In the world of modern agriculture, comprehending the intricate elements of heavy machinery is essential for effective maintenance and optimal performance. Every piece of equipment consists of various interconnected systems that work in harmony to achieve seamless functionality. Grasping these components can significantly enhance operational efficiency and prolong the lifespan of the machine.

Visual representation of machinery components serves as a valuable tool for both novices and experienced operators. By examining the arrangement and relationships of these elements, users can quickly identify potential issues and areas for improvement. This knowledge empowers them to make informed decisions regarding repairs and upgrades, ultimately leading to enhanced productivity.

Furthermore, a comprehensive exploration of each component fosters a deeper appreciation for the engineering behind these powerful machines. Understanding how each part contributes to overall performance allows users to delve into the mechanics of their equipment, ensuring they can address challenges effectively and maintain their machinery in top condition.

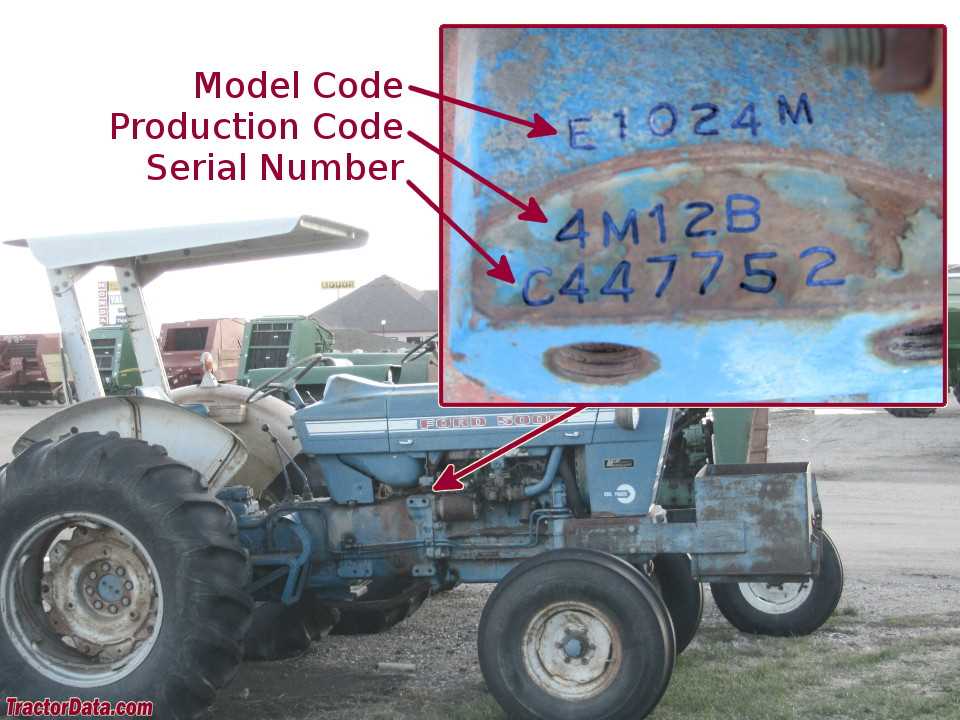

Overview of Ford 5000 Tractor

This section provides a comprehensive look at a specific agricultural machine known for its reliability and efficiency in various farming tasks. Understanding its key features and capabilities can greatly enhance operational success.

- Robust engine performance

- Versatile applications in farming

- Ease of maintenance and repair

- Comfortable operator environment

Farmers often appreciate this machine for its balance of power and fuel efficiency, making it an ultimate choice for diverse agricultural needs.

- Key specifications

- Common uses

- Maintenance tips

Delve into the intricacies of this machine to discover how it can enhance productivity and streamline operations in the field.

Key Features of the Ford 5000

This model stands out in the agricultural machinery landscape due to its remarkable combination of power, efficiency, and user-friendly design. A closer look reveals several aspects that contribute to its enduring popularity among operators and enthusiasts alike.

- Engine Performance: Equipped with a robust engine, this machine delivers reliable horsepower, enabling it to handle various tasks with ease.

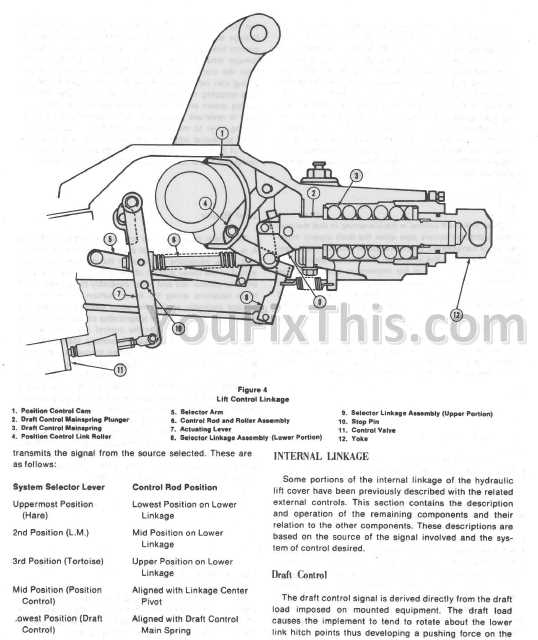

- Hydraulic System: The advanced hydraulic system provides excellent lifting capacity and versatility, making it ideal for a range of implements.

- Comfortable Operator Environment: The spacious cabin and ergonomic controls enhance user comfort, allowing for long hours of operation without fatigue.

- Durability: Built with high-quality materials, it is designed to withstand the rigors of daily use in demanding conditions.

- Versatile Attachments: Compatibility with numerous attachments expands its functionality, making it suitable for various agricultural tasks.

Overall, this model’s key features ensure that it remains a reliable choice for those seeking efficiency and performance in their farming operations.

Common Parts for Maintenance

Regular upkeep of agricultural machinery is crucial for optimal performance and longevity. Identifying essential components that require attention can help prevent costly repairs and ensure smooth operation.

- Oil Filters

- Air Filters

- Fuel Filters

- Belts and Hoses

- Battery

- Tires

Each of these elements plays a significant role in the functionality of the equipment. Keeping them in good condition can greatly enhance efficiency.

- Check oil levels regularly to maintain engine health.

- Replace air and fuel filters to ensure proper airflow and fuel delivery.

- Inspect belts and hoses for wear and tear to prevent breakdowns.

Maintaining these components is vital for seamless operation in the field.

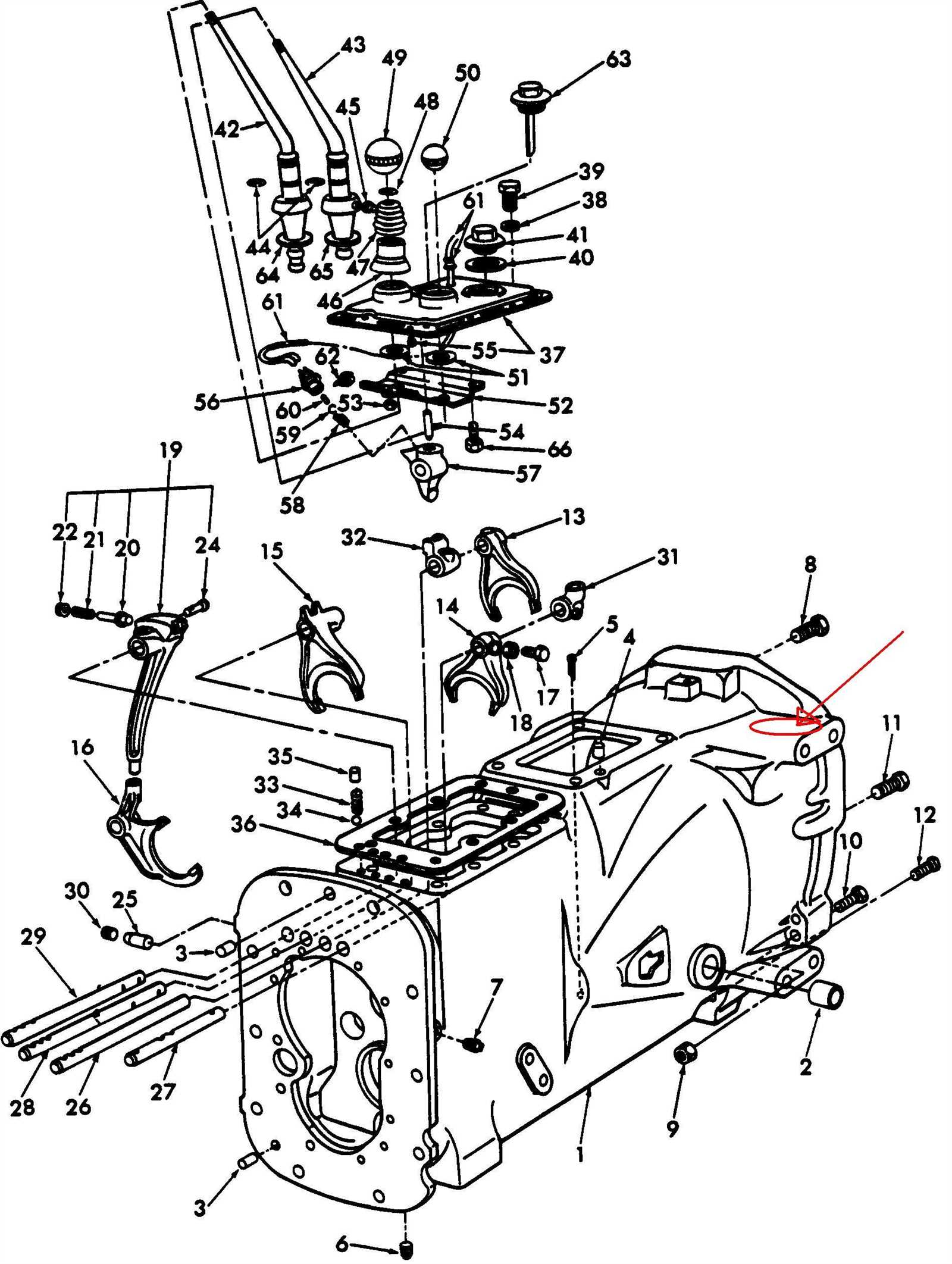

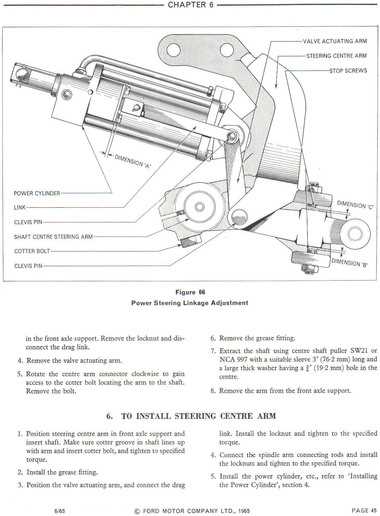

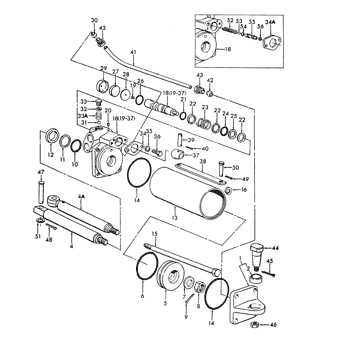

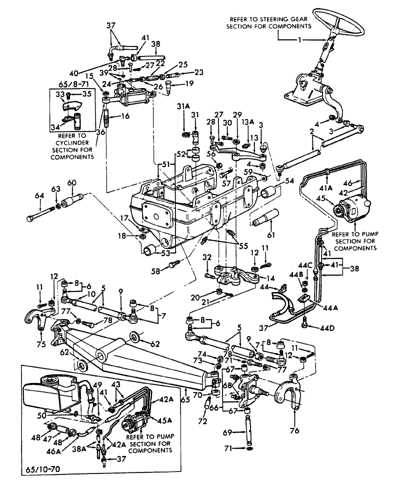

Understanding the Parts Diagram

Comprehending the visual representation of components is essential for effective maintenance and repair. Such illustrations serve as a guide to help identify each element’s function and location within a complex machine. By mastering these visuals, users can streamline troubleshooting and enhance their understanding of the equipment’s overall architecture.

Components and Their Functions

The representation typically categorizes each section, allowing individuals to quickly locate critical pieces. This structure not only aids in identifying specific items but also clarifies how various elements interact. Understanding these relationships is vital for anyone involved in upkeep or repair tasks, ensuring that the machinery operates efficiently.

Navigating the Visual Guide

To effectively use the visual aid, one should familiarize themselves with the symbols and notations employed. Each graphic often comes with labels that provide insight into the nature of the components, helping users to navigate through the intricacies of the machine with ease. A thorough grasp of these illustrations enhances the ability to diagnose issues and carry out necessary replacements or adjustments.

Where to Find Genuine Parts

When it comes to maintaining machinery, sourcing authentic components is crucial for ensuring optimal performance and longevity. Genuine replacements not only fit perfectly but also adhere to the highest quality standards, which is essential for any operator looking to keep their equipment in top shape. Understanding where to locate these trusted items can save time, effort, and money in the long run.

Authorized Dealers

One of the best ways to find reliable components is through authorized distributors. These dealers are certified to sell original items and often provide warranties that guarantee their authenticity. Establishing a relationship with a trusted dealer can lead to better pricing and access to specialized advice about your equipment.

Online Marketplaces

The internet offers a wealth of resources for those seeking quality components. Reputable online platforms often feature sections dedicated to original items, complete with customer reviews and ratings. Always verify the seller’s credentials and look for return policies to ensure satisfaction with your purchase.

Popular Aftermarket Options Available

Exploring aftermarket selections can significantly enhance the performance and longevity of your machinery. Many enthusiasts opt for these alternatives to improve efficiency, durability, and functionality.

- Upgraded air filters for better airflow and engine performance.

- Enhanced hydraulic systems for improved lifting capabilities.

- Custom seating options for increased comfort during operation.

- Performance exhaust systems to optimize engine output.

Choosing the right aftermarket components can lead to substantial improvements, ensuring that your equipment remains reliable and efficient for years to come.

Step-by-Step Repair Guide

This guide provides a comprehensive approach to restoring mechanical equipment efficiently. By following each stage methodically, you can ensure optimal performance and longevity of your machinery.

Preparation

Before beginning any repair, gather the necessary tools and components. Create a clean workspace to facilitate easy access to all materials. Understanding the machinery’s layout will also aid in identifying any issues.

Repair Process

Follow these steps for a systematic repair:

| Step | Description |

|---|---|

| 1 | Disconnect power and safety mechanisms. |

| 2 | Inspect for visible damage and wear. |

| 3 | Replace any damaged components with new ones. |

| 4 | Reassemble all parts, ensuring tight connections. |

| 5 | Test the equipment for proper functionality. |

By adhering to this structured approach, you can effectively maintain your machinery and enhance its operational reliability.

Tips for Identifying Components

Recognizing various elements of machinery can significantly enhance your maintenance and repair efficiency. By understanding how to identify each component, you can streamline your work and ensure optimal functionality.

- Consult Manuals: Always refer to the specific manuals, as they provide detailed information and visual references.

- Use Online Resources: Websites and forums dedicated to machinery can offer valuable insights and diagrams.

- Label Components: As you disassemble, label each part to avoid confusion during reassembly.

- Take Photos: Documenting your work with photographs can serve as a helpful reference.

By following these tips, you can ensure a more efficient process and reduce the risk of errors while working on your equipment.

Importance of Regular Maintenance

Here are some key reasons why regular maintenance is essential:

- Improved Reliability: Frequent checks and servicing help identify potential issues before they escalate, ensuring that the equipment operates smoothly.

- Enhanced Performance: Routine adjustments and cleanings can boost efficiency, leading to better fuel economy and productivity.

- Extended Lifespan: Consistent care can significantly increase the lifespan of machinery, allowing owners to get the most out of their investments.

- Safety Assurance: Regular inspections help ensure that all safety features are functioning properly, reducing the risk of accidents.

- Resale Value: Well-maintained equipment tends to retain a higher market value, making it more attractive to potential buyers.

By prioritizing regular maintenance, operators can ensure their machinery remains in top condition, ultimately leading to a more efficient and productive operation.

Upgrading Parts for Performance

Enhancing the components of your machinery can lead to significant improvements in efficiency and productivity. By selecting high-quality alternatives and implementing innovative modifications, operators can achieve better performance, reduced downtime, and increased longevity of their equipment. This section explores various upgrades that can be made to achieve optimal results.

Key Areas for Enhancement

When considering modifications, focus on critical areas that directly influence functionality. The most impactful changes often revolve around the engine, transmission, and hydraulic systems. Below is a summary of potential upgrades:

| Component | Upgrade Option | Benefits |

|---|---|---|

| Engine | Performance Tuning | Increased power output and efficiency |

| Transmission | Heavy-Duty Clutch | Improved durability and responsiveness |

| Hydraulic System | High-Flow Pumps | Faster cycle times and better lifting capability |

Considerations for Upgrading

Before proceeding with enhancements, it’s essential to evaluate compatibility and ensure that modifications align with the operational requirements. Consultation with experienced professionals can also provide valuable insights, ensuring that investments yield the desired improvements without compromising reliability.

Resources for Ford 5000 Owners

For enthusiasts and operators of vintage machinery, having access to reliable information and quality materials is essential for maintenance and restoration. This section aims to provide valuable resources that support the care and enhancement of these beloved machines.

Online Communities: Engaging with fellow aficionados can be incredibly beneficial. Numerous forums and social media groups are dedicated to sharing experiences, troubleshooting tips, and advice. Connecting with others who share your passion can lead to valuable insights and recommendations.

Repair Manuals: Comprehensive guides are crucial for understanding the mechanics and servicing procedures. Obtaining official manuals or well-researched alternatives can significantly aid in performing repairs and modifications, ensuring that you have the right information at your fingertips.

Parts Suppliers: Identifying reliable sources for components is vital for maintaining functionality. Many suppliers specialize in vintage machinery, offering both new and refurbished items. Researching and comparing options will help you find the best deals and quality for your needs.

Restoration Workshops: Consider reaching out to local experts or workshops that focus on similar models. These professionals can offer hands-on assistance and insights that can enhance your understanding and skills, making the restoration process smoother and more enjoyable.

Online Tutorials: Video platforms host a wealth of tutorials that cover various aspects of upkeep and restoration. Watching experienced individuals tackle common issues can provide practical knowledge and confidence for DIY enthusiasts.

Utilizing these resources can empower owners to maintain their machinery effectively, preserving its legacy for future generations.

Connecting with Other Enthusiasts

Building connections with fellow aficionados can enhance your understanding and enjoyment of machinery. Sharing experiences, knowledge, and resources creates a vibrant community where individuals can learn from one another. Whether through online forums, local clubs, or social media groups, the opportunity to engage with others who share your passion is invaluable.

Online Communities

Participating in digital platforms allows enthusiasts to delve into discussions about various models and techniques. These spaces often feature valuable insights, troubleshooting tips, and personal stories that can aid in maintenance and restoration projects. Engaging in these forums can be the ultimate way to expand your knowledge base.

Local Meetups

Attending local gatherings provides a chance to connect face-to-face with like-minded individuals. These events often showcase unique equipment and techniques, fostering a spirit of collaboration. Sharing ideas in person can lead to lifelong friendships and even mentorship opportunities.