speed adjustments.

- Indicator Lights: Visual signals that provide real-time status updates on machine performance and alerts for any malfunctions.

- Display Screen: A digital interface that presents important data such as battery levels, operational hours, and diagnostic information.

- Emergency Stop Button: A critical safety feature that immediately halts all operations in case of an emergency.

Instrumentation Features

- Battery Charge Indicator: Shows the current charge level, ensuring timely recharging.

- Hour Meter: Tracks the operational time, useful for maintenance scheduling.

- Temperature Gauge: Monitors the machine’s temperature, helping to prevent overheating and ensuring optimal performance.

Understanding these components and their functionalities enhances the operational reliability of the machinery, contributing to overall productivity in various industrial settings.

Commonly Replaced Parts in Forklifts

In the world of material handling equipment, certain components frequently require attention and replacement due to wear and tear. Understanding these elements can enhance the longevity and performance of the machinery, ensuring efficient operation in various tasks.

Some of the most commonly substituted components include:

- Batteries: Essential for power, batteries are often the first to show signs of decline, affecting overall functionality.

- Tires: Given their constant contact with surfaces, tires experience wear and must be replaced to maintain traction and stability.

- Brakes: As a critical safety feature, brake systems require regular inspection and timely replacement to prevent failures.

- Hydraulic Hoses: Subjected to high pressure and movement, these hoses can develop leaks and require prompt replacement.

- Filters: Air and fuel filters accumulate debris over time, impacting performance and efficiency.

Regular maintenance and timely replacement of these essential elements can greatly improve the efficiency and reliability of the machinery, minimizing downtime and maximizing productivity.

Safety Equipment and Accessories

Ensuring the safety of operators and those in proximity to industrial vehicles is paramount. Various safety gear and supplementary items are designed to enhance protection and improve overall operational efficiency. Understanding the importance of these components can significantly reduce risks associated with daily tasks.

Protective Gear

Operators should always utilize protective clothing and accessories to minimize injury during operation. Items such as helmets, gloves, and high-visibility vests play a crucial role in safeguarding personnel. Footwear with steel toes is essential for protecting against heavy objects, while ear protection is necessary to guard against noise pollution in busy environments.

Safety Accessories

In addition to personal protective equipment, several accessories contribute to a safer work environment. Warning lights and beepers can alert nearby individuals of moving machinery, while rearview cameras enhance visibility during operation. Incorporating these items into daily practices fosters a culture of safety and awareness, ensuring that all personnel remain secure while conducting their tasks.