Understanding the intricate network of mechanical elements in outdoor equipment is crucial for maintaining its efficiency and prolonging its lifespan. Each element plays a significant role in ensuring the overall functionality, working together to achieve optimal performance. This section provides insights into the key elements that make up the machine, focusing on how they interact and the importance of regular upkeep.

The following overview covers the essential units responsible for various operational tasks. With proper attention to these details, users can ensure smooth operation and avoid potential breakdowns. We’ll explore the structure, role, and interaction of these components to help you better understand the machine’s inner workings.

Overview of John Deere 260 Parts

This equipment is designed to provide reliable and efficient performance, thanks to its well-constructed and durable components. Each element of the machine works in harmony to ensure smooth operation and long-term usability in various working conditions.

Main Components

The essential elements include the drive system, which ensures proper movement, and the engine that powers the machine. Other significant parts, such as the cutting mechanisms, contribute to its effectiveness in completing specific tasks. These components are designed for robustness and durability.

Support Systems

Various support systems, including hydraulic and cooling mechanisms, play a critical role in maintaining the machine’s stability and operational efficiency. These systems are designed to reduce wear and tear, ensuring the equipment can function in challenging environments for extended periods.

Engine Components and Their Functions

The internal combustion system is comprised of various interconnected elements that work together to ensure smooth operation and power generation. Each component plays a critical role in maintaining efficiency, reliability, and performance during the machine’s operation. Understanding these elements will help in troubleshooting, maintenance, and optimal usage.

Main Engine Components

- Cylinder: The core part where fuel combustion occurs, generating energy for movement.

- Piston: Moves within the cylinder, converting pressure into mechanical force.

- Crankshaft: Transforms the linear motion of the piston into rotational energy.

- Valves: Control the intake of air and fuel and the exhaust of gases during operation.

- Spark Plug: Ignites the fuel-air mixture in gasoline engines, starting the combustion process.

Supporting Systems

- Steering Wheel: This is the interface used to direct the vehicle. Its design allows for easy grip and rotation.

- Steering Column: Connecting the wheel to the lower components, the column transfers motion and input from the driver to the mechanical system.

- Steering Gearbox: This part converts the rotary motion of the wheel into the necessary movement for the wheels, ensuring smooth direction changes.

- Tie Rods: These links connect the steering gearbox to the wheels, transmitting the movement required for directional shifts.

- Spindles: Attached to the wheels, spindles pivot when the wheel is tu

Understanding the Tractor’s Electrical System

The electrical system of any heavy-duty machine plays a critical role in ensuring smooth operation. It powers various components, from ignition to lighting, allowing the operator to efficiently control different functionalities. A properly functioning setup prevents mechanical failures and helps maintain consistent performance.

Component Function Battery Supplies the initial power to start the engine and run essential systems. Alternator Generates electricity to recharge the battery and power additional components during operation. Wiring Harness Distributes electrical energy to various parts, ensuring all systems receive power as needed. Starter Motor Engages the engine by converting electrical energy from the Blades and Cutting Deck Assembly

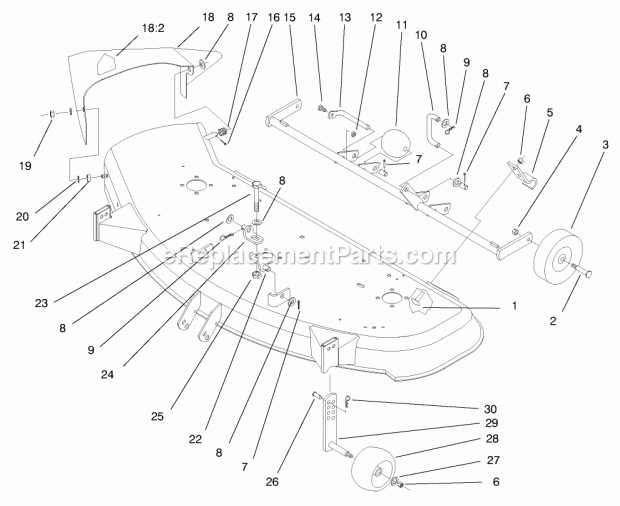

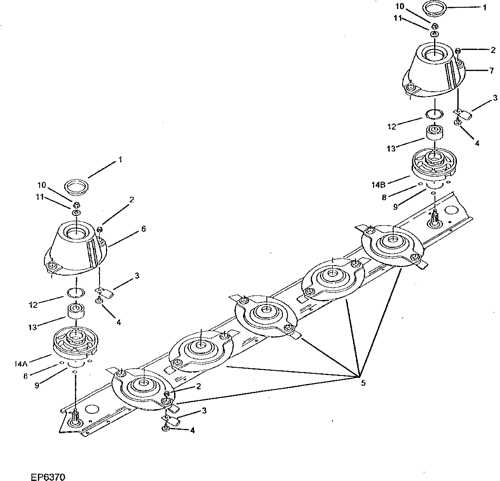

The blades and the mechanism responsible for cutting vegetation are key components to ensure efficient performance. The structure supporting the blades plays an essential role in achieving an even and precise trim.

Proper maintenance and assembly of these components are crucial for consistent operation. Here is an overview of the main elements involved:

- Blades: Responsible for the precise cutting of grass, they must be sharpened and balanced for optimal results.

- Deck frame: This structure holds the blades and ensures they are at the correct height for trimming.

- Spindles: These connect the blades to the power source and allow them to rotate at high speeds.

- Pulleys: They transfer the engine’s power to the cutting mechanism, facilitating blade movement.

Understanding how these parts interact is vital for proper assembly and long-term durability.

Fuel System Diagram and Parts

The fuel system is a crucial component of any outdoor equipment, ensuring the engine receives the necessary fuel for optimal performance. Understanding the layout and individual elements of this system can help with maintenance and troubleshooting.

This section outlines the key components involved in the fuel delivery process, including their functions and interactions within the system.

Component Description Fuel Tank Holds the gasoline needed for operation, designed to prevent leaks and provide easy access for refueling. Fuel Pump Moves fuel from the tank to the engine, maintaining appropriate pressure for consistent fuel delivery. Fuel Filter Removes impurities and contaminants from the fuel, protecting the engine from damage and ensuring efficient operation. Carburetor or Fuel Injector Mixes fuel with air in the correct ratio for combustion, crucial for engine efficiency and performance. Fuel Lines Hoses that transport fuel between the tank, pump, filter, and engine, designed to withstand pressure and prevent leaks. Transmission Components and Their Functions

The transmission system plays a crucial role in ensuring the efficient operation of any gardening machinery. It is responsible for transferring power from the engine to the wheels, allowing the equipment to move smoothly and perform various tasks. Understanding the different elements of this system and their specific functions can greatly enhance the performance and longevity of the equipment.

- Gearbox: This component regulates the speed and torque delivered to the wheels, facilitating optimal performance for different applications.

- Drive Belt: A vital link that transfers power from the engine to the transmission, ensuring smooth operation and preventing slippage.

- Clutch Assembly: This mechanism allows for the engagement and disengagement of the drive system, providing control over movement and enabling easy starts and stops.

- Axles: These are responsible for transferring the rotational force from the transmission to the wheels, allowing for efficient movement and maneuverability.

- Fluid Reservoir: This component houses the hydraulic fluid necessary for the operation of the transmission system, ensuring proper lubrication and cooling.

Each element within the transmission system has its own distinct function, contributing to the overall efficiency and effectiveness of the equipment. Regular maintenance and understanding of these components can lead to better performance and a longer lifespan of the machinery.

Brake System Breakdown

The braking mechanism is essential for ensuring safety and control while operating various machines. This system is designed to effectively reduce speed or bring the equipment to a complete stop when necessary. Understanding the components and their functions can help in maintaining optimal performance.

Components of the Braking Mechanism

This system comprises several key elements that work together to facilitate smooth operation. These include the brake pedal, which the operator presses to engage the system, and the brake discs or drums that provide the necessary friction to slow down the machine. Additionally, hydraulic lines and fluid are crucial for transferring force from the pedal to the braking components.

Maintenance and Troubleshooting

Regular inspection and maintenance of the braking system are vital to ensure its reliability. Common issues may include worn-out brake pads or fluid leaks. Identifying these problems early can prevent further damage and ensure safe operation. Always consult the equipment manual for specific maintenance guidelines.

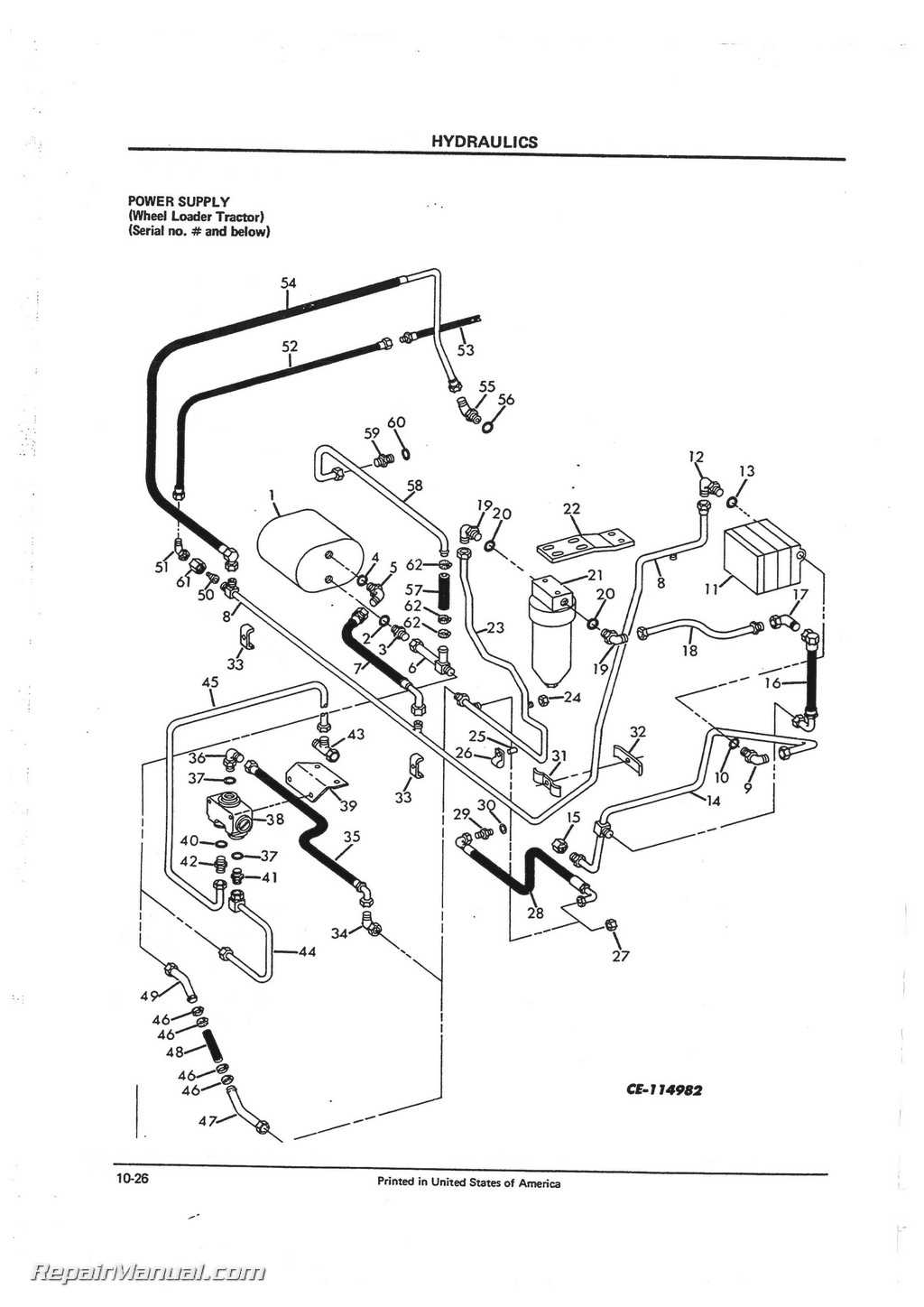

Hydraulic System Components

The hydraulic system is essential for the effective operation of various machinery. It utilizes fluid dynamics to transmit power and facilitate movement, making it a critical element in many mechanical applications.

Key elements of the hydraulic system include:

- Hydraulic Pump: This component generates the flow of hydraulic fluid, enabling the system to function efficiently.

- Actuators: These devices convert hydraulic energy into mechanical movement, allowing for precise control of various operations.

- Hydraulic Fluid: The medium through which power is transmitted within the system; its properties are crucial for performance.

- Valves: Control the flow and pressure of the hydraulic fluid, ensuring that the system operates smoothly and safely.

- Reservoir: Stores hydraulic fluid, providing a supply for the pump and maintaining system pressure.

Understanding these components is vital for troubleshooting and maintaining the hydraulic system effectively.

Front Axle and Suspension Components

The front axle and suspension system are crucial elements that contribute to the overall performance and stability of the vehicle. These components work together to ensure a smooth ride, providing support and control during operation. Proper maintenance and understanding of these parts can enhance functionality and extend the lifespan of the machine.

Key Elements of the Front Axle

The front axle serves as the foundation for the steering mechanism, allowing for controlled movement and maneuverability. It typically includes various fittings that connect to the wheels, ensuring even distribution of weight and aiding in traction. Regular inspections of these components can prevent wear and tear, ensuring optimal performance.

Suspension System Overview

The suspension system comprises multiple elements that absorb shocks and vibrations, enhancing comfort while operating. Springs, shock absorbers, and linkages are essential for maintaining stability and alignment, especially on uneven terrain. Keeping these components in good condition is vital for a reliable and efficient driving experience.

Exhaust System Overview

The exhaust mechanism is a crucial component in ensuring the efficient operation of an engine. It plays a significant role in directing harmful gases away from the combustion area, thereby enhancing performance and reducing emissions. Understanding the various elements of this system is essential for effective maintenance and troubleshooting.

Components of the Exhaust System

The exhaust system comprises several key components, including the manifold, pipes, muffler, and catalytic converter. Each part serves a specific function, contributing to the overall effectiveness of the system. The manifold collects exhaust gases from the engine, while the pipes transport these gases to the muffler, which minimizes noise and reduces back pressure.

Importance of Proper Maintenance

Regular inspection and maintenance of the exhaust system are vital to ensure optimal functionality. Failure to address issues such as leaks or blockages can lead to decreased performance and increased emissions. Routine checks can help identify potential problems early, preventing costly repairs and ensuring compliance with environmental standards.

Cooling System Components

The cooling system plays a crucial role in maintaining optimal operating temperatures within machinery. Its effective functioning ensures that the engine runs smoothly, preventing overheating and potential damage. Various elements contribute to the efficiency of this system, each designed to perform specific tasks.

- Radiator: This component dissipates heat from the coolant, allowing it to cool before circulating back to the engine.

- Water Pump: Responsible for circulating coolant throughout the system, ensuring consistent temperature regulation.

- Thermostat: Regulates the flow of coolant based on temperature, allowing the engine to reach optimal operating conditions.

- Coolant Hoses: Flexible tubes that transport coolant to and from the various components of the cooling system.

- Cooling Fan: Helps to increase airflow through the radiator, enhancing the cooling process.

Each of these components plays a vital role in ensuring the longevity and efficiency of the machinery. Regular maintenance and timely replacement of worn parts are essential to keep the cooling system functioning effectively.

Maintenance Tips

Regular upkeep is essential for ensuring the longevity and efficiency of your outdoor equipment. Implementing proper care techniques can prevent premature wear and enhance performance over time. By following a few straightforward maintenance practices, you can keep your machine in optimal condition.

Start by routinely checking fluid levels, including oil and coolant, to ensure they remain at appropriate levels. This helps in preventing engine overheating and maintaining smooth operation. Additionally, replace filters as recommended to keep contaminants at bay and promote better functionality.

Inspect the cutting components frequently for signs of damage or dullness. Sharpening or replacing blades as necessary will improve cutting performance and reduce strain on the engine. Furthermore, cleaning the equipment after use can prevent the buildup of debris and extend its life.

Finally, follow the manufacturer’s guidelines for seasonal storage, including draining fuel or using stabilizers. This proactive approach not only safeguards your investment but also prepares your equipment for reliable performance when it’s needed most.

Steering System and Key Parts

The steering mechanism plays a crucial role in ensuring smooth and precise navigation of the vehicle. It is designed to provide control over the direction, making it easier to maneuver in various conditions. The following key components are essential for the proper function of this system.