In the realm of farming equipment, a deep comprehension of the various elements that contribute to the overall functionality is essential. Each piece plays a pivotal role in ensuring efficiency and productivity in agricultural tasks. Whether for routine maintenance or complex repairs, having a clear representation of these elements can significantly enhance the user’s experience.

Recognizing the intricate relationships among different components allows operators to diagnose issues more effectively and implement solutions with confidence. This knowledge not only empowers individuals to maintain their machinery but also fosters a greater appreciation for the engineering behind these powerful machines.

By exploring the assembly and interconnections of these vital systems, enthusiasts and professionals alike can gain insights into optimizing performance. The visualization of these relationships offers clarity, transforming what may seem like a daunting task into a manageable endeavor.

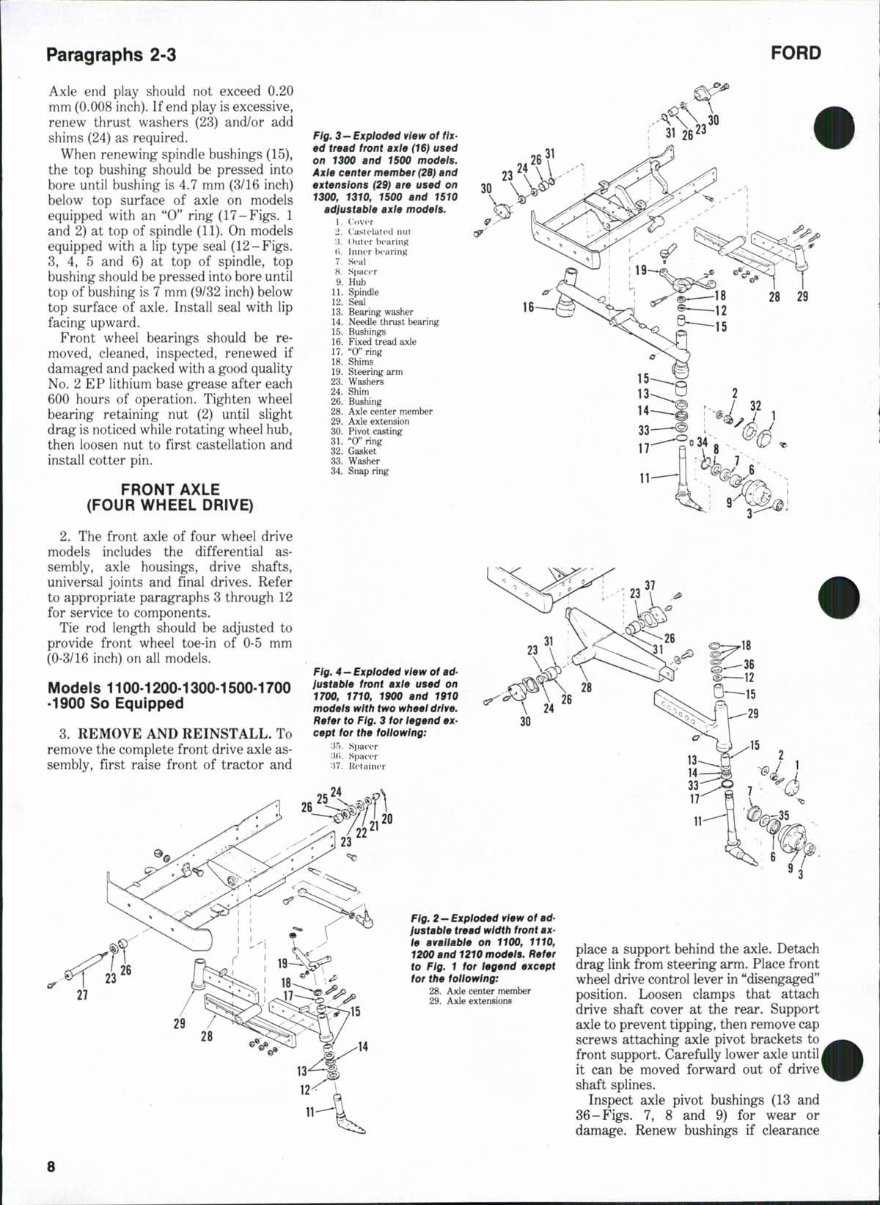

Understanding the Ford 1210 Tractor

This section provides insights into a popular agricultural machine known for its versatility and efficiency. With its robust design and functional capabilities, this vehicle serves a variety of tasks in farming and land management, making it a valuable asset for many users.

Key Features

- Compact size for ease of maneuverability

- Powerful engine options suitable for diverse applications

- User-friendly controls for enhanced operational comfort

- Durable construction to withstand harsh conditions

Applications

- Soil cultivation and preparation

- Transporting materials across fields

- Implementing various attachments for specialized tasks

- Maintaining landscapes and managing crops

Key Features of Ford 1210

This section highlights the essential characteristics of a renowned agricultural machine, known for its efficiency and reliability. It showcases how this model stands out in various applications, providing users with optimal performance and ease of use.

The compact design combined with powerful engine specifications makes it a favorite among farmers and landowners. The versatility allows it to handle a wide range of tasks, from plowing to hauling, ensuring that users can maximize productivity on their land.

| Feature | Description |

|---|---|

| Engine Power | Provides ample horsepower for demanding tasks. |

| Compact Size | Ideal for navigating tight spaces and small fields. |

| Durability | Built with robust materials to withstand heavy usage. |

| User-Friendly Controls | Simplified interface for ease of operation. |

| Versatile Attachments | Compatible with a variety of implements for different tasks. |

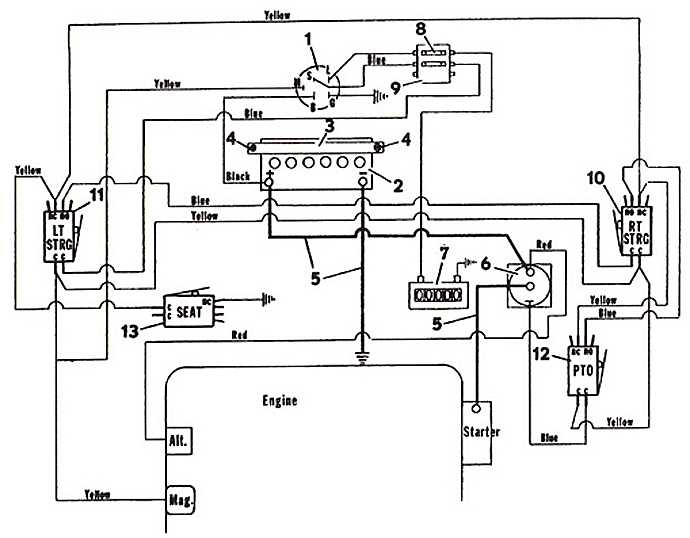

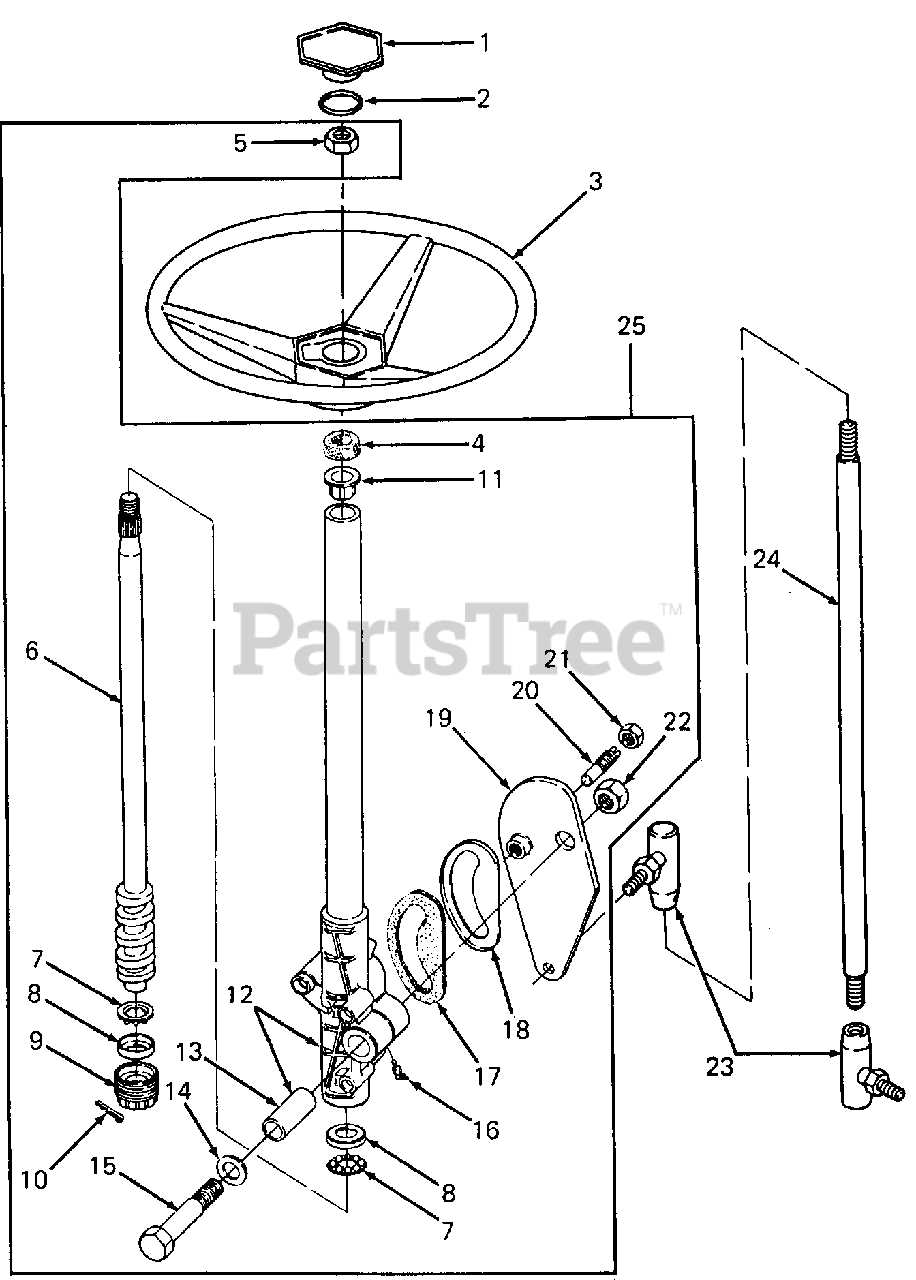

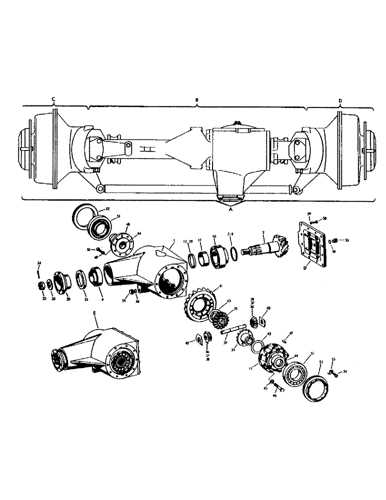

Importance of Machinery Component Schematics

Understanding the intricacies of machinery is crucial for effective maintenance and repair. Visual representations of individual elements serve as essential tools for both professionals and enthusiasts. These schematics facilitate a deeper comprehension of the entire system, ensuring that users can address issues efficiently and accurately.

Enhanced Troubleshooting

When a machine malfunctions, having a detailed visual guide can significantly simplify the diagnostic process. Users can:

- Identify specific components quickly.

- Trace connections and understand relationships between parts.

- Locate potential failure points with ease.

Streamlined Repairs

Visual aids not only assist in identifying problems but also aid in the repair process itself. Benefits include:

- Providing step-by-step instructions for disassembly and reassembly.

- Highlighting necessary tools and replacement items.

- Reducing the likelihood of errors during repairs.

Incorporating schematics into maintenance practices ultimately leads to increased efficiency and reduced downtime, making them indispensable resources for anyone working with machinery.

Common Issues with Ford 1210 Parts

When maintaining heavy machinery, various complications may arise that affect performance and longevity. Understanding these common challenges can help in identifying the need for replacements or repairs.

- Wear and Tear: Components can deteriorate over time, leading to decreased efficiency.

- Corrosion: Exposure to elements can cause rust, impacting functionality.

- Misalignment: Parts may become misaligned, resulting in operational difficulties.

- Fluid Leaks: Seal failures can lead to loss of essential fluids, compromising performance.

By addressing these issues promptly, operators can ensure their machinery remains in optimal condition.

Where to Find Parts Diagrams

Locating detailed schematics for machinery components can greatly enhance repair and maintenance efforts. Understanding the layout and relationships of various elements is crucial for effective troubleshooting and replacement. Fortunately, there are several reliable resources available for obtaining these valuable illustrations.

Online Resources

The internet is a treasure trove of information. Websites dedicated to machinery enthusiasts often provide extensive libraries of visual references. Manufacturer websites frequently have downloadable resources, offering clarity on component configurations. Additionally, forums and community groups can be invaluable, where users share experiences and illustrations.

Local Dealerships and Suppliers

Visiting local dealerships or suppliers can also yield fruitful results. Many establishments have printed manuals or can provide access to digital versions upon request. Establishing a relationship with these businesses can ensure that you receive the most accurate and up-to-date information for your needs.

Essential Tools for Repairs

When it comes to maintaining and restoring machinery, having the right equipment is crucial. A well-equipped workspace can significantly streamline the repair process, ensuring that tasks are completed efficiently and effectively. Below, we outline the must-have tools that every enthusiast should consider for their toolkit.

Basic Hand Tools

- Wrenches: A variety of sizes for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips to handle different types of screws.

- Pliers: Useful for gripping, twisting, and cutting wire.

- Socket Set: Essential for reaching fasteners in tight spaces.

Specialized Equipment

- Torque Wrench: Ensures fasteners are tightened to the correct specifications.

- Multimeter: Ideal for diagnosing electrical issues.

- Impact Wrench: Provides extra power for loosening stubborn bolts.

- Toolbox: Keeps everything organized and easily accessible.

Equipping yourself with these tools will enhance your ability to perform repairs and maintenance with confidence. A comprehensive toolkit not only facilitates the job but also contributes to a safer working environment.

Maintenance Tips for Ford 1210

Proper upkeep of machinery is essential for ensuring longevity and optimal performance. Regular checks and proactive measures can prevent potential issues and enhance efficiency over time.

Routine Inspections

Conduct frequent inspections of vital components, such as fluids, belts, and filters. Keeping an eye on wear and tear will allow for timely replacements, minimizing unexpected breakdowns.

Lubrication and Cleaning

Regularly lubricate moving parts to reduce friction and enhance functionality. Additionally, clean the exterior and interior to prevent dirt buildup, which can affect performance and longevity.

Popular Replacement Parts Explained

In the realm of machinery maintenance, understanding the essential components that often require substitution is crucial for optimal performance. This section delves into some commonly sought-after items that ensure longevity and efficiency in operation.

Key Components

- Filters: These play a vital role in keeping fluids clean and machinery running smoothly.

- Batteries: Reliable power sources are essential for starting and operating equipment.

- Belts: These help in transferring motion between different parts, crucial for functionality.

Importance of Quality

Choosing high-quality replacements can significantly impact performance. Investing in durable alternatives ensures fewer replacements over time and enhances overall efficiency.

Step-by-Step Repair Guide

This section provides a comprehensive approach to restoring machinery components effectively. By following these detailed instructions, you will gain insights into identifying issues and implementing solutions efficiently.

Begin by gathering all necessary tools and materials to ensure a smooth repair process. Familiarize yourself with the specific assembly and disassembly techniques related to your equipment.

Next, conduct a thorough inspection to pinpoint areas needing attention. Document any findings for reference as you proceed with the repair.

Once identified, carefully remove the affected components, taking care to maintain the integrity of surrounding parts. Follow a logical sequence to avoid confusion during reassembly.

After replacement or repair of damaged sections, ensure everything is clean and properly lubricated before reinstallation. Double-check all connections and fastenings to guarantee optimal performance.

Finally, test the machinery to confirm that the repairs were successful and that it operates smoothly. Regular maintenance checks will help prolong the lifespan of your equipment.

Comparing Aftermarket vs. OEM Parts

The choice between original and alternative components is a significant consideration for many equipment owners. Each category offers distinct advantages and potential drawbacks that can impact performance, reliability, and cost-effectiveness.

Original components are typically produced by the same manufacturer as the equipment itself. They are designed to meet specific standards, ensuring compatibility and durability. This option often provides peace of mind, as users can trust the quality and reliability that come from the original source.

On the other hand, alternative components are manufactured by third-party companies and can provide cost savings. While these parts may not always match the quality of their original counterparts, many are designed to perform equally well or even better in certain conditions. Additionally, the wide range of options available can allow for customization and enhanced performance.

Ultimately, the decision should be based on individual needs, budget constraints, and the intended use of the equipment. Weighing the pros and cons of both types can help users make informed choices that align with their operational requirements.

Safety Precautions During Repairs

When undertaking maintenance or repair tasks on machinery, prioritizing safety is crucial. Working with mechanical equipment involves inherent risks, and taking appropriate precautions can prevent accidents and injuries. It is essential to approach every project with a well-defined safety plan to ensure a secure working environment.

First and foremost, always wear protective gear. This includes safety goggles to shield your eyes from debris, gloves to protect your hands, and steel-toed boots to safeguard your feet. Additionally, ensure that you have ear protection if you are using loud tools.

Properly disconnect power sources before beginning any repairs. This action prevents accidental starts and reduces the risk of electric shock. If applicable, be sure to follow lockout/tagout procedures to ensure that machines remain inoperable while you work on them.

Maintain a clean and organized workspace. Clutter can lead to accidents, so keep tools and materials in their designated places. Make sure that the area is well-lit and free from hazards that could cause slips or falls.

Be mindful of your posture and lifting techniques. Use your legs instead of your back when lifting heavy components, and seek assistance when necessary. Proper ergonomics not only enhances safety but also reduces fatigue, allowing you to work more effectively.

Finally, always have a first aid kit accessible. In the event of an injury, having supplies readily available can make a significant difference. Familiarize yourself with basic first aid procedures to handle minor incidents promptly.

By adhering to these guidelines, you can ensure a safer working experience while conducting repairs on your equipment.

Tractor Parts Suppliers and Resources

Finding reliable sources for machinery components is crucial for maintenance and repair. Numerous vendors and platforms offer a variety of options, ensuring that users can access what they need efficiently.

- Local dealers: Often provide specialized support and genuine items.

- Online marketplaces: Great for comparing prices and availability across various suppliers.

- Salvage yards: A cost-effective option for second-hand components.

Additionally, many manufacturers maintain online catalogs and resources to assist users in locating the right components.

- Check manufacturer websites for comprehensive listings.

- Join online forums or communities for recommendations and advice.

- Utilize social media platforms to discover local suppliers.

By exploring these resources, users can ensure they find the ultimate solutions for their machinery needs.

Community Forums for Ford Owners

Engaging with fellow enthusiasts through online platforms is a fantastic way to share knowledge, experiences, and tips related to machinery and equipment. These interactive spaces provide a supportive environment for owners to discuss various aspects of maintenance, upgrades, and troubleshooting, fostering a sense of camaraderie among users.

Benefits of Joining Online Communities

Participating in these forums can significantly enhance your understanding of your equipment. Users often share valuable insights that can help you solve specific issues or improve performance. Additionally, these platforms serve as a repository of knowledge, where you can find discussions on similar challenges faced by others, saving you time and effort in the long run.

Finding the Right Community

When seeking a community, consider those with active members and diverse topics. Look for forums that encourage interaction and provide resources like guides, tutorials, and user-generated content. Engaging with these networks not only enhances your skills but also allows you to contribute your own knowledge, creating a beneficial cycle of learning.