In the realm of agricultural machinery, having a comprehensive understanding of the various components is essential for effective operation and maintenance. Knowledge of these elements not only aids in troubleshooting but also ensures the longevity and efficiency of the equipment. By exploring the intricate relationships between the different parts, users can enhance their operational skills and optimize their machinery’s performance.

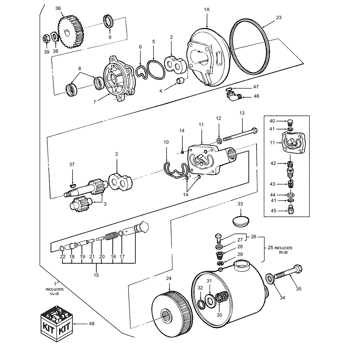

Each element of the machinery plays a vital role in its overall functionality. Familiarity with these components enables operators to identify potential issues quickly and take appropriate action. This guide provides a visual representation that outlines the key features and connections within the machinery, facilitating a deeper comprehension of its structure.

Moreover, recognizing how each part interacts within the system allows for more informed decision-making regarding repairs and replacements. Understanding the intricate network of mechanisms empowers users to maintain their equipment in peak condition, ensuring that it operates smoothly and efficiently for years to come.

The operator’s environment plays a crucial role in ensuring efficiency and comfort during operations. The layout and design of the cab significantly influence the ease of access to essential controls and instruments, allowing for a seamless interaction between the operator and the machine.

Within the cab, various controls are strategically placed to optimize the operator’s experience. These include steering mechanisms, throttle levers, and control panels that provide vital information about the machine’s performance. Proper organization of these elements enhances operational efficiency, making it easier for the operator to focus on tasks at hand.

| Control | Description |

|---|---|

| Steering Wheel | Used for directing movement and maneuvering the vehicle. |

| Throttle Lever | Regulates engine speed and power output for various tasks. |

| Control Panel | Displays key operational data and allows adjustments to settings. |

| Gear Shift | Facilitates changing speeds and directions, essential for various operations. |

| Brakes | Ensures safe stopping and control over movement. |

Overall, the design and functionality of these controls contribute significantly to the operational effectiveness of the machinery, making them essential for optimal performance in diverse tasks.

Maintenance and Replacement Parts

Regular upkeep and timely substitutions are vital for ensuring optimal performance and longevity of machinery. Routine inspections can help identify wear and tear, allowing for proactive measures to be taken before minor issues escalate into significant problems.

When it comes to maintaining equipment, several key components require particular attention:

- Engine Components: Regular checks on belts, filters, and oil levels are essential to keep the engine running smoothly.

- Hydraulic System: Inspect hoses and seals for leaks, and ensure fluid levels are adequate for efficient operation.

- Transmission: Monitor for any unusual noises or shifting issues, as these may indicate the need for adjustments or fluid changes.

- Wheels and Tires: Inspect tread depth and tire pressure to maintain traction and stability.

- Electrical System: Ensure all connections are secure, and batteries are charged to prevent starting issues.

Identifying components that may need replacement can significantly improve functionality and safety. Keep a list of essential replacements to streamline the maintenance process:

- Air filters

- Fuel filters

- Belts and hoses

- Brake pads and shoes

- Light bulbs

Establishing a maintenance schedule and adhering to it can prevent unexpected breakdowns and enhance the overall efficiency of operations.

Common Issues and Troubleshooting

Operating heavy machinery can lead to various challenges that may affect performance and efficiency. Identifying and resolving these issues promptly is crucial for maintaining optimal functionality. Below are some frequently encountered problems along with their potential solutions.

| Issue | Possible Causes | Suggested Solutions |

|---|---|---|

| Engine Won’t Start | Dead battery, fuel blockage, faulty ignition | Check battery connections, inspect fuel lines, test ignition system |

| Overheating | Low coolant, blocked radiator, faulty thermostat | Top up coolant, clean radiator, replace thermostat |

| Poor Performance | Dirty filters, incorrect fuel type, worn components | Replace air and fuel filters, ensure correct fuel is used, inspect and replace worn parts |

| Unusual Noises | Lack of lubrication, damaged bearings, loose components | Check oil levels, lubricate moving parts, tighten loose fittings |

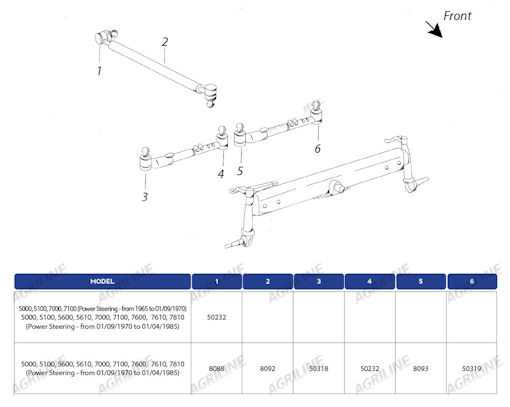

Parts Compatibility and Upgrades

Ensuring the proper functionality of agricultural machinery often involves evaluating the interchangeability of various components. This process can significantly enhance performance, extend the lifespan of equipment, and optimize operational efficiency. By considering the compatibility of different elements, operators can make informed decisions about replacements and improvements.

Assessing compatibility among components is crucial. Certain modifications may allow for the integration of upgraded mechanisms, leading to better reliability and performance. This approach not only enhances efficiency but also reduces the likelihood of breakdowns, contributing to smoother operations.

When looking to upgrade, it is essential to consult technical manuals or seek expert advice. Such resources provide valuable insights into which enhancements can be applied effectively without compromising safety or functionality. In addition, using components from reputable manufacturers ensures quality and performance.

Ultimately, understanding the nuances of component compatibility and potential upgrades is vital for maintaining machinery in optimal condition. This knowledge empowers operators to make strategic choices that enhance their equipment’s capabilities and longevity.

Resources for Parts Acquisition

Finding the right components for your machinery is essential for optimal performance and longevity. Several avenues exist for sourcing these essential items, whether you prefer purchasing online or visiting local retailers. Understanding where to look can save time and ensure that you obtain high-quality replacements or upgrades for your equipment.

Online Marketplaces

Digital platforms provide a vast array of options for acquiring components. Websites dedicated to machinery supplies often have extensive catalogs, allowing you to search by specific requirements. User reviews and ratings can guide you in selecting reliable sellers and products. Additionally, many platforms offer competitive pricing, making it easier to find budget-friendly solutions.

Local Dealers and Distributors

Establishing a relationship with nearby dealers can be beneficial. Local suppliers often have a better understanding of regional needs and can provide personalized service. They may also stock commonly required items, ensuring immediate availability. Networking with these professionals can lead to valuable insights about the best components for your specific machinery.