Understanding how various elements of a mechanical system fit together is crucial for ensuring its smooth operation. Whether you’re maintaining or repairing, knowing how different sections connect and function helps in preventing issues and improving efficiency.

In complex machines, each component plays a role in overall performance, from the engine to smaller mechanisms that influence movement and control. Recognizing these connections allows for easier troubleshooting and long-term upkeep.

Having a clear guide to all the essential elements not only simplifies the task but also aids in better planning when it comes to adjustments or replacements, ensuring everything continues to run smoothly.

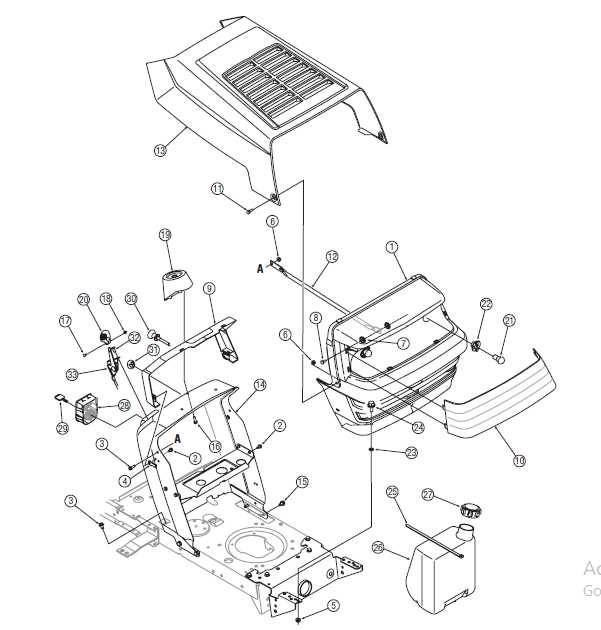

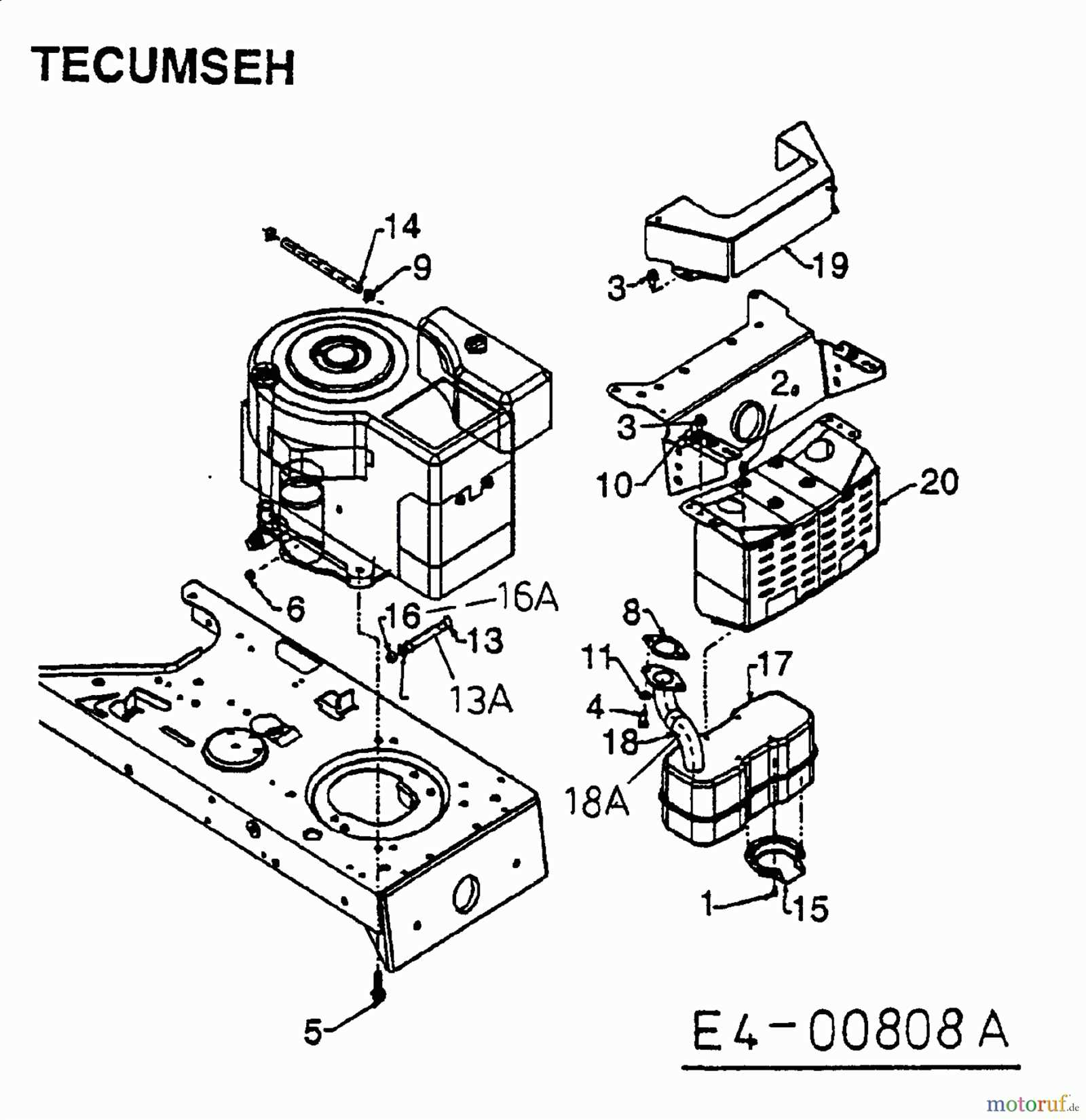

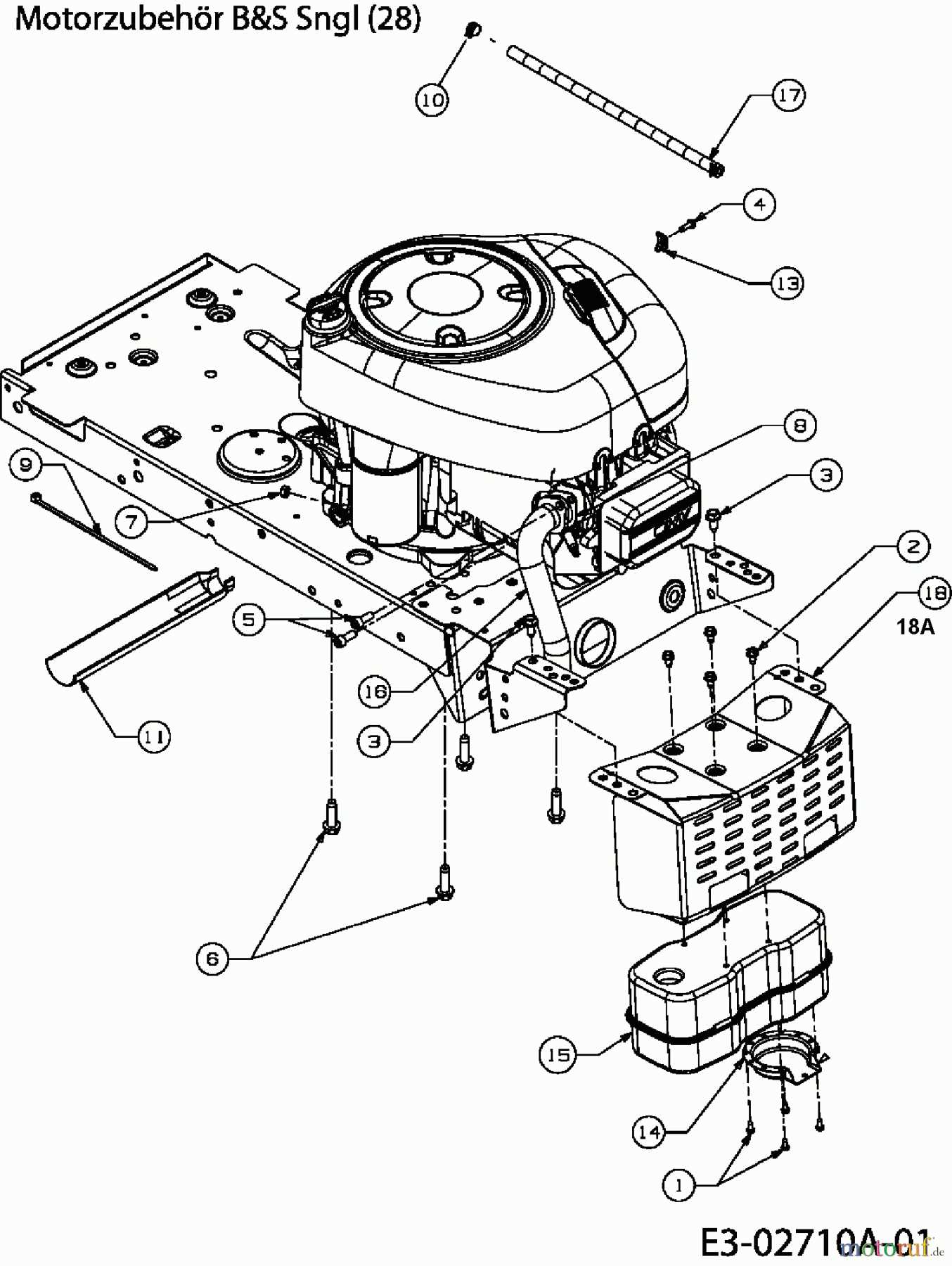

Understanding the Key Components of a Lawn Tractor

To ensure smooth and efficient operation, it’s important to familiarize yourself with the essential elements of your outdoor power equipment. These parts work together to handle various tasks, and understanding their roles can help with regular maintenance and troubleshooting.

Below is a breakdown of the primary components found in most machines used for garden upkeep:

- Engine: The powerhouse that provides the necessary energy for movement and operation. It typically runs on fuel and requires regular servicing.

- Transmission: Responsible for transferring power from the engine to the wheels, allowing for speed control and direction changes.

- Steering System: This mechanism lets the

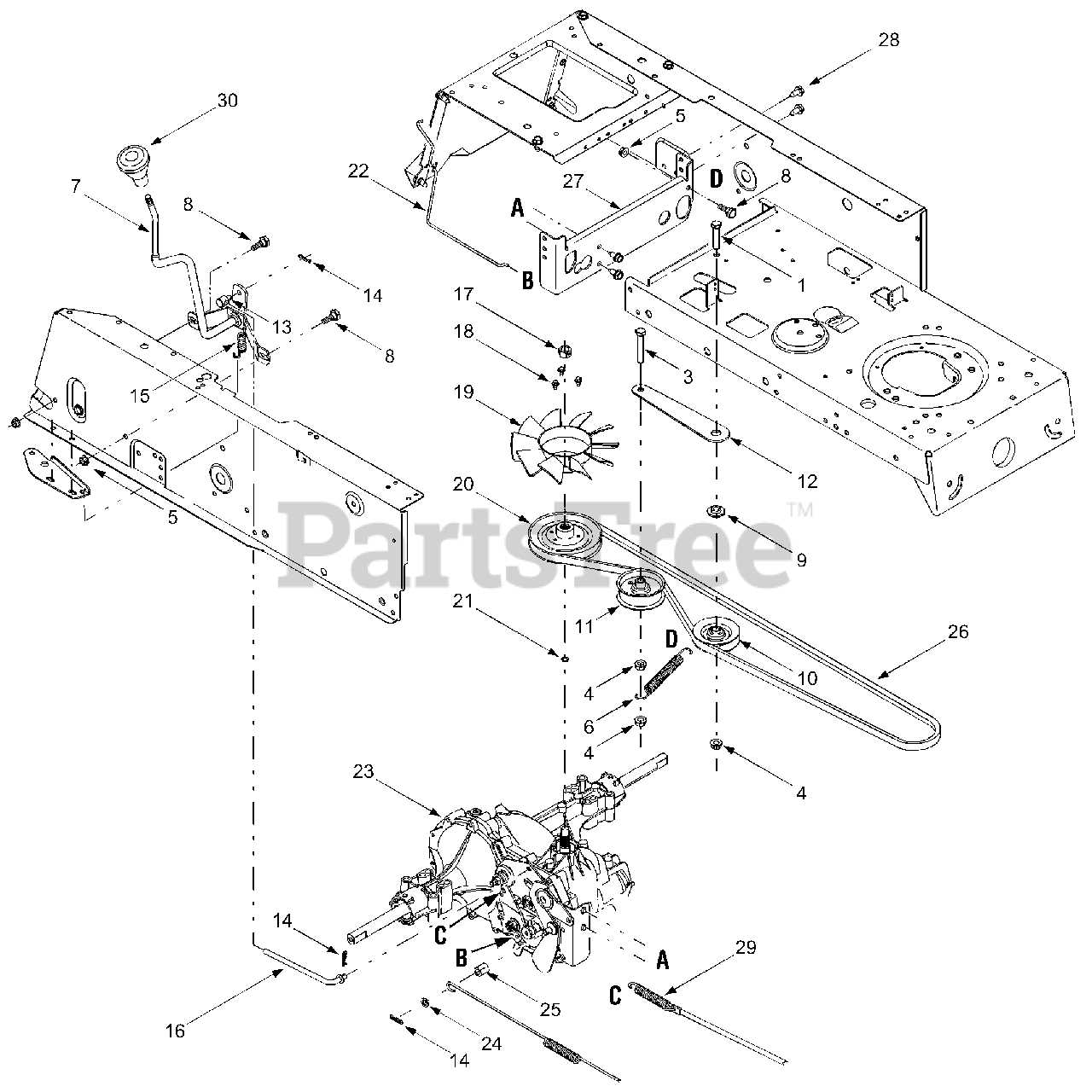

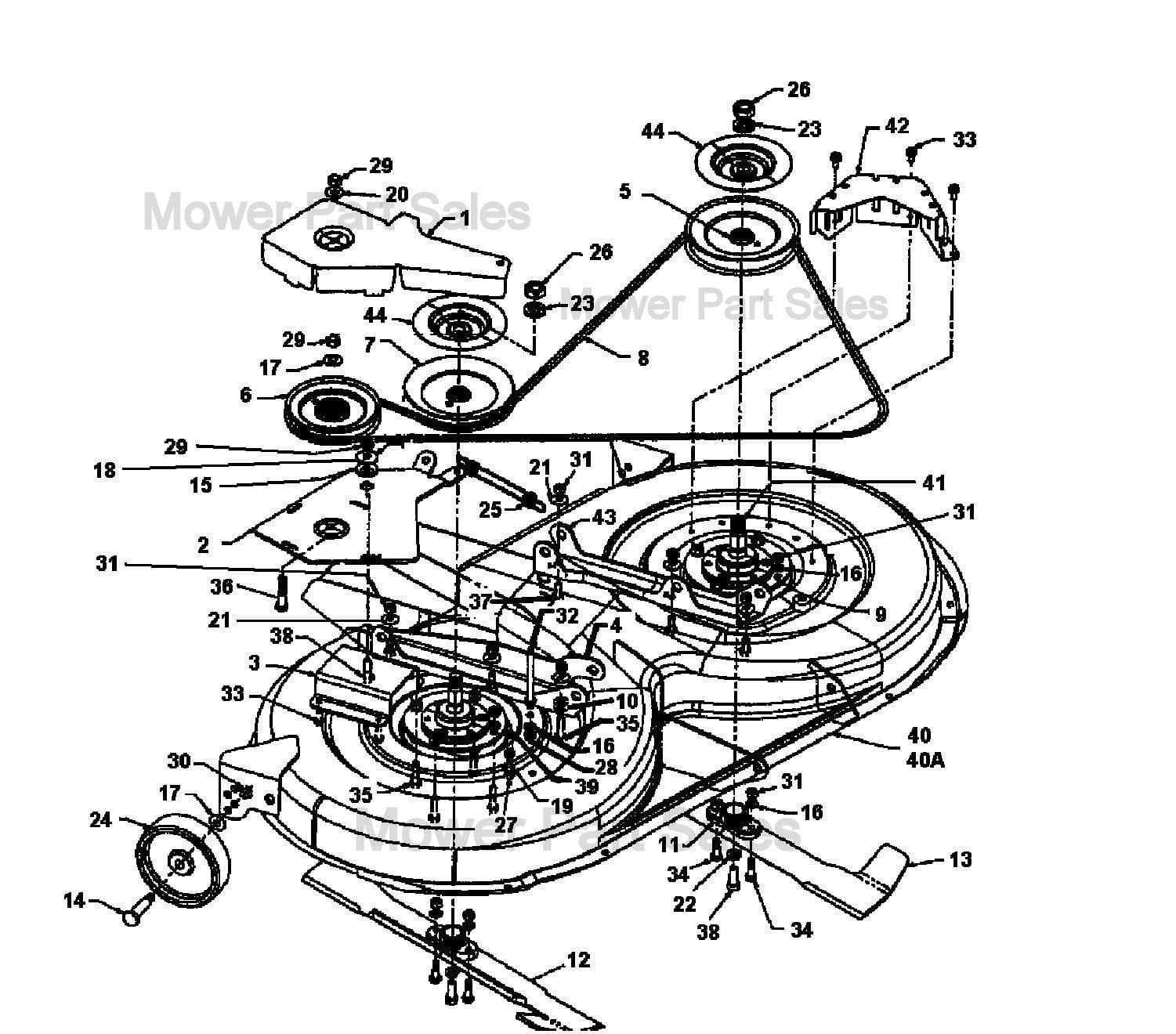

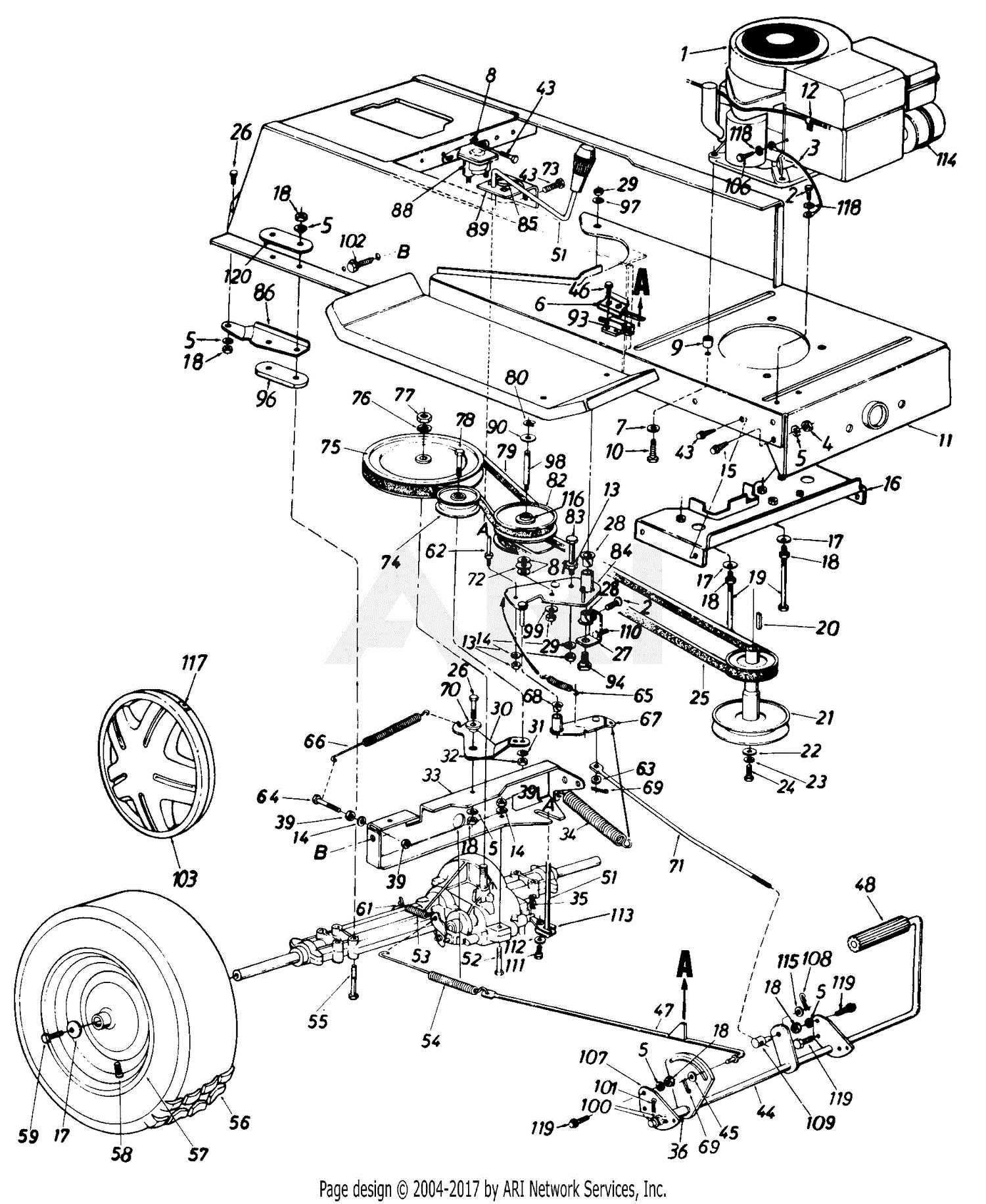

How the Drive System Works

The drive system is responsible for transferring power from the engine to the wheels, enabling smooth movement and efficient operation. This mechanism relies on a combination of components that work together to control speed, direction, and overall performance. Understanding how these parts interact helps in maintaining optimal functionality and prolonging the machine’s lifespan.

Key Components Involved

The system includes several key elements such as the transmission, belts, and pulleys. The transmission regulates the power output, while the belts and pulleys direct that energy to the necessary areas, ensuring smooth transitions between speeds. Proper alignment and tension are critical for these parts to function effectively.

Controlling Speed and Direction

Speed control is managed through a combination of the engine’s output and the transmission’s configuration. Adjusting the throttle allows for seamless changes in velocity, while steering

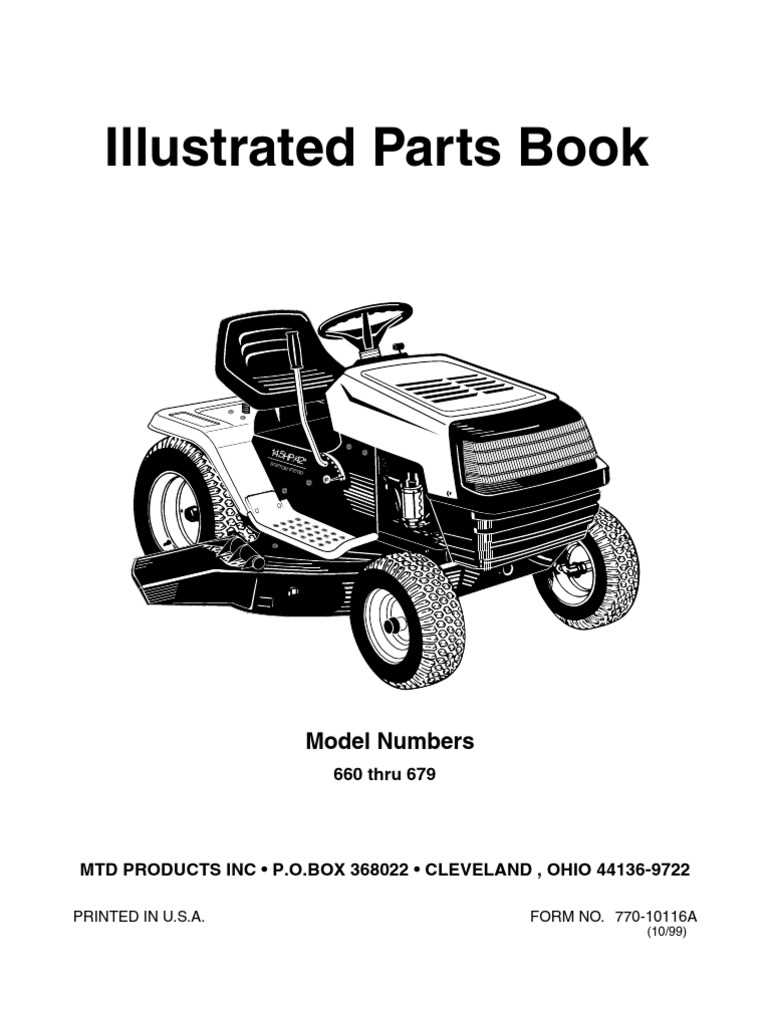

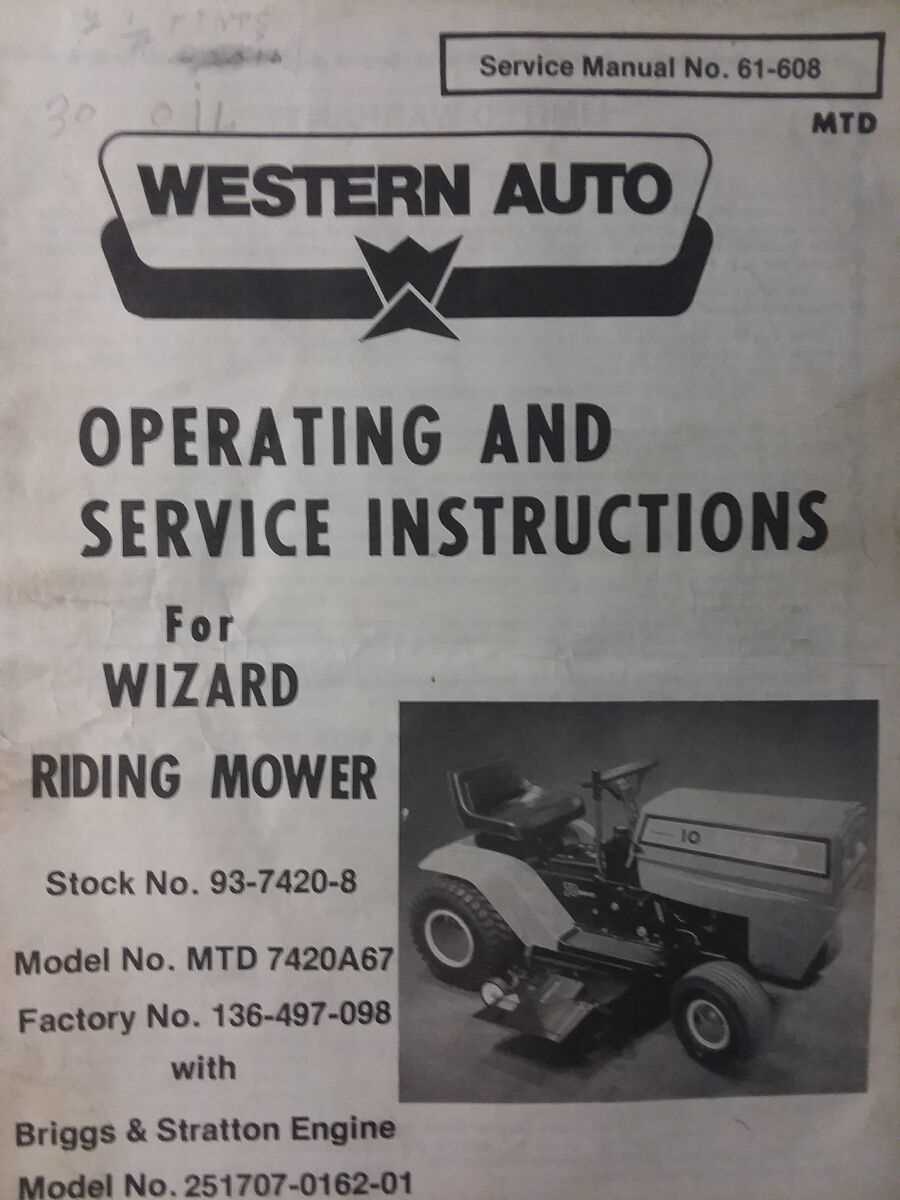

Identifying Essential Parts for MTD Models

Recognizing the key components for various machines is crucial for efficient operation and maintenance. Understanding these critical elements allows owners to perform regular inspections and replacements when necessary, ensuring the equipment functions smoothly. By identifying the most important elements, users can extend the lifespan of their machines and avoid unnecessary breakdowns.

Main Components to Consider

Each unit consists of several vital mechanisms that play a role in its overall performance. These include the power system, drive components, and control mechanisms, which work together to maintain functionality. Paying attention to the condition of these areas is essential for reliable operation.

How to Spot Wear and Tear

It is important to look for signs of wear in key areas such as belts, blades, and other moving parts. Regular maintenance checks, like inspecting for frayed edges or weakened materials, can help users identify when replacements are necessary. Ensuring proper lubricati

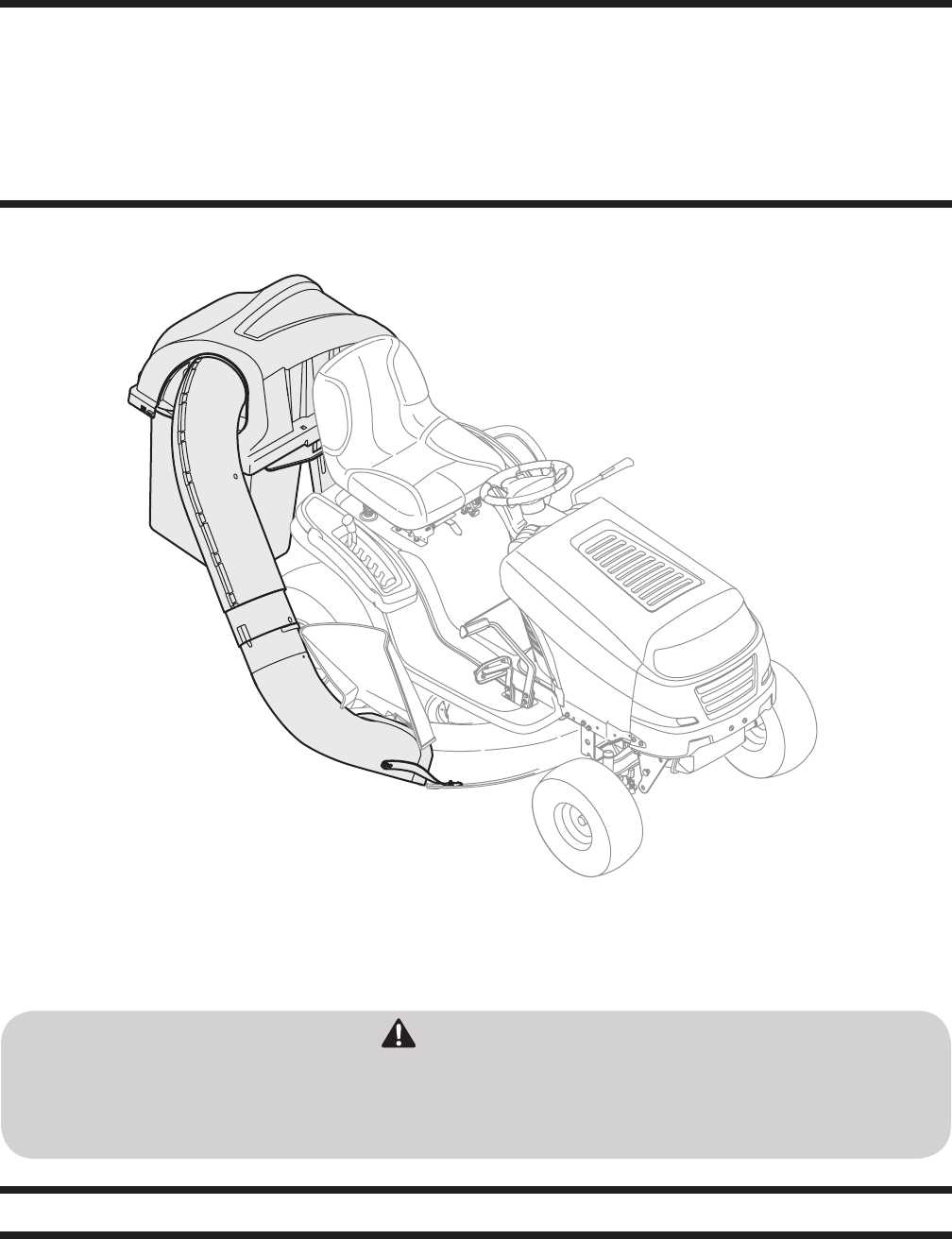

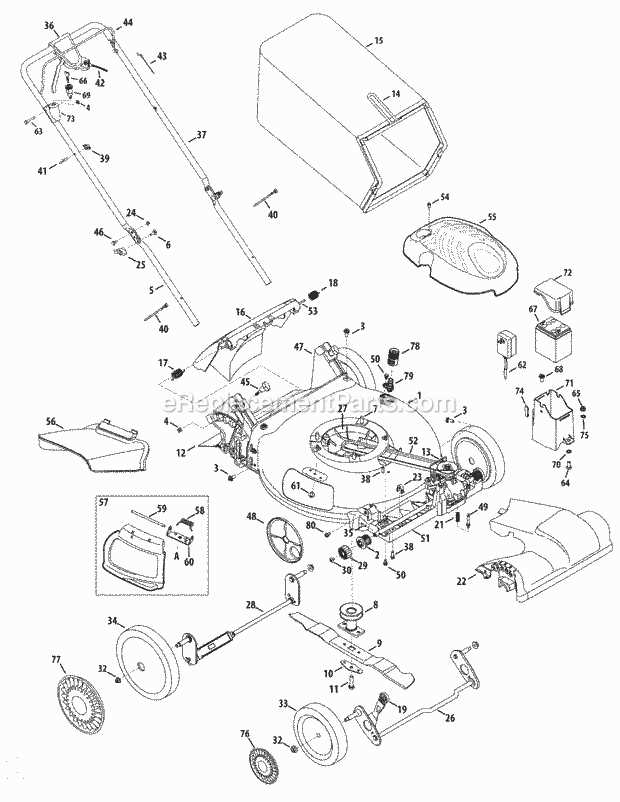

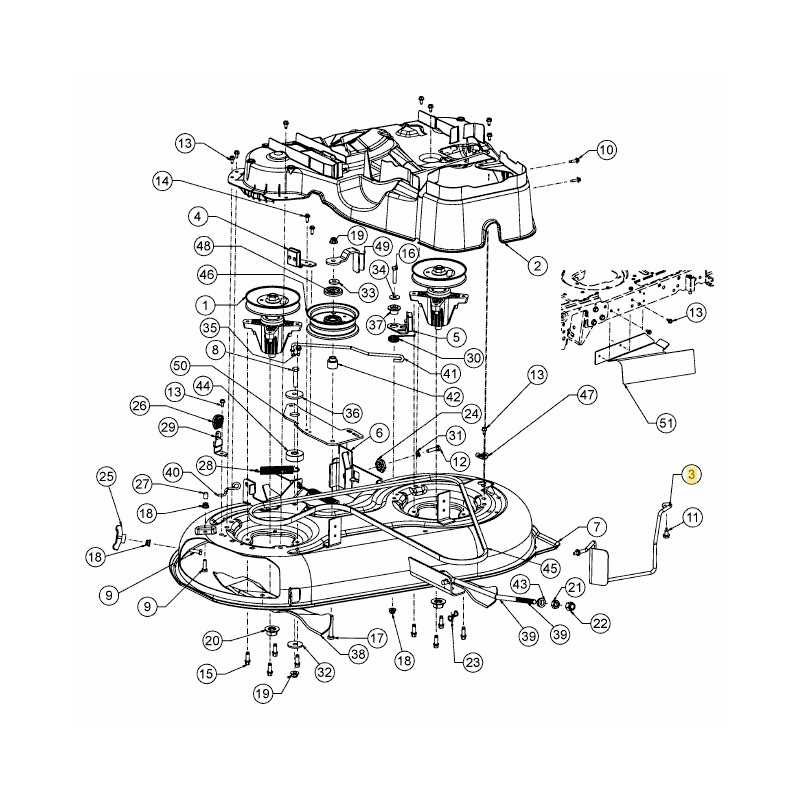

The Role of the Cutting Deck

The cutting deck is a key component responsible for transforming raw terrain into a neatly trimmed surface. It works by housing and supporting the blades that rotate at high speed, allowing them to cut vegetation with precision and efficiency. Properly functioning, this part ensures uniform results, contributing significantly to the overall performance and finish of the task.

Here is a simple breakdown of its core functions:

Function Description Blade Support Provides a secure base for blades to operate smoothly. Height Adjustment Enables control over the cutting height to suit different conditions. Debris Discharge Maintenance Tips for MTD Tractors

Regular upkeep is essential for keeping any type of outdoor machinery running smoothly. By following a few key practices, you can ensure your equipment operates efficiently and extends its lifespan. These tips focus on maintaining vital components and addressing potential issues before they lead to costly repairs.

Task Frequency Details Check Engine Oil Before each use Ensure proper oil levels and change it as per the manufacturer’s guidelines to avoid engine wear. Clean Air Filter Every 25 hours of operation Remove debris to maintain proper airflow and improve engine efficiency. Importance of the Engine in Lawn Tractors

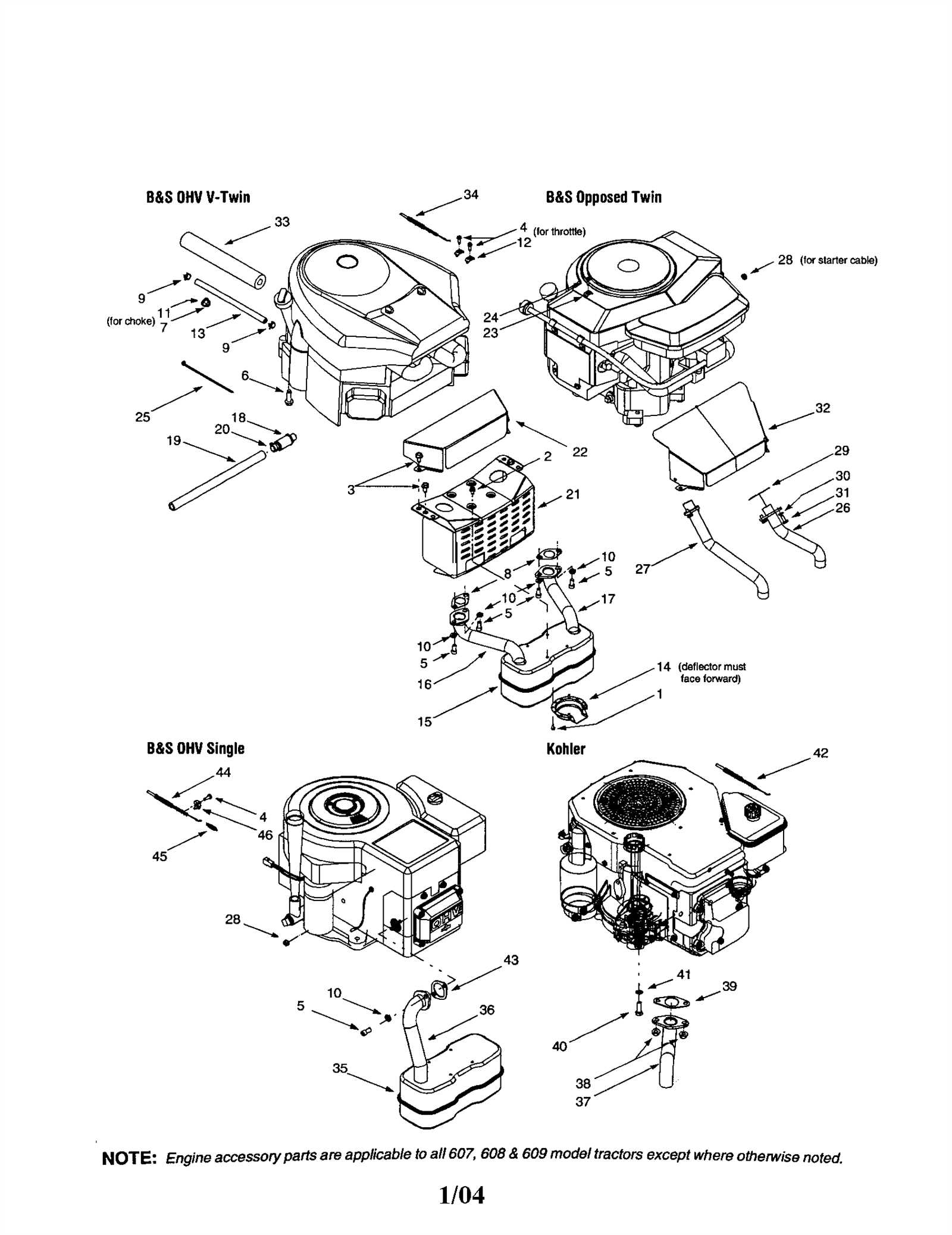

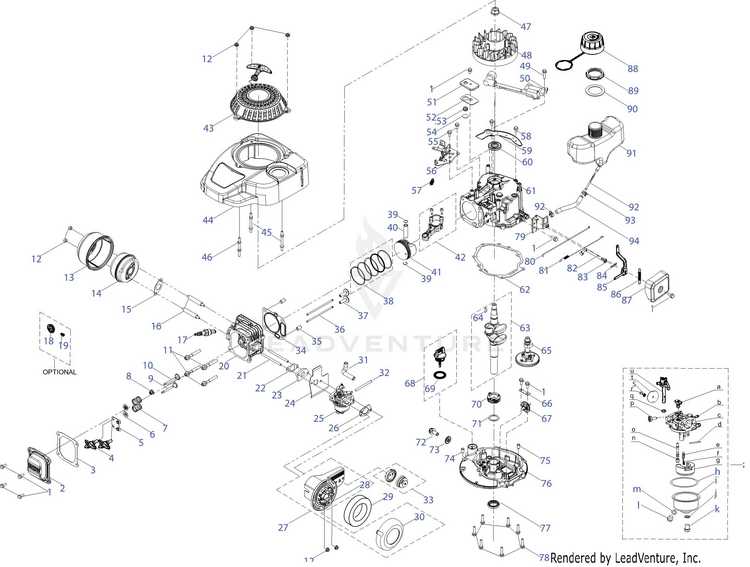

The engine is a crucial component that drives the overall functionality of garden maintenance equipment. Its performance directly influences the effectiveness and efficiency of the machine, ensuring that it operates smoothly and reliably during various tasks. A well-functioning power source can make a significant difference in the quality of the work done, affecting everything from cutting grass to transporting materials.

Efficiency and Power Output

A robust power unit enhances the operational efficiency of the machine. With a powerful engine, the equipment can tackle tougher terrains and thicker vegetation, reducing the time and effort required for tasks. The right power output also ensures that the equipment can handle various attachments, such as trailers or cutting implements, making it versatile for different gardening needs.

Maintenance and Longevity

Proper care of the engine is vital for ensuring its longevity and consistent performance. Regular maintenance, including oil changes and air filter replacements, can prevent potential issues and extend the lifespan of the equipment. Investing time in maintaining the engine not only safeguards the investment but also ensures optimal operation throughout its use.

Replacing Blades and Belts Efficiently

Maintaining optimal performance in garden machinery is essential for achieving a pristine outdoor space. Among the critical tasks is the replacement of cutting tools and drive components, which ensures that equipment operates smoothly and effectively. Understanding the correct procedures can significantly enhance the efficiency of these maintenance activities.

Step-by-step Guide: Begin by gathering the necessary tools and safety equipment before starting the replacement process. Ensure the machine is powered off and disconnected from any power source to avoid accidents. Once prepared, carefully lift the device to access the underside, where the components are located.

Blade Replacement: Detach the existing cutting implements by removing the fasteners that hold them in place. It is advisable to inspect the mounting areas for wear and damage before installing the new blades. Position the new implements securely, ensuring they are aligned correctly before tightening the fasteners.

Belts Installation: For drive components, begin by removing the old belts, checking for any signs of wear or damage. When installing new belts, follow the specific routing indicated in the user manual, ensuring proper tension for effective operation. Adjustments may be needed to achieve optimal tension and alignment.

By adhering to these steps, users can streamline the process of maintaining their equipment, leading to improved functionality and longevity of their machinery.

Troubleshooting Common Lawn Tractor Issues

Maintaining a garden machine is essential for ensuring its longevity and optimal performance. Understanding potential problems that may arise can save time and reduce frustration. This section outlines common issues and practical solutions that can help restore functionality.

Engine Problems

One of the most frequent complaints involves engine difficulties, which may manifest as hard starting or stalling. Inspect the fuel system for clogs or stale gasoline, as these can hinder performance. Additionally, check the spark plug; replacing it can often resolve ignition issues.

Cutting Performance Issues

A poorly functioning cutting mechanism can significantly impact the quality of work. Ensure that the blades are sharp and free from debris. If the device fails to cut evenly, adjusting the blade height may help achieve a more uniform cut. Regular maintenance and timely blade replacement are key to maintaining effective operation.

Choosing the Right Spare Parts

When it comes to maintaining machinery, selecting appropriate components is crucial for optimal performance. Ensuring the right fit and functionality can significantly impact the longevity and efficiency of the equipment.

Here are some key considerations to keep in mind while making your choice:

- Compatibility: Always verify that the replacement components match the specifications of your machine.

- Quality: Opt for high-quality items from reputable manufacturers to ensure durability and reliability.

- Cost: While affordability is important, be cautious of excessively low-priced options, as they may compromise quality.

- Warranty: Check if the parts come with a warranty, which can provide assurance of their performance and reliability.

- Reviews: Read user feedback to gauge the experiences of others with the specific components you are considering.

By taking these factors into account, you can make informed decisions that enhance the performance and extend the life of your machinery.

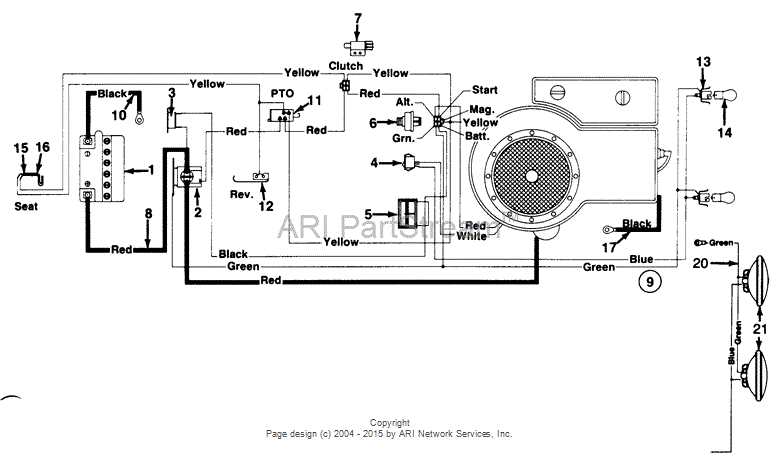

Understanding Electrical Systems in MTD Tractors

Electrical systems play a vital role in the functionality of outdoor machinery, providing the necessary power for operation and enhancing overall performance. These systems encompass various components that work in unison to ensure seamless operation and reliability, making it essential for users to have a solid understanding of their structure and function.

Key components of these electrical networks include batteries, switches, wiring harnesses, and safety mechanisms. Each part contributes to the efficient operation of the equipment and requires regular maintenance to prevent malfunctions.

Component Function Battery Stores electrical energy for starting and powering the system. Switches Controls the flow of electricity, allowing operators to start or stop the machinery. Wiring Harness Connects various electrical components, facilitating communication between them. Safety Mechanisms Protects the system from electrical overloads and ensures user safety. Safety Features and Their Maintenance

Ensuring the reliability of operational mechanisms is crucial for the well-being of users. Various protective elements are integrated into machines to minimize risks and enhance safety during usage. Regular inspection and upkeep of these components are essential to guarantee their effectiveness and longevity.

Common Safety Elements

- Emergency stop button

- Safety interlock systems

- Protective guards

- Operator presence controls

Maintenance Tips

- Regularly test the emergency stop button to ensure proper function.

- Inspect interlock systems for any signs of wear or malfunction.

- Keep protective guards clean and securely fastened.

- Check operator presence controls to confirm they respond as intended.

By adhering to a consistent maintenance schedule, operators can ensure that these vital safety features remain in optimal condition, significantly reducing the likelihood of accidents and injuries.