The effective maintenance of outdoor equipment relies heavily on a clear understanding of its individual elements. Each section of a machine serves a vital role in ensuring optimal performance and longevity. By comprehending the function and placement of various components, users can troubleshoot issues more efficiently and execute repairs when necessary.

Moreover, having access to visual representations of machinery assists in recognizing the intricate relationships between different parts. Such illustrations not only enhance the understanding of assembly and disassembly processes but also serve as valuable references during routine maintenance. A comprehensive overview of each segment empowers users to make informed decisions regarding repairs and upgrades.

In this section, we will explore the key features of a particular model, detailing its various components and their functions. This knowledge will aid enthusiasts and professionals alike in maximizing the efficiency of their equipment while minimizing downtime due to repairs.

This section provides a comprehensive look into the key components of the featured machine, focusing on its essential features and functionalities. By understanding the various elements that make up this equipment, users can enhance their maintenance efforts and ensure optimal performance. Each component plays a critical role in the overall operation, making it vital to familiarize oneself with the layout and functions.

Key Features and Functions

The machinery in question is designed with user-friendly attributes that cater to a wide range of tasks. Its robust construction ensures durability, while innovative design aspects facilitate ease of use. Users can expect reliable performance, allowing for efficient yard work, whether it involves mowing, hauling, or other landscaping activities.

Maintenance Considerations

Key Features of the Lawn Tractor

This section highlights the essential attributes that make this type of outdoor equipment stand out in gardening and maintenance tasks. Understanding these characteristics can help users appreciate its versatility and functionality in various landscapes.

Robust Build Quality

Durability is a critical aspect of this equipment, ensuring long-lasting performance even in challenging conditions. The construction often includes:

- High-strength materials that resist wear and tear.

- Weather-resistant components for reliable outdoor use.

- Solid chassis design to support heavy-duty applications.

Advanced Cutting Mechanism

The cutting system is engineered to provide a clean and precise finish. Key features include:

- Adjustable cutting heights to accommodate different grass types.

- Efficient blade design that enhances performance while minimizing fuel consumption.

- Easy access to the cutting deck for maintenance and cleaning.

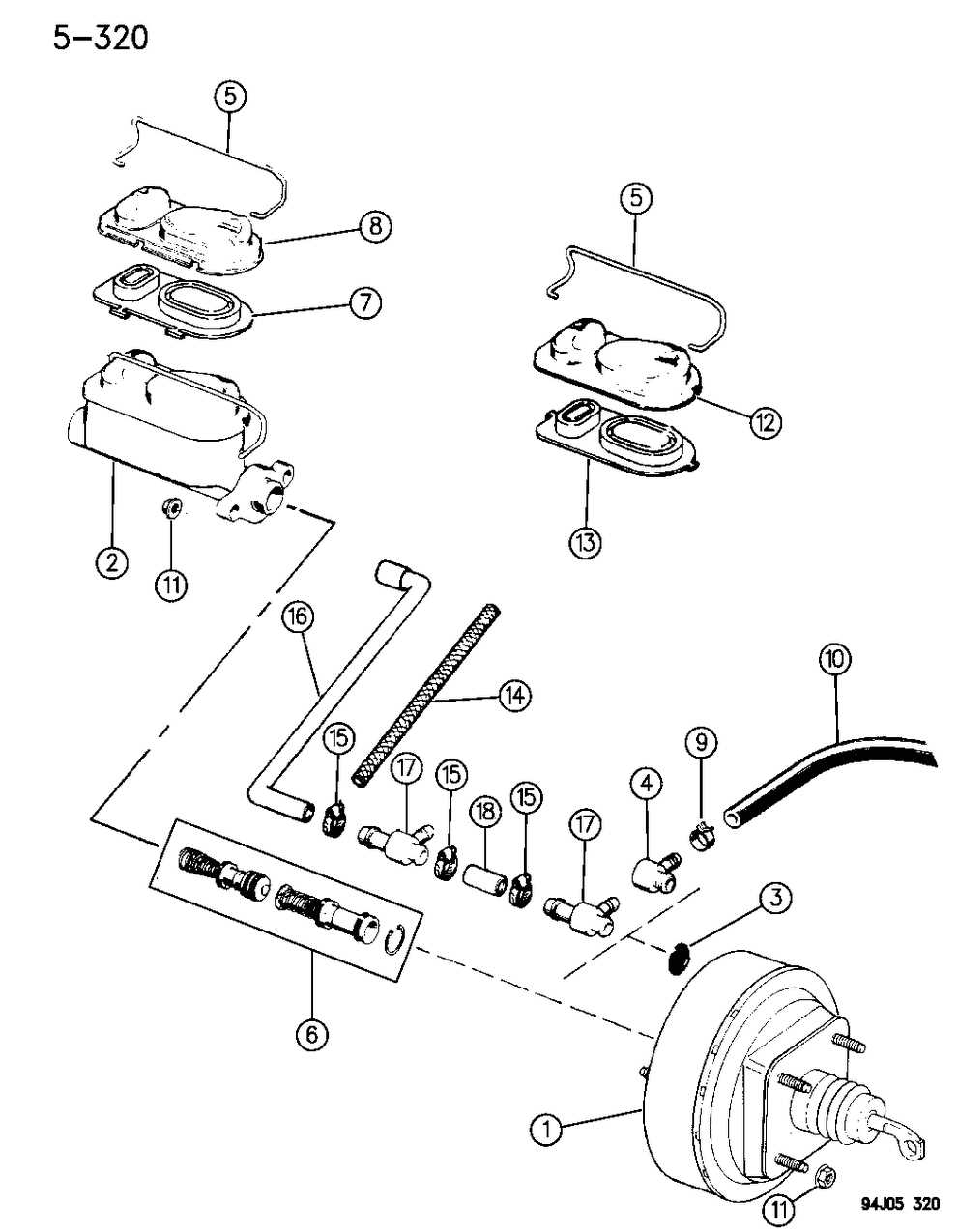

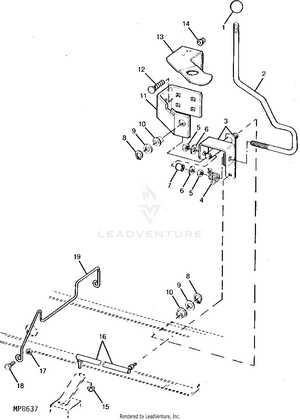

Identifying Major Components and Parts

This section focuses on the key elements that constitute a specific type of outdoor machinery. Understanding the essential components can enhance functionality, streamline repairs, and aid in maintenance tasks. By familiarizing oneself with these significant features, users can ensure optimal performance and longevity of their equipment.

Below is a table highlighting some of the critical components commonly found in this type of machinery:

| Component | Description |

|---|---|

| Engine | The primary power source, converting fuel into mechanical energy to drive the machine. |

| Transmission | Responsible for transferring power from the engine to the wheels, enabling movement and speed control. |

| Deck | The housing that protects internal mechanisms and often serves as a support structure for various parts. |

| Wheels | Facilitate movement and stability, enabling the equipment to navigate various terrains. |

| Control Panel | Interface for the operator, providing controls for starting, stopping, and adjusting settings. |

Understanding the Drive System Layout

The drive system is a crucial component in any outdoor equipment, playing a pivotal role in its overall functionality. By grasping the layout of this mechanism, users can enhance their comprehension of how power is transmitted from the engine to the wheels, ensuring smooth operation and optimal performance.

This assembly typically comprises various elements, including belts, pulleys, and gears, each working in harmony to facilitate movement. The arrangement of these components is designed to maximize efficiency, allowing the machine to navigate diverse terrains with ease. Familiarity with the drive configuration can also assist in troubleshooting issues and performing maintenance tasks effectively.

Understanding the intricacies of the drive system layout empowers operators to make informed decisions when it comes to repairs or upgrades. By visualizing how each part interacts within the assembly, users can appreciate the engineering that goes into creating reliable outdoor machinery. Ultimately, this knowledge contributes to better care and longevity of the equipment.

Electrical System Overview

The electrical system in outdoor machinery plays a crucial role in ensuring efficient operation and functionality. It consists of various components that work together to provide power and control essential features, enhancing performance and user experience.

Power Source is the backbone of the system, typically consisting of a reliable battery that supplies electricity for starting the engine and powering various accessories. This energy source must be maintained regularly to prevent issues that could hinder performance.

Another vital component is the starter motor, which is responsible for initiating engine operation. The effective functioning of the starter motor is essential for seamless ignition and overall machinery readiness.

The system also includes wiring harnesses that facilitate the connection between different electrical components. These harnesses are designed to withstand the rigors of outdoor use, providing a safe and organized way to distribute electrical power throughout the equipment.

Additionally, fuses and relays are critical for protecting the electrical system from overloads and ensuring safe operation. These elements act as safeguards, preventing damage to the components and maintaining system integrity.

Understanding the electrical layout is essential for troubleshooting and maintenance. Regular inspections and timely replacements of faulty components can greatly enhance the reliability and longevity of the machinery, ensuring optimal performance during operation.

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your outdoor equipment requires regular upkeep and attention to detail. Adopting a systematic approach to maintenance not only enhances performance but also minimizes the risk of unexpected breakdowns.

Regular Inspections: Conduct frequent checks of essential components to identify wear and tear. Look for signs of damage or looseness in belts, blades, and other crucial elements.

Keep It Clean: A clean machine operates more efficiently. Remove dirt, grass clippings, and debris from all surfaces, especially around the engine and air intake. This prevents overheating and promotes optimal airflow.

Fluid Levels: Monitor and maintain appropriate levels of oil, coolant, and fuel. Changing the oil regularly and ensuring that filters are clean will keep the engine running smoothly.

Sharpen Blades: Dull cutting edges can strain the engine and lead to uneven results. Regularly sharpen blades to maintain a clean cut and promote healthy growth in your yard.

Battery Care: Inspect the battery terminals for corrosion and ensure a secure connection. Clean terminals as needed and check the battery charge regularly to avoid starting issues.

Seasonal Maintenance: Adjust your maintenance routine according to the season. Winterizing your equipment can prevent damage during colder months, while spring preparation ensures it’s ready for use.

By following these guidelines, you can help ensure that your outdoor equipment remains in peak condition, delivering reliable performance throughout its lifespan.

Common Replacement Parts Explained

Understanding the essential components of your machine is crucial for maintaining its optimal performance. This section delves into frequently replaced items that ensure smooth operation and longevity. By being aware of these elements, users can better manage maintenance and repairs, avoiding potential downtimes.

Belts are vital for transferring power between different parts of the machinery. Over time, they can wear out or break due to regular use. Replacing worn belts promptly can prevent further damage and maintain efficiency.

Filters play a significant role in keeping the engine clean by trapping dirt and debris. Regularly replacing air and oil filters helps improve engine performance and prolong its life. Neglecting to do so can lead to decreased efficiency and costly repairs.

Blades are essential for achieving a clean cut. Dull or damaged blades can affect the overall performance, making it necessary to replace them when they show signs of wear. Sharp blades ensure a healthier appearance for your green spaces.

Battery health is crucial for reliable starting and operation. As batteries age, they may lose their ability to hold a charge, necessitating replacement. Keeping a fresh battery on hand ensures your equipment starts without hassle.

Tires are another component that often requires attention. Over time, tires can wear down, affecting traction and handling. Regularly checking tire condition and replacing them when necessary can enhance stability and safety.

By being proactive and familiar with these common components, operators can enhance their machinery’s performance and extend its lifespan, ultimately leading to more effective and efficient operation.

Safety Precautions During Repairs

Engaging in maintenance and repair tasks requires a thorough understanding of safety measures to ensure both personal well-being and the longevity of the equipment. By adhering to essential guidelines, individuals can minimize the risk of accidents and injuries while working on machinery.

Essential Safety Gear

Wearing appropriate protective equipment is crucial. This includes safety goggles to shield the eyes from debris, gloves to protect hands from sharp edges and chemicals, and sturdy footwear to prevent slips and falls. Always choose gear that meets safety standards for the specific tasks at hand.

Workspace Considerations

Maintaining a tidy and organized workspace is vital for safe operations. Ensure that tools are within easy reach and stored properly when not in use. Keep the area well-ventilated to avoid inhaling harmful fumes, and ensure that any spills are cleaned up immediately to prevent slips. Lastly, always have a fire extinguisher readily accessible in case of emergencies.

Resources for Obtaining Diagrams

Accessing comprehensive visual guides is essential for effective maintenance and repair tasks. Various sources offer valuable information to help users identify and source the necessary components for their machinery. Whether seeking manuals or online platforms, a wealth of resources exists to support individuals in their endeavors.

Online Platforms

Numerous websites specialize in providing detailed illustrations and manuals for various equipment. These platforms often feature search functions that allow users to easily locate the specific information they need. Community forums are also beneficial, where enthusiasts share insights and files related to their experiences.

Manufacturer Resources

Many manufacturers provide official documentation that includes essential visuals and specifications. Visiting the manufacturer’s website can yield downloadable content, including technical sheets and maintenance guides. Additionally, reaching out to authorized dealers can provide access to specialized resources and expert advice.

Where to Find Compatible Parts

Locating suitable components for your machinery can be a straightforward process if you know where to look. Whether you are in need of replacement items or upgrades, a variety of resources are available to assist you in finding exactly what you require. Below are some options to consider when searching for compatible elements.

| Source | Description |

|---|---|

| Authorized Dealers | Official dealers often provide a wide range of original equipment, ensuring quality and compatibility for your specific model. |

| Online Retailers | Numerous e-commerce platforms specialize in machinery components, offering competitive pricing and customer reviews to aid your decision. |

| Local Repair Shops | Local establishments may stock essential items and can provide expert advice on what will work best for your equipment. |

| Manufacturer’s Website | Visiting the manufacturer’s official site can provide access to manuals, catalogs, and ordering information for the right components. |

| Online Marketplaces | Marketplaces allow individuals to buy and sell used or new components, providing an opportunity to find rare or hard-to-get items. |