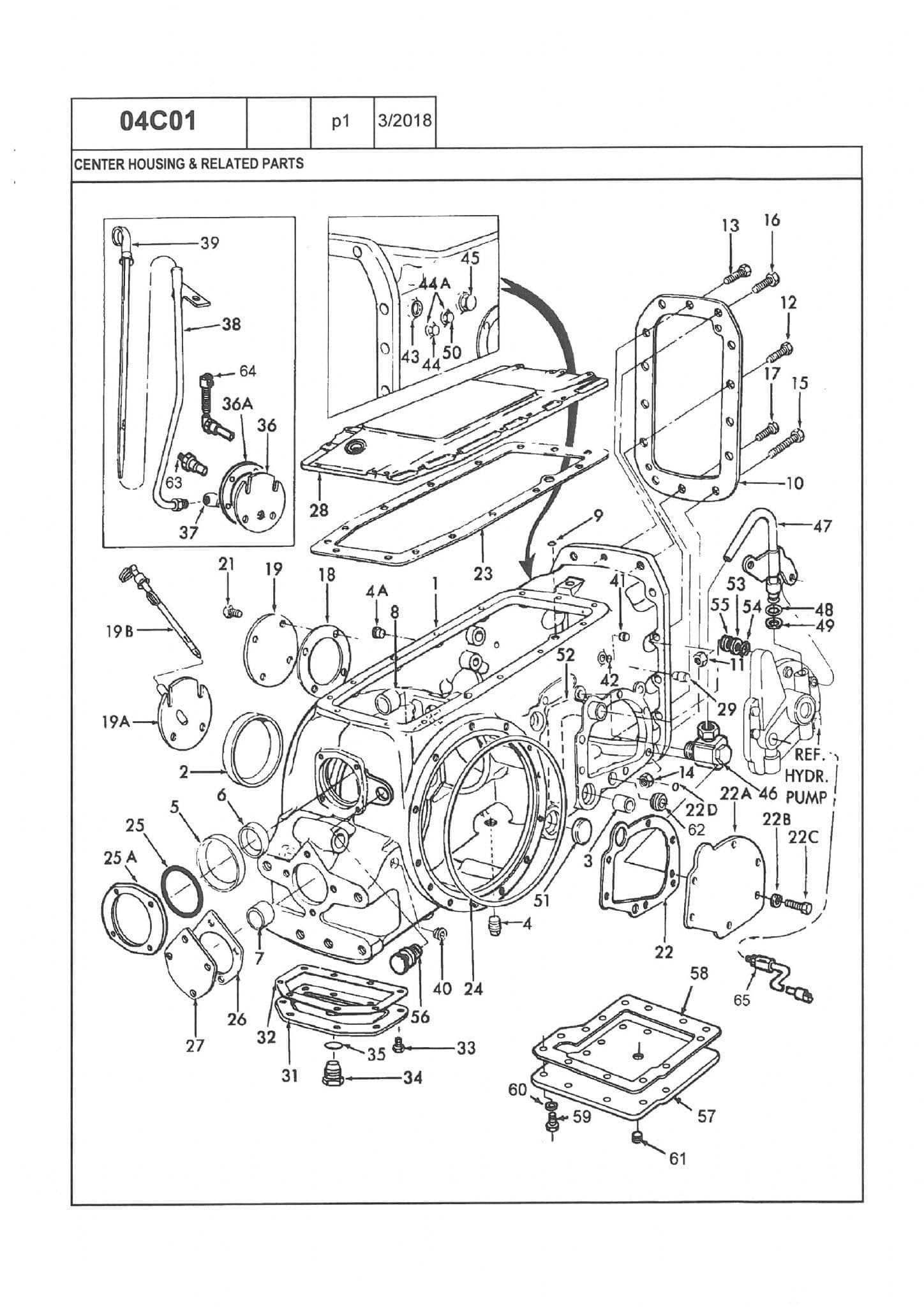

When maintaining or repairing agricultural equipment, it is crucial to have a clear understanding of how different mechanical elements are connected and organized. Knowing the structure of various assemblies and where specific elements are located can significantly streamline the repair process and reduce downtime.

Comprehensive visual guides play an essential role in assisting with the identification of mechanical components. These guides allow users to pinpoint specific connections, ensuring that they can replace or maintain key elements without confusion.

In this section, we’ll explore how detailed illustrations can enhance your understanding of machinery. With clear schematic layouts, even complex equipment becomes more accessible, helping you address mechanical issues with confidence and precision.

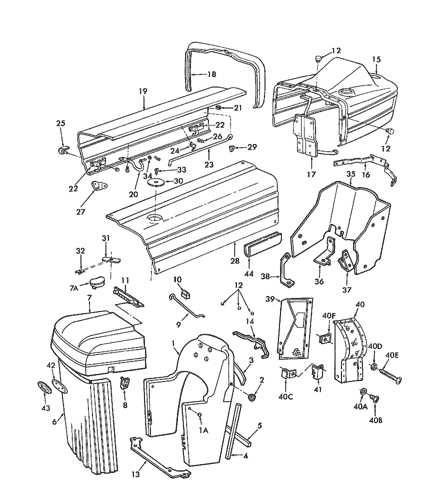

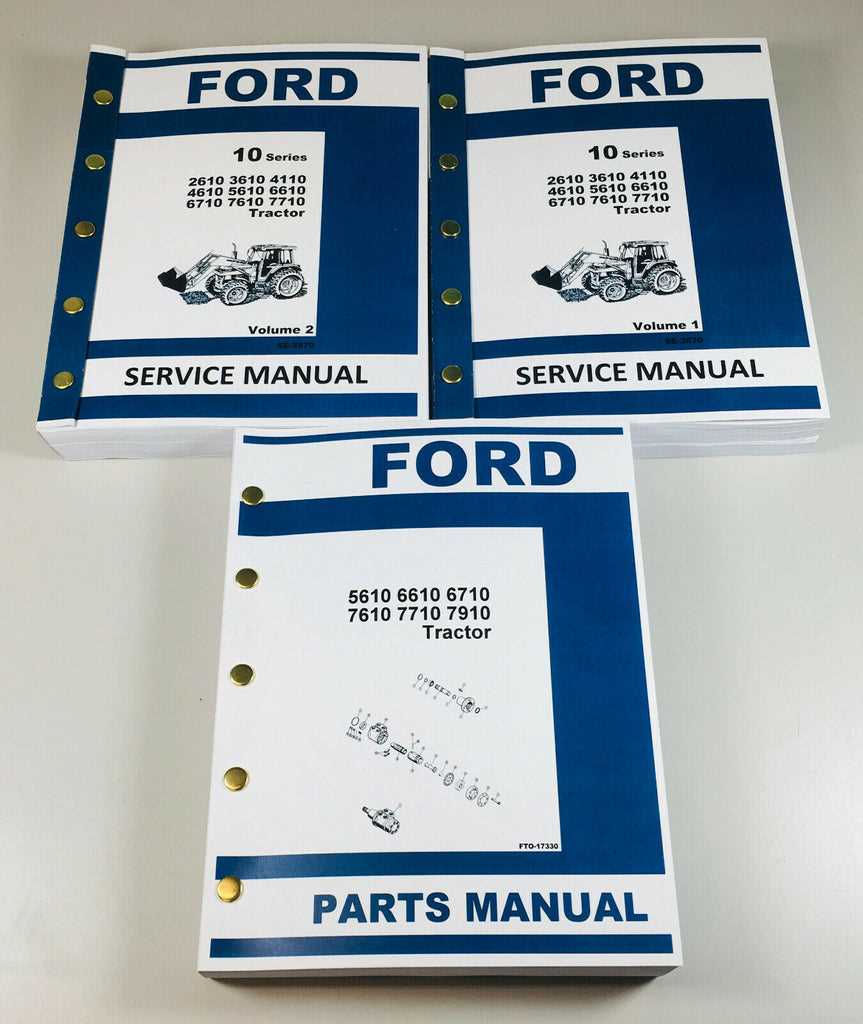

5610 Ford Tractor Parts Overview

This section provides a detailed look into the various components of an agricultural machine designed for medium-duty tasks. Each element plays a vital role in ensuring smooth operation and long-term reliability. Understanding how these mechanical pieces function together can help with maintenance and repairs, leading to increased efficiency in day-to-day operations.

Key Components

- Engine: The heart of the machine, providing the necessary power to handle diverse farming activities.

- Transmission: Ensures proper speed control and power distribution, vital for both fieldwork and transportation.

- Hydraulic System: Supports various attachments and tools, making the equipment versatile in its application.

- Braking System: A critical safety feature, responsible for controlling movement and stopping the vehicle efficiently.

- Cooling Mechanism: Prevents overheating by regulating the temperature of the engine during prolonged use.

Additional Features

- Electrical System: Powers essential functions like lighting and ignition, crucial for operation in all conditions.

- Tires and Wheels: Designed for durability and stability, ensuring optimal traction on various terrains.

- Steering Assembly: Provides control over navigation and maneuverability, allowing precise handling during tasks.

Engine Components and Functionality

The internal combustion system is composed of several crucial elements that work together to generate power. These elements are designed to convert fuel into energy efficiently, ensuring smooth and reliable operation. Understanding how these components interact can help maintain optimal performance and prolong the life of the equipment.

Main Power Generation Components

The core parts involved in power generation include the cylinders, pistons, and crankshaft. The pistons move within the cylinders, compressing the air-fuel mixture and igniting it, which creates the force needed to rotate the crankshaft. This movement is transferred into mechanical energy, driving the system forward.

Supporting Systems

Beyond the primary power generation, there are also systems that support the engine’s efficiency and cooling. These include the lubrication system, which reduces friction between moving parts, and the cooling system, which prevents overheating by regulating the temperature through circulation of coolant.

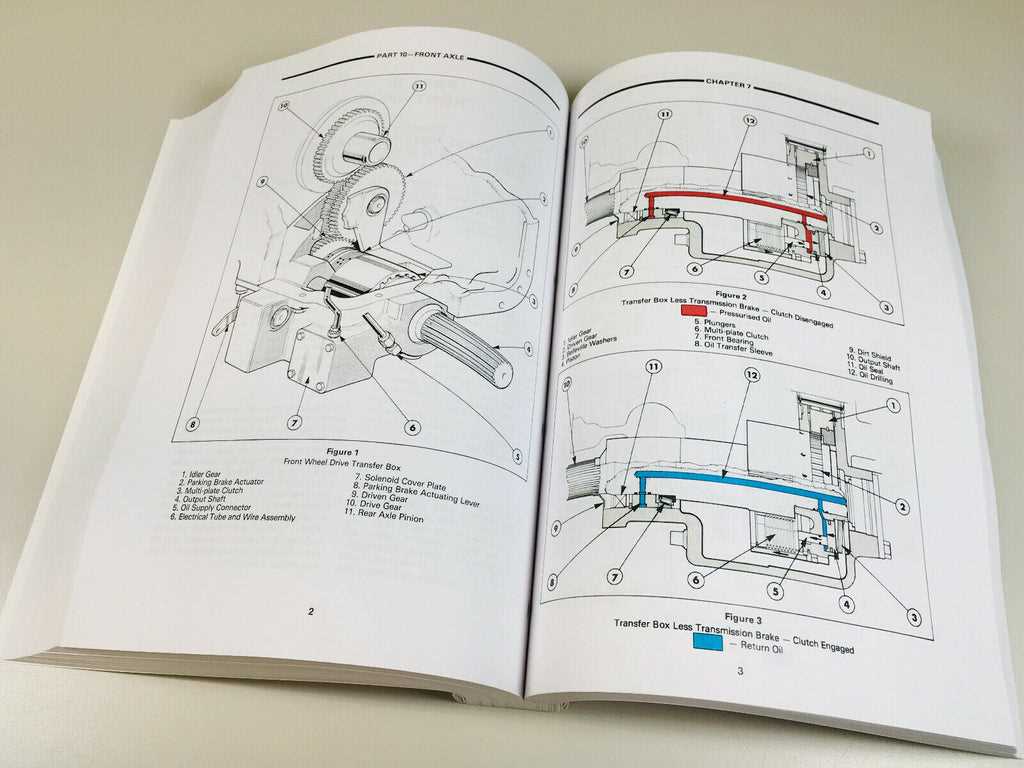

Hydraulic System and Its Role

The hydraulic system plays a vital role in ensuring the smooth operation of various machinery. Its ability to transmit power through pressurized fluid makes it an essential component for a wide range of mechanical tasks. This section will provide an overview of how the hydraulic mechanism functions and its significance in enabling equipment to perform efficiently.

- Efficient power transfer through fluid pressure

- Supports lifting, steering, and other mechanical operations

- Essential for precision and control in heavy machinery

By using hydraulic pressure, equipment can perform complex tasks with minimal manual effort. The system is designed to be both durable and reliable, ensuring longevity in demanding conditions. Proper maintenance of this mechanism is crucial to prevent malfunctions and ensure continuous performance.

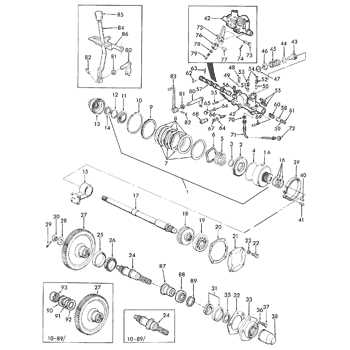

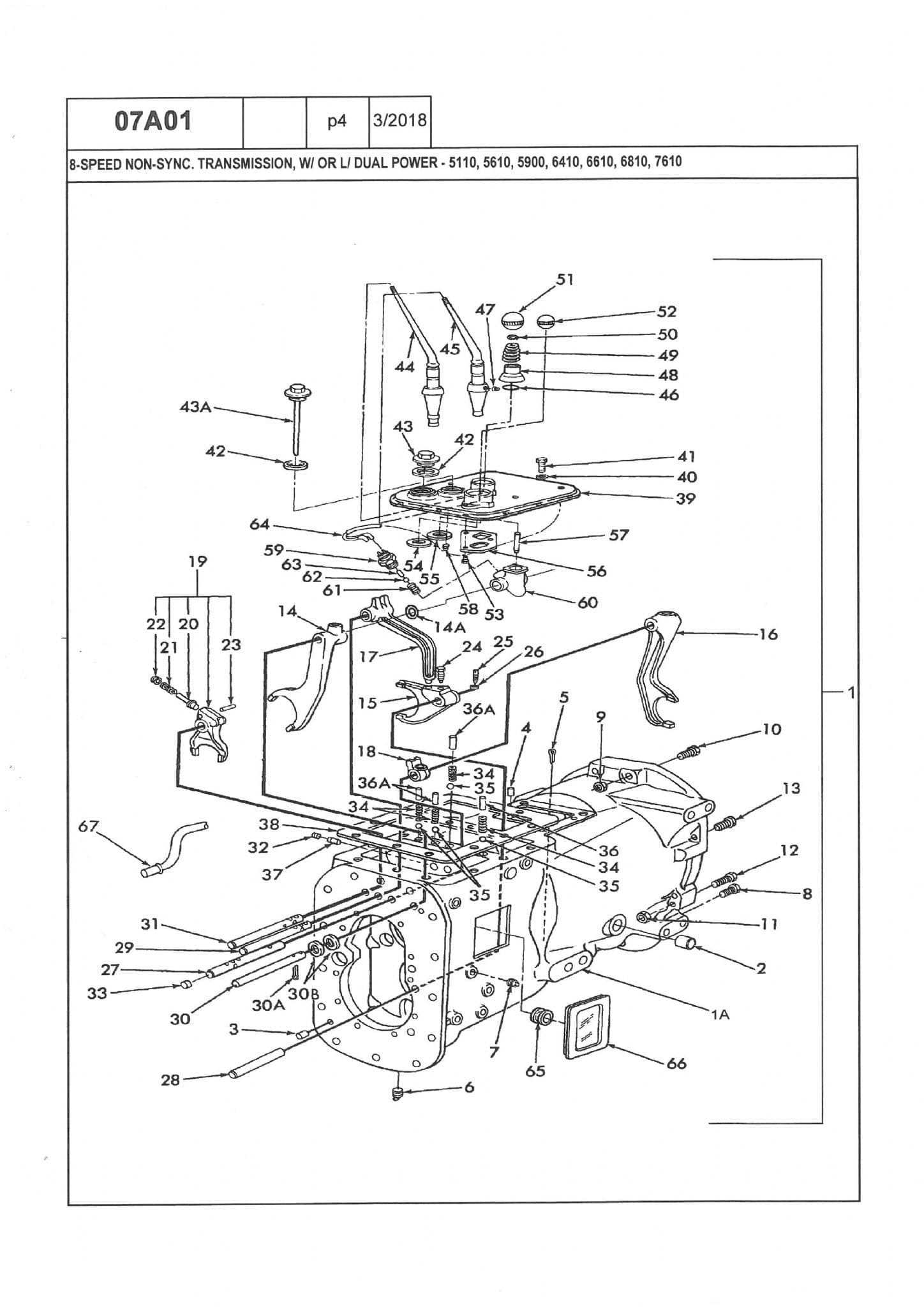

Transmission Assembly Breakdown

The transmission system is a vital component of any agricultural machinery, ensuring the efficient transfer of power from the engine to the wheels. Understanding its structure and how different elements interact can aid in maintaining smooth operation and troubleshooting potential issues. Below is a detailed breakdown of the transmission’s key sections and their functions.

Main Components

- Gearbox: Houses the gears that manage speed and torque.

- Clutch: Allows the disengagement of power from the engine to facilitate gear changes.

- Input Shaft: Transfers power from the engine to the gearbox.

- Output Shaft: Connects the gearbox to the drivetrain, delivering power to the wheels.

Gear Synchronization

- Synchronizers: Ensure smooth transitions between gears, reducing wear and improving efficiency.

- Shift Forks: Control the movement of gears, allowing selection of different speeds.

- Bearings: Provide support to the rotating shafts, ensuring smooth operation.

By regularly inspecting and understanding these components, operators can prevent costly breakdowns and ensure that the machinery remains functional for extended periods.

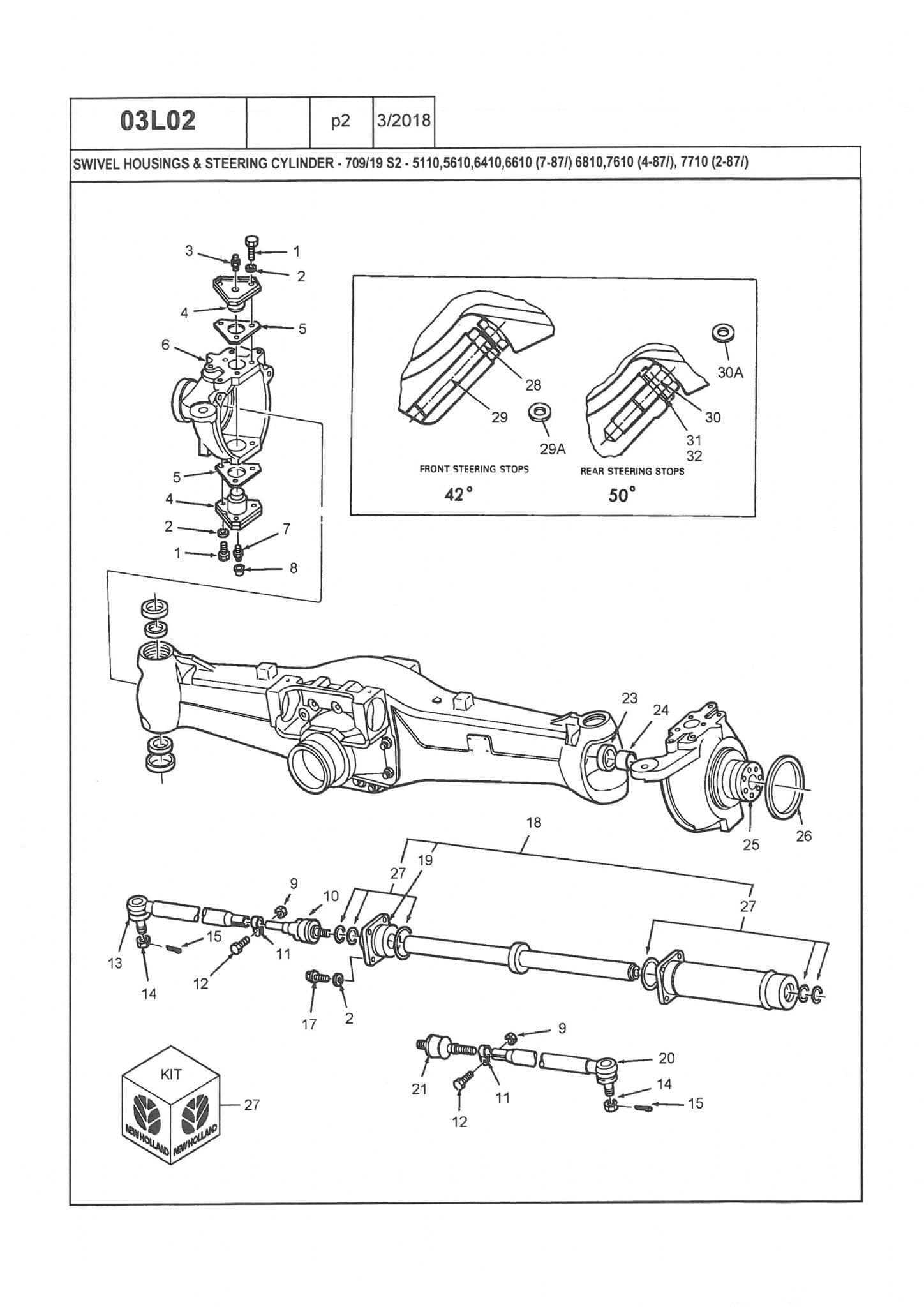

Steering Mechanism Details

The steering mechanism plays a crucial role in controlling the direction of movement. Its precise operation is essential for safe handling and effective navigation, especially when maneuvering heavy machinery in various conditions. Understanding how each component interacts within the system is key to maintaining smooth control.

Steering Wheel Assembly: The assembly includes the wheel, shaft, and linkages that transmit force. When turning the wheel, the movement is transferred through a series of connected parts, ensuring smooth directional shifts.

Hydraulic Support: In modern systems, hydraulic assistance helps reduce the effort required to steer. This mechanism uses pressurized fluid to enhance the force applied, providing smoother and more responsive steering with minimal physical strain.

Linkage System: The linkage connects the wheel to the rest of the mechanism, translating rotational movement into linear motion. This network of rods and joints ensures that the movement from the wheel is effectively transferred to the steering axles.

Axle Interaction: The final point of interaction is the axle system. Once the steering input reaches the axles, they adjust the direction of the machine’s movement. Proper alignment and maintenance of this part are crucial for consistent steering performance.

Brake System Parts Explanation

The braking system is a crucial component in any vehicle, ensuring safety and control during operation. It consists of various elements that work together to slow down or stop the vehicle effectively. Understanding these components is essential for maintaining optimal performance and safety.

Key Components of the Braking System

At the core of the braking mechanism is the brake pedal, which the operator presses to initiate the braking process. This action engages the master cylinder, converting the pedal’s motion into hydraulic pressure. This pressure is transmitted through brake lines to the brake calipers or wheel cylinders, which then activate the brake pads or shoes against the rotors or drums, providing the necessary friction to halt movement.

Importance of Maintenance

Regular inspection and maintenance of the braking system are vital. Components such as brake pads, shoes, and hydraulic fluids require periodic checks to ensure they are in good working condition. Neglecting these elements can lead to decreased performance, increased wear, and potential safety hazards.

Cooling System Components

The cooling system is vital for maintaining optimal operating temperatures in machinery, preventing overheating and ensuring efficient performance. This system comprises several key elements that work together to dissipate heat generated during operation.

The radiator serves as the primary component responsible for heat exchange. It cools the coolant fluid as it circulates, allowing heat to dissipate into the surrounding air. Additionally, the water pump plays a crucial role by ensuring the continuous movement of coolant throughout the system, promoting effective heat transfer.

Another essential part is the thermostat, which regulates the coolant’s temperature. It opens and closes to maintain the desired thermal conditions, preventing excessive heating or cooling. Furthermore, the hoses connecting these components facilitate the flow of coolant, ensuring that each part functions optimally.

Lastly, the expansion tank accommodates fluctuations in coolant volume due to temperature changes. It prevents pressure buildup and allows for safe operation, contributing to the overall reliability of the cooling system.

Electrical System and Wiring

The electrical framework is crucial for the efficient functioning of agricultural machinery. Understanding the wiring layout and components involved can aid in troubleshooting and maintenance, ensuring optimal performance and longevity.

Key components of the electrical system include:

- Battery: Provides the necessary power to start the engine and run various electrical systems.

- Alternator: Charges the battery while the engine is running, supplying power to the electrical components.

- Wiring Harness: A network of cables that connects all electrical components, allowing for the smooth flow of electricity.

- Fuses: Protect the electrical circuits by preventing overloads, ensuring safety and reliability.

- Ignition System: Facilitates the starting process and ensures that the engine runs smoothly.

Regular inspections of the electrical system can help identify potential issues before they escalate. Common maintenance practices include:

- Checking battery connections for corrosion or damage.

- Inspecting wiring for signs of wear or fraying.

- Testing fuses and replacing any that are blown.

- Ensuring the alternator is functioning correctly to maintain battery charge.

By familiarizing oneself with the electrical components and their functions, operators can enhance the reliability and efficiency of their machinery.

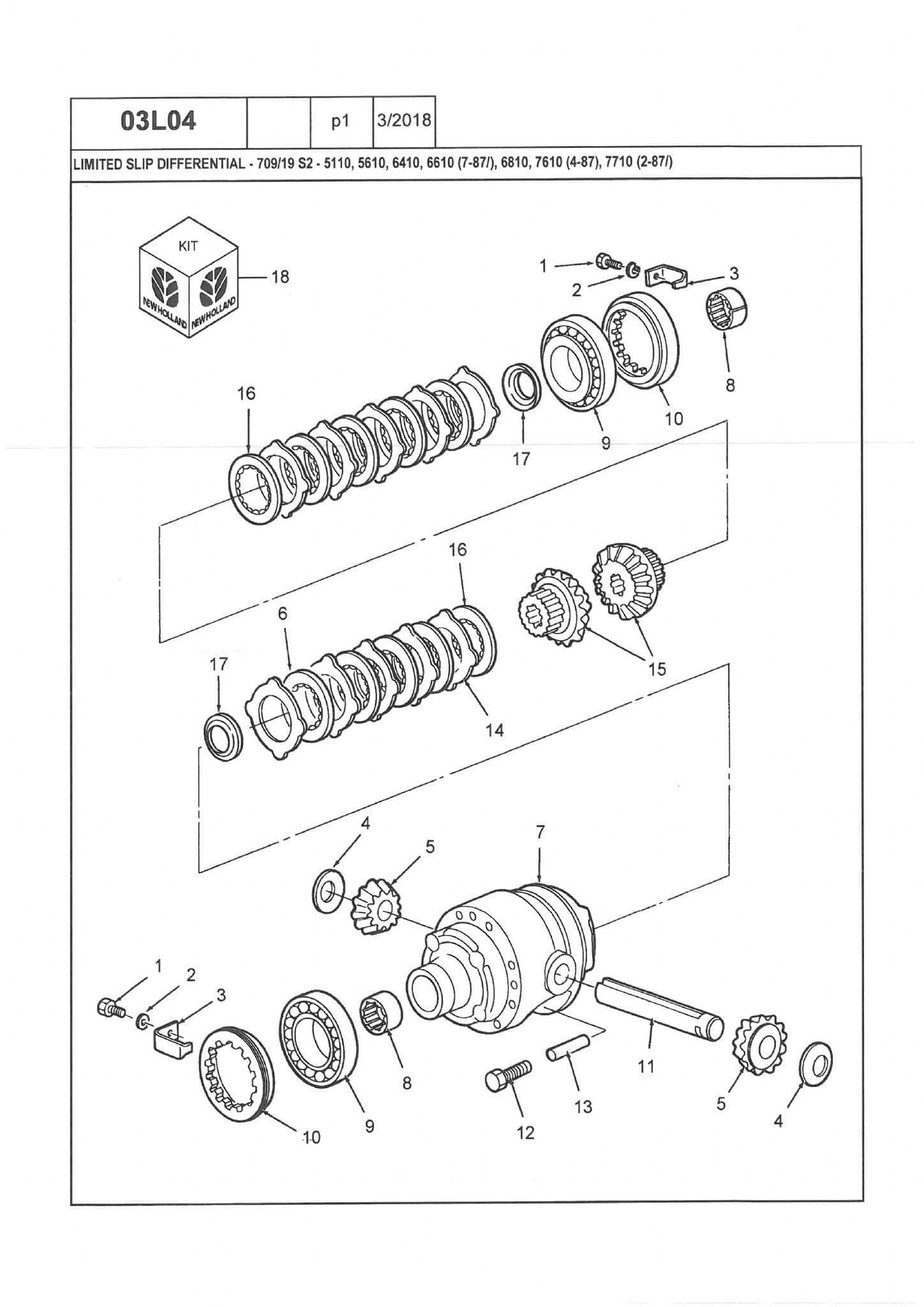

Front and Rear Axle Parts

The functionality of heavy machinery significantly relies on the integrity of its axle components. These elements are crucial for stability, load-bearing capacity, and overall performance. Understanding the various components associated with the front and rear axles enhances maintenance and operational efficiency.

| Component | Description |

|---|---|

| Spindle | The spindle connects the wheel to the axle, allowing for rotation while providing support for vertical load. |

| Hub | The hub houses the wheel bearings and facilitates the mounting of the wheel, ensuring secure attachment to the vehicle. |

| Axle Shaft | This is a critical component that transfers power from the engine to the wheels, enabling movement. |

| Leaf Spring | Leaf springs are used for suspension, absorbing shocks and maintaining ride height during operation. |

| U-Joint | The universal joint allows for flexibility in movement while connecting various axle components, accommodating different angles of operation. |

Fuel System Structure

The fuel system is a critical component that ensures the efficient operation of the engine by delivering the necessary fuel for combustion. Its design and arrangement play a vital role in optimizing performance and maintaining reliability. Understanding the elements of this system can enhance maintenance practices and improve overall functionality.

Key Components

Several essential parts make up the fuel delivery network. These include the fuel tank, fuel pump, filters, injectors, and lines. Each element serves a specific purpose in ensuring that clean fuel reaches the engine under the right pressure. The fuel tank stores the fuel, while the pump draws it from the tank and pushes it through the filters to remove impurities.

Fuel Delivery Process

The process begins with the fuel being drawn from the tank by the pump. It then passes through one or more filters, which are designed to trap contaminants that could harm the engine. After filtration, the fuel is directed to the injectors, which atomize it for optimal mixing with air in the combustion chamber. This precise delivery of fuel is crucial for achieving efficient combustion and maximizing power output.

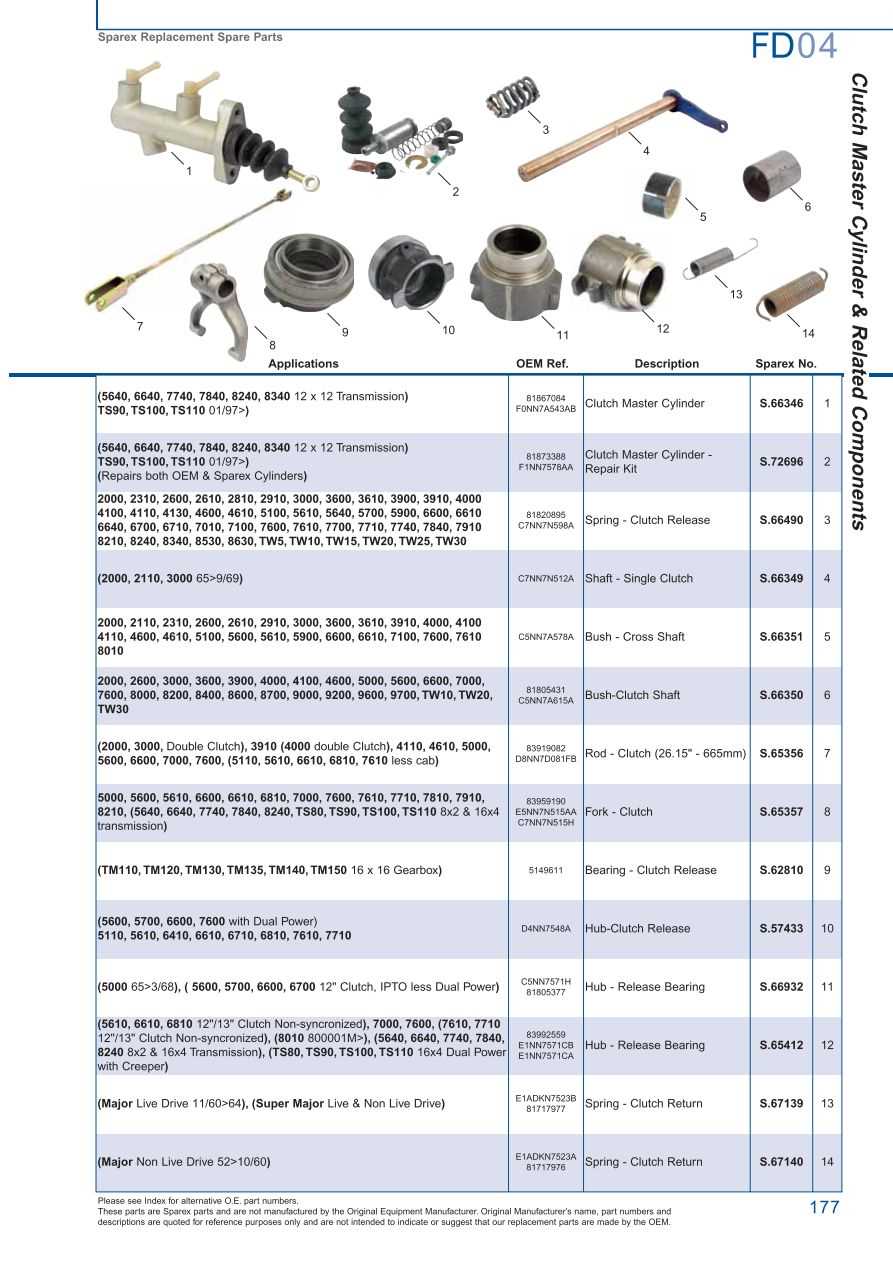

Clutch Mechanism Overview

The clutch mechanism is a crucial component in various machinery, serving as the interface between the engine and the drivetrain. It enables the operator to engage and disengage the power transmission smoothly, allowing for effective control over the vehicle’s movement and performance. Understanding the functionality of this system is essential for maintaining optimal efficiency and ensuring a seamless operation during use.

Components of the Clutch Mechanism

The clutch assembly consists of several key elements that work together to facilitate the engagement and disengagement of power. These components include the pressure plate, clutch disc, flywheel, and release bearing. Each part plays a vital role in ensuring the clutch operates smoothly and reliably.

| Component | Function |

|---|---|

| Pressure Plate | Holds the clutch disc against the flywheel when engaged, transmitting power. |

| Clutch Disc | Connects to the pressure plate and flywheel, allowing power transfer when engaged. |

| Flywheel | Serves as a connection point for the engine and clutch, providing a surface for the disc. |

| Release Bearing | Facilitates the disengagement of the clutch by pushing against the pressure plate. |

Importance of Regular Maintenance

Proper upkeep of the clutch mechanism is essential for longevity and performance. Regular inspections can prevent wear and tear, ensuring that each component functions as intended. Addressing any issues promptly can help avoid costly repairs and extend the lifespan of the entire system.

Exhaust System Diagram

The exhaust system plays a crucial role in the performance and efficiency of any engine. It is responsible for directing exhaust gases away from the combustion chamber and minimizing harmful emissions. Understanding the layout and components of this system is essential for effective maintenance and troubleshooting.

This system typically includes several key elements such as the exhaust manifold, catalytic converter, muffler, and tailpipe. Each component works in harmony to ensure the safe expulsion of gases while reducing noise levels and meeting environmental regulations. Familiarity with these parts can greatly aid in identifying issues and ensuring optimal functioning.

Regular inspections and timely replacements of worn or damaged elements within this system can enhance overall engine performance and longevity. Proper attention to the exhaust pathway not only promotes a healthier operating environment but also contributes to fuel efficiency and reduced emissions.