In the world of agriculture, maintaining the efficiency and functionality of machinery is crucial. Every operator understands the importance of knowing how each element works together to ensure smooth operation. This section aims to provide insights into the essential components that contribute to optimal performance.

Exploring the intricacies of these mechanical structures allows users to troubleshoot issues effectively. By delving into the specifics of each segment, one can identify wear and tear, enabling timely replacements. Knowledge of these essential units not only enhances operational capabilities but also prolongs the life of the machinery.

For those seeking to maximize their equipment’s potential, having access to a comprehensive visual reference is invaluable. Such resources empower users to navigate the complexities of assembly and repair with confidence, ultimately leading to a more productive farming experience.

Overview of Ford 600 Tractor

This section provides a comprehensive insight into a classic piece of agricultural machinery that has been a reliable workhorse for many farmers. Its robust design and versatility have made it a preferred choice for various tasks in the field.

Key Features

- Durable construction for long-lasting performance

- Powerful engine capable of handling various implements

- User-friendly controls for enhanced operation

- Compact size for maneuverability in tight spaces

Applications

- Plowing and tilling soil

- Hauling materials and equipment

- Landscaping and maintenance tasks

- Supporting irrigation systems

Key Features of the Ford 600

This section explores the distinctive attributes of a classic agricultural machine known for its reliability and efficiency. Designed to meet the needs of various farming tasks, it integrates innovative technology with practical design elements.

Power and Performance

The engine delivers robust horsepower, enabling effective operation across diverse terrains. Its ability to handle heavy-duty tasks while maintaining fuel efficiency sets it apart in its class.

Ease of Use

Featuring user-friendly controls, this implement offers seamless operation for both experienced operators and newcomers. The intuitive layout enhances productivity, allowing users to focus on their work without distraction.

Importance of Machinery Component Illustrations

Understanding the various elements of machinery is crucial for effective maintenance and repair. Clear visual representations serve as essential tools, allowing operators and technicians to quickly identify components and their functions, leading to more efficient troubleshooting and restoration processes.

Facilitating Repairs

Visual aids streamline the repair process by providing a clear reference. When individuals can easily locate and comprehend each piece’s role, it minimizes downtime and enhances overall productivity.

Enhancing Knowledge

Educational value is significant; these illustrations not only help in repairs but also enhance understanding of machinery operation. This knowledge empowers users to perform routine checks and address issues proactively, ultimately extending the lifespan of the equipment.

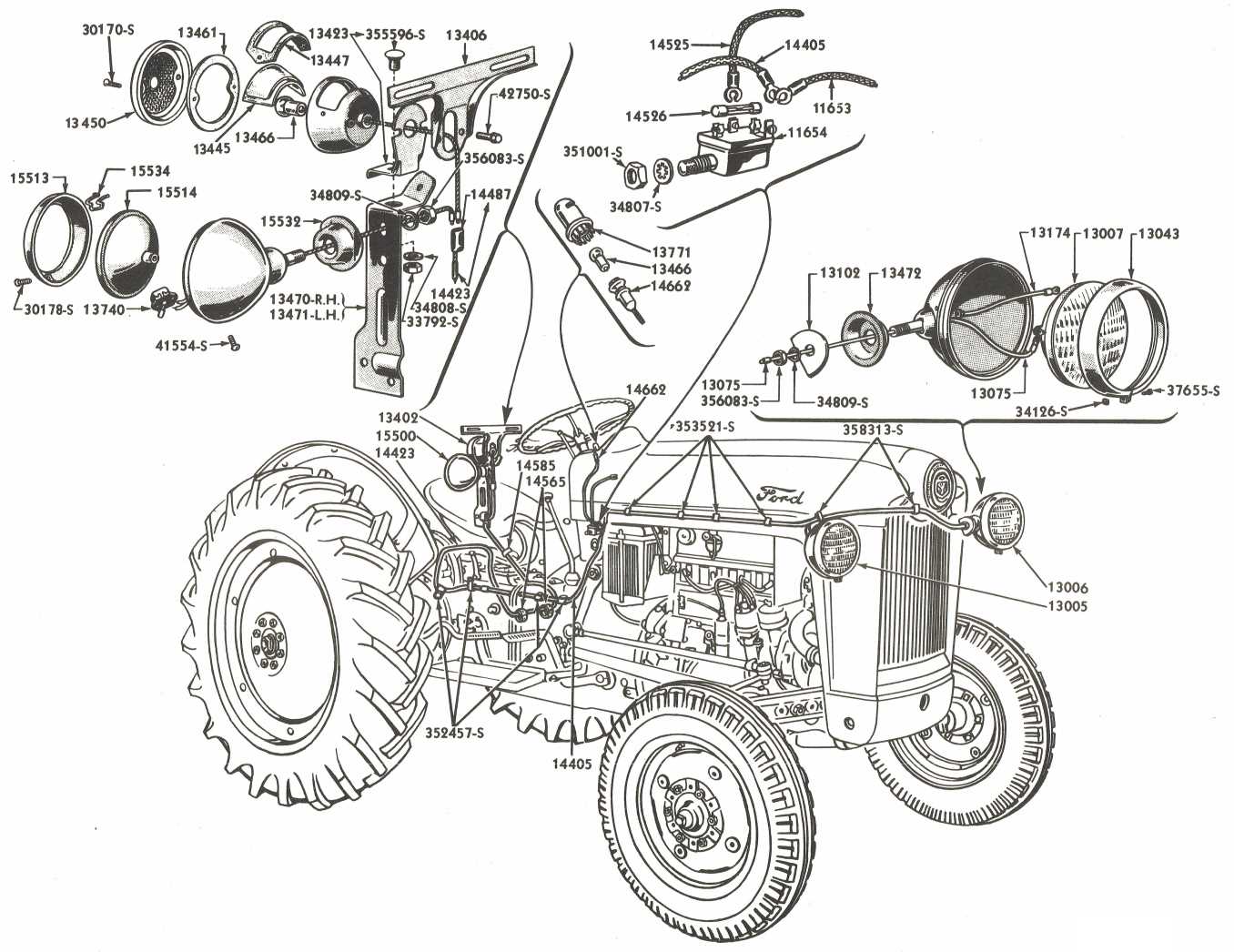

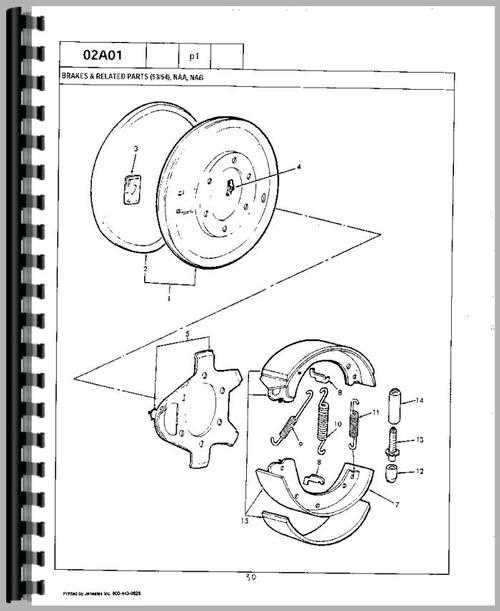

Main Components of Ford 600 Model

This section explores the essential elements that contribute to the functionality and performance of the specified model. Each component plays a vital role in ensuring optimal operation and efficiency, reflecting the intricate engineering involved in its design.

Engine: The heart of the machine, responsible for generating power and driving all operations. It features a robust design to withstand demanding tasks.

Transmission: This system facilitates the transfer of power from the engine to the wheels, allowing for smooth and adaptable movement across various terrains.

Hydraulic System: A crucial element that enables lifting and maneuvering heavy implements, enhancing versatility and operational capabilities.

Chassis: The framework that supports all components, ensuring stability and durability during operation. Its design is pivotal for weight distribution and balance.

Wheels: These provide traction and mobility, engineered to perform effectively under various conditions, ensuring reliable performance in the field.

Steering Mechanism: Essential for control and maneuverability, this system allows operators to navigate with precision, enhancing overall handling.

Cooling System: This component maintains optimal engine temperatures, preventing overheating and ensuring consistent performance during extended use.

Common Issues with Ford 600 Parts

Understanding the frequent challenges that arise with agricultural machinery components is essential for maintaining optimal performance. Various elements can deteriorate or malfunction, impacting efficiency and reliability.

- Wear and Tear: Over time, certain components can experience significant degradation.

- Oil Leaks: A common problem that can lead to decreased performance.

- Electrical Failures: Issues with wiring or connections can disrupt functionality.

- Cooling System Problems: Overheating due to radiator or coolant issues can occur.

Identifying these concerns early can prevent further complications and ensure smooth operation.

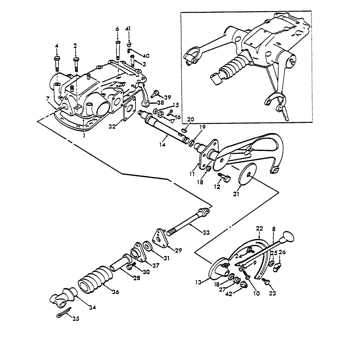

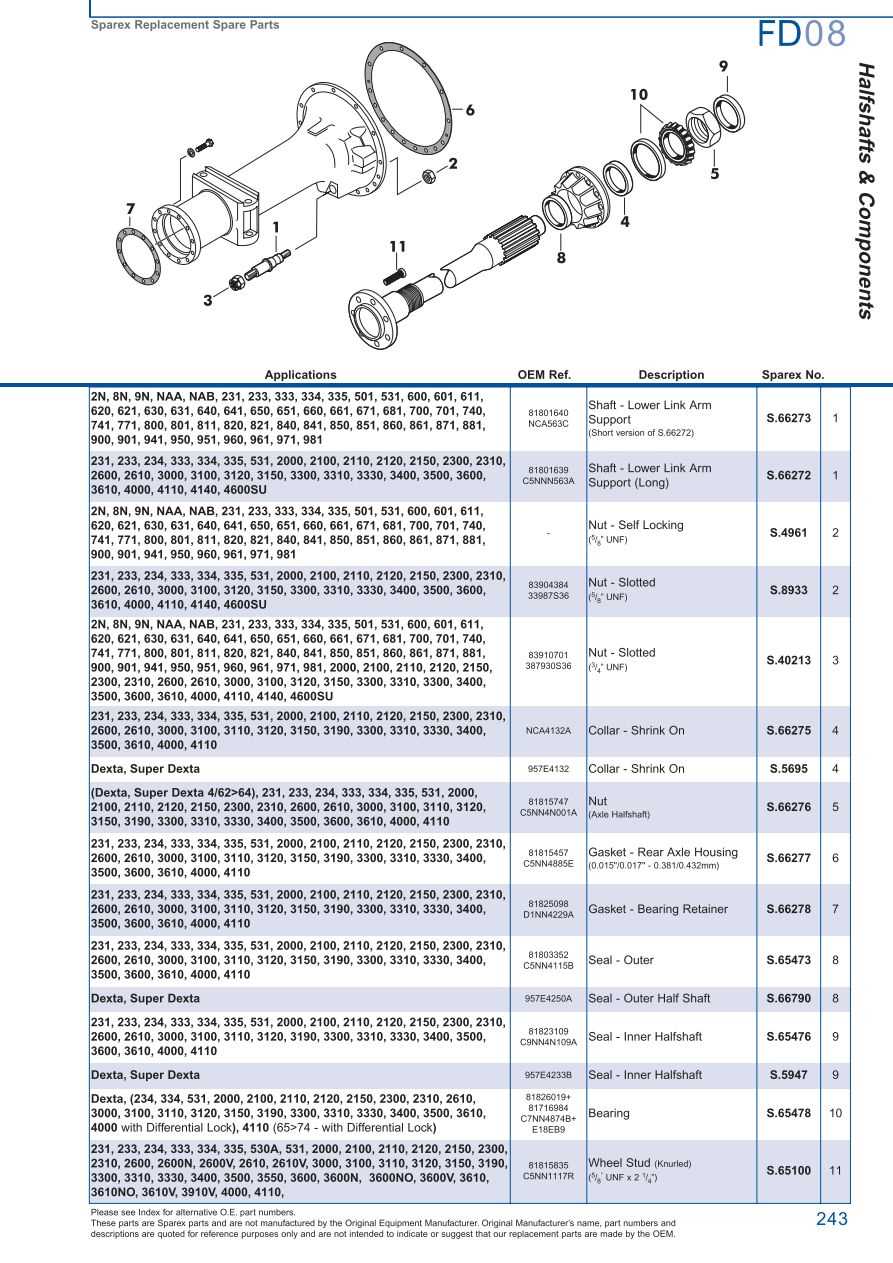

How to Read Parts Diagrams

Understanding schematic representations is essential for effective maintenance and repair. These visual aids illustrate various components, their connections, and the overall assembly, making it easier to identify what is needed for any project.

First, familiarize yourself with the symbols and notations used. Each illustration typically includes a key or legend that defines these elements, providing clarity on what each symbol represents.

Next, pay attention to the layout. Components are often arranged logically, showing how they interact within the system. Recognizing this organization can help in pinpointing specific items you may need.

Finally, take note of any reference numbers associated with each part. These identifiers are crucial when sourcing replacements or upgrades, ensuring that you acquire the correct items for your maintenance tasks.

Finding Authentic Ford 600 Parts

Acquiring genuine components for vintage machinery is essential for maintaining performance and reliability. It is crucial to ensure that replacements match the original specifications, as this guarantees compatibility and longevity. In this section, we will explore effective strategies for locating these vital elements, ensuring that enthusiasts can keep their machines in optimal condition.

Researching Trusted Sources

Start by identifying reputable suppliers known for offering authentic replacements. Online marketplaces, specialized retailers, and dedicated forums can provide valuable insights and recommendations. Engaging with fellow enthusiasts can also uncover hidden gems that may not be widely advertised.

Verification Techniques

Before making a purchase, confirm the authenticity of the components. Look for identifiable markings or part numbers that match the original specifications. Additionally, consider requesting documentation or certification from the seller to ensure you are obtaining the ultimate quality.

Comparing Aftermarket vs. Original Parts

When maintaining machinery, one critical decision involves choosing between replacement components. This choice can significantly impact performance, longevity, and overall reliability. Understanding the differences between generic options and those from the original manufacturer is essential for making informed decisions.

Advantages of Original Components

- Quality Assurance: Items from the original manufacturer are typically subject to rigorous testing and quality control.

- Compatibility: These components are designed specifically for the machinery, ensuring a perfect fit and optimal performance.

- Warranty: Original products often come with warranties, providing peace of mind and protection against defects.

Benefits of Aftermarket Options

- Cost-Effectiveness: Generic alternatives are often more affordable, making them an attractive option for budget-conscious consumers.

- Variety: There is a wider selection available, allowing users to choose from various brands and features.

- Availability: Aftermarket items are generally easier to find, especially for older or less common models.

Ultimately, the choice between these options depends on individual needs, preferences, and the specific requirements of the equipment in question.

Maintenance Tips for Ford 600 Tractor

Regular upkeep is essential for ensuring optimal performance and longevity of your machinery. Proper care can prevent costly repairs and enhance the efficiency of your equipment. Below are some essential guidelines to keep your machine in top shape.

1. Routine Inspections: Conduct regular checks of all vital components. Look for signs of wear and tear, leaks, or any unusual noises. Early detection can save you time and resources.

2. Fluid Levels: Always monitor and maintain proper fluid levels, including oil, coolant, and hydraulic fluids. This is crucial for smooth operation and to prevent overheating or mechanical failures.

3. Cleanliness: Keep the exterior and interior clean. Remove dirt and debris from filters and air intakes. A clean machine runs more efficiently and is less prone to issues.

4. Lubrication: Regularly lubricate moving parts to reduce friction and wear. Consult the manufacturer’s guidelines for recommended lubricants and intervals.

5. Battery Maintenance: Check the battery regularly for corrosion and ensure it is securely connected. Clean terminals and ensure proper electrolyte levels to maintain performance.

6. Tire Care: Inspect tires for proper inflation and tread wear. Adequate tire pressure ensures better traction and fuel efficiency.

7. Seasonal Preparations: Before harsh weather, prepare your equipment by checking antifreeze levels, inspecting belts, and storing it properly to avoid damage during downtime.

Following these maintenance tips will help you maximize the performance and lifespan of your machinery, ensuring it remains reliable for all your tasks.

Where to Buy Replacement Parts

Finding suitable components for your agricultural machinery can be essential for maintaining optimal performance and longevity. A variety of sources offer these essential items, ensuring that you can keep your equipment running smoothly. Whether you’re seeking OEM alternatives or aftermarket options, knowing where to look can save you time and money.

Online Retailers

The internet is a valuable resource for sourcing replacement items. Numerous online platforms specialize in agricultural equipment, providing extensive catalogs that allow you to compare prices and availability. Major e-commerce websites often feature user reviews, which can help you make informed decisions about quality and compatibility.

Local Dealers and Suppliers

Your nearest dealerships and suppliers can be a reliable option for obtaining components. They often stock a range of original items and may offer advice tailored to your specific model. Establishing a relationship with a local provider can also lead to personalized service and potential discounts on future purchases.

Step-by-Step Repair Guide

This section offers a comprehensive approach to effectively addressing mechanical issues, ensuring smooth operation and longevity of your equipment. By following these sequential instructions, you’ll gain confidence in troubleshooting and resolving common problems.

Identifying Issues

Begin by thoroughly assessing the machinery. Listen for unusual sounds, check for leaks, and observe performance inconsistencies. Document any symptoms to streamline the repair process.

Gathering Tools and Materials

Next, collect the necessary tools and replacement components. Having everything on hand will facilitate a more efficient repair experience. Refer to your service manual for specific requirements related to your model.

Enhancing Performance with Upgrades

Improving efficiency and power in machinery is essential for maximizing productivity. Various enhancements can be made to achieve superior performance, allowing operators to get the most out of their equipment. These upgrades can range from simple modifications to comprehensive overhauls, each contributing to better functionality and reliability.

One of the most effective ways to boost performance is through engine modifications. Upgrading components such as the air intake system and exhaust can significantly improve airflow, leading to increased horsepower and torque. Improved combustion efficiency not only enhances performance but also optimizes fuel consumption, making operations more cost-effective.

Another key area for enhancement involves the transmission system. By installing higher-quality gears or even exploring modern transmission technologies, operators can achieve smoother shifting and better power distribution. This results in improved traction and overall handling, making the equipment more responsive to various tasks.

Additionally, focusing on the hydraulic system can lead to remarkable improvements in lifting capacity and speed. Upgrading hydraulic pumps and cylinders enhances responsiveness, allowing for quicker and more efficient operation, particularly in demanding environments.

Finally, regular maintenance and thoughtful upgrades not only prolong the lifespan of the machinery but also ensure that it operates at peak performance. Investing in quality components and staying updated with the latest advancements can make a significant difference in overall productivity and effectiveness.

Customer Reviews on Ford 600 Parts

When it comes to maintaining and enhancing the performance of classic machinery, feedback from users is invaluable. Reviews offer insights into the quality, reliability, and functionality of components, allowing potential buyers to make informed decisions. This section highlights what customers are saying about various elements associated with this specific model, focusing on their experiences and satisfaction levels.

Quality and Durability

Many users emphasize the robustness of the components, noting that they stand the test of time even under heavy use. One reviewer stated, “I’ve used several replacement items over the years, and the durability has exceeded my expectations.” This sentiment is echoed by others who appreciate the high-quality materials used in the construction, which contribute to prolonged life and less frequent need for replacements.

Ease of Installation

Installation processes vary widely, but numerous customers report that components related to this model are designed with the user in mind. One enthusiastic owner mentioned, “The fit was perfect, and I completed the installation without any specialized tools.” Such positive feedback indicates that many find the installation straightforward, leading to a smoother maintenance experience.